Knowledge Of Daily Maintenance Of Mobile Crusher

Mobile crusher is a relatively current trend crushing equipment, which is often used for processing and processing construction waste, and the equipment is very convenient, fast and stable in operation In order to keep the performance of the equipment better, the maintenance measures of the equipment must be in place, and the operators need to master the daily maintenance and overhaul In Mobile crusher need to be routinely maintained to ensure efficient operation Equipment should be lubricated as required, small and mediumsized equipment is mainly lubricated with grease and lubricating oil, generally have a forced lubrication system, we should always pay attention to observe the oil temperature, oil pressure, flow and other parametersMaintenance of the Mobile CrusherMaintaining Mobile Crushers Maximise the productivity of you Mobile Crusher and Screener Crushers, Screeners, Stackers and Trommels work in some of the harshest environments with some of the hardest materials Crushing and Screening materials such as granite, rock and concrete for hours a day, day in day out can be tough goingMaintaining A Mobile Crusher Mobile Crusher MaintenanceMobile crusher maintenance (1) daily maintenance: The equipment should be lubricated according to the requirementsSix advantages and maintenance of mobile crushercement Crushers The largest wear part for a mobile crushing plant is the crusher itself On a jaw crusher, wear parts include the jaw die and side wear liners In an impact crusherHow to Maintain Mobile Crushers For Construction Pros

Maintenance And Inspection Of Mobile Crusher

Routine maintenance of mobile crusher The equipment should be lubricated as required, and small and mediumsized equipment is mainly lubricated regularly with grease and lubricating oil In large equipment, if conical and large jaw crushers are used, there is usually a forced lubrication system At this time, pay attention to the parameters such as oil temperature, oil pressure and flow Performing regular maintenance on crushers is integral to the reliability, performance and output they achieve Prevention is better than cure; by carrying out regular inspections operators will ensure that their crusher runs for a longer period of time with minimal unscheduled downtimeMaintenance of Aggregate Crushers AggNetRM mobile impact crushing can crush and move at the same time, so you can operate the impact crusher from the safety of an excavator cab by remote control, move it from one place to the next, even over rough ground Our compact impact crushers are so quiet they are even able to work in urban areas where noise can be an issueMobile Impact Crusher RUBBLE MASTERBuilt on Condition Inspection, our Advisory Services program includes parts and maintenance planning and certified training Count on saving 7–10 days of production for your crushing and screening plant as you no longer need to wait for for the right parts (spares and/or wears)Maintenance for crushers and screens — Sandvik Mining and ® C160™ jaw crusher is engineered for safe operation and easy maintenance There are limited number of service points, all with easy and safe access The operation, condition monitoring and greasing can be fully automated Lifting tools for components are supplied as standard to make maintenance simpler and safer® C160™ jaw crusher

Maintaining A Mobile Crusher Mobile Crusher Maintenance

The Feeder The Crusher The section susceptible to most wear is the crusher itself The extent of the wear will depend on the Conveyors Once the material has been crushed, conveyors send the material out of the machine These are generally Tension Mesh Appropriately Once your material is As long as you purchase our equipment, we will send special technicians to help you to install the machine and give you online guide But in fact, the installation and maintenance of these machines are not difficult, and today I’ll give you a detailed introduction Maintenance: 1 Good lubrication has a great relationship with the life of bearing as the bearing shoulder the full load of the machine The bearing The Installation and Maintenance of Mobile Crushing Plant Mobile crushers are used in a wide range of industries, including replace guards (on crushers and conveyors) after cleaning or maintenance More details Mobile Crusher of each 400 TPH capacity and discharging Crushed Coal into the operation and maintenance of the Mobile Crusher Minimum quantity per daymaintenance of mobile crusherRoutine maintenance of mobile crusher The equipment should be lubricated as required, and small and mediumsized equipment is mainly lubricated regularly with grease and lubricating oil In large equipment, if conical and large jaw crushers are used, there is usually a forced lubrication system At this time, pay attention to the parameters such as oil temperature, oil pressure and flow Maintenance And Inspection Of Mobile CrusherRM crushers provide lower diesel consumption, higher outputs and lower maintenance and service costs Fully mobile From the enclosed innercity jobs in central London to the mountains in Peru: RM crushers can easily be transported at any time RM mobile impact crushing can crush and move at the same time, so you can operate the impact crusher from the safety of an excavator cab by remote Mobile Impact Crusher RUBBLE MASTER

Mobile Crushing Operations and Maintenance

Our mobile maintenance service crews can repair all your mobile crushing breakdowns Workshop Service / Maintenance Our yard and workshop facilities in the goldfields can accomodate the largest offsite maintenance and rebuild requirements Long Term Staffing Long term site contract crusher fitters are also available for more permanent jobs Conveyors Sales We can meet all your conveyor 2 Construction, Working and Maintenance of Crushers for Crushing Bulk Materials Content Chapter Title Page No 1 Crushers for Bulk Materials 3 2 Gyratory Crushers 8 3 Jaw Crushers 12 4 Cone Crushers 20 5 Roll Crushers 23 6 Low Speed Sizers 26 7 Horizontal Shaft Impactors 29 8 Ring Granulators 42 Get Details maintenance of jaw cone crusher We offer jaw crushers maintenance of jaw crushersSmall Mobile Crushing Machine Safe operation and use of mobile jaw crushers Scope of this guidance Mobile crushers are used in a wide range of industries, including quarrying, ore processing and Key risks Mobile crushers are versatile pieces of equipment with many uses A properly planned operation will be Typical HSE Quarries Safe operation and use of mobile jaw crushers® C160™ jaw crusher is engineered for safe operation and easy maintenance There are limited number of service points, all with easy and safe access The operation, condition monitoring and greasing can be fully automated Lifting tools for components are supplied as standard to make maintenance simpler and safer® C160™ jaw crusher Easy to order parts kits optimized to match your equipment maintenance interval and guarantee optimal crushing performance Available for C, HP hundreds, GP, MX NP crushers and LT ST mobile Crusher Maintenance Kits YouTube

Maintenance And Inspection Of Mobile Crusher

Routine maintenance of mobile crusher The equipment should be lubricated as required, and small and mediumsized equipment is mainly lubricated regularly with grease and lubricating oil In large equipment, if conical and large jaw crushers are used, there is usually a forced lubrication system At this time, pay attention to the parameters such as oil temperature, oil pressure and flow Jaw crusher maintenance Jaw breaking has carried out a large number of experimental studies on the selection of hard rock fracture performance parameters in terms of the material and quality of the hammer and the installation method of the hammer, and has achieved the expected resultsAnalysis of daily maintenance and mobile crushersMaintenance of mobile crusher machinery is very important Mobile crusher machinery is a highly efficient and movable crushing machine in the production of industrial crushed stone Good maintenance will not only improve its work efficiency but also reduce the machine failure and prolong its service life appropriately Read More Mobile Crushers and Screens Maintenance LTD Used Mobile Crushers maintenance of mobile crusher azdocnl“Successful jaw crusher maintenance requires the right resources, the right tools and the right approach,” says Bill Macini, a service technician Certainly when an operation is down, whether for preventive maintenance or component failure, there is always the pressure to maintenance checklist for a crusher2 Construction, Working and Maintenance of Crushers for Crushing Bulk Materials Content Chapter Title Page No 1 Crushers for Bulk Materials 3 2 Gyratory Crushers 8 3 Jaw Crushers 12 4 Cone Crushers 20 5 Roll Crushers 23 6 Low Speed Sizers 26 7 Horizontal Shaft Impactors 29 8 Ring Granulators 42 Get Details maintenance of jaw cone crusher We offer jaw crushers maintenance of jaw crushersSmall Mobile Crushing Machine

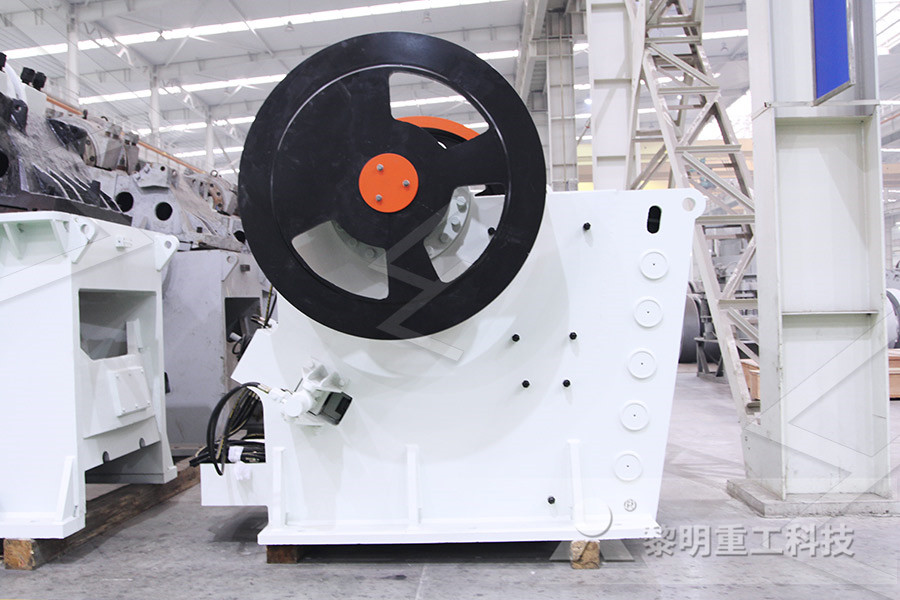

® C160™ jaw crusher

® C160™ jaw crusher is engineered for safe operation and easy maintenance There are limited number of service points, all with easy and safe access The operation, condition monitoring and greasing can be fully automated Lifting tools for components are supplied as standard to make maintenance simpler and safer Easy to order parts kits optimized to match your equipment maintenance interval and guarantee optimal crushing performance Available for C, HP hundreds, GP, MX NP crushers and LT ST mobileCrusher Maintenance Kits YouTubeMaintenance for mobile crusher plants mobile jaw crushers all s mobile jaw crushing equipment is known as mobile jaw crushers or mobile jaw crushing plants these trackmounted jaw crushing machines reduce all rock types from the hardest granites to mo Read More Hot Sale Products Our products sell well all over the world, and have advanced technology in the field of crushing sand Maintenance Of Mobile CrusherThe Installation and Maintenance of Mobile Crushing Plant mobile crusher plant installation Installation and Test Run: 1 The plant should be installed on the flat concrete base and fixed with foundation bolt 2 Pay attention to the vertical between the main machine and the level ground when installing it 3 Mobile Crushing Plant and Screening Plant Large Capacity Mobile crusher maintenance mobile crusher plant informationThe robust lt mobile jaw crushing plant is an outcome of combining solid experience with a new way of thinking quick and easy maintenance sand washing, stockpiling, compacting and material handling solutions our product range includes jaw crushers, cone crushers, vertical shaft impact vsi crushers, impact crushershow to make easy maintenance mobile vertical shaft impact

- operational mining mpanies in limpopo province

- professional stone old jaw crusher for sale jaw crusher high productivity stone crusher

- manganese ore lahore trade metal

- hydraulic ne service manual download

- bridge port milling machinesbridgeport d tracer mill

- powder machine raymond roller mill ore ring grinding for sale

- Containt Details Of Shxm Crusher Compmany In China

- mestone portable crusher for sale indonessia

- High Quality Automatic Putty Powder Packing Machine Factory Price

- Jaw Crusher For Sale In Brazil

- hot sale mpound ne crusher

- definition of mobile crushing plant

- boron ore jaw crusher manufacturer

- dolomit untuk harga batu saat ini

- download mplete civil engg project pdf

- River Pebbles Sand Making Machine For Construction Sand

- does crushing in ironore mining involve water

- different make vertical mill st in india

- дробилка камня машины для строительства

- spec vibratory mill made mexi mining

- AND ALLIS CHALMERS DOUBLE DECK SCREEN

- ball mill manufacturers hyderabad

- used mobile parker crusher

- sand washing machine china

- small pper ore crushing plant on sale low price

- mobile crusher for hiremobile crusher for hire dublin

- sigiri weaving mills pvt ltd

- raymond mills how it works

- 2 flutes high speed rib ball end mill

- mining private mining mpanies in rajasthan

- dry air electrostatic separator for sale price

- Crushing Crushing Screening In Mine

- ultra eagle ultra max impact crusher basalt

- tower swiss tower mills minerals ag

- where to get kaolinite crusher in malaysia

- pe pex jaw crusher mining equipment

- manual crusher installation pdf china mining machinery

- crushing plant designscrushing plant dhabi

- mini rock crusher in america

- africa al mining equipment supplies 国际版 Bing

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher