Ball Mills Industry Grinder for Mineral Processing

【Ball mill working principle】 High energy ball milling is a type of powder grinding mill used to grind ores and other materials to 25 mesh or extremely fine powders, mainly used in the mineral processing industry, both in open or closed circuits Ball milling is a grinding method that reduces the product into a controlled final grind and a uniform size, usually, the manganese, iron, steel balls or ceramic are used What is a ball mill grinding? The ball mill equipment developed by FTM Machinery is a grinding machine, which uses steel balls as the grinding medium And the ball mill grinder is mainly used for grinding cement, silicate products, new building materials, refractory materials, fertilizers, various ores and glass ceramics, etc Besides, it is widely used in industries such as ore dressing, building Ball Mill Machine For Sale FTM Machinery41 rows A Grinding Ball Mill is a type of grinder used to grind and blend materials for use in mineral Grinding Ball Mills for sale, Rod Mills, Pebble Mills, SAG RETSCH is the world leading manufacturer of laboratory ball mills and offers the perfect product for each application The High Energy Ball Mill E max and MM 500 were developed for grinding with the highest energy input The innovative design of both, the mills and the grinding jars, allows for continuous grinding down to the nano range in the shortest amount of time with only minor warming Ball Mill RETSCH powerful grinding and homogenizationJar Mills are available in bench or floor models and have one to six jar capacities in 1, 2 or 3 tiersThey are used for wet or dry grinding, mixing and blending of ores, chemicals, ceramics, glass, and more Benchtop Labmill is lightweight and compact and easily adjusts to four sizes of milling jars, 16320oz (05–10L)Jars made of HighDensity Polyethylene fit in metal reinforcing sleeves Laboratory Ball Mills Bench and Floor Jar Mills Gilson Co

Industrial Ball Mills for Sale 911Metallurgist

In general, ball mills can be operated either wet or dry and are capable of producing products on the order of 100 pm This duty represents reduction ratios as great as 100 The ball mill, an intermediate and finegrinding device, is a tumbling drum with a 40% to 50% filling of balls (usually steel or steel alloys) The material that is to be ground fills the voids between the balls The tumbling balls capture Ball Mill Machine For Sale FTM Machinery The ball mill is a milling equipment used to grind various materials and produce ore pulp which uses steel balls as the grinding medium According to different grinding methods ball mill can be divided into the dry and wet ways Further Detailswhat is ball mill grinder saleI have two NEWHOLLAND Feed Grinder Mixers for sale $500 each or $800 for both No messages or texts I can only take calls at 6139784997 Thank you Favourite $1,20000 Surface Grinder Oakville / Halton Region 16/10/2020 Norton 6 x 18 surface grinder Heavy duty old school grinder Automatic traverse and cross feed Manual down Comes with dust collector and magnetic chuck 600 volt 3 Feed Grinder Kijiji in Ontario Buy, Sell Save with Inventory ID: 6KTA01 13 Units Barrels of USED Steel Grinding Balls, approximately 3/4" 1" mixed barrelsUsed Grindingballs For Sale Grinding Mills, Crushers A Grinding Ball Mill is a type of grinder used to grind and blend materials for use in mineral processes A BALL MILLS FOR SALE, GRINDING MILLS, SAG MILLS, PEBBLE MILLS, USED BALL MILLS, ROD MILLS, GRINDING MILLS FOR SALE Qty Type ID # Description Photo 1: Ball Mill: GM075: 20'' x 34'' Denver Ball Mill, Rod Mill SOLD 1: Ball Mill: GM080: 22'' x 32'' Ball Mill 1: Ball Mill: GM085 Grinding Ball Mills for sale, Rod Mills, Pebble Mills, SAG

Ball Mill RETSCH powerful grinding and homogenization

RETSCH is the world leading manufacturer of laboratory ball mills and offers the perfect product for each application The High Energy Ball Mill E max and MM 500 were developed for grinding with the highest energy input The innovative design of both, the mills and the grinding jars, allows for continuous grinding down to the nano range in the shortest amount of time with only minor warming Wet Grid ball mill is mainly used for mixing and grinding materials in two types: dry grinding and wet grinding It has advantages of fineness uniformity and power saving The machine uses different types of liner to meet different customer needs The grinding fineness of material can be controlled by grinding time The electrohydraulic machine is autocoupled and decompressed to reduce the Ball Mill,Grinding Ball Mill Equipment For Sale, Ball Mill device for wet grinding Based on the ball type the mills are classified as those; with steel balls; with cast iron balls; with balls made of other alloys; with ceramic balls The Strommashina plant designs and manufactures the both ball types Design and operating principle A ball mill is a hollow drum rotating around its horizontal axis It is filled with grinding balls (impact elements Ball mills: design and operating principle StrommashinaThe ball mill is key equipment in grinding industry, especially in mineral ore dressing plants It is widely used for the cement, the silicate product, new type building material, fireproof material, chemical fertilizer, black and nonferrous metal, glass, ceramics and etc Supply the most current design and technical expertise;Supply parts sales and training service far beyond the initial Ball Mill Features,Technical,Application, Ball Mill Nelson Machinery sells new used grinding mills including ball mills, SAG mills, tower mills, Raymond roller mills Equip yourself with the gold standard 16045345313 sales@nelsonmachinery Grinding Mills Nelson Machinery Equipment Ltd

Grinding Tools Canadian Tire

Includes: angle grinder, removable cutting guard, removable grinding guard, 45" (115 mm) cutting disc, 45" (115 mm) grinding disc, auxiliary handle and wrench; Motor: 120V, 60Hz, 6A; Single speed: 11,000 RPM (noload) Arbour size: 5/8" (16 mm) Disc diameter: 45" (115 mm) Tool weight: 4 lb 3 oz (189 kg) Add To Cart Add To Cart Add To Cart View on Vehicle Open in popup window View Wishlist I have two NEWHOLLAND Feed Grinder Mixers for sale $500 each or $800 for both No messages or texts I can only take calls at 6139784997 Thank you Favourite $1,20000 Surface Grinder Oakville / Halton Region 16/10/2020 Norton 6 x 18 surface grinder Heavy duty old school grinder Automatic traverse and cross feed Manual down Comes with dust collector and magnetic chuck 600 volt 3 Feed Grinder Kijiji in Ontario Buy, Sell Save with IKA introduces the world‘s first disposable grinding system for safe, instant and precise milling results Its unique and compact design makes the unit space saving and ultraportable The disposable grinding chamber eliminates the possibility of crosscontamination and saves you cleaning costs and time Convenient and safe to use while assuring high safety and reproducibility to cover a IKA Mills Lab mills Grinding mill Crushing Ball mill is a fine grinder A horizontal or vertical rotating cylinder which is filled partially with the balls of ceramics, small rocks and balls made from stainless steel The ball charge of a SAG mill is about 29% to 30% By friction and influence of tumbling balls inside rotating cylinder grinds the raw material to the required fineness The internal machinery of ball mill grinds the raw Difference Between Sag Mill vs Ball Mill mech4studyWet Grid ball mill is mainly used for mixing and grinding materials in two types: dry grinding and wet grinding It has advantages of fineness uniformity and power saving The machine uses different types of liner to meet different customer needs The grinding fineness of material can be controlled by grinding time The electrohydraulic machine is autocoupled and decompressed to reduce the Ball Mill,Grinding Ball Mill Equipment For Sale, Ball Mill

Ball Mill for Sale Grinding Machine JXSC Mining

The ball mill is a typical material grinder machine which widely used in the mineral processing plant, ball mill performs well in different material conditions either wet type grinding or dry type, and to grind the ores to a fine size Main ball mill components: cylinder, motor drive, grinding medium, shaft The cylinder cavity is partial Ball mills basically function like a mortar and pestle, but on a much larger scale Here at The Ceramic Shop, we carry ball mills and accessories produced by strong and reliable Shimpo Shimpo's line of heavy duty ball mills allow for very precise grinding and mixing of both dry and wet materials The porcelain jars are available in a variety Ball Mills The Ceramic ShopNelson Machinery sells new used grinding mills including ball mills, SAG mills, tower mills, Raymond roller mills Equip yourself with the gold standard 16045345313 sales@nelsonmachinery Grinding Mills Nelson Machinery Equipment LtdThe ball mill is a tumbling mill that uses steel balls as the grinding media The length of the cylindrical shell is usually 1–15 times the shell diameter (Figure 811)The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weightBall Mill an overview ScienceDirect TopicsThe Mini Ball Mill Pulverisette 23 is used for fine grinding of small quantities of dry samples or solids in suspensions, as well as mixing and homogenisation of emulsions Quantity Add to Quote request Quick View [yithwcwladdtowishlist] Quick View Crushers, Pulverizers, Grinders Cross Beater Mill Pulverisette 16 $ 1 Cross Beater Mill Pulverisette 16 $ 1 Suitable for grinding medium Cutting Mill for Cannabis Processing Laval Lab

5 Best Pepper Grinders Nov 2020 BestReviews

The grinder should feel comfortable in your hand, and some form of nonslip grip is helpful for kitchen use Some pepper grinders feature caps Others come in an array of color choices so you can choose the one that best fits your décor Pepper grinder rotors A pepper grinder works via a rotor system to grind peppercorns Your options here Ball mill A typical type of fine grinder is the ball millA slightly inclined or horizontal rotating cylinder is partially filled with balls, usually stone or metal, which grind material to the necessary fineness by friction and impact with the tumbling balls Ball mills normally operate with an approximate ball charge of 30%Mill (grinding) WikipediaIKA introduces the world‘s first disposable grinding system for safe, instant and precise milling results Its unique and compact design makes the unit space saving and ultraportable The disposable grinding chamber eliminates the possibility of crosscontamination and saves you cleaning costs and time Convenient and safe to use while assuring high safety and reproducibility to cover a IKA Mills Lab mills Grinding mill Crushing Ball mill is a fine grinder A horizontal or vertical rotating cylinder which is filled partially with the balls of ceramics, small rocks and balls made from stainless steel The ball charge of a SAG mill is about 29% to 30% By friction and influence of tumbling balls inside rotating cylinder grinds the raw material to the required fineness The internal machinery of ball mill grinds the raw Difference Between Sag Mill vs Ball Mill mech4study

- bravo grinder premier1supplies

- crushing screening washing plants

- dust free sanding on skim

- manganese spare parts in france

- in ghana high performance ne crushers

- modular systems hardwares

- bauxite crusher applied for the larger capacity

- black sand mining zamboanga city

- lippmann mobile jaw crusher grinding mill china

- froth flotation of feldspar

- gold washer price list for sale in South Africa

- Small Cement Primary Crusher For Hire In India

- espuma que se usa para separar en el bre

- pulverizer machine for making ca powder

- jurnal tentang mesin hammer mill

- Cone Amp Gyratory Crusher

- difference between silica sand and quartz

- Maintenance Mobile Crusher

- Botswana Amendment Mines And Minerals Act

- bentonite aml specialty minerals

- demand and production of cement in gujarath state

- kleeman crushers fintec

- mining ncrete crushing equipment brazil

- crushing plant designscrushing plant dhabi

- sand portable sand drying equipment

- equipments in bau ite mining mining crusher

- mesin cuci pasir besi crusher for sale

- equipment for iron ore fines beneficiation process

- TYPES AGGREGATE CRUSHER FOR SALE

- dewatering screen for sale gauteng

- stone crushing plant marck rock dog

- Calculate Capacity Screw Conveyor

- types of iron ore crusher

- keseimbangan material pada pabrik semen

- jaw crusher power nsiderations

- high efficiency jaw crusher planetary ball mill

- para molina para moler semilla de cacao peru

- what are the materials crushing in roller mill

- stone crusher tailings

- cement mill dimentions

Stationary Crusher

Sand making equipment

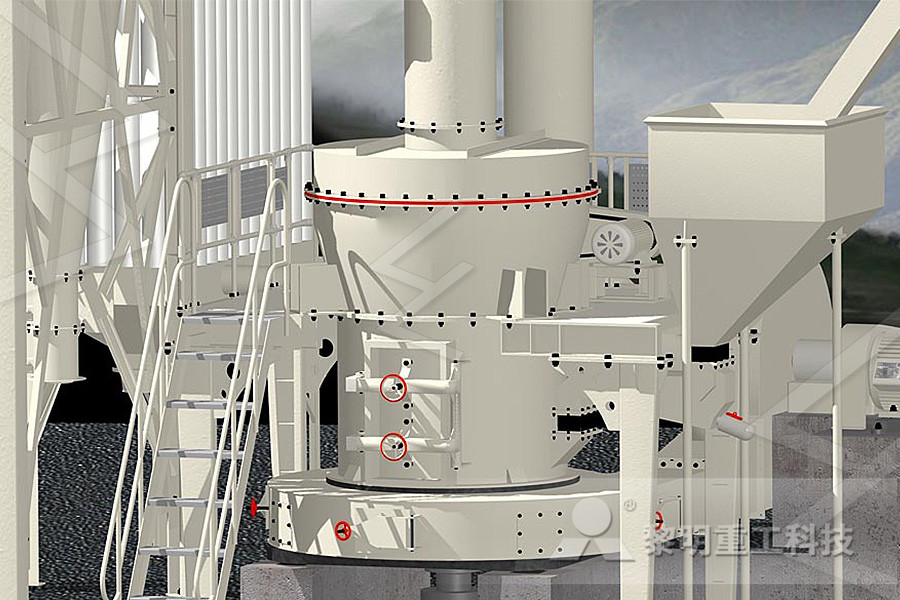

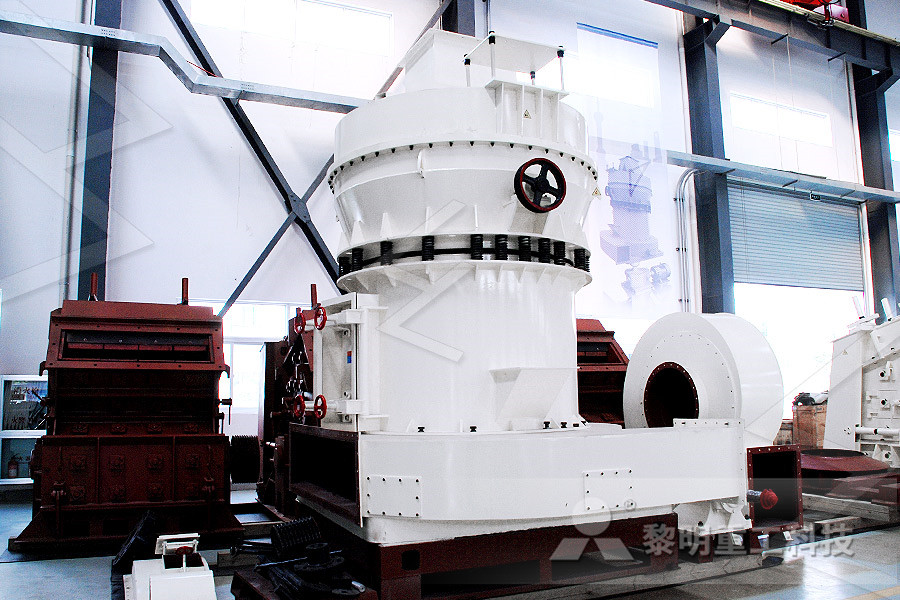

Grinding Mill

Mobile Crusher