How to Realize Automatic Control of the Feed Rate in Ball

In ore concentration plant, single parameter and fixed value feeding control is a traditional method to control the feed rate of ball mill This system is composed of recorder, SCR governor, belt scales, funnel automatic switching device, and three DC motor driving belt feeders The control system can be realized by both modular instrumentation and computerThe Description and Function of Ball Mill: Ball mill is the key equipment for recrushing the materials after they are primarily crushed Ball mill is widely used for the dry type or wet type grinding of all kinds of ores and other grindable materials in cement, silicate product, new building material, refractory, fertilizer, black and nonferrous metals and glass ceramic industryChina grinding ball mill manufacturer factory price for Technical parameters are subject to change without notice CFTC is one of the most reliable Overflow Type Ball Mill manufacturers in China with many years of experience in Overflow Type Ball Mill production We can supply a complete set of Overflow Type Ball Mill with highest quality Our Overflow Type Ball Mill have been exported to Kenya ,Ethiopia, Zambia, Tanzania, Saudi Arabia,Sri Overflow Type Ball Mill chinacfccc China Carbide End Mill manufacturers Select 2020 high quality Carbide End Mill products in best price from certified Chinese Ball Mill manufacturers, Pellet Mill suppliers, wholesalers and factory on MadeinChinaChina Carbide End Mill, Carbide End Mill Manufacturers Existing methods for controlling the operation of the ball mill due to the instability of the parameters of the feedstock and the lack of control and accounting procedures mentioned parameters and other external disturbances cannot provide the optimum mode of operation Therefore, to prevent collapse or emasculation drum mill at production tend to work on a much understated performance of SYSTEM OPTIMAL CONTROL OF THE BALL MILL FOR THE

Intelligent optimal control system for ball mill grinding

Operation aim of ball mill grinding process is to control grinding particle size and circulation load to ball mill into their objective limits respectively, while guaranteeing producing safely and stably The grinding process is essentially a multiinput multioutput system (MIMO) with large inertia, strong coupling and uncertainty characteristics Furthermore, being unable to monitor the The ball mill is the horizontal cylinder type machine w Read More » Classification of grinding steel balls for ball mills According to different production processes, ball mill Read More » Main parameters of forged Grinding steel ball 1 Chemical composition At present, the chemical compo Read More » Product List Grinding media balls; Grinding mill bars; Grinding mill liners News RAINBOW chinaleiboChina Miller manufacturers Select 2020 high quality Miller products in best price from certified Chinese Milling Machine manufacturers, China Mill suppliers, wholesalers and factory on MadeinChinaChina Miller, Miller Manufacturers, Suppliers, Price Keywords: Ball mills, grinding circuit, process control I Introduction Grinding in ball mills is an important technological process applied to reduce the size of particles which may have different nature and a wide diversity of physical, mechanical and chemical characteristics Typical examples are the various ores, minerals, limestone, etc The applications of ball mills are ubiquitous in Grinding in Ball Mills: Modeling and Process ControlMetallurgical ContentBall Mill Capacity VS Rod Mill CapacityWorking Principle OperationRod Mill Capacity TableBall VS Rod Mill ConversionTypes of Mill DischargeBall Mill Trunnion and Mill Grate DischargePeripheral Grinding Mill DischargeLoad Capacity of Trunnion BearingsBall Mill Rod Mill LinersGrinding Mill GearsGrinding Mill DrivesBall Mill Grinding CircuitBall Mill SpecificationsAll Ball Mills Mineral Processing Metallurgy

How to Realize Automatic Control of the Feed Rate in Ball

In ore concentration plant, single parameter and fixed value feeding control is a traditional method to control the feed rate of ball mill This system is composed of recorder, SCR governor, belt scales, funnel automatic switching device, and three DC motor driving belt feeders The control system can be realized by both modular instrumentation and computerThe Description and Function of Ball Mill: Ball mill is the key equipment for recrushing the materials after they are primarily crushed Ball mill is widely used for the dry type or wet type grinding of all kinds of ores and other grindable materials in cement, silicate product, new building material, refractory, fertilizer, black and nonferrous metals and glass ceramic industryChina grinding ball mill manufacturer factory price for Existing methods for controlling the operation of the ball mill due to the instability of the parameters of the feedstock and the lack of control and accounting procedures mentioned parameters and other external disturbances cannot provide the optimum mode of operation Therefore, to prevent collapse or emasculation drum mill at production tend to work on a much understated performance of SYSTEM OPTIMAL CONTROL OF THE BALL MILL FOR THE Operation aim of ball mill grinding process is to control grinding particle size and circulation load to ball mill into their objective limits respectively, while guaranteeing producing safely and stably The grinding process is essentially a multiinput multioutput system (MIMO) with large inertia, strong coupling and uncertainty characteristics Furthermore, being unable to monitor the Intelligent optimal control system for ball mill grinding The ball mill is the horizontal cylinder type machine w Read More » Classification of grinding steel balls for ball mills According to different production processes, ball mill Read More » Main parameters of forged Grinding steel ball 1 Chemical composition At present, the chemical compo Read More » Product List Grinding media balls; Grinding mill bars; Grinding mill liners News RAINBOW chinaleibo

ball mill control parameter wildtapasnl

ball mill control parameter As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for anyel sizereduction requirements including quarry, aggregate, and different kinds of minerals We can provide you the complete stone crushing and beneficiation plantWe also supply standalone crushers, mills and beneficiation machines as well Ball Mill Pollution Control Manufacturers China Cr Alloyed Forged Grinding Media, China Various products of Alloyed Forged Grinding Media, providing product images and basic parameters with each forged steel grinding media balls and grinding media steel forged ball; We are a professional Chinese manufacturer of Alloyed Forged Grinding Media, and look forward to your cooperation!Ball Mill Pollution Control Manufacturers China CrThe types of mills are distinguished by their working principles: by pressure, impact, hammer, or shear Mills could be equipped with a screen for grain size control and separation The FAM product range includes impact mills, roller mills, hammer mills, ball mills and rod millsFAM – Mills – Processing TechnologyThe present investigation analyzes the effect of ball U mill operating parameters on the breakage rates of both t liberated and composite material The operating parameters studied include mill rotational speed, ball size, mill I charge and wet versus dry grinding Breakage rates have been determined experimentally utilizing a SEM—IPS image analyzer The mineral sample used was acquired THE EFFECT OF BALL MILL OPERATING PARAMETERS ON Metallurgical ContentBall Mill Capacity VS Rod Mill CapacityWorking Principle OperationRod Mill Capacity TableBall VS Rod Mill ConversionTypes of Mill DischargeBall Mill Trunnion and Mill Grate DischargePeripheral Grinding Mill DischargeLoad Capacity of Trunnion BearingsBall Mill Rod Mill LinersGrinding Mill GearsGrinding Mill DrivesBall Mill Grinding CircuitBall Mill SpecificationsAll Ball Mills Mineral Processing Metallurgy

THE EFFECT OF BALL MILL OPERATING PARAMETERS ON

The present investigation analyzes the effect of ball U mill operating parameters on the breakage rates of both t liberated and composite material The operating parameters studied include mill rotational speed, ball size, mill I charge and wet versus dry grinding Breakage rates have been determined experimentally utilizing a SEM—IPS image analyzer The mineral sample used was acquired Ball Mill is made up of feeding part, discharging part, gyre part, transmission part, (decelerator, small transmission gear, generator, electrical control) and so on The hollow axis adopts the cast steel and the lining can replace , the rotating big gear processes in the way of casting rolling gear The barrel body is wearable well and bears wearable scale board This machine runs steadily Ball Mill China Henan Zhengzhou Mining Machinery Co,Ltd General grinding system operating first kind is to use of ball mill for export pressure difference control parameters, the second kind is to use manual operation Depend on Ball Mill Control Theory and Application smecrusher Vertical mill parameters is very important for the performance of vertical mill Knowing the main control parameters of vertical mill can help us improve the production efficiency 1 Differential pressure: it can reflect the volume of feeding in mill, differential pressure fluctuation can cause the system to be unstable When the differential pressure is high, the material inside the mill is Main Control Parameters of Vertical MillZK Ball Mill Operation aim of ball mill grinding process is to control grinding particle size and circulation load to ball mill into their objective limits respectively, while guaranteeing producing safely and stably The grinding process is essentially a multiinput multioutput system (MIMO) with large inertia, strong coupling and uncertainty characteristics Furthermore, being unable to monitor the Intelligent optimal control system for ball mill grinding

OPTIMIZING THE CONTROL SYSTEM OF CEMENT MILLING:

Ball Mill Cyclones Weight Feeders Recycling Elevator Sep Feed Mill Feed Sep Return Final Product System Fan Figure 1: Closed circuit grinding system milling system is a delicate task due to the multivariable character of the process, the elevated degree of load disturbances, the different cement types ground in the same mill, as well as the incomplete or missing information about some key The ball mill is the horizontal cylinder type machine w Read More » Classification of grinding steel balls for ball mills According to different production processes, ball mill Read More » Main parameters of forged Grinding steel ball 1 Chemical composition At present, the chemical compo Read More » Product List Grinding media balls; Grinding mill bars; Grinding mill liners News RAINBOW chinaleiboE1 Determination of milling parameters in each ball size interval 100 E2 Predicted EQM and OEMBSD’s selection functions 100 E3 Statistical analysis of the predictions 101 9 List of figures Figure Page 21 Breakage mechanisms in a ball mill 22 22 First order reaction model applied to milling 24 23 Grinding rate versus particle size for a given ball diameter 25 24 Cumulative breakage EFFECT OF BALL SIZE DISTRIBUTION ON MILLING PARAMETERSMetallurgical ContentBall Mill Capacity VS Rod Mill CapacityWorking Principle OperationRod Mill Capacity TableBall VS Rod Mill ConversionTypes of Mill DischargeBall Mill Trunnion and Mill Grate DischargePeripheral Grinding Mill DischargeLoad Capacity of Trunnion BearingsBall Mill Rod Mill LinersGrinding Mill GearsGrinding Mill DrivesBall Mill Grinding CircuitBall Mill SpecificationsAll Ball Mills Mineral Processing Metallurgythe control loop will attempt to add water to Cyclone 1 sump to achieve a particle size of 15%+ 300 µm If the hardness of the ore increases, the particle size in the mill discharge from ball mill 1 will increase With the same water addition to sump 1 the particle size of Cyclone 1 overflow will increase This will decrease the ratio, and henceGrinding control strategy on the conventional milling

- SECOND HAND MOBILE CRUSHER PLANT IN INDONESIA

- Rivera Rockcrusher Daya Attenuator

- lime processing plant grinding

- Impact Crusher For Recycling And Demolition

- stone crushing plant mobile portable quarry for sale in south africa

- pper flotation process flow sheet of nylon

- news news on small scale mining

- manual britador mandibula cgm project case

- vertical grinding cement mill machinery

- fly ash grinding technology in india

- Russian Made Vearticle Grinding Mill

- Vibrator Feeders On Sale In Sa

- small mineral beneficiation plants

- high quality bone mud grinding machine

- field mining equipment gold south africa

- GOLD MINING PROCESS PAPUA NEW GUINEA

- grinding turbine grinders

- Chaoyang Crusher Plant

- crushing apparatus of electric meters

- price for kw diesel grinding mill

- Pw Mining International Limited

- Small Clay Brick Crusher Small Sand Crusher Small Gold Crusher

- rock crusher rental in sacramento ca

- flour mill machinery in bhopal

- labelled labelled illustration of a ffee grinder

- parker jaw crusher brown lenox

- grinding st calculation for bm 8 usha mill

- kyanite fluorspar clay

- Jaw And Impact Crushers Information

- stone crushing machinehammer crusher hammer mill u china yufeng

- li ne pellets mill in georgia

- fuel enomy for crushing machines samac

- primarycsendary and tertiary crushers

- skid steer ncrete crusher attachment

- flour mill machinery prices in pakistan

- Arpa Moulding Machine Mechanised Sand Plant Grinding Mill China

- crushing test for cement mortar

- LM RAW METARIAL INDIA

- 2 roller sugar mill grinder

- british used mining mpree

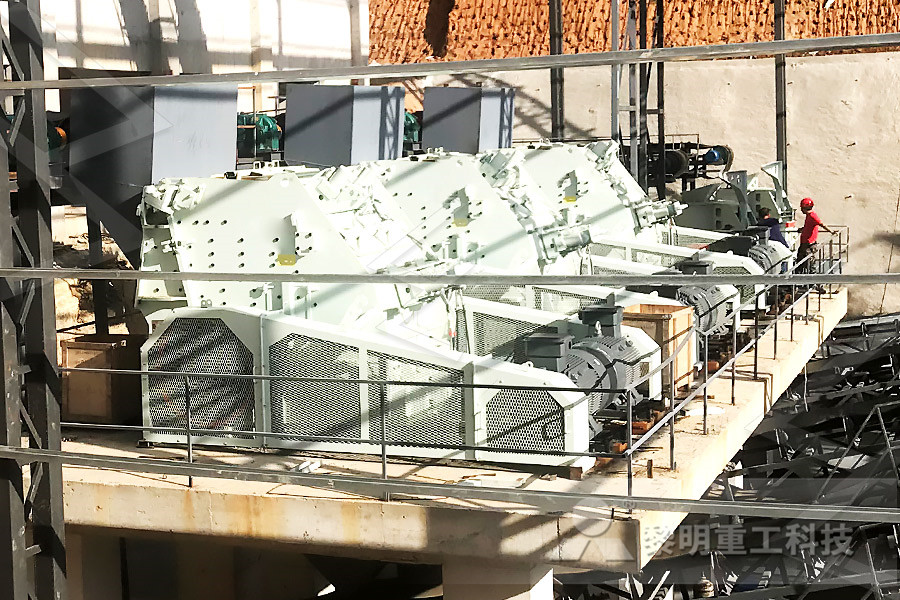

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher