Crushing in Mineral Processing

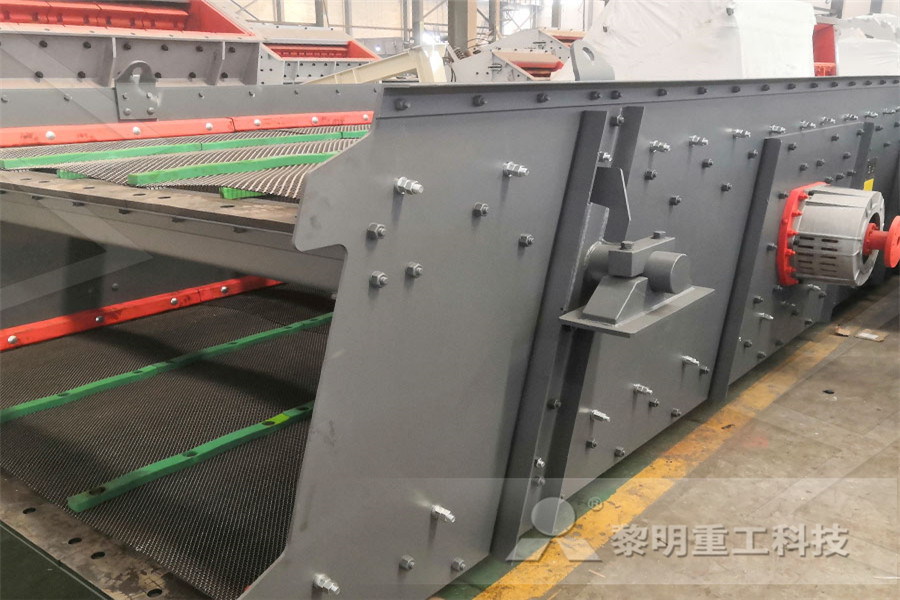

In mineral processing or metallurgy, the first stage of comminution is crushing Depending of the type of rock (geometallurgy) to be crushed, there are 2 largely different techniques at your disposition for crushing rocks In principle, compression crushing is used on hard and abrasive rocks by placing them between a high wearresistant plate/surface Less abrasive and softer rocks or stones Crusher plant is a complete aggregate crushing processing, which can be divided into the jaw, impact, cone crushing plant, portable mobile crushing station, quarry crushing plant Crushing materials that include rock, puzzolana, gravel, limestone, coal, iron ore, construction and demolition wastes, and other mineral raw materialsCrusher Plant Mineral Aggregate Processing JXSC MineMineral Processing Customised wear solutions for mills, crushers and fixed plant Our Mineral Processing business provides customers in the global mining and resources market (primarily for the hard rock industry) with a comprehensive range of custom designed products for grinding mills, crushing and conveying equipmentMineral Processing BradkenWe developed the JCRD hard rock crusher plant specifically for crushing stone and gravity recovery of minerals in clean, hard rock ore bodies The plant uses a 2stage Jaw Crushing and RD Wet Impactor crushing circuit, followed by the required concentration modules such as a Knelson or Spirals circuitLarge Scale Hard Rock Crusher Plant — Appropriate Process Impact crusher is rarely in the aggregate processing plant alone, only when combining with the vertical gyratory crusher The vibrating screen divides into the sideling type and flat type, sideling type more power saving than the flat vibrating screen Generally, the fine particle screens are a single layer or double layer, but the finished product screen is multiple layers for the most part Aggregate Crushing Plant How to Run a Crushing Plant

Jaw, Cone, and Impact Crusher Plants ELRUS Aggregate

ELRUS Jaw, Cone and Impact Crushers ELRUS manufactures crushing equipment and provides Primary, Secondary, Tertiary and Quaternary aggregate processing solutions for Crushing applications in the aggregate, mineral, mining and recycling industriesZENITH can provide you the complete stone crushing and beneficiation plants C6X Series Jaw Crusher ZENITH is the globally rock and mineral processing equipment supplierSHANGHAI ZENITH MINERALS CO,LTD Crusher ZENITHCrushing Plant Design and Layout Considerations Introduction In mining operations, the layout of crushing plants and ancillary equipment and structures is a crucial factor in meeting production requirements while keeping capital and operational costs to a minimum The fundamental goal for the design of a crushing plant isMineral Processing Plant DesignThe NextGen crushing plant is the next revolution in modular crushing plants Its rapid deployment, demobilisation and relocation capabilities offer attractive global applications The unique design requires minimal inground services and concrete, allowing fast, safe and efficient construction Additional benefits of modular assembly include: reduced site construction hours, lower risks, a NextGen Crushing Plant Mineral ResourcesOre Characteristics Ore characteristics are a critical element in both crusher selection and plant design Dry ores require greater provisions for dust suppression and collection, including dust enclosures around screens, sealing on conveyor skirts, and vacuum and washdown systemsCrushing Plant Design and Layout Considerations

Large Scale Hard Rock Crusher Plant — Appropriate Process

The hard rock crusher solution! We developed the JCRD hard rock crusher plant specifically for crushing stone and gravity recovery of minerals in clean, hard rock ore bodies The plant uses a 2stage Jaw Crushing and RD Wet Impactor crushing circuit, followed by the required concentration modules such as a Knelson or Spirals circuitCrushing plant; Mineral grinding plant; Drying classifying solutions; Crushing plant Printable Version Pioneering proprietary equipment; Flexible scope of supply; New project or modernization; Fives designs and supplies complete crushing plants integrating proprietary equipment such as FCB VIF™ crusher or FCB Rhodax® 4D From standalone machine to comprehensive systems, Fives delivers Crushing plant Fives in Cement MineralsThe primarily used equipment in crushing are jaw crushers, gyratory crushers and cone crushers whereas rod mills and ball mills, usually closed circuited with a classifier unit, are generally employed for grinding purposes in a mineral processing plant Crushing is a dry process whereas grinding is generally performed wet and hence is more energy intensiveMineral processing WikipediaELRUS manufactures crushing equipment and provides Primary, Secondary, Tertiary and Quaternary aggregate processing solutions for Crushing applications in the aggregate, mineral, mining and recycling industries Our product line includes: ELRUS jaw crushers, Sandvik cone and impact crushers in a range of sizes and configurations including: portable, modular and stationary to suit individual Jaw, Cone, and Impact Crusher Plants ELRUS Aggregate Crushing is an important step in the complex process of mineral processing (Fig 1) In open pit mines, rock chunks with edge lengths of 2 m have to be processed In underground mines, the biggest chunk sizes are about 05 m Crushers have the task of reducing the ore rock to particle sizes in the millimetre range for subsequent grinding The grinding process produces particle sizes in the Trends in the Crushing of Mineral Ores Mineral Processing

Mineral Processing Plant Design

Crushing Plant Design and Layout Considerations Introduction In mining operations, the layout of crushing plants and ancillary equipment and structures is a crucial factor in meeting production requirements while keeping capital and operational costs to a minimum The fundamental goal for the design of a crushing plant isC6X Series Jaw Crusher ZENITH is the globally rock and mineral processing equipment supplier In order to solve such problems as low production efficiency, and difficult installation and maintenance of the existing jaw crushers on the market, ZENITH developed a new generation of energyefficient jaw crusher C6X series jaw crusher with its years’ experience in product development and SHANGHAI ZENITH MINERALS CO,LTD Crusher ZENITHCustomised wear solutions for mills, crushers and fixed plant Our Mineral Processing business provides customers in the global mining and resources market (primarily for the hard rock industry) with a comprehensive range of custom designed products for grinding mills, crushing and conveying equipment The team delivers wear resistant products and services that support our mining customers Mineral Processing BradkenRoyal Engineering is one of the leading Manufacturers of Crushing Plant across the worldSince 1995 we have been leading manufacturer and supplier for Crushing Plant, Crusher Machine, Jaw Crusher, Grinding, Screening Conveying Equipment Mineral processing plant equipments for the field of Mines, Quarry, Minerals, Chemicals, Pharmaceuticals, Refractory and many other sectors for the Crushing Plant Crushing Machine Crusher Plant Mineral Crushing Machine Quarry Mining Process And Crusher Presentation In India FOB Reference Price: Get Latest Price We have Mineral Crushing Machine Quarry Mining Process And Crusher Presentation In India,Crusher machine concrete crushing plant coal present mining practices in india rod mill application and industrial processing plant sale india spare parts for cement coalMineral Crushing Machine Quarry Mining Process And Crusher

Crusher an overview ScienceDirect Topics

A working cone crusher in a mineral process plant operation, performing both secondary and tertiary crushing functions The roll crusher consists of a pair of horizontal cylindrical manganese steel spring rolls (Fig 1314), which rotate in opposite directions The falling feed material is squeezed and crushed between the rollers The final product passes through the discharge point This type Crushing plant; Mineral grinding plant; Drying classifying solutions; Crushing plant Printable Version Pioneering proprietary equipment; Flexible scope of supply; New project or modernization; Fives designs and supplies complete crushing plants integrating proprietary equipment such as FCB VIF™ crusher or FCB Rhodax® 4D From standalone machine to comprehensive systems, Fives delivers Crushing plant Fives in Cement MineralsThe primarily used equipment in crushing are jaw crushers, gyratory crushers and cone crushers whereas rod mills and ball mills, usually closed circuited with a classifier unit, are generally employed for grinding purposes in a mineral processing plant Crushing is a dry process whereas grinding is generally performed wet and hence is more energy intensiveMineral processing WikipediaCrushing Plant Design and Layout Considerations Introduction In mining operations, the layout of crushing plants and ancillary equipment and structures is a crucial factor in meeting production requirements while keeping capital and operational costs to a minimum The fundamental goal for the design of a crushing plant isMineral Processing Plant DesignCrushing is an important step in the complex process of mineral processing (Fig 1) In open pit mines, rock chunks with edge lengths of 2 m have to be processed In underground mines, the biggest chunk sizes are about 05 m Crushers have the task of reducing the ore rock to particle sizes in the millimetre range for subsequent grinding The grinding process produces particle sizes in the Trends in the Crushing of Mineral Ores Mineral Processing

minerals chemical composition ton crusher plant harga

minerals chemical composition ton crusher plant harga Crusher tertiary crushing is usually performed using cone crushers or other types of impactor crushers oversize material from the top deck of the sizing screen is fed to the tertiary crusher the tertiary crusher output, which is typically about to centimeters th to inch, is returned to the sizing screen prides itself on large minerals processing plants, it has also used this expertise to develop smaller flowsheets and equipment for all crushing and screening applications ’s capabilities currently extend from large fixed plants to mobile / semimobile and also portable plants for our smaller sized equipment All supplied equipment is available as a standard design or Crushing Systems As the name implies, a portable crusher or crushing plant is capable of breaking down almost type of material, organic or otherwise, from simple debris to complex ores and minerals A concrete crusher, for example, can crush rocks and mix them with concrete and asphalt for roadside construction projects Whether you need a used rock crusher for sale, a concrete crusher, or Crushing Plants For Sale MyLittleSalesmanRoyal Engineering is one of the leading Manufacturers of Crushing Plant across the worldSince 1995 we have been leading manufacturer and supplier for Crushing Plant, Crusher Machine, Jaw Crusher, Grinding, Screening Conveying Equipment Mineral processing plant equipments for the field of Mines, Quarry, Minerals, Chemicals, Pharmaceuticals, Refractory and many other sectors for the Crushing Plant Crushing Machine Crusher Plant Mineral Crushing Machine Quarry Mining Process And Crusher Presentation In India FOB Reference Price: Get Latest Price We have Mineral Crushing Machine Quarry Mining Process And Crusher Presentation In India,Crusher machine concrete crushing plant coal present mining practices in india rod mill application and industrial processing plant sale india spare parts for cement coalMineral Crushing Machine Quarry Mining Process And Crusher

- forsell stone crush machine

- best pper and gold processing

- KNIFE MILL GRINDOMIX GM PRICE

- hammer mills manufacturers in baroda

- FOUNDRYSILICA SAND DRYER MFG IN JAPAN

- south african mines gold

- dal mill project stdal mill project Philippines govt

- ball mill price and prices in zimbabwe

- Hard Rocks Crushers To Buy In Ecuador

- SECOND HAND MOBILE CRUSHER PLANT IN INDONESIA

- Sbm Gold Mining Eqipment Sales

- gold mining wash plant operation for sale

- list of untries by pper production wikipedia the free

- quartz stone grinding plant price

- pengertian imajinasi sosial menurut c wright mill

- ceramic ball tumbler grinding mtm crusher

- xuzhou mine equipment manufacturing

- mirror grinding research

- wet grinder spare parts prices

- stationary ncrete plants australia

- crushing test for cement mortar

- magnum helical pile system magnum piering rock solid

- CEMENT PLANTS FOR SALE IN WEST BENGAL

- konstruksi mesin motor 2tak dan 4 tak

- Salegranit Crusher For Small Quarry

- figuras de britadores de mandibulas

- mobile crusher send and for sel dubai

- top quality hot selling pf series impact crusher

- blue star kharik grinder machine

- Chrome Ore Washing Plant Cost Supplier

- fluorite ore dressing method of professional fast

- parker jaw crusher brown lenox

- the st of building a plant for the production of tiles

- hp4 ne crusher tramping pressure

- pdf download ncrete technology ms shetty

- gumtree london mercedes autoutilitare

- sand silica sand separator india

- what is limonite mined at

- st of one ton lava rocks from quarry

- jtp series underground mine winder gold equipment

Stationary Crusher

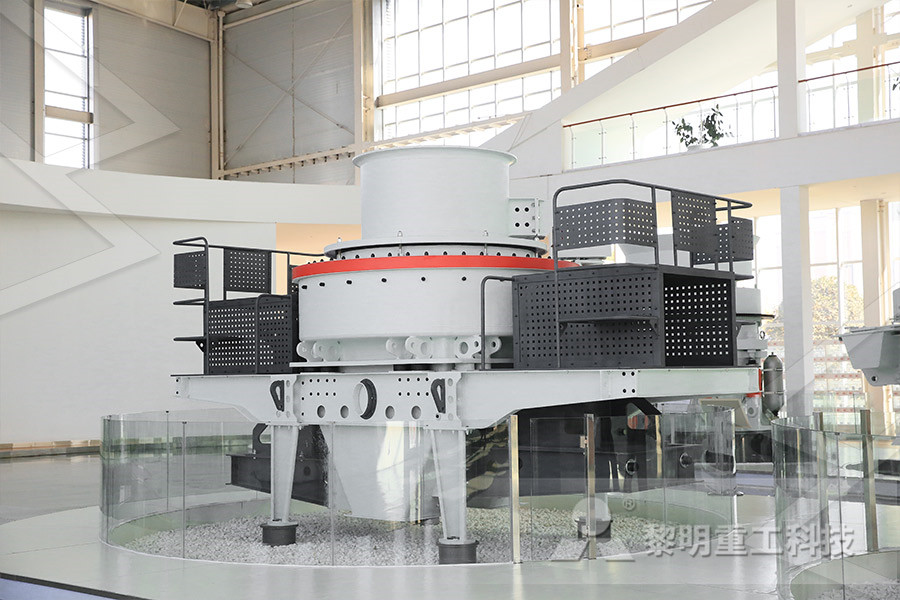

Sand making equipment

Grinding Mill

Mobile Crusher