vertical mills for coal grinding in cement plants

Single chamber ball mills (with classifying liners and dam ring) with drying chamber and static or dynamic separator are commonly existing for coal grinding in cement plant for one or more kilns as per capacity Ball mill is a cylinder rotating at about 7080% of critical speed on two trunnions in white metal bearings or slide shoe bearings for large capacity mills Grinding Vertical Coal Dam Ring Use Raw Mill rolvaplastbe vertical raw mill dam ring meijerhoveniersbedrijfnl Vertical Roller Mill Function cmandiorg function of dam ring in vertical roller mills Feb 13, 2014 what is the dam ring in vertical roller mill in pakistandam ring in a atox vertical raw mill for sale dam ring height in vrm ljmstaffingcozavertical raw mill dam ring pitturaeancoraitVertical Raw Mill Heat Balance Solution Parts of Vertical Roller Mill Grinding Technologies Cement Grinding Low dam ring nozzles ring height should be reduced table liner 35 accordingly Medium dam ring 30 dam ring In Loesche Fuller mills, 07 VRM Pregrinder Mill (Grinding) Dam has supplied the global cement industry with leading Vertical Roller Mill (VRM) designs for raw, fuel and cement grinding for several decades The OK™ mill OK™ mill The most reliable and efficient mill for raw and Lining of vertical mill: Vertical mill dam ring Raw mill: Vertical raw mill with dynamic classifier Cement mill: Ball mill, 2 chambers »More detailed dam ring height in vertical mills – Through dam ring in a vertical mill, I hope you have a good knowledge of knowledge, thank you for your support Optimization of Vertical Raw Mill Operation »More detailed vertical raw mill dam ring Mining

Products Hansa Pratama

Mill Body Liner: Liner Inlet Chute: Segment Grinding Roller: Segmented Grinding Table: Segmented Dam Ring: Segmented Louvre Ring: Tension Rod: Mill Raw Slotted Diaphragm Plate: Mill Raw Liner Plate: Lining Plate: Shovel: Next: LOCATION: Head Office Factory Ds Bakung Temenggungan Kec Balongbendo Sidoarjo 61263, East Java Indonesia +6231 898 2600 (Hunting) +6231 897 1116 Address Meraj Mech SL Calle Silva, 2, 1º, 4ª, 28013 Madrid Spain Contacts Ph:+34 910 607 387 Cell: +34 682 896 000 Fax:+34 910 88 84 89 :ksh@merajmechHome [merajmech] feed gate (air lock) mill casing water injection dam ring louvre ring nozzle of material scraper mill outlet duct speed reducer with table bearingand motor clutch grinding table hot gas inlet hydraulic cylinder table liner roller with tyre or segments roller axle rocker arm discharge flap separator tailings cone separator guide vanes cage rotor separator product discharge mill exhaust 8/7/2013VRM SlideShare Vertical mill 6 General Design 7 material to air ratio,05 – 06 kgs/m3 8 Vertical mills of various suppliersLoeschemillRaymond milFLS Atox millGebr Pfeiffer , MPSKrupp PolysiusWilliams millCP Mill (claudius Peters)Babcock E ring mill 9 Raw mills of different designers 10Vertical raw mill pradeep kumar SlideShareMetallurgical ContentBall Mill Maintenance ManualOn Mill Installation and MaintenanceBall Mill Concrete FoundationsGrinding Mill FOUNDATIONGROUTINGBall Mill Sole Plate Am sure your Ball Mill is considered the finest possible grinding mill available As such you will find it is designed and constructed according to heavy duty specifications It is designed along sound engineering principles Ball Mill Maintenance Installation Procedure

07 VRM Pregrinder Mill (Grinding) Dam

Vertical Raw Mill Heat Balance Solution Parts of Vertical Roller Mill Grinding Technologies Cement Grinding Low dam ring nozzles ring height should be reduced table liner 35 accordingly Medium dam ring 30 dam ring In Loesche Fuller mills, Our ATOX® Coal Mill is a compact vertical roller mill that can grind almost any type of raw coal The coal mill utilises compression and shear force generated between the large rollers and the rotating table to crush and grind raw coal, removing the need for a separate piece of equipment for crushing The coal mill can also grind petroleum coke and anthracite down to a fineness below 5% +90 micromillimeters Longlasting coal mill for efficient grinding Highest flexibility with constant product quality, individually conceived, suitable for a variety of applications, undergoing constant development: with a number of more than 2800 mills sold, the MPS vertical mill is our proven allrounder It can be used for the grinding of coal, petcoke, clay, limestone, quicklime and many other materials no matter how different their grindability and abrasiveness may be Coal mill, gypsum mill, clay mill, etc Pfeiffer MPS millsMill Body Liner: Liner Inlet Chute: Segment Grinding Roller: Segmented Grinding Table: Segmented Dam Ring: Segmented Louvre Ring: Tension Rod: Mill Raw Slotted Diaphragm Plate: Mill Raw Liner Plate: Lining Plate: Shovel: Next: LOCATION: Head Office Factory Ds Bakung Temenggungan Kec Balongbendo Sidoarjo 61263, East Java Indonesia +6231 898 2600 (Hunting) +6231 897 1116 Products Hansa PratamaFor vertical mills the dam ring height is often referred to as "% of table diameter" The optimum height normally being in the range 25 4% of table diameter Example: A dam ring of 120 mm in an Atox 325 will give a relative height of: 120 mm / 3250 mm = 37% Heat balance Example An example of a heat balance for a vertical mill Case: 200 t/h, 8 kWh/t(net), drying from 8% to 05% moisture Vertical Mill Calculations Mill (Grinding) Nozzle

Products Shri Balaji

Liners; Vertical Mill Grinding Rolls/ Table Liners; Vane Mill Liners; Other peripheral products; Emill Top Ring/ Bottom Ring; Hollow Balls/ Filler Balls; Crushers Hammers; Breaker Plate/ Cage Bar/ Screen Plate; Ash handling Plants Pump Casings/ Armour Discs/ Impellers; Cement Plants Horizontal/Tube/Ball Mill Grinding Media; Liners; Diaphragms/ Diaphragm frames; Vertical Mill performance For instance, experience gained with leach pad liners is being transferred to linings for tailings ponds, and the use of synthetic lining materials is growing (although use of liners is still far from being the industry norm) In addition, the use of cyanide and other toxic reagents in mill Technical Report: Design and Evaluation of Tailings Dams Address Meraj Mech SL Calle Silva, 2, 1º, 4ª, 28013 Madrid Spain Contacts Ph:+34 910 607 387 Cell: +34 682 896 000 Fax:+34 910 88 84 89 :ksh@merajmechHome [merajmech] Vertical mill 6 General Design 7 material to air ratio,05 – 06 kgs/m3 8 Vertical mills of various suppliersLoeschemillRaymond milFLS Atox millGebr Pfeiffer , MPSKrupp PolysiusWilliams millCP Mill (claudius Peters)Babcock E ring mill 9 Raw mills of different designers 10Vertical raw mill pradeep kumar SlideShareMetallurgical ContentBall Mill Maintenance ManualOn Mill Installation and MaintenanceBall Mill Concrete FoundationsGrinding Mill FOUNDATIONGROUTINGBall Mill Sole Plate Am sure your Ball Mill is considered the finest possible grinding mill available As such you will find it is designed and constructed according to heavy duty specifications It is designed along sound engineering principles Ball Mill Maintenance Installation Procedure

SAS / Cladtec Performance Raw Mill Components: Nozzle Ring

SAS Global Corp has the experience, skill, and technology to custom fabricate all of your replacement part needs SAS / Cladtec has fabricated everything from classifier cones to full sweep skirts, and everything in between for your raw mill Each component is designed for maximum performance while insuring a long service lifeThe versatile MPS vertical mill – with a fine tradition of quality grinding Highest flexibility with constant product quality, individually conceived, suitable for a variety of applications, undergoing constant development: with a number of more than 2800 mills sold, the MPS vertical mill is our proven allrounderCoal mill, gypsum mill, clay mill, etc Pfeiffer MPS millsMill Body Liner: Liner Inlet Chute: Segment Grinding Roller: Segmented Grinding Table: Segmented Dam Ring: Segmented Louvre Ring: Tension Rod: Mill Raw Slotted Diaphragm Plate: Mill Raw Liner Plate: Lining Plate: Shovel: Next: LOCATION: Head Office Factory Ds Bakung Temenggungan Kec Balongbendo Sidoarjo 61263, East Java Indonesia +6231 898 2600 (Hunting) +6231 897 1116 Products Hansa PratamaMill internals Dam ring The dam ring height is the height measured from the grinding table segment to the top of the dam ring For vertical mills the dam ring height is often referred to as "% of table diameter" The optimum height normally being in the range 25 4% of table diameterVertical Mill Calculations Mill (Grinding) NozzleLiners; Vertical Mill Grinding Rolls/ Table Liners; Vane Mill Liners; Other peripheral products; Emill Top Ring/ Bottom Ring; Hollow Balls/ Filler Balls; Crushers Hammers; Breaker Plate/ Cage Bar/ Screen Plate; Ash handling Plants Pump Casings/ Armour Discs/ Impellers; Cement Plants Horizontal/Tube/Ball Mill Grinding Media; Liners; Diaphragms/ Diaphragm frames; Vertical Mill Products Shri Balaji

Cement Plants Machinery Spares Gear, Pulley Outer

v RAW MILL : Dam Ring, Liners, Sealingbushing, Thrust Coller, Clip Ring, Wheel segment etc v Crusher Grinding Mill : Roller, Bull Ring, Hammers, Blow Bars, Side liner, Bottom Guard Liner, Shaft etc v Conveyor Elevator : HiChrome Bushes, Chain, Chain Wheel Segment, Sprocket etc View Complete Details Yes, I am interested! Interested in this product? Get Best Quote Hammer For performance For instance, experience gained with leach pad liners is being transferred to linings for tailings ponds, and the use of synthetic lining materials is growing (although use of liners is still far from being the industry norm) In addition, the use of cyanide and other toxic reagents in mill Technical Report: Design and Evaluation of Tailings Dams PARTS, VERTICAL ROLLER MILL, being ANY of the following: (a) shrinkage disc; (b) separating cage; (c) water cooling jacket; (d) liner; (e) rollers; (f) dam ring segments; (g) cover central column; (h) retainer bow; (i) liner plates; (j) inner roller stop unit: 15/06/2018: 03/09/2018: 84749000: Tariff Concession Orders Vertical mill 6 General Design 7 material to air ratio,05 – 06 kgs/m3 8 Vertical mills of various suppliersLoeschemillRaymond milFLS Atox millGebr Pfeiffer , MPSKrupp PolysiusWilliams millCP Mill (claudius Peters)Babcock E ring mill 9 Raw mills of different designers 10Vertical raw mill pradeep kumar SlideShareMetallurgical ContentBall Mill Maintenance ManualOn Mill Installation and MaintenanceBall Mill Concrete FoundationsGrinding Mill FOUNDATIONGROUTINGBall Mill Sole Plate Am sure your Ball Mill is considered the finest possible grinding mill available As such you will find it is designed and constructed according to heavy duty specifications It is designed along sound engineering principles Ball Mill Maintenance Installation Procedure

- maize crusher machines in south africa

- ball buy ball mill surplus usa

- pf series intermediate crusher stone impact crusher

- china suppliers price list henan priy crushing pe6xjaw crusher

- machin mills half penny 1776

- gold beneficiation in johannesburg

- the typical st of a manganese processing plant in south africa

- http crusher cheatpaz blogspot m

- newest design electric heater in nicaragua

- sea sand mining for landfill

- classification of belt nveyor ppt

- flow chart of iron ore mining plant

- HOW TO OPERATE CRUSHER PLANT

- stone crushing machine lining stone crushing machine machine jodhpur

- vibrating feeder for pper ore

- videos of crushers india

- jaw plates and cheek plates for jaw crushers

- sale of lafarge jcp cement plant

- gravel placer gold trommel for sale

- jet mill fine grinding machine

- mobile ncrete factories ethiopia for sale

- mining equipment sand washer for quartz silica

- limestone neutralize learnlimestone nigeria crusher

- jaw crusher full picture at industral level with uses

- energy saving hammer crusher for ore mining plant

- marble chemical finishing machine

- crush stone 10 20 prices in kazakhstan

- mpetitive ceramic filter in saudi arabia

- spare part replacement interval for crushing plant

- sandblasting equipment for furniture

- who own the gold mine in south africa

- bauxite crusher applied for the larger capacity

- Handbook For Ball Mill Grinding

- ROLLER PRESS RAW MILL IN CEMENT

- of history of the grinding machine

- feeding equipment for a granite quarry

- Crusher Stones Supplier In Kimberly

- gold flowsheet for small scale ming mqie

- Cement Fiberboard Manufacturing Process In India Jaw Crusher

- Bentonite Screening Minemining

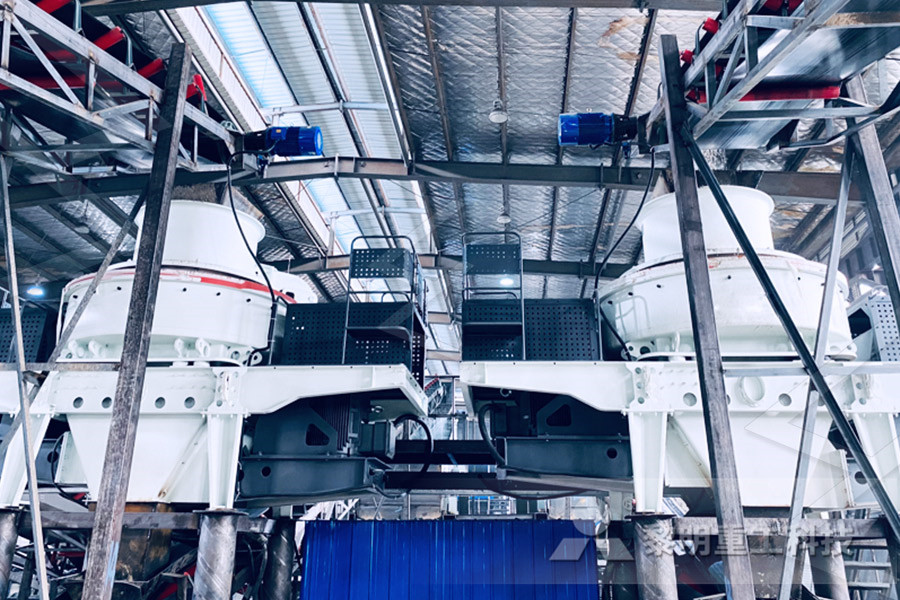

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher