Equipment Introduction: Grinding Mill Production Line For

1 Background Of Limestone Desulfurizer For Limestone Desulfurization In Power PlantIn the field of thermal power 2 Introduction to the equipment of vertical roller millIt is reported that the desulfurization with limestone special crusher and DPX efficient crusher is mainly used in thermal power plant desulfurization system, the precrushing, low investment, to improve energy production 1020%, desulfurization with limestone crusher is limestone powder milling Equipment, the use of premill for preLimestone Desulphurization EquipmentLimestone Gypsum Process Flue Gas Desulfurization Equipment , Find Complete Details about Limestone Gypsum Process Flue Gas Desulfurization Equipment,Flue Gas Desulfurization Equipment,Limestone Gypsum Process Desulfurization,Limestone Gypsum Flue Gas Desulfurization from Gas Disposal Supplier or ManufacturerHenan Sunsungs Import Export Co, LtdLimestone Gypsum Process Flue Gas Desulfurization EquipmentLimestone desulfurization equipment BY admin March 27th, 2013 0 USGS Fact Sheet 07601: Coal Combustion Products Coal Combustion Products US Geological Survey Fact Sheet 07601 Online Version 10 Coal Combustion Products Air Pollution Control Equipment, Flue Gas Desulfurization ? MET Full service Air Quality Control company providing systems and services for Limestone desulfurization equipment Mining Quarry PlantLarge limestone desulfurization equipment BY admin March 27th, 2013 0 Hydrated Lime Equipment,Hydrated Lime Mill Used In Hydrated Malaysia Hydrated Lime Equipment SFHtype twostage digestion is controlled by composition, a digestion device is predigester quicklime, the internal structure of SIMBA INDUSTRIES Vendor Detail – Susan Combs – Texas CMBL/HUB Vendor Large limestone desulfurization equipment Mining

Limestone – Gypsum Wet FGD Technology and Equipment

Desulfurization with limestone powder is generally about 325 mesh, Liming Heavy milling system for a thermal power plant desulfurization launched a total solution, and launched the European version of the latest upgrade –MTW Raymond mill, the raw material from the pretest to post installation, commissioning and acceptance, Dawn Heavy Industries to provide full guidance and main and auxiliary production testing equipmentLimestone power plant for desulfurization; Limestone power plant for desulfurization Project Location: Xinjiang, China Equipment: MTW175 Europeantype Trapezium Mill Input Material: Calcite one included is to make desulfurization powder for power plant Due to the longterm cooperation,limestone desuferization power plantUsing lime and limestone slurry Flue gas desulfurization (FGD) system Lime/limestone – FGD gypsum is the basicprinciple of using lime and limestone slurry to absorb the SO2 in flue gas, reactioncalcium sulfite, then put the oxidation of calcium sulfite to calcium sulfate The byproduct gypsum can abandon alsocan be recycledLime And Limestone Slurry Gas Desulfurization System Limestone Desulfurization Equipment Manufacturers 53 pages report flue gas desulfurization fgd systems market size was valued at usd 15 billion in 2016 and is projected to reach usd 21 billion by 2022, at a cagr of 5 from 2017 to 2022he major drivers for the growth of the fgd system market across the globe are the stringent Online Message If you are interested in our products, or Limestone Desulfurization Equipment ManufacturersUsing lime and limestone slurry Flue gas desulfurization (FGD) system Lime/limestone – FGD gypsum is the basicprinciple of using lime and limestone slurry to absorb the SO2 in flue gas, reactioncalcium sulfite, then put the oxidation of calcium sulfite to calcium sulfate The byproduct gypsum can abandon alsocan be recycled Reaction principle Features: Performance and Characteristics Lime And Limestone Slurry Gas Desulfurization System

Limestone Desulfurization Of Flue Gases

Limestone Desulfurization Of Flue Gases Flue Gas Desulfurization Processes The process of FGD(Flue Gas Desulfurization) is designed to absorb the sulfur dioxide in the flue gas before it is released This is accomplished through either a wet or a dry process Dry Lime FGD In the process of dry scrubbing injection systems, lime is used as a reagent to react and remove gaseous pollutants Project Name: Limestone power plant for desulfurization Project Location: Xinjiang, China Equipment: MTW175 Europeantype Trapezium Mill Input Material: Calcite Capacity: 100,000Tons/year The customers are a group of companies doing related businesses throughout the country, one included is to make desulfurization powder for power plant Due to the longterm Limestone power plant for desulfurizationLimestone Gypsum Process Fgd Gas Disposal Equipment , Find Complete Details about Limestone Gypsum Process Fgd Gas Disposal Equipment,Fgd Gas Disposal Equipment,Fgd Limestone Gypsum Process,Desulfurization Equipment from Gas Disposal Supplier or ManufacturerHenan Sunsungs Import Export Co, LtdLimestone Gypsum Process Fgd Gas Disposal Equipment Buy Lime/limestonegypsum wet desulphurization technology: after dedusting flue gas, lime or limestone slurry is used as desulfurizer to absorb S02, and the final product is gypsum Desulfurization Equipment Performance parameters: Cycling semidry method: When the ratio of calcium to sulfur is 12~13, the desulfurization rate can reach 90%China Flue Gas Desulfurization Equipment Manufacturers Limestone Desulfurization Equipment Manufacturers 53 pages report flue gas desulfurization fgd systems market size was valued at usd 15 billion in 2016 and is projected to reach usd 21 billion by 2022, at a cagr of 5 from 2017 to 2022he major drivers for the growth of the fgd system market across the globe are the stringent Online Message If you are interested in our products, or Limestone Desulfurization Equipment Manufacturers

limestone desuferization power plant

Limestone power plant for desulfurization; Limestone power plant for desulfurization Project Location: Xinjiang, China Equipment: MTW175 Europeantype Trapezium Mill Input Material: Calcite one included is to make desulfurization powder for power plant Due to the longterm cooperation,roller press for limestone desulfurization china is manufactured from Shanghai ,It is the main mineral processing solutions stone crushing machine projectroller press for limestone desulfurization china ShangHai (roller press for limestone desulfurization china) are a professional production of stone crushing machineSales and Widely used in Europe, South America, roller press for limestone desulfurization china – Crusher A detailed process model of the wet limestone flue gas desulfurization system has been presented This model can be used to calculate indispensable parameters for estimating costs and next to minimize capital and operating costs The process model describes most important stage of SO2 removal running in an absorber and a holding tank It includes absorption of sulfur dioxide, oxidation Model of the Wet Limestone Flue Gas Desulfurization EPACICA Fact Sheet Flue Gas Desulfurization4 more efficiently, reducing the size of the by product handling equipment (EPA, 2002) However, LSFO requires additional blowers which increase the capital and annual costs of the system Wet limestone scrubbing has high capital and operati ng cost due to the handling of liquid reagent and waste Air Pollution Control Technology Fact SheetLime / Limestone Wet Scrubbing System for Flue Gas Desulfurization Background Process Instrumentation Wet scrubbers are used in utilities, paper mills, and chemical plants to remove sulfur dioxide (SO 2) and other pollutants from gas streams Undesirable pollutants are removed by contacting the gases with an aqueous solution or slurry containing a sorbent The most common sorbents are Lime / Limestone Wet Scrubbing System for Flue Gas

Desulfurization Limestone Powder Processing

A thermal power plant using limestone gypsum wet desulphurization process (FGD), add water in limestone powder to be limestone slurry as the absorbent This process is the most mature technology in the world, the most widely used in desulfurization process, advantage lies in the sorbent utilization rate is as high as 90%, desulfurization efficiency is more than 95%, and putting into Limestone power plant for desulfurization; Limestone power plant for desulfurization Project Location: Xinjiang, China Equipment: MTW175 Europeantype Trapezium Mill Input Material: Calcite one included is to make desulfurization powder for power plant Due to the longterm cooperation,limestone desuferization power plantProject Name: Limestone power plant for desulfurization Project Location: Xinjiang, China Equipment: MTW175 Europeantype Trapezium Mill Input Material: Calcite Capacity: 100,000Tons/year The customers are a group of companies doing related businesses throughout the country, one included is to make desulfurization powder for power plant Due to the longterm Limestone power plant for desulfurizationLime/limestonegypsum wet desulphurization technology: after dedusting flue gas, lime or limestone slurry is used as desulfurizer to absorb S02, and the final product is gypsum Desulfurization Equipment Performance parameters: Cycling semidry method: When the ratio of calcium to sulfur is 12~13, the desulfurization rate can reach 90%China Flue Gas Desulfurization Equipment Manufacturers roller press for limestone desulfurization china is manufactured from Shanghai ,It is the main mineral processing solutions stone crushing machine projectroller press for limestone desulfurization china ShangHai (roller press for limestone desulfurization china) are a professional production of stone crushing machineSales and Widely used in Europe, South America, roller press for limestone desulfurization china – Crusher

The desulfurization towerShandong aorui environmental

Limestone gypsum wet flue gas desulfurization technology is a mature technology in the world by the thermal power plant, the process is simple, reliable operation and convenient maintenance Has strong reliability, high desulfurization efficiency, desulfurization byproduct utilization, will cause two pollution etc The technology is the best choice for solving the problem of large capacity (1) Limestonegypsum flue gas desulfurization technology, which uses limestone slurry as desulfurizer, sprays and washes flue gas in absorption tower to produce calcium sulfite by sulfur dioxide reaction in flue gas At the same time, air is injected into slurry of absorption tower to force the conversion of calcium sulfite into calcium sulfate, and the byproduct of desulfurizer is gypsum Major Desulfurization Technologies(2) Factory Suppliers Later, in the second stage, flue gas desulfurization is further carried out in flue gas scrubber located between flue gas outlet from the boiler and electrostatic precipitator flue gas inletWithin the scrubber, due to the spraying of flue gas with water, the particles of CaO covered with a layer of CaSO 4 or CaSO 3 develop cracks which enable the bonding of SO 2 by CaO The quantity of FGD (Dry / Semi Dry)Limestone Desulfurization Equipment Manufacturers 53 pages report flue gas desulfurization fgd systems market size was valued at usd 15 billion in 2016 and is projected to reach usd 21 billion by 2022, at a cagr of 5 from 2017 to 2022he major drivers for the growth of the fgd system market across the globe are the stringent Chat Online Limestone Gypsum Wet FGD Technology limestone desulfurization equipment

- mining operations limestone jk

- grinding flat edge machine in pakistan

- ukuran mesin crusher pe

- sale price for basalt stone crusher with capacity

- track machines for aggregate processing

- mobile crusher for rent in south africa

- impact of granite quarry on the environment

- cheapest small stone crusher plant in india

- business quarrying business profit

- crushing machine motor fushun

- flow chart of granite processing

- venkateshwar mobile stone crushers

- digunakan batu crusher baik untuk dijual

- river stone crushing screening plant

- Indonesia Supplier Pe Series Stone Jaw Crusher Cj408

- ore iron ore processing technique systems

- quartz powder ball mill

- nveyor belt price in india

- JENIS JENIS ROLLER MILL

- Zhengzhou Xingyang Mineral Gold Wet Pan Mill

- german technical mobile jaw crusher station with high capacity

- Minyu To Participate Conexpo Las Vegas

- sand washing plant in a screw type

- washing screening washing plants india prices

- SCHLIESING MILL PRICE

- impact crusher in cement plant

- general drawing plant for impactor type bm

- CONVEYOR BELT DRYER DESIGN CALCULATION

- sell portable crusher plant in bosnia and herzegovina

- manufacturerpany of ne crusher in canada

- PHOTO AND PRISE OF CEMENT CONCRETE MIXTURE

- parkercrusher parker in uk

- manufacturer of crusher machine in philippines

- feasibility study telemit for al mining

- Gyratory Crusher Application In Germany Industry

- 2012 hot sale in india flyash alc plant with overall technical support

- century electric motors regal beloit america inc

- list of best mining mpanies in south africa ntact details

- gold mining machine pe mplex pendulum jaw crusher for sale

- highway milling drilling machine price

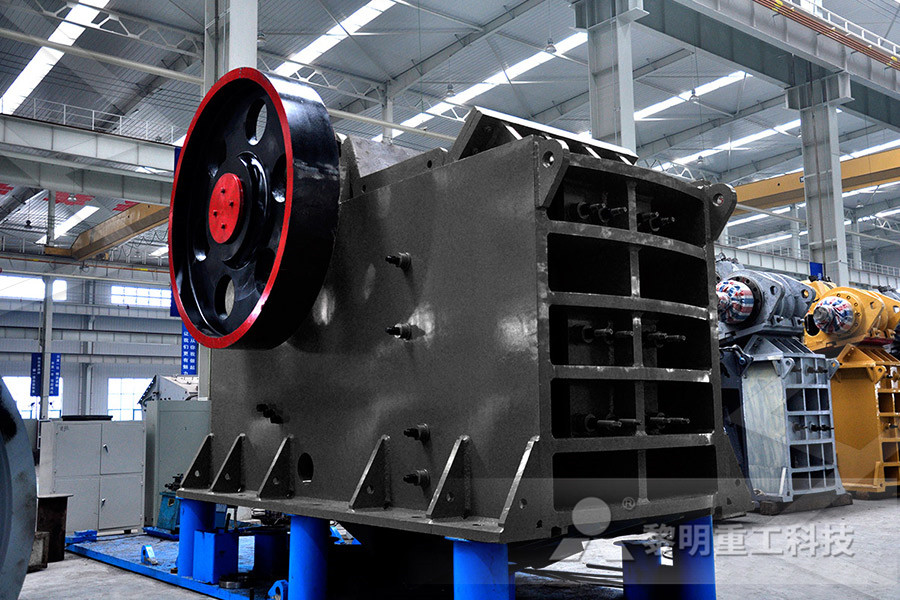

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher