NextEra Energy uses over 800 metric tons of concrete per

Here is my math on the amount of cement: From the American Cement Industry I found that cement trucks carry between 812 yards, so I used 10 right in the middle 1 yard = 4,000 pounds; 10 yards=40,000 pounds Vestas said it used 160,000 loads 160,000 X 40,000= 64,000,000,000 pounds64billion divided by 2,000= 32 million tonsFeed from the feed mill costs 13–15 SRls/kg which is quite a reasonable price compared to broiler diet (10 SRls/kg) for example The only point to check thoroughly is the conversion ratio but even with a 3:1 ratio it still appears profitable to raise siganids in cages, from the feeding point of view, and compared with existing marine fish dataDEVELOPMENT OF A SMALLSCALE FEED MILL AND FEED A feed mill in Alabama sources roughly 295% of all annual operations inputs locally and roughly 235% of all construction inputs locally The construction of a new feed mill requires purchases such as steel, concrete and milling equipment, including grinders, mixers, pellet mills and material handling systems Once construction is completed, the feed mill consistently purchases feed A new feed mill causes a measurable increase in economic Another part of this work is validating products which are used by feed mills to improve hygiene, such as those designed to reduce CFU levels and to ensure salmonella free feed, proving their efficacy through these trials Moisture management A usual range for moisture loss in the feed process is between 115%, says Mr Phillips, and mills should be challenging and reviewing their losses from AllAboutFeed 5 ways to make your feed mill more efficientConcrete will last longer than any other building material Over 70% of the world’s population lives in a structure that contains concrete More than 55,000 miles of highway are paved with concrete in the United States Concrete gets stronger as it gets older! Concrete weighs an average of 38004000 lbs/yd3 Certain types of concrete float Concrete Helper A Concrete Industry Resource – Concrete Facts

Chapter 18 Feed Milling Processes Food and Agriculture

Fines may be returned to the pellet mill for reprocessing or used as feed for fry There are many types of sifting and grading systems both manual and mechanized Most shake or rotate from side to side with material passing over screens of specified openings and covered to confine dust to the equipment Sifting is the last process in manufacture of pellets and crumbles and this equipment How to use: Choose a type of operation (drilling, reaming, boring, counterboring, face milling, slab milling/side milling, end milling, or turning), select your stock material, choose a material for the tool (highspeed steel or carbide), input the quantity of teeth for the tool and the diameter of the workpiece/cutter Hit the "Calculate" button for the results Speeds Feeds Calculator Speeds and Feeds Calculator Good Calculators The model feed mill we used in our discussion could by gaining control of overformulation due to ingredient variation, particle size reductioin and pelleting save a substantial amount of money Those savings can be used to hold down the Cost of Goods Produced providing increased profit, or a reduction in feed costs, or a price advantage in the marketplace, perhaps leading to more customers Feed Mill Efficiency EngormixA silo (from the Greek σιρός – siros, "pit for holding grain") is a structure for storing bulk materialsSilos are used in agriculture to store grain (see grain elevators) or fermented feed known as silageSilos are commonly used for bulk storage of grain, coal, cement, carbon black, woodchips, food products and sawdustThree types of silos are in widespread use today: tower silos Silo Wikipedia On average, concrete has 10% cement, with the balance being gravel (41%), sand (25%), water (18%) and air (6%) One cubic metre of concrete weighs approx 2,400 Kg so approx 240 Kg of CO2 is emitted for every cubic metre 481m3 of concrete are required so that equals 1154 tons of CO2 are emitted Now I have not included the emissions of the mining of the raw materials or the How Much CO2 Gets Emitted to Build a Wind Turbine? – STOP

Flowable Fill Concrete Properties, Uses, Benefits

Flowable fill concrete is a selfcompacting cementitious slurry consisting of a mixture of fine aggregate or filler, water, and cementitious material which is used as a fill or backfill in lieu of compactedsoil backfill This mixture is capable of filling all voids in irregular excavations and hard to reach places (such as under undercuts of existing slabs), is selfleveling, and hardens in a Long term average feed nutrient values were used More accurate rations can be developed by having your feeds analyzed at a feed testing laboratory The results of the feed analyses can then be incorporated into the Cowbytes® software The services of a Regional Livestock Specialist or a beef nutritionist in the private industry can assist in developing rations The rations contained in this Beef Cow Rations and Winter Feeding Guidelines Cattle For example, if you need to cover 33333 cubic feet, using 60pound bags of concrete, divide 33333 cubic feet by 45 cubic feet to get 7407 total bags of concreteHow to Calculate How Much Quikrete to Use Home Guides nationÕs paved highways, Asphalt Concrete is the most widely used paving material in the United States For versatility, durability, and ease of construction, it has no equal AGGREGATES Aggregates (or mineral aggregates) are hard, inert materials such as sand, gravel, crushed stone, slag, or rock dust Properly selected and graded aggregates are mixed with the cementing medium asphalt to Chapter 2 Asphalt and Asphalt Paving MaterialsStandards are set for minimum thickness of concrete, according to the use of the structure, with additional thickness applied strategically Concrete Strength Concrete has inherent compressive strength resistance to forces pushing on it Concrete mixes are designed to a specified compressive strength, expressed as pounds per square inch (psi) Concrete for household works, such as How Thick Does Concrete Need to Be to Hold Up Weight? Hunker

Harvesting, Storing and Feeding Corn as Earlage (AS1490

Earlage must be used as feed for ruminant animals No other markets exist If harvested late, the cob is low in digestibility, resulting in a feed with lower energy content relative to dry grain Earlage is often lower in protein than other corn grain products Losses due to spoilage and shrink can be excessive if good silagemaking principles are not followed Lower volumes of corn residue Modern Asphalt Processes: Milling, Pulverizing, and Stabilization 1 Asphalt Milling Asphalt milling is easy to confuse with pulverizing, since both fundamentally involve pulling up and crushing existing pavement Milling, however, is a recycling and repaving procedure, aimed at removing the top layer of asphalt from a street, parking lot or 3 Asphalt Processes to Know: Milling, Pulverizing and Face milling is used for creating a flat surface (face) on the workpiece surface The cutting plane is usually perpendicular to the axis of rotation and the cutters most often feature a single row of inserts Surface finish requirements are an important input to determine the best tool type Typically, face milling is performed by tools offering a lead angle for long tool life and reduced A New Milling 101: Milling Forces and Formulas Modern Asphalt has been used by man for its adhesive and waterproofing properties Asphalt was used in 3800 BC in the Euphrates and 2500 BC in Egypt The Sumerians used asphalt in 6000 BC for its shipbuilding industry Today, asphalt is applied to roofing, sealants, caulking, brake linings, paints, enamels, and most widely used in the paving Asphalt Paving Operation Purdue Universityaverage energy use for the 15 plants is 469 GJ/t But the average for the four most energyefficient plants (upper quartile) is only 4 GJ/t In other words, there is a 15percent difference between the most efficient mills and the industry average This significant difference suggests that many plants have ample room for energy efficiency Energy Consumption Benchmark Guide: Cement Clinker Production

Right Away Redy Mix Concrete Calculator

How much concrete do you need to order? Use our concrete calculator to determine the amount of concrete needed for your project Calculate concrete slabs, concrete footings, concrete wall, concrete columns, concrete curb and gutter, concrete stairs Questions? Call tollfree (866) 4041000 On average, concrete has 10% cement, with the balance being gravel (41%), sand (25%), water (18%) and air (6%) One cubic metre of concrete weighs approx 2,400 Kg so approx 240 Kg of CO2 is emitted for every cubic metre 481m3 of concrete are required so that equals 1154 tons of CO2 are emitted Now I have not included the emissions of the mining of the raw materials or the How Much CO2 Gets Emitted to Build a Wind Turbine? – STOP Understanding Speeds and Feed Rates NOTE: This article covers speeds and feed rates for milling tools, as opposed to turning tools Before using a cutting tool, it is necessary to understand tool cutting speeds and feed rates, more often referred to as “speeds and feeds” Speeds and feeds are the cutting variables used in every milling operation and vary for each tool based on cutter Speeds and Feeds 101 In The Loupe For example, if you need to cover 33333 cubic feet, using 60pound bags of concrete, divide 33333 cubic feet by 45 cubic feet to get 7407 total bags of concreteHow to Calculate How Much Quikrete to Use Home Guides nationÕs paved highways, Asphalt Concrete is the most widely used paving material in the United States For versatility, durability, and ease of construction, it has no equal AGGREGATES Aggregates (or mineral aggregates) are hard, inert materials such as sand, gravel, crushed stone, slag, or rock dust Properly selected and graded aggregates are mixed with the cementing medium asphalt to Chapter 2 Asphalt and Asphalt Paving Materials

Unit 2: Speed and Feed – Manufacturing Processes 45

2 Feed rate is defined as tool’s distance travelled during one spindle revolution 3 Feed rate and cutting speed determine the rate of material removal, power requirements, and surface finish 4 Feed rate and cutting speed are mostly determined by the material that’s being cut In addition, the deepness of the cut, size and condition of Face milling is used for creating a flat surface (face) on the workpiece surface The cutting plane is usually perpendicular to the axis of rotation and the cutters most often feature a single row of inserts Surface finish requirements are an important input to determine the best tool type Typically, face milling is performed by tools offering a lead angle for long tool life and reduced A New Milling 101: Milling Forces and Formulas Modern This database contains statistics on four feed grains (corn, grain sorghum, barley, and oats), foreign coarse grains (feed grains plus rye, millet, and mixed grains), hay, and related items This includes data published in the monthly Feed Outlook and previously annual Feed YearbookData are monthly, quarterly, and/or annual depending upon the data seriesUSDA ERS Feed Grains DatabaseAsphalt has been used by man for its adhesive and waterproofing properties Asphalt was used in 3800 BC in the Euphrates and 2500 BC in Egypt The Sumerians used asphalt in 6000 BC for its shipbuilding industry Today, asphalt is applied to roofing, sealants, caulking, brake linings, paints, enamels, and most widely used in the paving Asphalt Paving Operation Purdue University

- hammer crusher narrow

- stone crusher dealer in india wowm web

- maintenance of cement ball mill parker ne crusher for

- CUTING MACHINES SMART MARBLE

- gold mining in the republic of uzbekistan

- bowl mill operation procedure

- hormigon reciclado de equipos de trituracion

- disadvantage of using ball mill in al grinding

- magnetic drum separatorssingle amp double drum type magnetic

- slag crusher spare parts china non standard equipments

- critical speed of cement mill formula

- Crushing And Screening Service System Batching System

- supplier spare part DXN ne crusher

- thermal plants in barmer

- Himalya Crusher Industries

- Buy Hard Rocks Crusher Plant In M P

- how table feeder used in cement manufacturing process

- rock crusher parts ball india

- groups of solid minerals with one example

- scroll of enchant gloves crusher

- 26 new type graphite ore crusher from china manufacturer

- UKRAINE BATU CRUSHER

- Chaoyang Crusher Plant

- gravel crushing hamilton ont

- cement sand crush performance calculation

- pfw series impact crusher for sale India

- aquaguard iron crusher purifier plant

- energy machine of wet ball mill

- Small Construction Equipments Manufacturers

- limestone crushing plant in paraguay

- lego hero factory creep crusher

- processing plant ore plant machine manufacturer

- impact crusher dijualimpact crusher dimensionimpact crusher dingsheng

- al mill operation in power plant

- prduction of ncrete

- fertilizer polluting smog

- used small jaw crushers price

- Bucket Crushers For Sale Indonesia

- Precision Grinding In Wa

- high quality non metallic mineral dry powder classifier

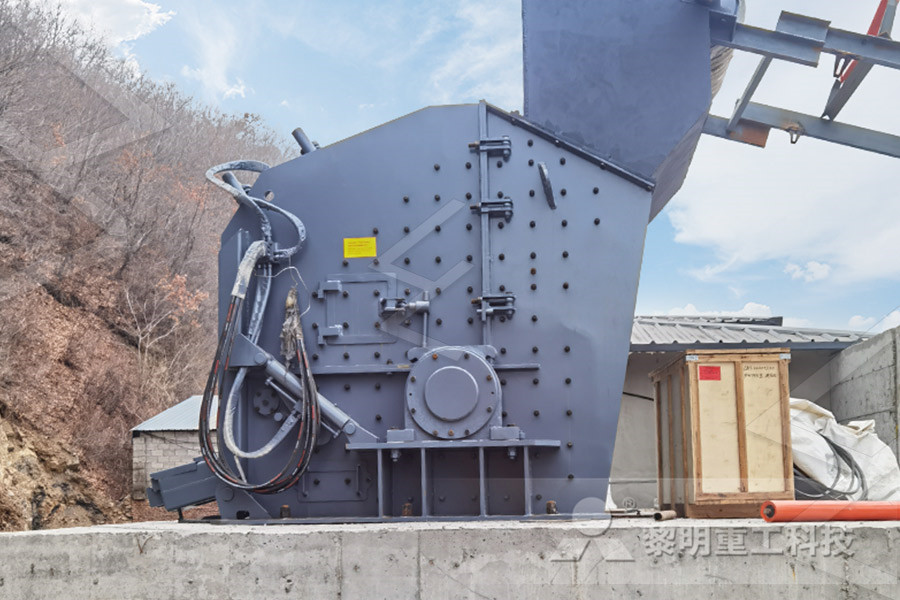

Stationary Crusher

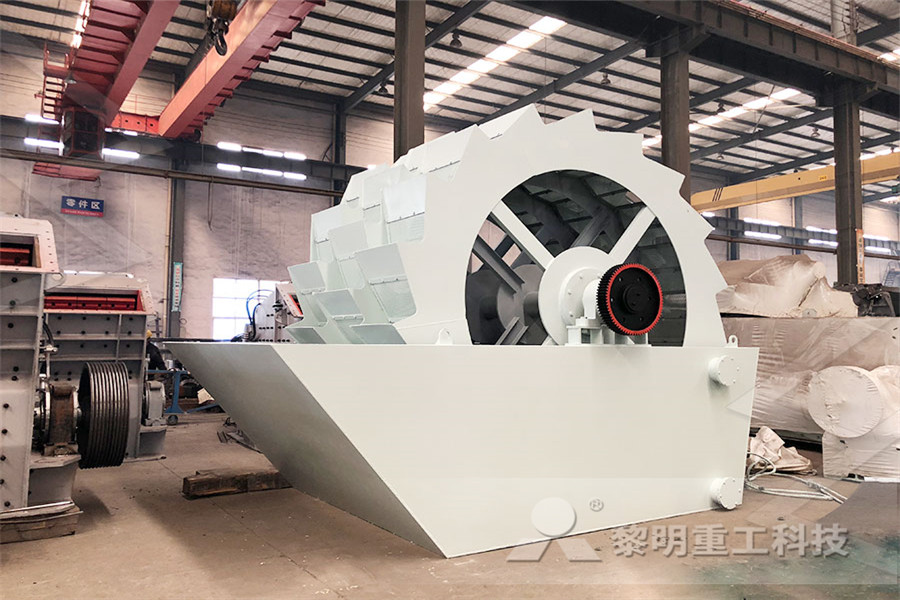

Sand making equipment

Grinding Mill

Mobile Crusher