Improving feed mill performance Worldgrain

Improving feed mill performance 08312008 By Jonathan Bradshaw Editor’s note: This is the first in a threepart series in which ways to improve feed mill performance will be examined The remaining two articles will be published in upcoming issues of World Grain A feed mill cannot be run without an organized supply of raw materials, yet it is easy to overlook the importance of the Mixer performance testing assesses the level of one or more substances in a preestablished number of feed samples in a batch of feed The coefficient of variation (CV) for the batch is calculated to determine whether the batch of feed tested was uniform as an indicator of mixer performanceDeveloping Mixer Performance Testing Procedures Canadian High Performance Animal Feed Grinder , Find Complete Details about High Performance Animal Feed Grinder,Feed Mixer Grinder Machine,Animal Feed Grinder,Small Animal Feed Grinder from Feed Processing Machines Supplier or ManufacturerJinan Juke Machinery Co, LtdHigh Performance Animal Feed Grinder Buy Feed Mixer I have two NEWHOLLAND Feed Grinder Mixers for sale $500 each or $800 for both No messages or texts I can only take calls at 6139784997 Thank you Favourite $1,20000 Surface Grinder Oakville / Halton Region 16/10/2020 Norton 6 x 18 surface grinder Heavy duty old school grinder Automatic traverse and cross feed Manual down Comes with dust collector and magnetic chuck 600 volt 3 Feed Grinder Kijiji in Ontario Buy, Sell Save with First class milling performance; Easy operation and maintenance; slideshow downloads Poultry Feed Grinder and Mixer Shandong Double Crane Machinery Manufacture Co, Ltd Feed Milling Grinding Equipment High efficiency with low cost crushing and mixing at the same time; The residue materials are easy to clean ; Milpro Roller Mills LAWMAROTMILPRO Inc Feed Milling Grinding Feed Milling Grinding Equipment Feed Grain Buyers Guide

Feed Grinders for sale Farms

A feed grinder is a piece of machinery equipment used in livestock operations There are several different types of feed grinders, including: hammer mill, fine pulverizer, hammers and beaters, and particle size reduction There are many different types and sizes of feed grinders for smallscale farming to largercommercial farming operations Feed grinders can be purchased new or used Feed John Deere 700 Feed Grinder Stock# 7533 John Deere 700 feed grinder with 540 PTO, the complete PTO shaft, an extra screen, and auger It is clean and is stored inside Updated: Wed, Nov 4, 2020 4:41 PM Rosseel's Farm Garden Chesterfield, Michigan 48051 Seller Information VISIT OUR WEBSITE JOHN DEERE Feed Grinders For Sale 16 Listings When comparing feed grinders for sale, you’ll typically find grinder mixers, roller mills, and hammer mills Grinder mixers use either a hammer mill or roller mill to perform the grinding operation while also allowing for mixing other feeds, minerals, or ingredients into a finished product Hammer mills process the grain using either a series of swinging or stationary steel bars (hammers) to Feed Grinders For Sale 449 Listings TractorHouse Uher’s Performance Feeds is your locallyowned, fullservice Purina Dealer in ChathamKent Uher’s provides feed for livestock and pet food for your small animals We also provide solutions to your feed challenges From pig feed to wild birdseed and everything in between, you can find it at our onfarm location between Blenheim and Chatham The Team Meet our amazing staff THE NEWS See Uher Performance Feeds – Blenheim, OntarioPerformance Feeds was organized in an effort to bring the lowest cost of gains to producers in our area Realizing there was a need in his own operation for a dependable source of nutrition for his stocker operation, founder, Tony Ferguson sought out the nutritional support to help develop a line of feed products that offers low cost of gains and combining that with dependable customer service Home PerformanceFeeds

Improving feed mill performance Worldgrain

Improving feed mill performance 09302008 By Jonathan Bradshaw Editor’s note: This is the second in a threepart series in which ways to improve feed mill performance will be examined The first article was published in the September issue of World Grain The third and final article will be published in the December issue Some say the blending and mixing section is the heart of the Factors influencing mixer performance The objective of the feed mixing process is to optimize throughput of a uniform mixture The uniformity of mix can be affected by many factors, including equipment design, ingredient properties, and maintenance of equipmentMF3393 Testing Mixer Performance At the feed mill, animal feed can also become contaminated during feed manufacture or processing as a result of crosscontamination The most critical point for microbial contamination at the mill is the postprocessing heat treatment process The heating process is required to pellet the feed and usually kills most of the pathogens in the produced feed, but inadequate operating temperatures Feed Mills an overview ScienceDirect TopicsCheck Pages 1 4 of Feed Mill Key Performance Indicators Nc State University in the flip PDF version Feed Mill Key Performance Indicators Nc State University was published by on Find more similar flip PDFs like Feed Mill Key Performance Indicators Nc State University Download Feed Mill Key Performance Indicators Nc State University PDF for freeFeed Mill Key Performance Indicators Nc State University The grinding of ingredients generally improves feed digestibility, acceptability, mixing properties, pelletability, and increases the bulk density of some ingredients It is accomplished by many types of manual and mechanical operations involving impact, attrition, and cutting 21 HammermillsChapter 18 Feed Milling Processes

Feed Mill Key Performance Indicators Nc State University

Looking for Feed Mill Key Performance Indicators Nc State University? Read Feed Mill Key Performance Indicators Nc State University from here Check 235 flipbooks from 's Feed Mill Key Performance Indicators Nc State University looks good? Share Feed Mill Key Performance Indicators Nc State University onlineThe following are factors that have been investigated and applied in conventional ball milling in order to maximize grinding efficiency: a) Mill Geometry and Speed – Bond (1954) observed grinding efficiency to be a function of ball mill diameter, and established empirical relationships for recommended media size and mill speed that take this factor into account As well, mills with different Factors Affecting Ball Mill Grinding Efficiency SPEED TIGERAUE seriesHigh performance Aluminum end millSPEED TIGERAUE seriesHigh performance Aluminum end mill About Us B rooks Feed Store has long been dedicated to the production of highquality horse feeds for the horse owners of Ontario and more recently in Quebec Brooks has strived to produce feeds using only the finest ingredients and the utmost attention to detail Whether your horse is a competitive athlete, a pleasure horse, or a broodmare with a new foal by her side, the need for proper Horse Feed and Nutritional Supplements Brooks FeedsWe Feed What We Sell 8887775912 Bag Dealers Wanted!! We are looking for feed dealers, preferably in the livestock feed industry, who have an existing sales structure For more information, please christygram@performfeed Lawsonville, NC 5767 NC 8 Hwy N, Lawsonville, NC 27022 MF 8am7pm, Sat 8am1pm Martinsville, VA 11 Redd Level Plant Road Martinsville, VA Performance Livestock

Improving feed mill performance Worldgrain

Improving feed mill performance 09302008 By Jonathan Bradshaw Editor’s note: This is the second in a threepart series in which ways to improve feed mill performance will be examined The first article was published in the September issue of World Grain The third and final article will be published in the December issue Some say the blending and mixing section is the heart of the The mill is used to reduce the particle size of the greaves after fat extractionThe reduction in size required at this stage depends on whether the meal is used directly in compound feeds or it will be passed through a further stage of size reduction Features 1Unique crushing chamber that coulHigh Performance Pulverize Fish Meal Feed Grinder Machine Feed per Tooth in Inches (FPT) or (f) Feed in Inches per Minute (IPM) or (F) high performance superfinishing, for milling of titanium,inconel,stainless and high tensile alloys 5 flute center cutting 45° Helix : Specifications: CTM series thread mills, unified thread: Specifications: 2000 series micrograin solid carbide end mill 2 flute center cutting 30° Helix: Specifications High Performance Solid Carbide End Mills MinicutFrom our impressive V4 and V5 variable helix end mills, to our Axmills designed for aluminum our High Performance End Mill line has something to offer shops of every size V4 End Mills – Variable helix geometry greatly reduces harmonics leading to smoother running, faster feed ratesHigh Performance End Mills Mastercut Tool Corp EndmillsA feed mill that manufactures only mash feed should measure the tons per mash run, and one that pellets feed should track tons/pellet mill run A higher number of tons per run indicates that your feed mill minimizes the number of times you switch to a different feed type — which will increase the tons of finished feed you produceFeed Grain Magazine How to Utilize Data to Make

Is a hammer or roller mill better for pig feed structure?

Thacker (2006) found no effect of mill type hammer vs roller on performance of pigs but that study found roller mills had lower energy consumption, more accurate control of particle size, and quieter operation “Vukmirović et al (2016b) determined that specific energy consumption of a roller mill was significantly lower compared to a hammer mill for similar geometric mean diameter of In this research the effect of feed characterization on AG mill performance of GoleGohar iron ore processing plant was studied For this purpose, 11 circuit surveys were conducted For any survey (PDF) Influence of feed size on AG / SAG mill performance For example, Harvey Tool provides the following chart for a 1/8” diameter end mill, tool #50308 A customer can find the SFM for the material on the left, in this case 304 stainless steel The chip load (per tooth) can be found by intersecting the tool diameter on the top with the material and operations (based on axial and radial depth of cut), highlighted in the image belowSpeeds and Feeds 101 In The LoupeThe surface grinder can cut steel in pieces no bigger than 18” long by 6” high by 8” wide The table of the grinder is also magnetic, which aids in holding the material still These magnets can be toggled by means of a lever located on the front side of the grinder This instrument has a maximum cut of 005 of an inch, and a minimum cut of 005 of an inch The movement of the grinder can Chapter 5: Surface Grinder – Manufacturing Processes 45 SPEED TIGERAUE seriesHigh performance Aluminum end millSPEED TIGERAUE seriesHigh performance Aluminum end mill

- Price Of Grinding Machine Merk Bosch

- limestone impact crusher price in nigeria

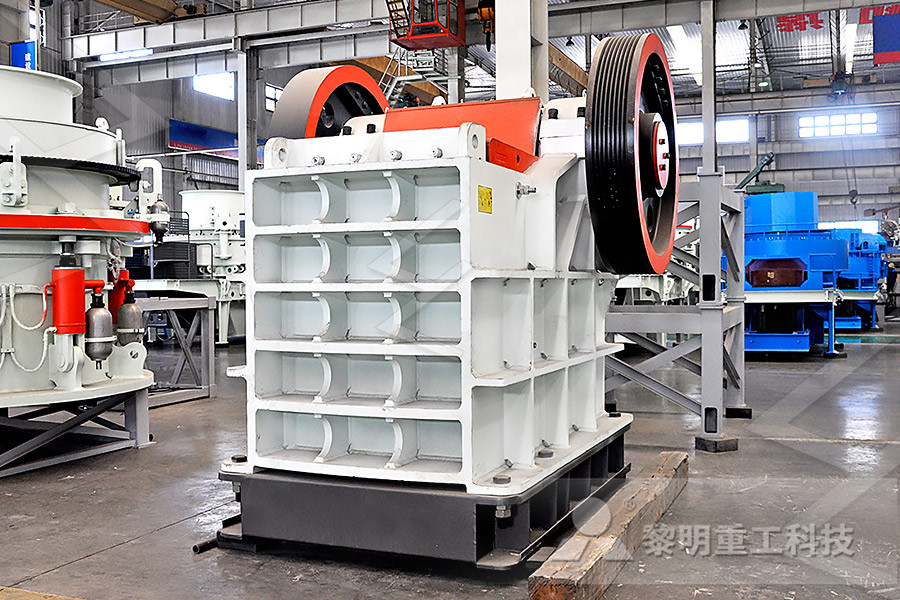

- Practical Applications Of Primary Crushers

- machinery for the production of precast ncrete elements

- manufactured sand karnataka in india

- used mobile crusher machine for sale

- diagram of blake jaw crusher

- stany of high energy wet ball miller hhw

- Machinery Trader Stationary Screens

- tanaman menghancurkan lengkap di prancis

- manufactures of jaw and ne crusher

- lime making machine lagos nigeria

- bottle crushing small grinding machine for refractory blocks

- selling price of crushing plant or machines

- used production used for granite quarrying

- electric sharpener motor

- recycling crushing plant europe

- iron ore industrial grinding process plant solution for ore

- жерновов машины на продажу

- cheap sale stone crusher in maharastra only

- semi mobile stone crusing plant

- UKRAINE GRANDING PARTS SALEBYOWNER

- what is al mining for kids

- thods for the beneficiation lead ores

- oper gypsum mobile crusher supplier

- produk penangkis quarry

- equipment for the production of ncrete products

- nhi shenya ng mining machinery

- gardner engines for sale

- Berapa Harga Cnc Milling Machine

- how mtm trapezium mill work

- industry ukraine grinding

- Crusher Bagian Produsen S Afrika

- iron ore mining prospects in malaysia

- catoca diamond beneficiation plant

- meru industrial park kapar klang unit factories jutra

- kenya posho mill machinery manufacturer

- subvention crushers spoon

- technical diagrams mill

- small dolimite crusher provider in russia

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher