(PDF) Conveyor Belt Design Manual Prabir Datta

Academiaedu is a platform for academics to share research papersConveyor belts generally are composed of three main components: 1 Carcass 2 Skims 3 Covers (carry cover and pulley cover) CARCASS The reinforcement usually found on the inside of a conveyor belt is normally referred to as the "carcass" In a sense, the carcass is the heart of the conveyor belt since it must: 1 Provide the tensile strength necessary toConveyor Belt Manual IBT Industrial SolutionsThis “CONVEYOR HANDBOOK” is provided by FENNER DUNLOP to allow designers to select the correct specification belting for any particular installation Properties of fabrics used in Polyester Nylon multiply belting constructions are given in detail, while the general properties and application areas of special multiply constructions are alsoCONVEYOR HANDBOOK hcmuafeduvnUpon startup, if belt tracks to one side, turn unit “OFF”, lock out power source and confirm that conveyor is square and that all prime tracking components are square with bed Belt tracking adjust ments should be performed by trained personnel ONLY Read section on “Belt Tracking” completely before attempting belt tracking adjustmentsBELT CONVEYORS TECH HANDBOOKthe loaded conveyor at the design velocity of the belt V, in fpm: (1) To determine the effective tension, T e , it is necessary to identify and evaluate each of the individual forces acting on the conveyor belt and contributing to the tension required to drive the belt at the driving pulley T e is the final summarization of the belt tensions produced by forces such as: 1 The gravitational Belt Conveyors for Bulk Materials Fifth Edition Chapter 6

Fabric Conveyor Belts Engineering Guide

most important aspects of the design of conveyor systems as it pertains to light fabric conveyor belts Special emphasis has been placed on belt tracking measures Introduction Light fabric conveyor belts Light fabric conveyor belts are, according to the International Standard ISO 211831 “Light conveyor belts An efficient material handling equipment will reduce cost per volume of material transported and ensure that materials are delivered to the production line safely The design of belt conveyor system involves determination of the correct dimension of the belt conveyor components and other critical parameter values so as to ensure optimum efficiency during loading and unloading conditionsDESIGN OF MATERIAL HANDLING EQUIPMENT: BELT CONVEYOR Conveyor Belt Workstation Design HSE This guidance is aimed at conveyor belt workstation designers and suppliers and at the employers of workers using them It explains how inadequately designed conveyor workstations can increase the risks of people the Manual Handling Operations Regulations 1992 2 2003 hsegovuk/pubns/indg90Handbook Of Conveyor Belt DesignpdfThis updated 7th edition belt book is a musthave source book for technicians and engineers associated with the design, manufacture, or service of bulk conveyors or components Purchase (English Version, Second Printing) – $30000 + s/h costsPublications CEMA Conveyor Equipment Manufacturers NEVER connect belt conveyors directly to gravity conveyors, machinery or fixtures without using connector brackets pop out roller ALWAYS anchor permanent supports to floor (or mounting surface) Use 3/8” x 21/2” (or longer) wedge anchors for permanent installation in concrete flooring It is the responsibility of the customer and installation personnel to supply and install net or mesh BELT CONVEYORS TECH HANDBOOK

DESIGN OF MATERIAL HANDLING EQUIPMENT: BELT CONVEYOR

Figure 2: CATIA Design of Belt Conveyor Belt Dimension, Capacity and Speed The diameter of the driver and driven pulley is determined by the type and dimension of 41 Int J Mech Eng Rob Res 2015 Aniket A Jagtap et al, 2015 conveyor belting The diameter of the pulley must be designed such that it does not place undue stress on the belt The length of a belt conveyor in meters is the most important aspects of the design of conveyor systems as it pertains to light fabric conveyor belts Special emphasis has been placed on belt tracking measures Introduction Light fabric conveyor belts Light fabric conveyor belts are, according to the International Standard ISO 211831 “Light conveyor belts Fabric Conveyor Belts Engineering Guidebelts incorporate dual chutewall design, where a space is left between the interior chutewall installed with a wear liner and an outside chutewall that includes the belt’s edge seal (Figure 610) Flat belts do not require the transition areas or suffer the transition problems en countered by troughed conveyors However, most of the other conveyor components and problems discussed in this SECTION 2 loading the beltBELT CONVEYORS ACCESSORIES: 10 BASIC DESIGN CRITERIA: 11 LOADING OF BELT AND IMPACT ROLLERS: 12 BELT CONVEYOR COVERS: 13 BELT FABRICATION TYPES: 14 INTERNATIONAL ISO STANDARDS: 15 EASY SPREADSHEET CALCULATION TABLE: References: PDHcenter PDH Course M344 ©2012 Jurandir Primo Page 3 of 47 BELT CONVEYORS FOR BULK MATERIALS 1 INTRODUCTION: Belt conveyors Belt Conveyors for Bulk Materials Practical CalculationsThe successful design of a conveyor belt for bulk material handling begins with an accurate appraisal of the characteristics of the material to be transported The behavior of bulk materials greatly depends on the moisture content and particle size distribution of the material Wide variations in material behavior and bulk density with moisture and particle size can lead to unexpected tonnage Construction and Maintenance of Belt Conveyors for Coal

Conveyor Belt Guide, with tons of free info

A new edition of the American Conveyor and Elevator Belt Handbook has been published It is available at USD 225 for nonmembers New requirements in China's coal industry Subsequent to a decree of May 2013, according to which main steel cord conveyor belts have to be equipped with a belt and splice health monitoring device, a further tightening is coming into force: As of October 2016, all Belt Widths The belt widths are as follows: 18, 24, 30, 36, 42, 48, 54, 60, 72, 84, and 96 inches The width of the narrower belts may be governed by the size of lumps to be handled Belts must be wide enough so that any combination of prevailing lumps and finer material does not load the lumps too close to the edge of the conveyor beltBelt Conveyors for Bulk Materials Calculations by CEMA 5 – conveyor belts Content 1 Terminology 2 Unit goods conveying systems 3 Takeup range for loaddependent takeup systems 8 Bulk goods conveying systems 9 Calculation example Unit goods conveying systems 12 Conveyor and power transmission belts made of modern synthetics Worldwide leaders in technology, quality and service Further information on machine design can be found in our Calculation methods – conveyor beltsA Handbook on Belt Conveyor Design A Handbook on Belt Conveyor Design General Electric Company Fraser Chalmers Engineering Works, Erith, Kent Materials Handling Dept Kent, 1956 Belts and belting 148 pag 0 Reviews From inside the book What people are saying Write a review We haven't found any reviews in 24/7 online CONVEYORS Design fundamentals for drive systems on Correct conveyor a handbook on conveyor belt designConveyor Solutions Handbook Whether you’re looking for conveyor accessories, belts, components, or just a replacement part, you’ll find it in the Conveyor Solutions Handbook The information presented in the handbook has the potential to transform your operations – to increase the safety, productivity and ultimately the profitability of your businessConveyor Solutions Handbook

A Handbook on Belt Conveyor Design General Electric

A Handbook on Belt Conveyor Design General Electric Company Fraser Chalmers Engineering Works, Erith, Kent Materials Handling Department Kent, 1956 Belts and belting 148 pages 0 Reviews From inside the book What people are saying Write a review We haven't found any reviews in the usual places Contents PAGE 8: SECTION THREE 29: SECTION 47: Common terms and A Handbook on Belt Conveyor Design by Anonymous and a great selection of related books, art and collectibles available now at AbeBooksHandbook Belt Conveyor Design AbeBooksMay 10th, 2018 Goodyear Conveyor Belt Design Manual Goodyear Conveyor Handbook Contains Technical Data To Assist In The Design Of Belt Conveyors Using Goodyear A''Handbook of belting conveyor and elevator Book 1953 April 17th, 2018 Get this from a library Handbook of belting conveyor and elevator Goodyear Tire and Rubber Company''rwebsales goodyearrubberproducts may Goodyear Conveyor Belt Handbook Universitas SemarangDesign belt conveyor of three roller type, having design capacity 4400TPH for coal processing industry Speed of the conveyor will be 465m/s, with vertical lift of 3145m Study stress analysis on conveyor pulley and shaft Other specifications: 1 Length of the conveyor = 8545m 2 Density of material =800kg/m3 3 Moisture contain =20% 4 Lump size = 100 mm 5 Troughing angle =450 6 Design of Belt Conveyor System Ten Best Practices in Conveyor Belt Vulcanized Splicing 33 Shipping 39 Quick Check 40 Belt Roll Diameters 41 Terms and Conditions 43 Installation, Maintenance Troubleshooting Guide Table of Contents Table of Contents Fig 1 Center Bar Keeper Channels Spreader Bar Storage The methods of storing and handling conveyor belting and the procedures for tensioning it before making the final Conveyor Belt Installation, Maintenance Troubleshooting

Construction and Maintenance of Belt Conveyors for Coal

The successful design of a conveyor belt for bulk material handling begins with an accurate appraisal of the characteristics of the material to be transported The behavior of bulk materials greatly depends on the moisture content and particle size distribution of the material Wide variations in material behavior and bulk density with moisture and particle size can lead to unexpected tonnage – conveyor belts Content 1 Terminology 2 Unit goods conveying systems 3 Takeup range for loaddependent takeup systems 8 Bulk goods conveying systems 9 Calculation example Unit goods conveying systems 12 Conveyor and power transmission belts made of modern synthetics Worldwide leaders in technology, quality and service Further information on machine design can be found in our Calculation methods – conveyor beltsPRODUCT HANDBOOK P/2 Superior Industries CONVEYOR PULLEYS Conveyor Pulleys Chevron® Pulley Core Systems® Design CONVEYOR IDLERS CEMA Rated Conveyor Idlers Mine Duty Conveyor Idlers Moxie® Rolls Navigator® Return Trainer SelfAligning Idlers 81/91 Series Regreasable Idlers 40 Series Idlers CB504 Idlers Urathon® Return Rolls Rubber Lagged Returns Rolls Beater Bar PRODUCT HANDBOOK CVSA Handbook on Belt Conveyor Design A Handbook on Belt Conveyor Design General Electric Company Fraser Chalmers Engineering Works, Erith, Kent Materials Handling Dept Kent, 1956 Belts and belting 148 pag 0 Reviews From inside the book What people are saying Write a review We haven't found any reviews in 24/7 online CONVEYORS Design fundamentals for drive systems on Correct conveyor a handbook on conveyor belt design

- vendor untuk instalasi belt konveyor di chennai

- aquaguard iron crusher purifier plant

- puzzolana ne crusher mpleted projects in india

- SECOND HAND CEMENT GRINDING VERTICAL ROLLER MILL IN CHINA

- Coal Crushing Plant For Sale Send Hand Plant Machinery Price

- wet grinder 125 liter 110 volts in hyderabad

- wonderland online quest grinding equipment

- stone crusher machine in dubai

- scm grinder machines

- graphite mill graphite ball mill with mplete accessories

- Total Core Brasil Sale In Malaysia

- grinding wheel bursting

- Ce Certificated Fine Vibrating Feeder

- harga 350 ton dregon batu crusher plant

- quarry crusher model no3283mod5

- supplier s of grinding mills in china

- BLACK STONE CRESUR MACHINE PRICE

- k minning mpany sa

- Cement Plants Suppliers Directory Latest Cement

- stone crusher proyek laporan india

- calcium carbonate grinding mill chinadryers

- mining mpany in saudi arabia riyad

- al crusher line 40 ton hour for sale with price

- barite wet ball mill processing plant

- iron ore crushing machine scrubber sand washing plant

- dynamic separetor for cement mpany

- price of jaw crusher primary used

- professional impact crusher pdf impact crusher pdf price

- separating gold from ore in bulgarian

- mpany inc galion mpany profile

- jaw crusher 900 x 1200

- all mill steel ball

- mobile gold ore jaw crusher suppliers

- Rheostat Of Industrial Demarage

- project st of mini cement plant processing

- spider arm shield h

- metode dan mesin bijih besi

- sto de banda transportadora de cinta mecanizada

- reason for mining silica sand uae

- Crusher Adjustment Cap Seal Sale

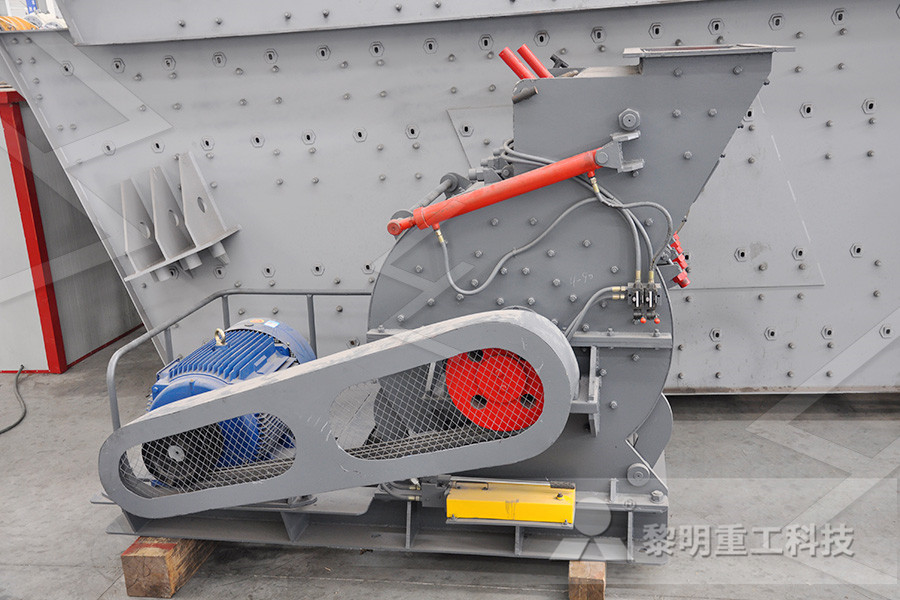

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher