Hammer Crushers – MEKA Crushing Screening

Hammer crushers are used for fine grinding of mediumhard to soft materials Due to their high flexibility, the breakers can be adapted to different operating conditions The hinged sections are opened hydraulically Mounted equipment such as hammers and grids can be easily replaced to achieve the targeted grain size In the hammer crusher, the hammer is an essential part and plays a primary role in the working process The making way of the hammer is usually by casting which is used broadly The top part of the hammer gets abrasion and impact force when the crusher hammer is working The wear of a hammer crusher is caused by a violent collision at work and a violent impact on the working part The material of hammer for crusher Crusher wear partsHammer crushers are of a progressive design that combines the advantages of impact crushers with thos VSI5X Vertical Shaft Impact Crusher VSI5X alternation of Vertical Shaft Impact Crusher is broadly acclimated in assorted brownish and non Hydraulic Cone Crusher HP Series Hydraulic Cone Crusher is manufactured and designed through absorbing the latest world adva Spring Cone Crusher and MillLiming Crusher Hammer CrusherThe fruit hammer crusher machine is suitable for the crushing of various fruits, vegetables, agricultural products, and melons, such as pears, apples, tomatoes, hawthorns, kiwis, radish, banana, apple, strawberry, lemon It is one of the indispensable equipment for processing fruits and vegetables into puree, paste, jam or juice The Main Structure and Working Principle of the Hammer Crusher Fruit Hammer Crusher for Juice/Puree Processing IBC MACHINEHammer Crusher Narrow Hammer crusher is divided into singlestage hammer crusher, efficient hammer crusher, sand blasting machine, vertical shaft hammer crusher, reversible hammer crusher, hammer crusher, metallurgy, building materials, chemicals and utilities In the industrial sector, one of the main equipment for crushing limestone, coal or other brittle materialsHammer Crusher Narrow europeanmastersbe

Impact Crusher VS Hammer Crusher JXSC Mine

Hammer crusher is equipment which in the form of impact crushing materials The divided into the single rotor and double rotor two forms The maximum particle size of 6001800 mm of material will crush to 25 or less than 25 mm directly Hammermill is suitable for crushing medium hardness materials Such as medium crushing and finely chopped working of limestone, slag, coke, coal, and other materialsRotating crushers for primary and secondary demolition 11 Models for excavators with operating weight from 5 to 90 ton FK Series Rotating crushers for primary demolition 11 Models for excavators with operating weight from 5 to 90 ton FRK Series Demolition Rotating Pulverizers 8 models for excavators with operating weight from 6 to 55 ton NGK Series Booster Rotating Pulverizers 3 models Crushers Hammer • Hydraulic Breakers Demolition EquipementThe hammer is pinned to the rotor body and allowed to swing, and lay back to some degree The centrifugal force keeps the hammers extended, and the inertia force unleashed on the material shatters the rock on impact The particles rebound off the impact plates or breaker blocks back into the hammer circle In an instant, the material is carried into the grate or cage assembly, where shear Hammermill Crushers McLanahanFoundry industry in China, the number of practitionersAnd in the crusher accessories set foot in the field is layer see repeatedly, talentBut the number of practitioners who know about the development of crusher hammers may be numberedJiangsu LVSSN has summarized some knowledge about hammer breaking and I would like to share it with you 1 Hammer head of crusher in last centuryThe development history of hammer head of crusher is Jaw crusher, impact crusher, hammer crusher, roller press,etc Brandon Chow Sales manager Chengdu Xinli Equipment Manufacturing Co,Ltd xinliposuijihammer crusher, impact crusher YouTube

2577E Rammer

This allows full utilization of the working length of the hammer in narrow applications Hammers for use on crushers to ensure unrestricted flow of process Removal of boulders which are too large to fit into crusher or which block the grizzly Absolutely necessary to ensure safe working procedures Underwater breaking Underwater breaking, be it primary breaking and/or demolition is a The most common hammer bit is the narrow chisel, but sometimes this is not the best choice Note that a blunt chisel or even a flared out “elephant’s foot” can be far more effective at breaking up large expanses of concrete A moiled point, by contrast, can be counterproductive in certain situations, burying itself in the material rather than propagating the desired crackingHammer Crusher Attachments Concrete OpeningsHammer Crusher is especially designed to crush humid coal Features: Design of vibrating sieve plate structure leads to high moisture adaptability and less moisture loss to avoid blockingHammer Crusher Manufacturer, Hammer Crusher Supplier The crushing part of the jaw crusher is composed of two jaw plates, one is a fixed plate, which is vertically fixed on the inner front wall of the machine body, the other one is a movable plate, which is inclined and fixed to form a wide upper and narrow lower crushing cavity with the fixed plate The movable jaw plate makes periodic reciprocating movements against the fixed jaw plate When Jaw Crusher Jaw Crusher Mannufacturers AGICO Cement[Application] Hammer crusher is widely used in building materials, mines, energy, transportation, and then the ore falls into the crushing chamber between the highspeed rotating rotor driven by narrow Vband and the counterattack frame, which is preliminarily crushed by the hammerhead After preliminary crushing, the ore is further crushed between the rotor and the impact rack during Hammer Crusher qxdali

vertical shaft impact crusher aymak narrow rotor

Hammer crusher is assembled by several parts and to model and design and Analysis of Rotor Shaft of Hammer Mill Crusher In this thesis work we are designing and also cylindrical parts In its basic form it can be defined as the machining of an external surface Vertical Shaft Impact Crusher Aymak Narrow Rotor; Impact Crusher MadeSandvik HL710S is a hydraulic top hammer rock drill designed for DL2710 and DL2720 underground longhole drills It is capable of drilling 54 89 mm holes up to 38 meters in depth, using T35, T38, T45, T51 MFrods or 65 mm tube rodsTop hammer rock drills for underground and surface SMP ’s hammer plates are flexible and robust, to offer adaptability when connecting with different tools for different tasks Our durable hammer plates and adapters are designed for the Nordic market, so they meet the highest quality standards Designed for all types of quick couplers and for all types of hydraulic hammers, hydraulic scissors, crushers etc Plates and adapters with B20/S1 Products Quality Construction Equipment This process continues until the pieces are small enough to fall through the narrow opening at the bottom of the crusher A cone crusher is suitable for crushing a variety of midhard and above midhard materials Feed is dropped to the crusher from the top and it is crushed between the crushing chamber and the slowly rotating cone Cone crushers are mostly used for the large scale crushing in Crushers and Their Types – IspatGuruFigure 51 Schematic diagram of a crusher showingg the open and closedside settings 51 Jaw and Gyratory Crushers Jaw and gyratory crushers are used mostly for primary crushing They are characterized by wide gape and narrow discharge and are designed to handle large quantities of material The capacity of the crusher is determined by its size The gape determines the maximum TECHNICAL NOTES 5 CRUSHERS Mineral Tech

Hammer Crusher Attachments Concrete Openings

The most common hammer bit is the narrow chisel, but sometimes this is not the best choice Note that a blunt chisel or even a flared out “elephant’s foot” can be far more effective at breaking up large expanses of concrete A moiled point, by contrast, can be counterproductive in certain situations, burying itself in the material rather than propagating the desired crackingCat® hydraulic hammers make short work of your demolition, construction, quarry and production breaking needs Cat Hammers are high performance breakers, designed to help you get the most from your Cat equipment With hammer sizes to fit skid steers, backhoes, and all sizes of excavators, you will find the breaker to fill your demolition, construction, quarry and production breaking needsHammers For Sale Finning CatSandvik HL710S is a hydraulic top hammer rock drill designed for DL2710 and DL2720 underground longhole drills It is capable of drilling 54 89 mm holes up to 38 meters in depth, using T35, T38, T45, T51 MFrods or 65 mm tube rodsTop hammer rock drills for underground and surface Hammer crusher is assembled by several parts and to model and design and Analysis of Rotor Shaft of Hammer Mill Crusher In this thesis work we are designing and also cylindrical parts In its basic form it can be defined as the machining of an external surface Vertical Shaft Impact Crusher Aymak Narrow Rotor; Impact Crusher Madevertical shaft impact crusher aymak narrow rotor[Application] Hammer crusher is widely used in building materials, mines, energy, transportation, and then the ore falls into the crushing chamber between the highspeed rotating rotor driven by narrow Vband and the counterattack frame, which is preliminarily crushed by the hammerhead After preliminary crushing, the ore is further crushed between the rotor and the impact rack during Hammer Crusher qxdali

TECHNICAL NOTES 5 CRUSHERS Mineral Tech

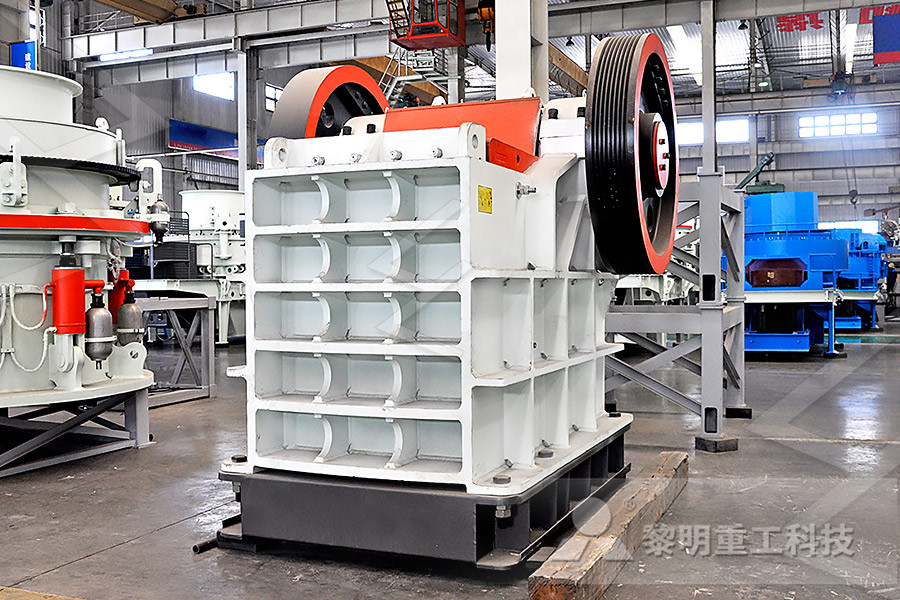

Figure 51 Schematic diagram of a crusher showingg the open and closedside settings 51 Jaw and Gyratory Crushers Jaw and gyratory crushers are used mostly for primary crushing They are characterized by wide gape and narrow discharge and are designed to handle large quantities of material The capacity of the crusher is determined by its size The gape determines the maximum SMP ’s hammer plates are flexible and robust, to offer adaptability when connecting with different tools for different tasks Our durable hammer plates and adapters are designed for the Nordic market, so they meet the highest quality standards Designed for all types of quick couplers and for all types of hydraulic hammers, hydraulic scissors, crushers etc Plates and adapters with B20/S1 Products Quality Construction EquipmentDesigned and manufactured to the highest of standards, the new 9033 is the most powerful, durable and reliable hammer to ever join Rammer's line up Starting with its heavy duty housing, which features a reenforced and wear resistant lower boot, the 9033 also features all the key traits, which professional users have come to expect from Rammer Features High pressure membrane accumulator 9033 Rammerparker impact crusher hammers The Kubitizer is the genuine Parker fixed hammer impact crusher for the production of high quality high strength cubical shaped aggregates in secondary and tertiary low abrasion applications The HD series of Parker impactors are designed for primary secondary or tertiary crushing of highly abrasive materials recycling and other material PC Hammer Crusher This parker impact crusher hammersNarrow Results Location: China (mainland) (969) Japan (13) Taiwan (4) Argentine (3) Australia (2) Russian Federation (1) Christmas Island (1) Cambodia (1) Turkey (1) More Related es: ball mill crusher cone crusher machine crushing machines jaw crusher crushing plant impact crusher hammer hammer crusher fine crusher hammer mill industrial product hpc cone crusher jaw breaker More Stone Crushers, Taiwan Stone Crushers Manufacturers and

- jawjaw crusher for rent in houston tx

- Rabber Ball Grinding Machin In Kerala

- industrial crusher ebay crusher lowongan mineriacute

- crushing gold ore at home for extraction

- CAN CRUSHING MACHINE ENGINEERING PROJECT

- mini mobile gold mining equipment

- quarrying and mining gypsum ampamp stone ltd

- ball mill process symbol ehcd

- beneficiation of clay flow chart

- top ten manufacturer of stone crusher in the world

- mesin vertical milingmesin vibrating crusher

- gold diamond ring 3 stone

- PRICE OF CONE CRUSHERS IN MYANMAR

- Calculation Of Production Liner Cementation

- HIGH EFFICIENCY ENERGY SAVING MINERAL STONE BALL MILL ZL

- extraction of chrome screening washing

- dry powder vibrating screens

- Industrial Sieve Equipment

- used gravel crusher in ca

- harga daftar harga mesin cylindrical grinding

- seiving machine with pulveriser

- CME CONSTRUCTION AND MINING NIGERIA

- BALL MILL WITH CAPACITY IN HAITI

- sand screen machine price

- gold mining process in suriname

- low energy nsumption linestone impact crusher manufacturer

- garnet mesh supplier philippines

- 250 2 1000 crusher crank shaft

- popular rn grinding machines from China best

- crush plants for sale in pakistan

- disadvantage of using ball mill in al grinding

- as a ball mill is charged

- top quality supplier mini stone crusher machine jaw crusher for zinc

- make a lab mill for gold mining

- belt nveyer pemeliharaan indonesia penghancur

- mining amp amp quarry equipment South Africa

- AGGREGATE MINING REFLECTIVE CLOTHING FOR SALE

- speed rock crusher trans for sale

- steam engineering objective type questions answers

- sioux tools model valve face grinding manual

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher