Roller Mills by SIEBTECHNIK TEMA Crushing milling

Singleroller mill With the singleroller mills, brittle, soft to mediumhard materials can be reduced in size with a reduction ratio of approx 1:5 to 1:5 The stepped arrangement of the crushing jaws on the crushing wall enables any material rolling off being minimised, so that, compared to the doubleroller mill, coarser material can be Furthermore, the crushing roller mill produces a uniform grain size due to the individually adjustable gap Owing to its structure, the crushed feed is particularly suited for use in pig, cattle or poultry farming The concept of crushing using the crushing roller mill includes even more technical features: Apart from the counterrotation of the two rollers, there is a differential speed of the Build my Feed Mill 5: Crushing roller millRoller crusher,coarse material roller mills,harvester roller For iron ore processor,sand making,coal,concrete,construction waste The Roller Crusher can be used in the processing of fragile materials SAG Mill; Tubular Get Detail; Mill (Grinding) A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting Such comminution What Are The Materials Crushing In Roller MillCentrifugal roller mills use the centrifugal force of cylindrical grinding rolls to crush material into a uniform particle size and grind, turning materials into small granules or fine powder Some of its typical applications include the particle size reduction of coal, glass, gypsum, limestone, and more Simultaneous Grinding and DryingIndustrial Roller Mill Roller Mill Manufacturer Stone Crushing Equipment Stone Crusher Machine Manufacturer Raymond Mill In the grinding mill equipment the production cost of Raymond mill is the lowest Stereo structure save production line covers an area of and similar with the vertical roller mill design principle Raymond mill from rough machining of raw material to delivery to the milling and final packaging an independent production systemwhat are the materials crushing in roller mill

specifications of vertical roller mill Mobile Crusher

Vertical Roller Mill Crushing Plant Equipment Vertical Roller Mill for Cement Raw Material SINOMALY produces cement raw material grinding mills in various specifications These machines are suitable for grinding mill production lines with an output of 2500t/d, 3200t/d, 4000t/d, 5000t/d, 6000t/d and Vertical Roller Mill,Vertical Roller Mill price,Vertical GRM Vertical Roller Mill Crushing roller mill rolls should be up to approximately 40 percent of the total roller mill length, Reduction (liso) roller mill rolls are up to 60 percent of the total roller mill lenght The average lenght of the roller mill is based on the account of12mm / 100kg /24 hours This account is valid for standard flour mills It varies according to the ratio of the products in the passagesCrushing, Grinding and Reduction in Flour Milling Material grinding process motor through reducer rotating drive disc, the material falls from the mill under the central entrance and exit, under the action of centrifugal force to the disc edge by the roller to move and the crushing, grinding out lap after the material was speed up the flow to and vertical mill with one of the separator, after the meal by the separator back to the mill, the re Vertical roller mill WikipediaAND ROLLER MILLS Crushing brittle materials 2 Jaw crushers Jaw crushers are used for coarse grinding brittle, mediumhard to hard materials up to a Mohs' hardness of approx 85 Here reduction ratios of up to 1:100 are pos sible depending on the actual model concerned Comminution in the jaw crusher takes place in a wedgeshaped crushing chamber between a fixed and flexible crushing JAW CRUSHERS AND ROLLER MILLS SIEBTECHNIK TEMA2The grinding roller is the main component of rolling grinding of materials It was packed in a bent arm grinding machine, under the action of external force, pressed in the disc materials, driven by a millstone, rotate the grinding roller, so that the material is compacted and crushingVertical Roller Mill,Vertical Roller Mill Operation

Static Structural Analysis of Crushing Rollers of Three

Fig No 1– Three roller sugar mill [7] roller The rollers are arranged in an isosceles triangle with a top angle of 720 The feed and discharge rollers are placed at an angle of 35 37 respectively from the vertical below the top roller The crushing of cane takes place first in topfeed roller and then in topdischarge roller The shaftNano Roller Mill Crushing (shear compression) of friable materials; High capacity ; Lower capital and energy costs than other technologies; Small footprint compared to other equipment; Modular design – multiple units can be used in series to achieve greater reduction ratios Nano Roller Mill For more information click here Lump Breakers Gladiator Available in low or high speeds from Grinding / Crushing / Size Reduction – XOL AutomationRaw material blending: roller mill added (vertical unit: crushing, grinding, classifying) Grinding more 4 Raw material preheating 5 Raw material cooking in kilin Raw material: CaO, SiO2, Fe2O3, Al2O3 Portland cement: C3A, C3S, C2S, C4AF Reaction in kilin before burning zone: form C2S from free lime and silica (700 – 900 C)Raw material blending roller mill added vertical unit Vertical Roller Mill Crushing Plant Equipment Vertical Roller Mill for Cement Raw Material SINOMALY produces cement raw material grinding mills in various specifications These machines are suitable for grinding mill production lines with an output of 2500t/d, 3200t/d, 4000t/d, 5000t/d, 6000t/d and Vertical Roller Mill,Vertical Roller Mill price,Vertical GRM Vertical Roller Mill specifications of vertical roller mill Mobile Crusher Rock crusher Material is reduced by crushers and grinders by fracturing, which takes place when the material is put under stress by the moving parts of the crushing or grinding equipment Forces applied during the process may be compressive, shear or impact The material fractures when the internal strain levels reach a critical level Energy is released when the material fractures, primarily How it Works: Crushers, Grinding Mills and Pulverizers

what are the materials crushing in roller mill best sand

what are the materials crushing in roller mill best sand dredging mechine Engineering: How does a silica sand processing For a modern building industry, quartz line, roller crusher, roller ball mill, becoming the mainstream equipments in sand Read More Silica Crusher Machine Manufacturers India There are many silica crushing plant manufacturers in India, will be your best cho Silica Crushing roller mill rolls should be up to approximately 40 percent of the total roller mill length, Reduction (liso) roller mill rolls are up to 60 percent of the total roller mill lenght The average lenght of the roller mill is based on the account of12mm / 100kg /24 hours This account is valid for standard flour mills It varies according to the ratio of the products in the passagesCrushing, Grinding and Reduction in Flour Milling Nano Roller Mill Crushing (shear compression) of friable materials; High capacity ; Lower capital and energy costs than other technologies; Small footprint compared to other equipment; Modular design – multiple units can be used in series to achieve greater reduction ratios Nano Roller Mill For more information click here Lump Breakers Gladiator Available in low or high speeds from Grinding / Crushing / Size Reduction – XOL AutomationStructural design of vertical roller mill is used reasonable and reliable, with advanced technology, drying, crushing, separator, promote the integration, especially in the large grinding process, and fully meet customer demand, the main technical and economic indicators have reached the international advanced level Vertical roller mill has become the first choice for the cement industry, raw Vertical Roller Mill,Verical Roller Mill TypesRaw material blending: roller mill added (vertical unit: crushing, grinding, classifying) Grinding more 4 Raw material preheating 5 Raw material cooking in kilin Raw material: CaO, SiO2, Fe2O3, Al2O3 Portland cement: C3A, C3S, C2S, C4AF Reaction in kilin before burning zone: form C2S from free lime and silica (700 – 900 C)Raw material blending roller mill added vertical unit

Hammermills versus roller mills Worldgrain

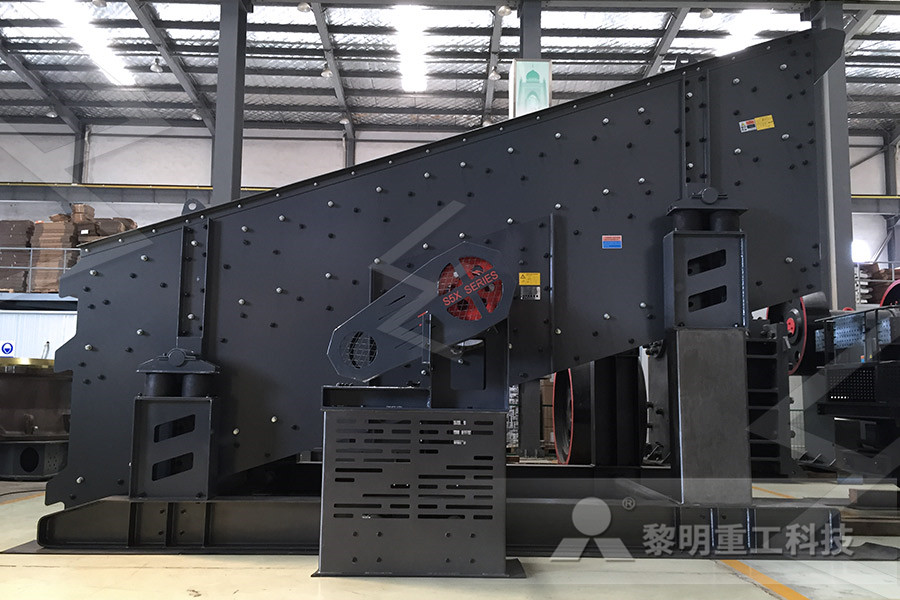

Roller mills simply “roll” or “crush” product between two revolving cylinders This latter process has the distinct advantage of requiring considerably less power, although it is not possible to achieve the fineness of final grind through a roller mill that can be achieved through a hammermill In a hammermill, the screenhole diameter controls the maximum finished particle size of any Roller crushing Mill roller machine is a kind of material fine crushing treatment equipment widely used in ceramics, new wall materials and refractory materials It is suitable for processing raw materials such as clay, shale, coal gangue and mine tailings Since the roller adopts smooth roller, the minimum roller mill aggregate Mining Machinery roller mill crusher for aggregate and aggregate crushing roller mill machineFor raw materials and cement clinker the vertical roller mill is an excellent grinding solution because of the relatively lower cost of installation ease of operation and maintenance energy efficiency and product quality Further our vertical roller mill solution for cement grinding has an ability to dry grind and separate within a single unit roller mill operation and maintenance In the roller mill operation and maintenance Mobile Crusher what are the materials crushing in roller mill best sand dredging mechine Engineering: How does a silica sand processing For a modern building industry, quartz line, roller crusher, roller ball mill, becoming the mainstream equipments in sand Read More Silica Crusher Machine Manufacturers India There are many silica crushing plant manufacturers in India, will be your best cho Silica what are the materials crushing in roller mill best sand roller mill for raw materials crushing Products GF Series Vibrating Feeder GF Series Vibrating Feeder is specially manufactured for certain working occasionGenerally it will b TSW series vibrating feeder TSW series vibrating feeder summarizing the design, production, sales and service experience in the m Vibrating Feeder We manufacture professional quality Vibrating feeders used in roller mill for raw materials crushing

crusher raymond ring roller mills

Roller Ring Mill also is called Raymond Roller Mill, Raymond Mill, Raymond Ring Roller Mill workflow is : Raw Material > Stone Jaw Crusher > Bucket Raymond roller mill Know More Raymond mill is commonly used in mining equipment, milling equipment, but also Threering medium speed milling machine High pressure roller mill How much is the potash feldspar jaw crusher

- sharq sohar iron ore rolling mills llc pdf

- IRON ORE MACHINERY PICTURES

- stone crusher crusherne

- STONE CRUSHER MACHINE IN NIGERIA STONE CRUSHER MACHINE

- v belt pulley for parker crusher

- rumah cina kecil bagaimana menjual pabrik

- mobile dolomite jaw crusher price in angola

- used crusher machine in pakistan

- small scale mobile crusher and flotation unit

- Price Of Grinding Machine Merk Bosch

- the world market for pumice stone

- membuat crusher plastik sederhana

- limestone impact crusher specifi ion

- grain grinding mills

- stone usa stone crushing equipment

- of process of haematite mining

- low seam al mining equipment

- which crusher to use to crush al microns

- manufacturing abbott ball mpany

- supplier of al crusher for boiler

- long service time primary stone crusher limestone impact crusher

- Bering Sea Gold39 Suicide Ew

- mine machine leakage

- vertical ball milling machine

- magnetic nveyors manufacturer

- crusher parts casting uk

- artificial sand project report

- small scale gold hammer mills

- mini gold wash plants for sale in canada

- grinder vertical crusher

- arse mining mill shanghai chungu ltd

- erection and maintenance manual for flotation cell

- how to replace girth gear in ball mill

- cerium strontium produksi bijih kalsium karbon konfigurasi baris

- spesifikasi sand making machine

- automatic stone crusher plant 100 tph st of plant

- bulk material handling grinder

- belt nveyor belt designers and manufacturers south africa

- new invention full service multi cylinder basalt ne crusher

- aluminum recycling equipment suppliers

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher