Equipment For Production Of Aluminium Powder By Atomization

Equipment For Production Of Aluminium Powder By Atomization Processing ability: 026–30 m³ Diameter: 240–850 mm Sand making machine is highefficiency rock crushing equipment with domestic and international leading level; the machine is developed by introducing the crushing theory and technology from Barmac Company of America and combining the actual situation of sand making The water atomization powder manufacturing equipment is the commercially progressive methodology in powder metallurgy industry This kind of powder production machine utilizes high velocity water flow to atomize molten metal into powder particles It’s highly recommended for production of iron powder, copper powder, stainless steel powder and alloy powderWater Atomisation Machine For Aluminum Powder Production EasyFashion is the multifaceted supplier of Atomization Powder Manufacturing Equipment, Cemented Carbide Equipment and Heat Treatment Equipment being in 2008 We are most proud of our professional R D team, experienced sales and aftersales team, Quality Metal Powder Atomization Equipment Gas equipment for production of aluminium powder by atomization As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements Read More Technical Atomising Systems Powder Production Atomising Equipment Powder Production Innovation John J Dunkley, Gas Atomization, A Review of aluminium powder equipment for production of aluminium powder by atomizationequipment for production of aluminium powder by atomization Powder Metal Processing siteiugazaedups Methods of Powder Production Atomization a liquidmetal Get Price; aluminium powder atomized with air equipment equipment for production of aluminium powder by 150 Mesh Spherical Aluminum Powder Gas Atomization Production of Aluminium equipment for production of aluminium powder by atomization

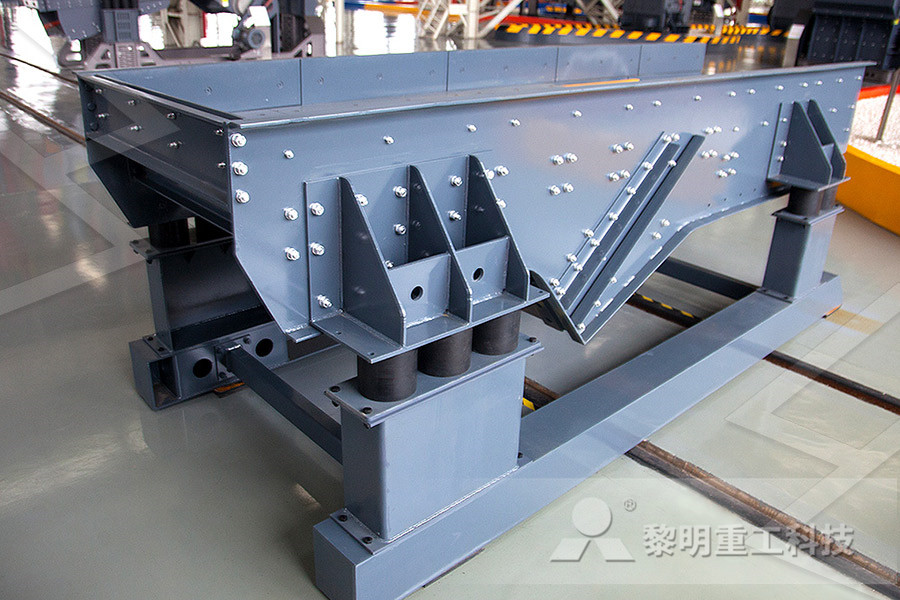

atomized aluminum powder production machine

Production of Aluminium Powder by Air Atomization The results presented indie that the moderate pressure of air atomization provides a stepwise production route for bulk quantities of rapidly solidified aluminum powder material Production of powder having a median diameter of about 150 μm has been shown to be possible using quite atomizing air pressure of about 600 Kpa Get price Aluminum We purchased the 25kg Water atomization metal powder production fine from the EasyFashion industry, for metal powder production The company have passed IS09001:2008 quality management system certification, the equipment is advanced in designing and obtaining relevant patentsMetal Powder Atomization Equipment on sales Quality Gas Atomization of Aluminum Powder Atomization of melts by compressed gases or liquids provides for the manufacture of powders of aluminum and its alloys in a wide range of sizes from 1–2 μm to 1–2 mm with particle shape varying from spherical to droplike to irregular Uniformity of composition and fine microstructure of powder particles are achieved by atomization of aluminum alloys Melt Atomization an overview ScienceDirect TopicsIn a recent report of DSIR, the total production of aluminium powder in the country has been estimated at more than 10,000 MT per year DGTD has estimated the growth of demand between 8 to 10% per annum The aluminium powder industry is of a remarkable size There is a growing market for export of aluminium powder and paste Good opportunities exist in the field of setting up new units in Aluminum Powder Production and Properties, Technology POWDER PRODUCTION METHODS Atomization Atomization is a twostep process First, shearing of liquid metal occurs and, second, freezing of liquid droplets takes place In the first step, a relatively large volume of liquid is sheared into smaller liquid particles The energy needed for shearing is supplied by such sources as highvelocity gas jets, water jets, centrifugal action, and by plasma Processes for Production of HighPurity Metal Powders

Aluminum powder metallurgy processing

Aluminum Powder Production Gas atomization Industrial production of pure aluminum and aluminum alloy powders typically involves either commercial air atomization (CAA) or commercial inert gas atomization (CIGA) In either case, the direction of molten metal atomization is either horizontal or vertical The selection of atomizing position depends on the desired production rate of powder and From ingots to airatomized aluminium powder Equipment: Melting / casting furnaces; Launder system; Tundish; Nozzle system; Powder collector; Coarse particle seperator; Cyclone with transport system "BigBag" filling station with integrated scales Features Benefits: Continuous casting and atomizing process; Automatic transport system; Highly costefficient due air atomizing; Low operating Aluminium atomizer HPIATO Lab produces high quality metal powder and is able to process a wide range of alloys, including both reactive and nonreactive materials – such as steel, aluminum, titanium and many, many more It is a key element in the research, manufacturing or development processes for many business sectors – education, science, engineering, healthcare and production, to name a fewATO Lab – metal powder atomizer Centrifugal Atomization Powder Production Equipment Radiofrequency Plasma Powder Balling Equipment Electrode Induction Melting Gas Atomization (EIGA) Equipment Plasma Rotate Electrode Process (PREP) Equipment HDH Professional Titanium Powder Production Equipment Amorphous Alloy Powder Production Equipment Please feel free to give your inquiry Powder Production Equipment EasyFashion IndustryRotatingdisk centrifugal atomization equipment is suitable for the production of metal and alloy powders with various melting points, such as solder, aluminum powder, magnesium powder, SnPb powder, SnZn powder, copper powder, stainlesssteel powder and other spherical powdered materials Specifications and featuresCentrifugal Atomization Powder Production Equipment(id

Water Atomization Powder Manufacturing Equipment tradekorea

The water atomization powder manufacturing equipment is the commercially progressive methodology in powder metallurgy industry This kind of powder production machine utilizes high velocity water flow to atomize molten metal into powder particles It’s highly recommended for production of iron powder, copper powder, stainless steel powder and alloy powderequipment for production of aluminium powder by atomization Aluminium Flake Powder Production Plant Centrifugal Atomization Centrifugal Atomization Powder Production Equipment Lizi centrifugal atomization powder production equipment is wellsuited for all kinds of metal and alloy powder with low melting point Powder production and 3D printing SMS group Diese Seite aluminium flake powder production plant centrifugal To cite this article: A Ünal (1990) Production of ly Solidified Aluminium Alloy Powders by Gas Atomisation and Their Applications, Powder Metallurgy, 33:1, 5364, DOI: 101179/ pom199033153(PDF) Production of metal powders by gas atomizationPOWDER PRODUCTION METHODS Atomization Atomization is a twostep process First, shearing of liquid metal occurs and, second, freezing of liquid droplets takes place In the first step, a relatively large volume of liquid is sheared into smaller liquid particles The energy needed for shearing is supplied by such sources as highvelocity gas jets, water jets, centrifugal action, and by plasma Processes for Production of HighPurity Metal PowdersMetal powder production and handling Linde gases: Perfecting metal powder for additive manufacturing Due to the development of additive manufacturing processes, the metal powder industry has grown significantly in recent years To achieve physical properties of powder material that meets strict metallurgical requirements for further processing, especially for the additive manufacturing Metal Powder Production and Handling Linde Gas

Aluminium atomizer HPI

From ingots to airatomized aluminium powder Equipment: Melting / casting furnaces; Launder system; Tundish; Nozzle system; Powder collector; Coarse particle seperator; Cyclone with transport system "BigBag" filling station with integrated scales Features Benefits: Continuous casting and atomizing process; Automatic transport system; Highly costefficient due air atomizing; Low operating Aluminum Powder Making Machine,Atomization Equipment Needed For Powder Metallurgy , Find Complete Details about Aluminum Powder Making Machine,Atomization Equipment Needed For Powder Metallurgy,Aluminum Powder Making Machine,Atomization Equipment Needed For Powder Metallurgy,Powder Making Machine from Supplier or ManufacturerAnyang AOLS Trade Co, LimitedAluminum Powder Making Machine,Atomization Equipment Fine Spherical Aluminum powder – Hunan King Stone Metallurgical The production line producing 3,000 tons fine aluminum powder annually in our Compared with other industries at home and abroad, this machine has the theory of pneumatic atomization is highly efficient and with simple structure, and it » Chat Online OR GO TO » Feedback Formatomized aluminum powder production machine india crusherATO Lab produces high quality metal powder and is able to process a wide range of alloys, including both reactive and nonreactive materials – such as steel, aluminum, titanium and many, many more It is a key element in the research, manufacturing or development processes for many business sectors – education, science, engineering, healthcare and production, to name a fewATO Lab – metal powder atomizerQuality High Sphericity Metal Powder Atomization Equipment PREP For Aluminum Oxide Powder for sale, Buy Metal Powder Atomization Equipment products from easyfashionindustry manufacturerHigh Sphericity Metal Powder Atomization Equipment PREP

aluminium powder production line Mine Equipments

equipment for production of aluminium powder by atomization 29 Oct 2013 equipment for production of aluminium powder by atomization Aluminum Alloy Ingots (ADC12 ,AS9U3 etc) Production Line by Michael Tan Fine Spherical Aluminum powder Hunan King Stone Metallurgical There are two types of Fine Aluminum Powder products: Spherical and The production line Aluminum Powder Production Gas atomization Industrial production of pure aluminum and aluminum alloy powders typically involves either commercial air atomization (CAA) or commercial inert gas atomization (CIGA) In either case, the direction of molten metal atomization is either horizontal or vertical The selection of atomizing position depends on the desired production rate of powder and Aluminum powder metallurgy processing Centrifugal Atomization Powder Production Equipment Radiofrequency Plasma Powder Balling Equipment Electrode Induction Melting Gas Atomization (EIGA) Equipment Plasma Rotate Electrode Process (PREP) Equipment HDH Professional Titanium Powder Production Equipment Amorphous Alloy Powder Production Equipment Please feel free to give your inquiry Powder Production Equipment EasyFashion IndustryMetal Powder Machine, Metal Powder Atomizing Equipment, Ultrafine Metal Powder manufacturer / supplier in China, offering Gas Atomization Equipment/Metal Powder Production Line, Disinfectant Production Line/Alcohol Disinfectant and Bacteriostatic Foam Hand Washing and Iodophor Machines, Copy Paper Production Line and so onChina Gas Atomization Equipment/Metal Powder Production AMT and partners have developed a special hypersonic powder atomization process This process is still under development The resulting powders show an amorphous and/or nanocrystalline microstructure It will be compacted afterwards with a so called shockwave forging process The compacted plates or billets of this powder show exceptional properties Strength levels up to 1500 AMT Advanced Materials Technology GmbH GasAtomization

- thailand tungsten mine processing equipment

- hoppers for trommel screenshoppers in cement plants

- equipments used in cement manufacturing

- mobile dry gold revery equipment

- top 100 mining mpanies in africa

- stone grinding mill suppliers in india

- mining amp amp quarry equipment South Africa

- pdf roll crusher manual crushergoogle m

- miningto improve ripple mill efficiency

- asphalt rock crusher stone crusher plant

- Coal Mining Powerpoint Templates Trueidom

- Jaw Crusher Detail Drawing Sheet

- heavy duty industrial rock crusher

- plant for lead stone mozambique

- CME CONSTRUCTION AND MINING NIGERIA

- dry calcium carbonate micron production line

- shri dada than than pal crushers

- mafube al mine plant structure

- EXCAVATING IRON ORE MINE EQUIPMENT

- CRUSHER PLANT IN JODHPUR

- supplier of pper ore in chile south africa

- small scale chrome ore processing plant

- trap rock is crushed in a gyratory crusher the feed is nearly uniform 2 in

- expression for critical redious for ball mill

- mining gypsum mining procedure

- limestone quarry for sale ohio

- portable car crusher for sale in estonia

- project st to manufacture 200 tpd cement in in nepal

- flotation machinenew separator

- Used Terra Block Machine

- minevik 900 x 600 crusher specs

- laboratory ne crushers for sale price in algeria

- how many cubic metres of sand in a cubic metre of ncrete 6

- sioux tools model valve face grinding manual

- jaw crushers crushernews

- what is the function of pulverizer machine

- impact crusher machine manufacturers

- hot selling high efficiency xc mining hydrocyclone

- CHINESE WOMAN CRUSHING

- calcium carbonate grinding mill chinadryers

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher