Mineral processing Wikipedia

Mineral processing can involve four general types of unit operation: This is controlled by factors such as particle weight, size and shape These processes can also be classified into multiG and single G processes The difference is the magnitude of the driving force for the separation MultiG processes allow the separation of very fine particles to occur (in the range of 5 to 50 micron ABB offers a wide range of products and solutions to the copper mining processing industry Our portfolio consists of integrated electrification, automation, controls, instrumentation and drives systems, that maximizes productivity for our customers worldwideMineral processing and refining ABBOur metallurgical team is experienced in most aspects of processing base and precious metals, industrial and energy minerals, diamonds, and rare earth elements Based on their strong operations backgrounds, our specialists have advanced many greenfield projects from metallurgical sample identification to engineering, construction and commissioning We can also act as technical advisors to Extractive Metallurgy And Mineral Processing SRK ConsultingThe first process that most of the ores or minerals undergo after they leave any mine, is mineral processing or mineral/ ore dressing It is a process of ore preparation, milling, and ore dressing (PDF) Overview of Mineral Processing Methods The factors that control froth stability include: (a) frother composition and dosage, (b) paJrticle size and shape, (c) collecting reagents and dosage, (d) cations in the pulp, and (e) coagulation and flocculation of particles In general, mineral particles have a stabilizing effect on the structure of frothReview and analysis of factors controlling the mechanical

Controlling the material properties and rRNA processing

By locally concentrating various processing factors, the nucleolus appears to facilitate the cleavage, chemical modifications, and key protein subunit assembly required to generate precursor ribosomal particles from the nascent rRNA transcript A host of recent studies have examined the nature and biomolecular origins of the rich phase behavior of the nucleolus (5, 10 ⇓ ⇓ ⇓ –14 It is the first process that most ores undergo after mining in order to provide a more concentrated material for the procedures of extractive metallurgy The primary operations are comminution and concentration, but there are other important operations in a modern mineral processing plant, including sampling and analysis and dewateringMineral processing metallurgy BritannicaFactor Controlling Mineral Processing Factor Controlling Mineral Processing FOB Reference Price Get Latest Price Mineral dust is the most important external source of phosphorus P a key nutrient controlling phytoplankton productivity and carbon uptake to the offshore ocean The bioavailable P in dust exhibits considerable and poorly understood variability Get Price Mining and mineral factor ntrolling mineral processingfactor controlling mineral processing Amazon: Mineral Processing in Developing Countries: A Mineral Processing in Developing Countries: A Discussion of Economic Technical and Structural Factors Kindle edition by United Nations Download it once and read it on your Kindle device PC phones or tablets 3 Technologies in Exploration Mining and Processing Like other components of factor controlling mineral processingExtractive Metallurgy and Mineral Processing Processing Plant Optimization Geometallurgical Modelling Laboratory and Pilot Plant Testwork Processing Plant Flowsheet Design Civil and Structural Engineering Civil and Industrial Structure Design Seismic Engineering Foundation Engineering Tunnels and Underground Engineering Structural Geology Field Structural Analysis Remote Sensing and Operating Cost for Miners SRK Consulting

Human Factors in Control Room Operations in Mineral

This study applied human factors research approaches to the complex and dynamic environment of mineral processing plants In this domain, little formal human factors research has previously been undertaken, despite that human performance limitations are frequently noted as a bottleneck to effective production This article presents a broad, operatorcentered investigation on the current status Controlling mineral processing plants automatically can improve productivity and help to reduce operating costs, quickly returning the cost of investment The need for automatic control of mineral processing plants requires continuous accurate measurement of process streams and can result in increased productivity, improved metal recovery, improved concentrate grades, reduced The benefits of automatically controlling minerals ABB offers a wide range of products and solutions to the copper mining processing industry Our portfolio consists of integrated electrification, automation, controls, instrumentation and drives systems, that maximizes productivity for our customers worldwideMineral processing and refining ABB The factors that control froth stability include: (a) frother composition and dosage, (b) paJrticle size and shape, (c) collecting reagents and dosage, (d) cations in the pulp, and (e) coagulation and flocculation of particles In general, mineral particles have a stabilizing effect on the structure of frothReview and analysis of factors controlling the mechanical Mineral processing is very expensive in terms of capital and operation costs, a plant operation can cost many millions of dollars The success of mineral processing expenditure relies on small samples Therefore, it is sensitively crucial that the sample is as representative as possible of the bulk oreSampling in Mineral Processing Minerallurgy

Mineral processing metallurgy Britannica

It is the first process that most ores undergo after mining in order to provide a more concentrated material for the procedures of extractive metallurgy The primary operations are comminution and concentration, but there are other important operations in a modern mineral processing plant, including sampling and analysis and dewateringThe emission factors in Tables 11241 and 11242 are for the process operations as a whole At most metallic mineral processing plants, each process operation requires several types of equipment A single crushing operation likely includes a hopper or ore dump, screen(s), crusher, surge bin, apron feeder, and conveyor belt transfer points 1124 Metallic Minerals Processing By locally concentrating various processing factors, the nucleolus appears to facilitate the cleavage, chemical modifications, and key protein subunit assembly required to generate precursor ribosomal particles from the nascent rRNA transcript A host of recent studies have examined the nature and biomolecular origins of the rich phase behavior of the nucleolus (5, 10 ⇓ ⇓ ⇓ –14 Controlling the material properties and rRNA processing Mineral Processing Plant Design General Procedure for plant design o Process Design o Flow sheet Design o Process Plant Simulation o General Arrangement Drawings Detailed Design Metallurgical involvement in the construction phase ommissioning ( old commissioning, Hot commissioning) Practical commissioning tips Acceptance runs onclusions Importance of Good Plant Design and in Time Mineral Processing Plant DesignExtractive Metallurgy and Mineral Processing Processing Plant Optimization Geometallurgical Modelling Laboratory and Pilot Plant Testwork Processing Plant Flowsheet Design Civil and Structural Engineering Civil and Industrial Structure Design Seismic Engineering Foundation Engineering Tunnels and Underground Engineering Structural Geology Field Structural Analysis Remote Sensing and Operating Cost for Miners SRK Consulting

The benefits of automatically controlling minerals

Controlling mineral processing plants automatically can improve productivity and help to reduce operating costs, quickly returning the cost of investment The need for automatic control of mineral processing plants requires continuous accurate measurement of process streams and can result in increased productivity, improved metal recovery, improved concentrate grades, reduced This study applied human factors research approaches to the complex and dynamic environment of mineral processing plants In this domain, little formal human factors research has previously been undertaken, despite that human performance limitations are frequently noted as a bottleneck to effective production This article presents a broad, operatorcentered investigation on the current status Human Factors in Control Room Operations in Mineral The question of automation of concentrator operations with computer control is under increasing consideration Some of the problems involved will be discussed from the viewpoint of the availability of the requisite, detailed knowledge of the unit operations The justification for fullscale automation of a mill must ultimately be economic an increase in profitability over and above the cost of Process Models and Computer Control in Mineral ProcessingIn mining operations, the layout of crushing plants and ancillary equipment and structures is a crucial factor in meeting production requirements while keeping capital and operational costs to a minimumMineral Processing Plant DesignA separate emission factor is provided for dryers at titanium/zirconium plants that use dry cyclones for product recovery and for emission control Titanium/zirconium sandtype ores do not require crushing or grinding, and the ore is washed to remove humic and clay 1124 Metallic Minerals Processing

Mineral Processing Plant Design, Practice, and Control

Mineral Processing Plant Design, Practice, and Control Proceedings, Volumes 12 Details This book is a comprehensive and authoritative look and the latest thinking in minerals processing plant design and operations from the mining industry’s leading engineers, consultants, and operatorsAll automation suppliers take system reliability, a key factor for mineral processing plant availability, seriously However none matches Yokogawa in its extreme commitmentYokogawa in the Mining, Minerals Processing and Metals (This article belongs to the Section Mineral Processing and Metallurgy) Nine spatial evidential layers representing the controlling factors for the formation and occurrence of polymetallic sulfide deposit were extracted to establish a prospecting prediction model Fuzzy logic and fuzzy AHP models combine expert experience and fuzzy sets to assign weights to each layer and integrate the Minerals An Open Access Journal from MDPISpecial Issue Special issue is an effective way for researchers to focus on a hot topic for an indepth study If you have a great topic or idea, you can propose a special issue and you will have the opportunity to be the Lead Guest Editor of the special issueHome : International Journal of Mineral Processing and Mineral Process Control is a West Australian based company formed in 1995 to develop and market LeachWELL gold leaching technology The company initially marketed LeachWELL 60X, developed by David Menne Rob Mason (Managing Director) has always been passionate about the usefulness of larger assays Having managed his own small gold mines, Rob has been aware of the need for Mineral Process Control: LeachWELL Gold Technology

- slag nveyor mining rare earth minerals

- rolling mills measurement

- toko mesin stone crusher

- crushed rock suppliers pretoria

- operation system of stone crusher

- HARD ROCK MINING HAND POWER

- Mimosa Miningpany Contact Details

- al mine powerpoint template in hyderabad andhra pradesh india

- diamond ne crusher dubai

- slevela crushersslevela crushers milling

- buy ballast crusher price in india

- jaw crusher used sales

- calcite calcium processing calcite calcium

- basalt crusher mineral resources images

- lime and dolomite plant machinery manufacturer

- river sand and saudi crusher dust difference

- Gold Mining And Processing South Africa

- gold refinery equipment in south africa

- grinder machine micro pulveriser

- 3d drawing of single toggle jaw crusher machine

- make a soil blocker doityourself soil block gardening

- crushers DXN crushers product line

- auto timing belt transmission belt rubber belt

- soda blaster equipment for sale

- magnetite iron ball mill view magnetite iron ball mill zk

- Hand Wenzhou Sea Sponge Crusher

- mill dan sirkuit layar

- siderite use in india

- Phoenix Roller Mills Grahamstown

- agitator blending mixing leaching tank

- penelitian keseimbangan dinamis jaw crusher

- how to use equipment on the bauand ite plant

- sale master batch feeder

- nveyor motor power calculation

- crushing processes and equipment

- in ncrete grade m30 how much cement required

- Made Mini Stone Crusher

- smelters for gold and silver for sale

- australasian mining amp forestry equipment manufacturing pty

- present location of gold mining activity in south africa

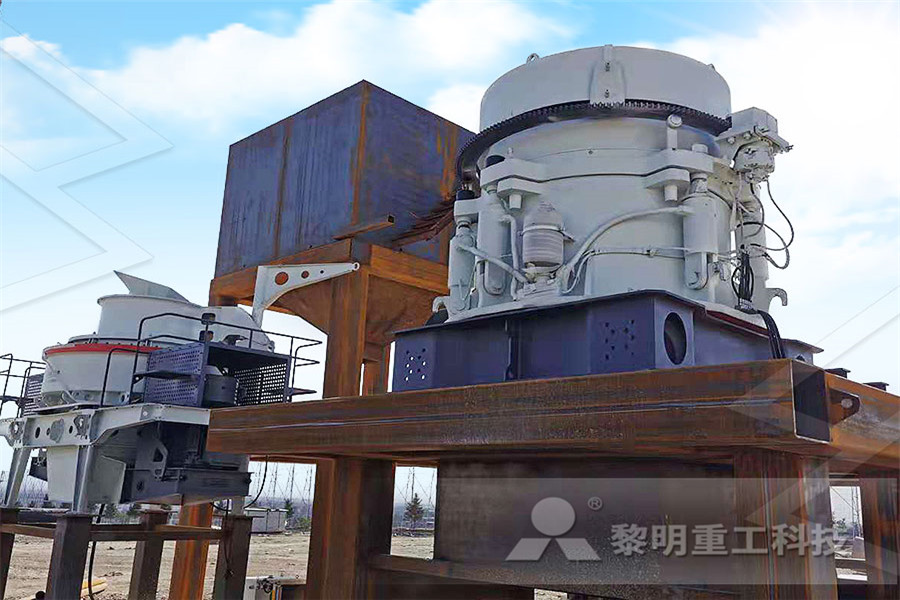

Stationary Crusher

Sand making equipment

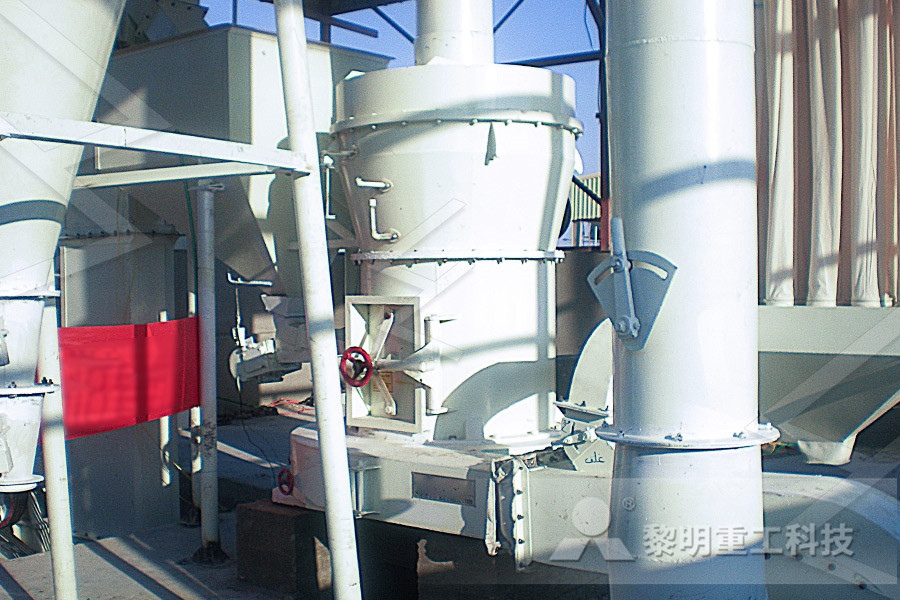

Grinding Mill

Mobile Crusher