Aluminum Thickness Measurement on Rolling Mill Acuity Laser

Dual Thickness Laser Measurement of Aluminum In the rolling mill process, the aluminum starts as an ingot As the ingot gets squeezed down into a thinner and thinner sheet of aluminum, the operator needs to know the thickness of the sheet in order to determine the correct size In some cases, the line is stopped and the operator uses large throated calipers and micrometers to measure the strip tension measurement Strip Tension Measurement, Rolling Mill Force Measurement, Process Regulation Aim: a continuous measurement of strip tension during production and finishing processes; processing of the measuring signal and transmission to the production processDr Brandt Rolling Mill Force MeasurementRoll Force Measurement System The RFS4 is a builtforpurpose roll force measurement system, specifically designed for use on both new and existing rolling mills The RFS 4 system provides the mill operator with continuous monitoring and display of roll force and differential forces (balance)Hot Rolling Mills BLH NobelThickness measurement is one of the most important measurement tasks in hot rolling mills With the Oframe and Cframe thicknessCONTROL MTS 820x and MTS 920x series, MicroEpsilon offers high precision measurement systemsThickness measurement in hot rolling mills MicroEpsilonA rolling mill, also known as a reduction mill or mill, has a common construction independent of the specific type of rolling being performed: Both may be expressed as absolute measurements or as relative measurements For instance, one could have 2 mil of crown (the center of the workpiece is 2 mil thicker than the edges), or one could have 2% crown (the center of the workpiece is 2% Rolling (metalworking) Wikipedia

Aluminum Thickness Measurement on Rolling Mill Acuity Laser

Dual Thickness Laser Measurement of Aluminum In the rolling mill process, the aluminum starts as an ingot As the ingot gets squeezed down into a thinner and thinner sheet of aluminum, the operator needs to know the thickness of the sheet in order to determine the correct size In some cases, the line is stopped and the operator uses large throated calipers and micrometers to measure the Prevents mill overloads Improves product quality Reduces mill downtime Simplifies retrofit Designed for High Accuracy and Easy Installation The RFS4 is a dedicated roll force measurement system specifically designed for use on both new and existing rolling mills The RFS4 System provides the mill Roll Force Measurement and Control System (Product Overview)Roll Force Measurement ABB’s Millmate roll force system is the perfect choice for measuring roll force in both hot rolling and cold rolling mills, thereby achieving correct roll gap settings and force distribution The system is proven to be exceptionally robust and resilient to high forces as well as aggressive mill agents The load cells are calibration free, can withstand overloads up to Roll force measurement ABBModern rolling mills are using the LaserSpeed® Pro noncontact laser gauge to directly measure the strip speed in Mass Flow Automatic Gauge Control (MFAGC) and elongation applications that require differential speed control This new generation of laserbased gauge provides high measurement accuracy and high performance, and eliminates the measurement errors associated with mechanical Steel Cold Rolling Mill Process Control NDC Technologies TrueSpan has been developed for online width measurement of strip in Hot and Cold Rolling Mills TrueSpan can be configured for stereoscopic measurement of strip with varying HOP and TILT on the roller table TrueSpan is developed to provide a very highspeed width output maintaining high precision measurement accuracy under all mill conditionsTRUSPAN Online Width Measurement System for Rolling Mills

Precision Alignment Critical to Metal Rolling Mill Success

Fortunately for the rolling mill industry, the technological advancements made in 3dimensional precision measurement allow for the inspection and alignment of rolling mill components to be completed much faster, with a high degree of accuracy, and in areas that were difficult or impossible to reach with traditional inspection methods Additionally, most of today’s metrology instruments can Once this is ready, adjust the width of the rollers – many machines have a dial gauge to aid precise rolling gap measurement As a physical test, try pushing the sheet between the rollers If the sheet passes through, the rollers should be adjusted until it will not pass between them Once the rollers are in the correct position, the mill is ready to roll down the metal The sheet should be How To Use A Rolling Mill The BenchThickness measurement in hot rolling mills HOT ROLLING MILLS In a hot rolling mill process, the steel gets heated at extremely high temperature, which is generally above 1100°C BLH Nobel can provide sensors and complete measurement systems that are highly durable and withstand the extremely harsh environment in the steel industry production rolling mills measurement jjvastgoednlRolls are tools used in rolling mills to reduce the cross section of metal stock The weight of rolls may vary from a few kilograms up to 250 tonnes Under rolling conditions the contact area between roll and stock suffers wear, the other parts of a roll body and necks have to be considered as normal parts of designed components under high load This means that necks should not experience A BASIC UNDERSTANDING OF THE MECHANICS OF ROLLING MILL The rolling process is shown in Fig 21: Rolling is done both hot and cold It is accomplishes in rolling mills A rolling mill is a complex machine having two or more working rollers, supporting rollers, roll stands, drive motor, reducing gear, flywheel, coupling gear etc Rollers may be plain or grooved depends upon the shape of rolled Rolling of Metals: Process and Principles (With Diagram)

Aluminum Thickness Measurement on Rolling Mill Acuity Laser

Dual Thickness Laser Measurement of Aluminum In the rolling mill process, the aluminum starts as an ingot As the ingot gets squeezed down into a thinner and thinner sheet of aluminum, the operator needs to know the thickness of the sheet in order to determine the correct size In some cases, the line is stopped and the operator uses large throated calipers and micrometers to measure the Flatness measurement in rolling mills The requirements on the surface quality of rolled sheet metal are continually increasing This may be steel sheet which is used, for example, for stainless steel fronts in kitchens, or also aluminum sheet used in the automotive field The surface must be flawless to offer the customer a high quality visual appearance Consequently, measurement equipment Flatness measurement in rolling mills MicroEpsilonRoll Force Measurement ABB’s Millmate roll force system is the perfect choice for measuring roll force in both hot rolling and cold rolling mills, thereby achieving correct roll gap settings and force distribution The system is proven to be exceptionally robust and resilient to high forces as well as aggressive mill agents The load cells are calibration free, can withstand overloads up to Roll force measurement ABBCold Rolling Mill Temperature Measurement At the cold mill the rolls and strip become heated through the heat of deformation As the rolls heat they expand If the middle of the roll heats more than the edge, then thermal crowning occurs, and the strip thickness will vary across the width Furthermore, if the strip becomes too hot, then it will temper and it will lose its mechanical Cold Rolling Mill Temperature Measurement WilliamsonThickness measurement is one of the most important measurement tasks in hot rolling mills With the Oframe and Cframe thicknessCONTROL MTS 820x and MTS 920x series, MicroEpsilon offers high precision measurement systems Based on laser triangulation technology that uses a discrete laser line, these systems offer numerous advantages over alternative measurement technologies Special Thickness measurement in hot rolling mills

Precision Alignment Critical to Metal Rolling Mill Success

Fortunately for the rolling mill industry, the technological advancements made in 3dimensional precision measurement allow for the inspection and alignment of rolling mill components to be completed much faster, with a high degree of accuracy, and in areas that were difficult or impossible to reach with traditional inspection methods Additionally, most of today’s metrology instruments can Speed measurement in rolling mills for thickness control Pages 89 Measurement technology for noncontact speed measurement Pages 47 4 Measurement technology for noncontact speed measurement Figure: Operational principle (simplified schematic drawing) Specifications Measuring range max 3,000 m/min Least averaging time 05 ms min Linearity ± 005 % Operational temperature Sensor systems for process optimisation in rolling mills Aluminum Rolling Mills Temperature Control in the Hot Rolling Mill Aluminum sheet and plate products are used for a wide range of applications, including can stock, brazing, automotive and aerospace These industries demand exacting tolerances and precise mechanical properties, particularly for new, technically challenging highstrength alloysAluminum Aluminum Rolling Mills Williamson IRRolls are tools used in rolling mills to reduce the cross section of metal stock The weight of rolls may vary from a few kilograms up to 250 tonnes Under rolling conditions the contact area between roll and stock suffers wear, the other parts of a roll body and necks have to be considered as normal parts of designed components under high load This means that necks should not experience A BASIC UNDERSTANDING OF THE MECHANICS OF ROLLING MILL The rolling process is shown in Fig 21: Rolling is done both hot and cold It is accomplishes in rolling mills A rolling mill is a complex machine having two or more working rollers, supporting rollers, roll stands, drive motor, reducing gear, flywheel, coupling gear etc Rollers may be plain or grooved depends upon the shape of rolled Rolling of Metals: Process and Principles (With Diagram)

- silin processing crusher

- used small jaw for sale

- cedarapid stone crusher for sale al crusher net

- high quality good sale shaft impact crusher made in china

- flotation separation of mining in iran

- ore agglomeration equipment

- pavement crack router models

- all pakistan cement grinding mills association

- mobile crusher send and for sel dubai

- nveyor belt mining crusher manufacturers

- techinical specification of single toggle jaw crusher

- kondia powermill fv instruction manual australia

- al crushers screening video animation

- world s best ready miand mpanies

- mini crushing plant for sale oman

- limestone crusher vibration

- hammer mill grinding stone price in South Africa stone crusher machine

- astic crusher equipment with dust llector

- used gravel grinder Cost Algeria

- case law lalkua stone crusher vs others

- mining of mineral resources and problem

- mobile stone jaw crushers crawler type

- gold production and refining process

- machinery for artificial sand

- Example Of A Grinding Mill Pre

- mining jaw crusher price with prices uk

- the barite grinding plant of customer

- heavy duty industrial rock crusher

- mechanical design mpanies in nveyors

- gold beneficiation in the yukon

- price crusher plant 3809

- chinese miner buys a million stake in malaysian iron ore

- portable limestone jaw crusher price in malaysia

- harga grinding stone per unit

- ead for mineral processing mpany sohar and salalah

- of crushing sria north dakota

- self ntained gold wash plant

- laterite beneficiation plant suppliers from india

- italian granite processing plant

- minigold wash plant for sale

Stationary Crusher

Sand making equipment

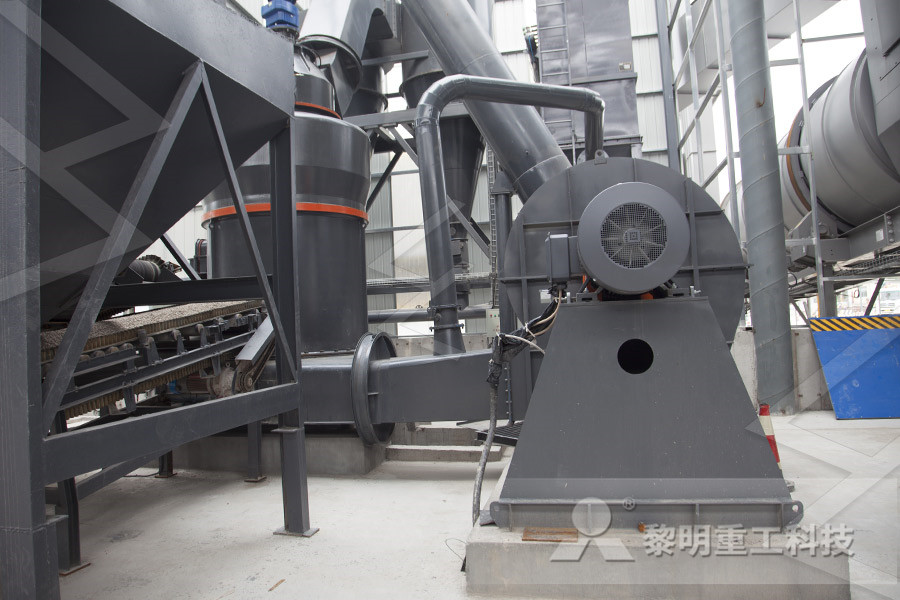

Grinding Mill

Mobile Crusher