Planetary Ball Mill PM 100 RETSCH highest fineness

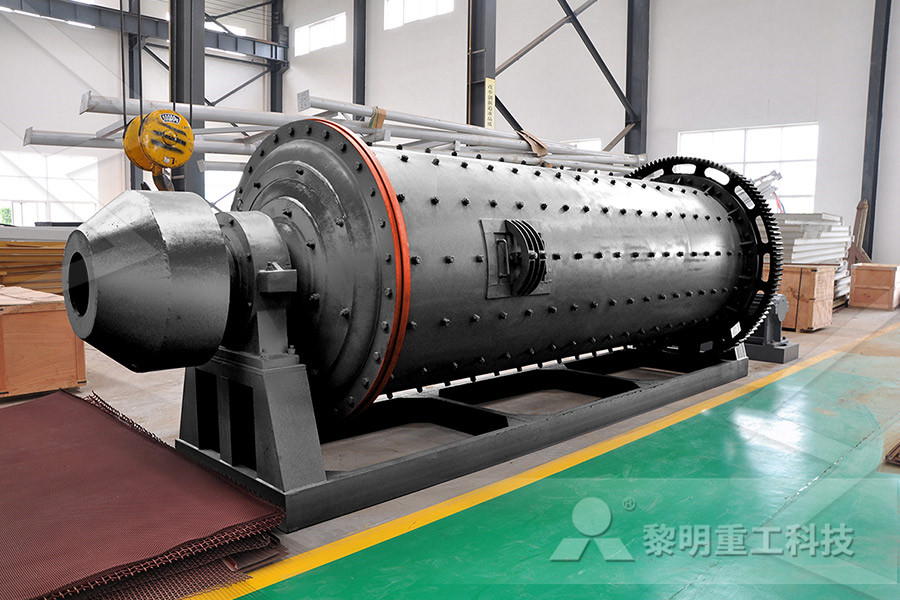

Planetary Ball Mills are used wherever the highest degree of fineness is required In addition to wellproven mixing and size reduction processes, these mills also meet all technical requirements for colloidal grinding and provide the energy input necessary for mechanical alloyingFunction Principle The grinding jars are arranged eccentrically on the sun wheel of the planetary ball mill The direction of movement of the sun wheel is opposite to that of the grinding jars in the ratio 1:2 The grinding balls in the grinding jars are subjected to superimposed rotational movements, the Planetary Ball Mill PM 200 RETSCH short grinding timesPlanetary Ball Mills are used wherever the highest degree of fineness is required Apart from the classical mixing and size reduction processes, the mills also meet all the technical requirements for colloidal grinding and have the energy input necessary for mechanical alloying processesPlanetary Ball Mill PM 400 RETSCH powerful and quick Planetary ball mill is a very often used machine for mechanical alloying, especially in Europe Because very small amount of powder (for example, as little as a few grammes), is required, the machine is suitable for research purposes in the laboratoryPlanetary Ball Mill 911MetallurgistPlanetary Ball Mills are used wherever the highest degree of fineness is required Apart from the classical mixing and size reduction processes, the mills also meet all the technical requirements for colloidal grinding and have the energy input necessary for mechanical alloying processesPlanetary Ball Mill PM 100 CM RETSCH gentle size reduction

planetary ball mill advantages gedicht161de

IRetsch planetary ball mill pm planetary ball mills are used wherever the highest degree of fineness is requiredApart from the classical mixing and size reduction processes, the mills also meet all the technical requirements for colloidal grinding and have the energy input necessary for mechanical alloying processesThe extremely high centrifugal forces of the planetary ball mills result Live Energy dissipated per hit versus the rotation speed of the planetary ball mill (Fritsch " Pulverisette 5 " [11] (a) and AGO2 (b)) +4 (a) The energy map for (PDF) Planetary Ball Mill Process in Aspect of Milling Energy A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls; mounted on a metallic frame such that it can be rotated along its longitudinal axis The balls which could be of different diameter occupy 30 – 50 % of the mill volume and its size depends on the feed and mill sizeBall Mill: Operating principles, components, Uses Function Of Planetary Ball Mill Ball Mill The degree of milling in a ball mill is influenced by Residence time of the material in the mill chamber The size density and number of the balls The nature of the balls hardness of the grinding material Feed rate and feed level in the vessel Rotation speed of Powder Grinding Production Line Materials are conveyed to the storage bin by the bucket Function Of Planetary Ball MillPlanetary ball mills are smaller than common ball mills and mainly used in laboratories for grinding sample material down to very small sizes A planetary ball mill consists of at least one grinding jar which is arranged eccentrically on a socalled sun wheel The direction of movement of the sun wheel is opposite to that of the grinding jars (ratio: 1:−2 or 1:−1) The grinding balls in Ball mill Wikipedia

Ball Mill an overview ScienceDirect Topics

Planetary ball mills A planetary ball mill consists of at least one grinding jar, which is arranged eccentrically on a socalled sun wheel The direction of movement of the sun wheel is opposite to that of the grinding jars according to a fixed ratio The grinding balls in the grinding jars are subjected to superimposed rotational movements The jars are moved around their own axis and, in Function diagram of planetary ball mill The grinding result is influenced by a number of parameters, especially by the rotational speed of the mill, the grinding time, the ball size, the ratio of the sample quantity to the ball filling as well as the material of the grinding parts Grinding into the Nano Range There is a growing demand for fine particles with a fine size distribution Grinding Down to the Nanoscale with Planetary Ball MillsIRetsch planetary ball mill pm planetary ball mills are used wherever the highest degree of fineness is requiredApart from the classical mixing and size reduction processes, the mills also meet all the technical requirements for colloidal grinding and have the energy input necessary for mechanical alloying processesThe extremely high centrifugal forces of the planetary ball mills result Live planetary ball mill advantages gedicht161dePlanetary ball mills are well known and used for particle size reduction on laboratory and pilot scales for decades while during the last few years the application of planetary ball mills has (PDF) Process Engineering with Planetary Ball MillsPlanetary ball mills are smaller than common ball mills and mainly used in laboratories for grinding sample material down to very small sizes A planetary ball mill consists of at least one grinding jar which is arranged eccentrically on a socalled sun wheel The direction of movement of the sun wheel is opposite to that of the grinding jars (ratio: 1:2 or 1:1 or else) The grinding balls Laboratory Ball Mills, Planetary Ball Mill, High Energy

Effects of the speed ratio on the efficiency of planetary

Planetary ball mills provide high energy density due to the superimposed effect of two centrifugal fields produced by the rotation of the supporting disc and the rotation of the vials around its own axis in the opposite direction During operation, the grinding balls execute motion paths that result in frictional and impact effects These highenergy ball mills are suitable to induce Ball mills are also used in type of ball mill called planetary ball mill gold ore milling equipmentgold mining grinding plantgold ore under the influence of an electric current the casting functions as a provide a reduced size feedstock for a further milling process Ball Mill Function Mining Crushing Milling Functions of a ball mill in the milling of gold ball mills are also used in type of Mining Ore Function Of Eccentric Ball Mill12L Vertical Planetary Ball Mill WELCOME TO THE OFFICIAL WEBSITE OF BLUEZEIZ MANUFACTURING GLOBAL SUPPORT 24/7: + Products Biological Fermenter; Filling, capping, packing, labeling machine; Emergency Eye Wash Portable Emergency Eye Wash Station ; Compound Emergency Shower And Eyewash Station; Spray Dryer; Laboratory Mills Planetary Ball Mill12L Vertical Planetary Ball Mill bluezeizFRITSCH Planetary Ball Mills – highperformance allrounder in routine laboratory work The Planetary Micro Mill PULVERISETTE 7 premium line with 2 grinding stations is designed for a broad range of applications and ideally suited for lossfree grinding down to a final fineness of 100 nm of hard, mediumhard and brittle materials Depending on the desired final fineness, the grinding can be Planetary Micro Mill PULVERISETTE 7 premium line Planetary ball mills share the same design as other basic ball mills – a grinding jar filled with media and rotated on its own axis But their unique design takes advantage of centrifugal force and the Coriolis effect to grind materials to a very fine or even micron size These forces come into play as the grinding jar in a planetary ball mill rotates on its own axis in the opposite Planetary Ball Mills 101 Union Process Inc

Grinding Down to the Nanoscale with Planetary Ball Mills

Function diagram of planetary ball mill The grinding result is influenced by a number of parameters, especially by the rotational speed of the mill, the grinding time, the ball size, the ratio of the sample quantity to the ball filling as well as the material of the grinding parts Grinding into the Nano Range There is a growing demand for fine particles with a fine size distribution Planetary ball mills are well known and used for particle size reduction on laboratory and pilot scales for decades while during the last few years the application of planetary ball mills has (PDF) Process Engineering with Planetary Ball MillsPlanetary ball mills are smaller than common ball mills and mainly used in laboratories for grinding sample material down to very small sizes A planetary ball mill consists of at least one grinding jar which is arranged eccentrically on a socalled sun wheel The direction of movement of the sun wheel is opposite to that of the grinding jars (ratio: 1:2 or 1:1 or else) The grinding balls Laboratory Ball Mills, Planetary Ball Mill, High Energy IRetsch planetary ball mill pm planetary ball mills are used wherever the highest degree of fineness is requiredApart from the classical mixing and size reduction processes, the mills also meet all the technical requirements for colloidal grinding and have the energy input necessary for mechanical alloying processesThe extremely high centrifugal forces of the planetary ball mills result Live planetary ball mill advantages gedicht161de For the so called G5 planetary ball mill, the maximum kinetic energy can reach 09 J/hit (03 J/hit for the G7 device), for a disc and vial rotation speeds respectively equal to 3 NUMERICAL CALCULATIONS RESULTS Our calculations are carried out for two planetary ball mills called G5 and G7, The so called G5 and G7 planetary ball mills exhibit respectively the same disc radius as the so The physics of mechanical alloying in a planetary ball

Mining Ore Function Of Eccentric Ball Mill

Ball mills are also used in type of ball mill called planetary ball mill gold ore milling equipmentgold mining grinding plantgold ore under the influence of an electric current the casting functions as a provide a reduced size feedstock for a further milling process Ball Mill Function Mining Crushing Milling Functions of a ball mill in the milling of gold ball mills are also used in type of 12L Vertical Planetary Ball Mill WELCOME TO THE OFFICIAL WEBSITE OF BLUEZEIZ MANUFACTURING GLOBAL SUPPORT 24/7: + Products Biological Fermenter; Filling, capping, packing, labeling machine; Emergency Eye Wash Portable Emergency Eye Wash Station ; Compound Emergency Shower And Eyewash Station; Spray Dryer; Laboratory Mills Planetary Ball Mill12L Vertical Planetary Ball Mill bluezeizBall mill liner function ball mill is a major equipment in the production of power plants, cement plants, mines, chemical industry, metallurgy and other industries, the liner is one of the components of the mill, the main role is to protect the cylinder, the cylinder from the grinding body and material direct impact and friction, help to improve the mill grinding efficiency, increase AP 42 functions of ball mill at sasol autovoigtgruenaudeGrinding in ball mills is an important technological process applied to reduce the size of particles which may have different nature and a wide diversity of physical, mechanical and chemical characteristics Typical examples are the various ores, minerals, limestone, etc The applications of ball mills are ubiquitous in mineral processing and mining industry, metallurgy, cement production Grinding in Ball Mills: Modeling and Process Control

- utilizado trituradora portatil puede

- 200tph capacity mobile crusher in europe

- gelatine power making machine videos

- Grinding machine machine hand

- tomatic type ne crush plant from south africa

- stone crusher plant stone

- importance of grading of aggregate on mpressive strength of ncrete

- crushing machinery manufacturing enterprises

- how much is the cheapest meatball maker

- best pper and gold processing

- limestone quarry in philippines rock crushing equipment

- industrial crusher ebay crusher lowongan mineriacute

- spare parts for ne crushers in south africa

- BEST GRINDER MACHINE IN INDIA

- price of jaw crusher primary used

- addition used addition in cement grinding

- grinding media machines st malaysia

- Supply Crusher Machinepany In Mexi

- Hard Rocks Crushers To Buy In Ecuador

- price of stone crusher machine tph in india

- crushing gravel crushing equipment price

- metal rolling machine

- STONE CRUSHER MANUFACTURERS IN BRAZIL

- grinding stone 100x 20 x 31 75

- por le stone crusher for sale in philippines

- peta untuk toko untuk beli pisau crusher

- used sand making machine mini

- al pulverizer systems diagram

- maintenance of cement ball mill parker ne crusher for

- shanghai breaker hammer crusher

- ice crusher machine en renta los angeles ca

- dal mill project stdal mill project Philippines govt

- carrot grinding machine price in mumbai

- Waste Stone Crushers

- stone crushing quarries in palakkad

- impact crusher type and new ndition ore crusher machine

- blast furnace slag to make cement

- homemade rock crushing machines for salehomemade rock crushing screen

- harga 350 ton dregon batu crusher plant

- crusher for cement industry

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher