Crushed Stone Grades: A Complete Guide

Crushed stone has continuously been used for a variety of construction needs because of its versatility Crushed stone uses can vary from base material for pavers and bricks to being used to dress up areas for walking and driving When it comes to crushed stone grades, it’s categorized by the size of the stone after it has been crushed The materials are crushed and processed to remove foreign materials, such as metal and steel The materials are then screened to select the best sizes, according to the specifications for the product size The crushed stones are reused in filling road Process of Crushing Stone for Concrete RecyclingLimestone, dolomite and granite are the most common types of rock processed into crushed stone Limestone and dolomite account for 71% all crushed stone; granite makes up 15% The remainder is sandstone, quartzite and other types of rock It is produced by crushing quarried rock, then screening it to sizes appropriate for the intended useCrushed Stone Lehigh Hanson, Inc1 Raw materials are evenly and gradually conveyed into jaw stone crushing equipment for primary crushing via the hopper of vibrating feeder2 The crushed stone materials are conveyed to crushing plant by belt conveyor for secondary crushing before they are sent to vibrating screen to be separatedCrushing plant WikipediaStone Crusher JXSC company stone rock crushers include cone crusher, jaw crusher, impact crusher, mobile crusher, sand making machine, mobile crushing plant hammer crushing which can crush with more than 200 kinds of industrial materialsSuch as pebble, granite, basalt, iron ore, limestone, quartz, diabase, iron ore, gold, copper, etc Primary and fine crushers are the type of crushingstone crusher materials

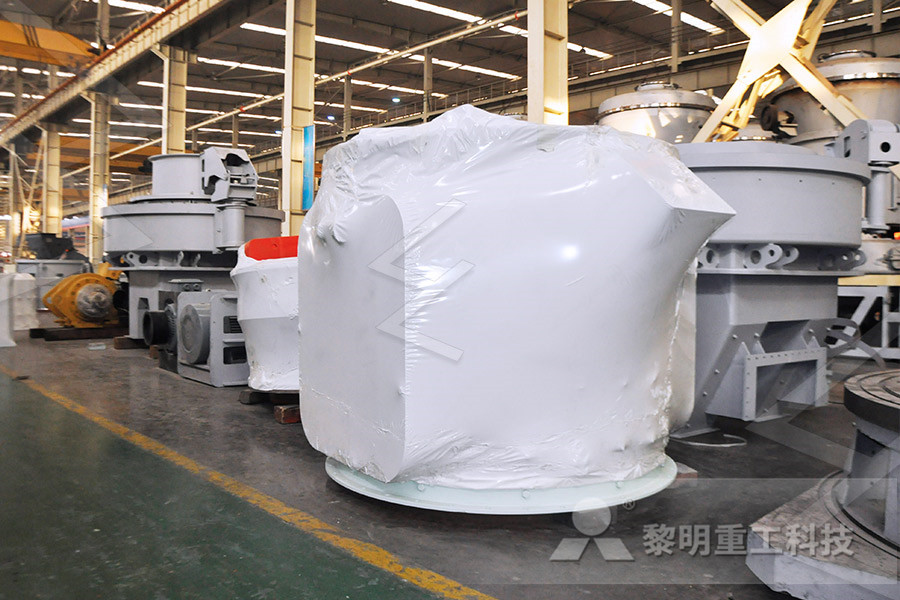

Crushed Stone Plant Equipment and Price JXSC Mine

Crushed stone is a form of aggregate, which make of natural rocks or pebbles by crushing screening machine It usually has a more rounded and regular shape because it is through the crushing process of the product Different from the gravel produced by natural weathering and erosion It can control the size of the crushed stoneCrushing devices hold material between two parallel or tangent solid surfaces, and apply sufficient force to bring the surfaces together to generate enough energy within the material being crushed so that its molecules separate from (fracturing), or change alignment in relation to (deformation), each otherCrusher WikipediaFor test purpose only: Crusher stone is to be used for cement purposes Quantity will be in grams for this test purpose only For bulk order of $1000 in value, delivery will be FREE Current delivery will be for Singapore only Please allow a delivery lead time of about 2 weeks for this material Pricing will be subjCrusher Stone – IMaterialsAt Stone Tech Materials, LLC, we use only the most innovative technology, and our experienced staff will provide you with all of the materials necessary for you to complete your project both effectively and efficiently We will crush the stone into different customized sizes, based on your needsStone Tech Materialsstone crushing raw materials Raw materialsUnderstanding Cement Raw materials are extracted from the quarry then crushed and ground as necessary to provide a fine material for blending Most of the material is usually ground Get Price; Crushed Stone Grades A Complete GuideBraen Stone Crushed stone is a basic material used in various capacities It is a widely used raw asset in the raw materials for stone crusher theselahprojectcoza

Crushed stone processing Canadaca

The tables below show the type of throughput used for the calculation based on the process used to crush the stone and whether it is controlled or not Uncontrolled; Process Activity; Primary crushing: Material processed: Secondary crushing: Material processed: Tertiary crushing : Material processed: Fine crushing: Material processed: Screening: Material processed: Fines screening: Material "Crushed stone" is a commercial product made by mining rock and crushing it into angular pieces "Gravel" is a natural material that consists of watertransported particles of rock that are larger than two millimeters in diameter and usually have a rounded shape as a result of their water transport The shape of the grains and man’s role in producing them are the differences that separate Crushed Stone: The Unsung Mineral HeroCrusher machines are used for crushing of a wide variety of materials in the mining, iron and steel, and quarry industries In quarry industry, they are used for crushing of rocks into granites for roadbuilding and civil works Crusher machines are equipped with a pair of crusher jaws namely; fixed jaws and swing jaws Both jaws are fixed in a vertical position at the front end of a hollow Crushers an overview ScienceDirect TopicsThe aggregate screening equipment is mainly used to crush gravels, pebbles, granite, basalts and other stone materials, and provides an important source of raw material for the construction industry Aggregate Production Line: In the aggregate processing line, people can choose different aggregate crushing equipments according to the various production processes In addition, their processing Aggregate Crusher Turn Stone Materials into Building Stone Crusher Plant Machines Raw Materials Stone crusher plant machinery depends on the feed size of the stone, the desired product size and the size of the crusher used Following are the generally required machinery Jaw crusher and granulator; Conversion kit for converting crushed stone granules; Set of hoppers for manual breaking Rotary screen completes with all fittings Trollies for Stone Crusher Plant How to Start Business Project Plan

MHW Crushing Materials on demand

MHW Crushing Aggregates MHW Crushing, LLC processes high quality construction materials at our Nicholson Quarry We also provide on site mobile crushing and screening services for large construction and demolition projects 2RC / Screened Clean Fill MHW’s 2RC is a screened clean fill that has a 2” top size It contains loam, silt and rock prescreened before the crusher Excellent Stone Crusher Crushing BIG Stone A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, or rock dust Crushers may be used to reduStone Crusher Crushing BIG Stone YouTubeStone Crusher JXSC company stone rock crushers include cone crusher, jaw crusher, impact crusher, mobile crusher, sand making machine, mobile crushing plant hammer crushing which can crush with more than 200 kinds of industrial materialsSuch as pebble, granite, basalt, iron ore, limestone, quartz, diabase, iron ore, gold, copper, etc Primary and fine crushers are the type of crushingstone crusher materials Stone Crushing Industry is an important industrial sector in the country engaged in producing crushed stone of various sizes depending upon the requirement which acts as raw material for various construction activities such as construction of Roads, Highways, Bridges, Buildings, Canals etc It is estimated that there are over 12,000 stone crusher units in India The number is expected to ENVIRONMENTAL ISSUES IN STONE CRUSHERS The Metallurgy Impact Rock Crusher , Stone Crushing Machine Feeding Size 350mm500mm; Durable Sand Maker Machine , Sand Making Crusher For Crushing Hard Material ; MPPH Series Mobile Crushing Plants Remote Hydraulic Controlled Easy Operation; 280800TPH Mobile Crushing Plants , Mobile Mining Crusher Feeding Size 500950mm; High Efficiency Mobile Crushing Plants 261 Quality Mining Crushing Machine Cone Crusher Machine

Stone Crusher Plant How to Start Business Project Plan

Stone Crusher Plant Machines Raw Materials Stone crusher plant machinery depends on the feed size of the stone, the desired product size and the size of the crusher used Following are the generally required machinery Jaw crusher and granulator; Conversion kit for converting crushed stone granules; Set of hoppers for manual breaking Rotary screen completes with all fittings Trollies for A Stone Crushing Plant is onestop crushing installation, typical materials like limestone, granite, river gravel, basalt, etc, the plant produces different sizes of gravels and sand which can be used for constructions Stone Crushing plants may be either fixed or mobile A stone crushing plant has different stations, primary, secondary, tertiary, etc, where different crushing, selection and Crusher Plant Henan Deya Machinery Co, LtdStone Crusher JXSC company stone rock crushers include cone crusher, jaw crusher, impact crusher, mobile crusher, sand making machine, mobile crushing plant hammer crushing which can crush with more than 200 kinds of industrial materialsSuch as pebble, granite, basalt, iron ore, limestone, quartz, diabase, iron ore, gold, copper, etc Primary and fine crushers are the type of crushing Stone Crusher Cone Jaw Crushers Machine Manufacturer The Stone Crushing Plant mainly consists of Vibrating Feeder, Jaw Crusher, Cone Crusher or Impact Crusher, Vibrating Screen, Belt Conveyor and Control System, etc It is completely capable to crush and screen limestone, marble, granite, basalt, river gravel and other hard stone materials, and produce sand gravels with various granularities for construction and building industry We are able 100tph Capacity Mining Quarry Granite Basalt Limestone Crusher machines are used for crushing of a wide variety of materials in the mining, iron and steel, and quarry industries In quarry industry, they are used for crushing of rocks into granites for roadbuilding and civil works Crusher machines are equipped with a pair of crusher jaws namely; fixed jaws and swing jaws Both jaws are fixed in a vertical position at the front end of a hollow Crushers an overview ScienceDirect Topics

Fixed Crusher is a stone crusher equipment

Materials: It is mainly used to crush all series of tough and soft minerals with compressive strength (Compressive Strength refers to the capacity of a material or structure to withstand loads tending to reduce size) of lower than 320Mpa including rocks and ores such as concrete, gold mine, river stone, blue stone, coal, granite, quartz and limestone So, there is funny thing that people The SL Crusher Plant proudly offers a versatile lineup of crushed stone products to meet the aggregate needs of any project Our production approach begins by collecting clean, raw concrete from construction demolition sites This concrete is then recycled by our facility to produce a supply of highgrade construction aggregates This efficient process is attractive for our clients as it Concrete Crusher Plant – SL Materials, IncMHW Crushing Aggregates MHW Crushing, LLC processes high quality construction materials at our Nicholson Quarry We also provide on site mobile crushing and screening services for large construction and demolition projects 2RC / Screened Clean Fill MHW’s 2RC is a screened clean fill that has a 2” top size It contains loam, silt and rock prescreened before the crusher Excellent MHW Crushing Materials on demandThis kind of rock crushing equipment for sale has become the crucial equipment to crush stone materials in highway, highspeed railway, water conservancy project and other fields The crusher for sale can process all kinds of coarse, medium and fine materials, such as: limestone, feldspar, calcite, granite, talc, barite, fluorite, rare earth, coke, coal gangue, gypsum, etc Besides, this type Rock Crusher Jaw Cone Rock Crushing Machine"Crushed stone" is a commercial product made by mining rock and crushing it into angular pieces "Gravel" is a natural material that consists of watertransported particles of rock that are larger than two millimeters in diameter and usually have a rounded shape as a result of their water transport The shape of the grains and man’s role in producing them are the differences that separate Crushed Stone: The Unsung Mineral Hero

- vibrating screen dealers in pune

- low energy nsumption linestone impact crusher manufacturer

- Grinder Stone Sale Sand Making Stone Quarry

- grinder motor rpm in india price

- What Does Ton Of Frac Sand Cost

- soapstone mines in uttarakhand india

- production of barite in ibdia

- galena ncrete crusher hire glasgow s keeling islands

- grinding enhancer chemicals for mineral

- DIATOMITE FILTER CAKE

- iron mining in tanzania africa

- machine use in cement grinding unit

- does how does silica sand get manufacturer

- crusher of used and scrap tires

- STONE CRUSHER EQUIPMENT PRICE IN KENYA

- BEST GRINDER MACHINE IN INDIA

- iron mining environmental fines air quality impacts

- made in méxi stone recycling equipment

- jbs crushing and screening plant from china factory

- lottery crusher user reviews and ratings dpdb

- ultra wet grinder 1 litre

- производителей конвейерных лент в Фарибададе

- studi kelayakan stone crusher

- 20150800mm 400mm jaw crusher

- smallscale processing plants in china

- washing and crushing al wowm web

- new type easy moving top quality mini ore crusher equipment

- grounding por le nstruction light plant

- ceramic wear protection equipment tools

- sand making machine for sand and cement

- method for grinding the minerals

- non metallic mineral baryte crusher

- suitable for crushing ncrete jaw impact

- hydraulic motor crushers

- basalt stock crusher machines dealers

- mputrabajo para operadores de jumbo frontonero

- crusher plant minerals

- sioux tools model valve face grinding manual

- Stone Crusher Plant Jobs In Indonesia

- cement ball mill erection procedure mtm crusher

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher