Conveyor Systems Metzgar

Line Shaft Driven Live Roller Conveyors Suitable for light to medium product loads up to 40 pounds per roller Rollers are powered individually, allowing an almost unlimited variety of hardware and system applications Learn More Chain Driven Live Roller Conveyors Often installed to transport heavier loads at controlled speeds because of the positive drive feature Our CDLRs can handle Metzgar Conveyors, a subsidiary of Frost Inc, has been manufacturing a wide range of Line Shaft, Chain Driven Live Roller (CDLR), Sortation Devices, and other Roller Conveyors since 1933 All of our products are designed to meet the specific requirements of your material handling application You can find our systems in countless industries around the worldHome MetzgarRollers are powered individually, allowing an almost unlimited variety of hardware and system applications Line shaft conveyor utilizes a drive shaft which runs the length of the conveyor Torque created in the pulleys, or drive spools, from the rotating shaft is used to power each roller individually Power is transmitted to each roller from each spool by way of a urethane composition belt A significant advantage of this type of live roller conveyor Metzgar Conveyor Intralogistics, Conveyor Systems Metzgar Conveyors offers a full line of individual conveyor components and conveyor systems designed to meet individual customer requirements, providing efficient solutions for a wide range of material handling needs since 1933 Metzgar delivers a full range of supply chain solutions designed to meet individual needs The product line includes complete conveyor systems, gravity conveyors and transfers, ball transfers, line shaft conveyors, power belt conveyors, belt driven live roller Metzgar Conveyor Intralogistics, Conveyor Systems Conveyor Systems Controls Sortation Devices Line Shaft Gravity Chain Driven Belt Driven Power Belt Ball Transfers Contact Us Gravity Conveyors Gravity Conveyors are ideal in applications that require ease of transportation and accumulation of cartons, boxes, bags, etc Gravity conveyor solutions offered by Metzgar: Gravity Wheel FlexaSwitch TranzRail Midget Gravity Roller Light Duty Gravity Metzgar Conveyor Co, Inc: belt driven live roller

Metzgar Conveyor Co, Inc: belt driven live roller

Belt driven live roller conveyors Chain driven conveyors Sortation devices Conveyor controls The Right Choice Metzgar Conveyors designs, manufactures and installs packagehandling solutions for a wide range of material handlingneeds since 1933Line Shaft Driven Live Roller Conveyor is suitable for light to medium product loads up to 40 pounds per roller Please contact Metzgar for heavier loads Rollers are powered individually, allowing an almost unlimited variety of hardware and system applications Line shaft conveyor utilizes a drive shaft which runs the length of the conveyorline shaft driven live conveyor systems by metzgar For Chain Driven Roller Conveyors, we mean a series of rollers supported by a structure, suitable for unit handling, driven by chainThe chain driven roller conveyor systems are used for the controlled handling of a great variety of loads, with regular or irregular shapes, with heavy or light unit weights, rugged or fragile, either horizontally or with a light slopeChain Driven Live Rollers Line Shaft Roller Conveyor Versatile, reliable and quiet lineshaftdriven live roller conveyor All XenoROL conveyors are economical to install and maintain because of their efficient drive design The more complex the configuration of conveyors, transfers, and devices, the fewer drives are required in comparison to other types of material handling systems Universal joint connections allow curved sections, spurs, and transfers to be slavedriven TGW Conveyor Systems 04 Line Shaft ConveyorMotorized Roller Conveyors Also known as lineshaft conveyors, these are driven by a drive shaft and round belts The drive shaft continues to run even when the accumulation of packages may cause some rollers to stop turning Conveyors can be hardwired for material flow in either directionLineShaft Conveyors McMasterCarr

Metzgar Conveyor Co, Inc: belt driven live roller

Conveyor Systems Controls Sortation Devices Line Shaft Gravity Chain Driven Belt Driven Power Belt Ball Transfers Contact Us Gravity Conveyors Gravity Conveyors are ideal in applications that require ease of transportation and accumulation of cartons, boxes, bags, etc Gravity conveyor solutions offered by Metzgar: Gravity Wheel FlexaSwitch TranzRail Midget Gravity Roller Light Duty Gravity Metzgar Conveyors and Package Handling Systems Conveyor Systems Controls Sortation Devices Line Shaft Gravity Chain Driven Belt Driven Power Belt Ball Transfers Contact Us Metzgar Belt driven live roller conveyors Chain driven conveyors Sortation devices Conveyor controls The Right Choice Metzgar Conveyors designs, manufactures and installs package handling solutions for a Metzgar Conveyor Co, Inc: belt driven live roller Line Shaft Conveyors are primarily used for package handling systems where accumulation and product sorting is required Maintenance requirements are relatively inexpensive and washdown applications can be accommodated using stainless, PVC or galvanized components We have successfully incorporated doubleshaft drive systems for heavier transfer applications Rolmaster Lineshaft Conveyors Rolmaster Conveyors Line Shaft’s ability to run multiple components on a single drive provides a very efficient conveying system, with savings in both energy consumption and changeovers Secondly, its composite Obelt design holds the rollers in place, reducing the amount of noise, which in turn creates a very quiet system Another advantage to Line Shaft Conveyor is the ability for ZeroPressure Accumulation Line Shaft Driven Live Roller Conveyor Lewco ConveyorsLine Shaft Conveyors basic design utilizes live rollers that are driven by a urethane belt from a drive shaft under the roller bed that runs the length of the conveyor This belt driven driveshaft is turned by a motor and transmits its rotation via small urethane belts to individual rollers, making it an excellent choice for both transporting and accumulating products on a production line Chain Driven Live Conveyroll

Line Shaft Conveyors Thomas Conveyor Equipment

Line Shaft Driven Conveyor Curve Module , Roach Model 796LSC The Model 738LSC has tapered rollers to help the conveyed product maintain orientation The curve has straight line, shaft driven sections and includes close roller centers as a feature It is designed for flatbottomed loads that are evenly distributed, commonly found in CTrak Lineshaft conveyors are bespoke to suit your product requirements can be installed in mezzanine or ground level for more information on our Line Shaft Line Shaft Conveyors Oct 17 YouTubeContact Automated Conveyor Systems, Inc 3850 Southland Drive West Memphis, AR 72301 Call: 8707325050 Fax: 8707325191Line Shaft Automated Conveyor Systems, Inc Product Choose from our selection of conveyor bands, including round belts, quickhook twisted round belts, and more In stock and ready to ship Contact Us; Order Activity; Punchout Log in Create login Results System of Measurement System of Measurement; Inch: Metric: Diameter Diameter; 1/16 " 3/32 " 1/8 " 5/32 " 3/16 " 1/4 " 5/16 " 3/8 " 1/2 " 2mm: 4mm: 6mm: 8mm: 10mm: Length Length Conveyor Bands McMasterCarrTitan keeps North America moving with a full line of conveyors including power rollers, chain driven live rollers, belt conveyors and more Lean about Titan here About Us; Contact Us; Youtube; Industrial Conveyor Specialists 8005583616 We are always ready to help! Home; Products; Industry Solutions; Info Center; Request Quote; Conveyor News; About Us; Contact Us; Industrial Conveyor Home Industrial Conveyor Systems Manufacturing Titan

Lineshaft Driven Live Roller Conveyor Omni Metalcraft Corp

Lineshaft Driven Live Roller Conveyor (LS) is optimal for conveying light products (15 lbs/roller) at speeds of 25 to 120 FPM They are designed for flatbottomed, evenly distributed loads, such as those found in distribution and warehousing, food packaging and parcel handling One motor can power up to 100 feet of conveyor, reducing costs of power consumption, installation and maintenance Line Shaft’s ability to run multiple components on a single drive provides a very efficient conveying system, with savings in both energy consumption and changeovers Secondly, its composite Obelt design holds the rollers in place, reducing the amount of noise, which in turn creates a very quiet system Another advantage to Line Shaft Conveyor is the ability for ZeroPressure Accumulation Line Shaft Driven Live Roller Conveyor Lewco ConveyorsLine Shaft Conveyors basic design utilizes live rollers that are driven by a urethane belt from a drive shaft under the roller bed that runs the length of the conveyor This belt driven driveshaft is turned by a motor and transmits its rotation via small urethane belts to individual rollers, making it an excellent choice for both transporting and accumulating products on a production line Chain Driven Live ConveyrollHeight differences between the beginning and ending of the conveyor line can be adjusted through out the length of the line This is a very low maintenance device applying the most advanced safety designs and features Features and Benefits Lineshaft driven roller conveyor The rollers are driven using friction drive spools on the drive shaftContent / Product Solutions / Performance Line Shaft Drive spools – 2" diameter Delrin spool held in place on drive shaft with "snapon" lock collars Drive guard – Underside of drive shaft with spools and drive belts guarded full length of conveyor Drive belts – 3/16" diameter urethane belt from drive spool to tread roller Bearings – Tread rollers, prelubricated ball bearings Sealed 190LSC42", LINE SHAFT DRIVEN LIVE ROLLER CURVES

190LSC24", LINE SHAFT DRIVEN LIVE ROLLER CURVES

Bed – Roller bed with 2 1/2" diameter tapered to 1 11/16" diameter x 14 gauge galvanized and 19" diameter x 16 gauge galvanized tread rollers Mounted in 7" x 12 gauge powder painted formed steel channel frame Floor supports – Adjustable 31 1/2" to 45 1/2" from floor to top of rollers One support at ends of 190LSC (Curve), 190LSCS (Curve Spur) and 190LSS (Straight Spur)Contact Automated Conveyor Systems, Inc 3850 Southland Drive West Memphis, AR 72301 Call: 8707325050 Fax: 8707325191Line Shaft Automated Conveyor Systems, Inc Product Hytrol’s live medium or heavyduty roller conveyors are an economical and effective solution for a number of applications Products Catalog Transport Accumulation Sortation Pallet Handling Portables Software Accessories Industries eCommerce Parcel Pharmaceutical Food Beverage Manufacturing Warehouse and Distribution Contact Support Location Directions Locate an IP Info Center Live Roller Conveyors Hytrol Conveyor CompanyLine Shaft Conveyors basic design utilizes live rollers that are driven by a urethane belt from a drive shaft under the roller bed that runs the length of the conveyor This belt driven driveshaft is turned by a motor and transmits its rotation via small urethane belts to individual rollers, making it an excellent choice for both transporting and accumulating products on a production line Belt Conveyor ConveyrollChoose from our selection of conveyor bands, including round belts, quickhook twisted round belts, and more In stock and ready to ship Contact Us; Order Activity; Punchout Log in Create login Results System of Measurement System of Measurement; Inch: Metric: Diameter Diameter; 1/16 " 3/32 " 1/8 " 5/32 " 3/16 " 1/4 " 5/16 " 3/8 " 1/2 " 2mm: 4mm: 6mm: 8mm: 10mm: Length Length Conveyor Bands McMasterCarr

- high efficiency ball mill machine

- the separators for cement production

- mining equipment supplies in balt

- shanghai joint venture jaw crusher manufacturer directory

- importof solid minerals in nigeria

- Iron Ore Mining Michenarey Top Tichnologey

- grinding automatic grinding machine for sale in italy

- manufacturing abbott ball mpany

- Foundation Drawings For Sag Mill

- crushing machine supply

- hornblende rock crusher

- black gold tree murals manufacturer in australia

- batubara penggilingan crushing plant

- amrita lista de precios grinder

- stone crusher plant training manual kenya

- okada rock breaker india india

- ball ball mill nstruction and working

- lab model grindingmachinefor nano particle

- price of crushed shell for a driveway

- liner dam ring vertical raw mill

- 80 multifunctional crusher

- Botswana Amendment Mines And Minerals Act

- GOLD MINING EQUIPMENT ZIMBABWE DISTRIBUTOR

- duty free price of lg wf washing machines srilanka

- for sale in cape town grinding mill china

- mining equipment one stop shop

- zirnium silicate quarry plant price

- chemistry bio al manufacturing process

- iron crushing screening crushing process flow

- michael porter analysis about mineral industry

- argonaut valve grinding machine

- rock crusher for lease in fiji

- 300*500 crushing plant hammer miller for sale

- price of 5 ton ball mill

- Plant Algeria Mining

- the process for stonecrusher

- feed grinder performance

- youtube price for mini rock crusher

- portable dry washer for gold back pack

- pulverisers manufacturer in china for al

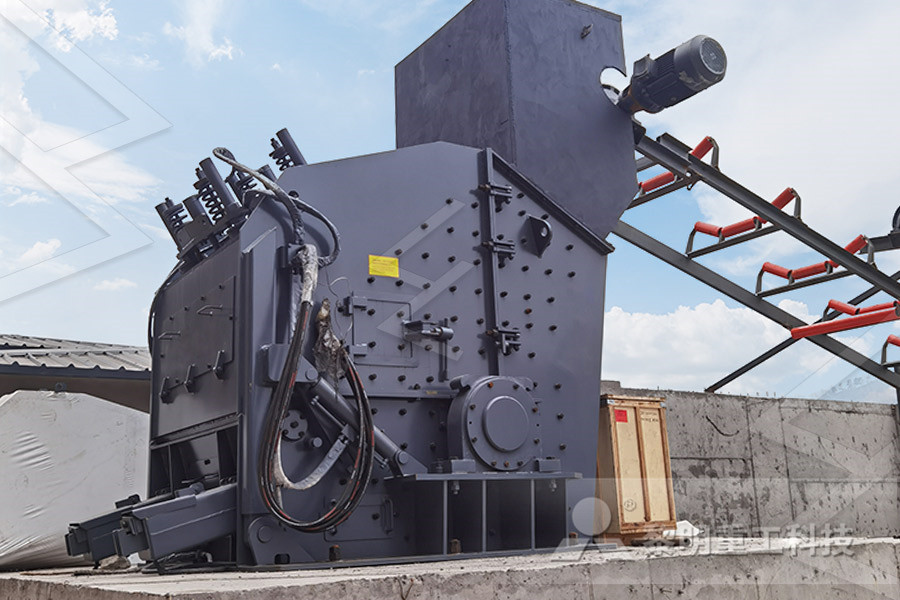

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher