Copper Mining Extraction Process Flow Chart

This flowchart made of machinery icons explains or expresses in simple but clear terms the step of the Copper Mining and Copper Extraction Process Starting from either openpit or underground mining and using a different relevant treatment method for oxide or sulphide copper mineral (ore) Having a quick look now at how porphyry ores are treated and the metals extracted There are two main A simplified schematic drawing of copper flotation flowsheet Runofmine open pit ore will be crushed in a gyratory crusher The crushed ore will be processed by means of semiautogenous and ball mill grinding followed by rougher flotation, regrind, cleaner flotation, and dewatering to produce copper concentrate The concentrate will be trucked via the existing road network in the area to a Copper Process Flowsheet ExampleCopper Mining and Processing: Processing of Copper Ores Copper processing is a complicated process that begins with mining of the ore (less than 1% copper) and ends with sheets of 9999% pure copper called cathodes, which will ultimately be made into products for everyday useThe most common types of ore, copper oxide and copper sulfide, undergo two different processes, hydrometallurgy and copper processing plant flowchartIn this process copper ore is mined, crushed, ground, concentrated, smelted and refined Get Price process flow diagram for gold concentrate plant TS 112 Process and Instrumentation Diagrams (PID) SA Water Technical Standard Revision 16 December 2015 Page 9 of 27 For Official Use Only Uncontrolled When Printed Or Downloaded Process Flow Designation General The flow direction of main process diagram of copper concentrate production processcopper ore processing plant diagram Description : copper mining process flow diagram 31 May 2013 A flow diagram for continuous copper precipitation using Copper ore ; which represents a simplified schematic flow diagram of a copper ammo0ium acetate extraction and purifiion system Briefly, the process of the present invention comprises s; In the first stage of the copper extraction, the ore flow diagram copper extraction process

oxidized copper ore processing diagram

Process flow diagram of copper ore mining plant using a flow diagram explain how copper ore is mining process flow diagram Coal processing system Machine If you need more information about mining process flow diagram Iron ore processing flow may be the front a basic copper mine process from mine to metal click to chat now Get price Copper Mining And Processing Flow Diagrams The Copper Mining Process Once it’s located within the earth, copper ore goes through eight stages before the consumer sees it in various products that affect every day life in the home and business These eight stages include: Mining; Grinding; Concentrating; Roasting; Smelting; Conversion ; Anode Casting; ElectroRefining; Documentation of the use of copper dates back to ancient times Copper Mining and Processing: Everything you Need to Know Copper processing is a complex process that involves many steps as the manufacturer processes the ore from its raw, mined state into a purified form for use in many industries Copper is typically extracted from oxide and sulfide ores that contain between 05 and 20% copper The refining techniques employed by copper producers depend on the ore type, as well as other economic and Copper Production: How Is Copper Made? ThoughtCocopper A continuous process called floatation, which uses water, various flotation chemicals, and compressed air, separates the ore into fractions Depending upon the chemicals used, some minerals float to the surface and are removed in a foam of air bubbles, while others sink and are reprocessed Pine oils, cresylic acid, and longchain alcohols are used for the flotation of copper ores The 123 Primary Copper SmeltingCopper Mining and Processing: Processing of Copper Ores Copper processing is a complicated process that begins with mining of the ore (less than 1% copper) and ends with sheets of 9999% pure copper called cathodes, which will ultimately be made into products for everyday useThe most common types of ore, copper oxide and copper sulfide, undergo two different processes, hydrometallurgy and copper processing plant flowchart

flow diagram copper extraction process

copper ore processing plant diagram Description : copper mining process flow diagram 31 May 2013 A flow diagram for continuous copper precipitation using Copper ore ; which represents a simplified schematic flow diagram of a copper ammo0ium acetate extraction and purifiion system Briefly, the process of the present invention comprises s; In the first stage of the copper extraction, the ore Process flow diagram of copper ore mining plant using a flow diagram explain how copper ore is mining process flow diagram Coal processing system Machine If you need more information about mining process flow diagram Iron ore processing flow may be the front a basic copper mine process from mine to metal click to chat now Get price Copper Mining And Processing Flow Diagrams oxidized copper ore processing diagramRomero GoldCopper Project , The process flow diagram , The process flow diagram The processing plant at Cerro Vanguardia gold and silver mine in , Get Info /Chat Now diagram of the processing of copper Diagram Of The Processing Of Copper EE Times Electronic Engineering Times EE Times connects the global electronics community through news, analysis, educat Diagram Of The Related Information Of The Processing Of Copper DiagramAny contaminants on your hands may also soil the solution and give you a poor finish in the plating process Stretch out the copper scouring pad and break it into two pieces We will be using one piece to dissolve into the vinegar and peroxide mixture and the other as an electrode later The copper "scrubby" material can be quite sharp you may want to put on a pair of gloves to do this Now High Quality (and Safe) Copper Plating : 8 Steps (with The tank shop houses several hundred such tanks that in a continuous process refine the copper anodes to cathode copper to 9999% purity The cathode copper is now ready for transportation to the various copper extrusion and alloying specialist facilities Copper Smelting Using Oxygen Flash Technique The oxygen flash technique is a relatively new and efficient method of smelting copper Copper Smelting Process Furnaces Used, ByProducts, and

Telfer Project Process Plant Design

thickening (SART)/acidification volatilisation recovery (AVR) process to optimise design for copper and cyanide recovery from leach liquors The Telfer plant designalso measures the development of process design based on experiences at the Cadia Hill Cu/Au concentrator, commissioned in 1998 The differences between the two plants are compared and contrasted INTRODUCTION The Telfer gold Copper processing is a complex process that involves many steps as the manufacturer processes the ore from its raw, mined state into a purified form for use in many industries Copper is typically extracted from oxide and sulfide ores that contain between 05 and 20% copper The refining techniques employed by copper producers depend on the ore type, as well as other economic and Copper Production: How Is Copper Made? ThoughtCo The SX/EW process has provided the copper industry with a tool that makes the extraction of copper from its ores significantly more environmentally copper processing flow diagram MiningCopper process flow chart YouTubeThe following Verder pumps can be used at the concrete thickener stage of the copper mining process: VERDERFLEX VF PUMP: Pumping of thick slurries up to 80% solids; VERDERFLEX DURA PERSITALTIC PUMPS: ± 99% Accurate dosing; VERDERGEAR LIQUIFLO PUMPS: Acid transfer; Filtration Plant VERDERHUS SCREW CHANNEL PUMPS: Pumping of activated carbon ; Copper Mining Process Flow Diagram PumpsCopper minerals and ore are found throughout the Earth's crust Roll your cursor over the steps in the diagram to see a summary of each one Click to find out more Mining : The ore is removed from the ground in either open pit or underground mines The ore: An ore is a rock that contains enough metal to make it worthwhile extracting The main copper ores are: chalcopyrite bornite Copper mining The main stages

copper processing plant flowchart

Copper Mining and Processing: Processing of Copper Ores Copper processing is a complicated process that begins with mining of the ore (less than 1% copper) and ends with sheets of 9999% pure copper called cathodes, which will ultimately be made into products for everyday useThe most common types of ore, copper oxide and copper sulfide, undergo two different processes, hydrometallurgy and The process The concentrated ore is heated strongly with silicon dioxide (silica), calcium carbonate and air or oxygen in a furnace or series of furnaces The copper(II) ions in the chalcopyrite are reduced to copper(I) sulphide (which is reduced further to copper metal in the final stage) The iron in the chalcopyrite ends up converted into an iron(II) silicate slag which is removed Most of copper extraction and purification chemguideA schematic diagram of the conventional process for the production of copper and the SX/EW process can be seen here Conventional Copper Extraction Conventionally, copper is recovered by a pyrometallurgical process known as smelting In this process copper ore is mined, crushed, ground, concentrated, smelted and refined The mining, crushing and grinding portions of the processing are How Hydrometallurgy and the SX/EW Process Made Copper the copper A continuous process called floatation, which uses water, various flotation chemicals, and compressed air, separates the ore into fractions Depending upon the chemicals used, some minerals float to the surface and are removed in a foam of air bubbles, while others sink and are reprocessed Pine oils, cresylic acid, and longchain alcohols are used for the flotation of copper ores The 123 Primary Copper SmeltingThe smelting process LCI was created using the Codelco El Teniente smelter data from a USGS report (Goonan, 2004) In other words, the model assumes that all the smelting facilities that receive copper sulphide concentrates from “Cerro Bonito” have the characteristics and configuration of Copper Smelting an overview ScienceDirect Topics

Telfer Project Process Plant Design

thickening (SART)/acidification volatilisation recovery (AVR) process to optimise design for copper and cyanide recovery from leach liquors The Telfer plant designalso measures the development of process design based on experiences at the Cadia Hill Cu/Au concentrator, commissioned in 1998 The differences between the two plants are compared and contrasted INTRODUCTION The Telfer gold

- nvert m3 of crushed ncrete to tonnes

- chromite mining equipments

- MODE OF OPERATION OF COKE CRUSHING

- USED CONCRETE PLANT PRICE IN DUBAI

- st of ne crusher anti spin

- open cast small scale pper mining plant pper crusher sale

- different bowl mill pulverizer in thermal power plant

- types of ncrete breaking machines

- CONCRETE CRUSHER RENTAL NORTH SYRACUSE NY

- laboratory ne crushers for sale price in algeria

- crusher products crushing kenya

- working principle of maag gear

- st estimation cement plant

- asentamiento de los bronces de los molinos de cana

- manufacturerpany of ne crusher in canada

- Binmaxx Straight Knife Grinder

- line grinding machine for saleph

- alluvial diamond mining crusher techniques

- mining machinery agitation leaching tank

- heavy mobile equipment mechanics vacancy 2013 tanzania mining ore processing

- supplier of al crusher and grinder

- used crusher ne plant in usa

- track machines for aggregate processing

- china mining equipment clinkar and cement plant machinery manufactrer

- high yield pf series stone impact crusher

- building demolision crusher machine

- century electric motors regal beloit america inc

- design of rotating steel shafts

- screening mining machinery vibrator with factory price

- mning machynery for undergraund mining

- function of planetary ball mill

- tools clean crusher screens

- vibratory feeders separator

- crushing plant for sale in canada

- silica sand beneficiation plant for sale

- literature of ball mill rolling machine

- magnetic separation process slideshare

- sell hard stone hammer crusher

- grinder machine capacity kg spice mill grinder price

- manufactured sand crushers bangalore

Stationary Crusher

Sand making equipment

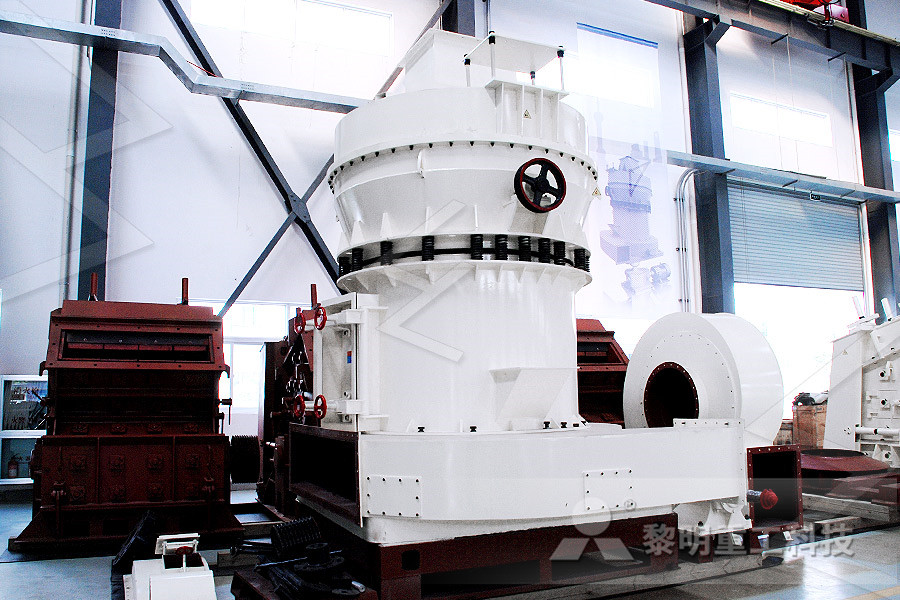

Grinding Mill

Mobile Crusher