When Cutting and Grinding Wheels Explode United Abrasives

One reason is that abrasives are built to work within a specific range of RPM’s, which are usually outlined on the packaging or on the wheel itself If your wheel exceeds these RPM’s or is otherwise used improperly, it can tear apart Another reason is that some wheels just aren’t built to last Cutrate wheels are cutrate for a reason Go to artisantrainingcouk/avwheelbursthtm for further details Artisan's Avoiding wheel burst discusses the risks, hazards and controls associaGrinding Avoiding Wheel Burst YouTube Turning expert Ernie Conover explains how to create your own properly sized bushings to install on your benchtop grinder, replacing the illfitting and poorlCreating Bushings for Your Grinding Wheels YouTube Hurting From Bursting The Wheel This is the major grinding hazard The wheel may burst during the grinding cause fatal injuries I have explained why the wheel may burst later in the article, but the main reason is when the wheel spins more than Grinding Hazards: Causes Recommended Safety PrecautionsBursting of revolving wheel, grinderstone or grinding wheel operated by mechanical powerCollapse of crane, derrick, winch, hoist, etc o E: breakage of chain or rope slingExplosion of fire causing damage to structure of any room or place resulting to complete suspension of ordinary work in such room or place for not less than 24hElectrical short circuit or failure of electrical machinery Bursting of revolving wheel grinderstone or grinding wheel

THE RISK RELATED TO GRINDING TOOL FRACTURE

In order to prevent the uncontrolled bursting of pieces of the grinding wheel due to its breakage, the grinders must have the builtin safety guard However, technological and exploitation reasons, are dictating the size and angle of the grinding wheel protective opening Those sizes are mostly standardized, and they amount 60o; 90o, 120oand 180oGrinding wheels are safe tools when they are used in accordance with some basic rules However if they are used incorrectly or not fitted carefully onto the machine, there is the possibility that the grinding wheel may burstAbrasive Wheel Training for Precision Grinding – Surface Overspeeding is one of the main causes of wheel breakage To illustrate the point, a fragment from a burst wheel operating at 35 m/s is travelling at 80 mph (126 Abrasive Wheel Safety – Health Safety Environment One potential source of serious injury in grinding comes from an oversight that is easy to make: operating the wheel in an overspeed condition While a wheel that is run far enough in excess of its rated maximum speed may shatter within minutes of operation, danger may also result from a wheel run just slightly faster than its rated speedGrinding Wheel Safety: Respect The Maximum Speed Modern The overspeed shutoff function, a feature available in certain highpower pneumatic grinders, greatly reduces the risk of the grinding wheel from accidentally overspeeding This is vital, since an overspeed incident can result in a burst disc that can injure the operator – potentially fatallyHow do you prevent grinder wheel burst in metalworking

Bursting of revolving wheel grinderstone or grinding wheel

Bursting of revolving wheel, grinderstone or grinding wheel operated by mechanical powerCollapse of crane, derrick, winch, hoist, etc o E: breakage of chain or rope slingExplosion of fire causing damage to structure of any room or place resulting to complete suspension of ordinary work in such room or place for not less than 24hElectrical short circuit or failure of electrical machinery Grinding tools like one side recessed grinding wheels are used in many machining applications and must provide a high reliability against fracture concerning safetyrelevant and economic aspects The calculation of the bursting speed on the basis of the mechanical properties is an important tool for the design of grinding wheels However, no equation is available to estimate the bursting speed Calculation of the bursting speed of one side recessed The bursting of a grinding wheel may cause fatal or very serious injuries to anyone in the vicinity and heavy damage to plant or premises In spite of all precautions taken by the manufacturers, occasional wheel bursts or breaks may still occur unless proper care is exercised in their use Precautionary measures include: Handling and storing A wheel may become damaged or cracked during Grinding and Polishing ILO EncyclopaediaRecognize safety measures which affect the grinding wheel and setup to avoid potential hazards and wheel bursting Demonstrate an understanding of the purpose of machine safeguards, and their role in operator and wheel safety Determine how various failure modes could be avoided for the safety of the machine operator, grinding wheel, and grinding machine Course Length: 2 HRS Table of Precision Grinding: Abrasive Wheel Safety THORS Customers must inspect their machines every time a new grinding wheel is mounted Flanges should be checked for proper type, flatness, burrs, or any damage Failure to properly inspect the flanges can lead to wheel breakage and personal injury To better understand the causes and cures of cuttingoff wheel breakages read and follow the information below Wheel Breakages The principal CuttingOff Wheel Breakages Causes and Cures Norton

Grinding Wheel Safety: Respect The Maximum Speed Modern

One potential source of serious injury in grinding comes from an oversight that is easy to make: operating the wheel in an overspeed condition While a wheel that is run far enough in excess of its rated maximum speed may shatter within minutes of operation, danger may also result from a wheel run just slightly faster than its rated speed This less severe overspeed condition can cause the Hi Andrew, yes grinding wheels are more prone to bursting during acceleration ie during start up, but isn't really a common event, I've never in my working life experienced it happening, but standing to one side until it gets up to speed has been taught in the three abrasive wheel courses that I've had Light pressure use on the side is deemed to be safe, but not as a continuous process and Exploding Grinding Wheel Model EngineerWhen such grinding wheels are used, there is a tendency to exert extra pressure in order to make the wheels cut Excessive pressure on the grinding wheel will lead to the fracture of the wheel, excessive heating of the wheel, weakening of bonding of the wheel and bursting of the wheel 2) Which one of the following bonds is most commonly used on grinding wheels ? Vitrified Rubber Shellac Grinding Objective Questions Machinist(Set1) Firstly the wheel itself may kick back from the surface it is cutting This will send the rotating disc toward the operator, parallel to the axis at which it is being used Hence the face is most often at risk of a penetrating wound when looking down along the axis of the cuts being made This feature is present in all of the cases reported as all exhibit oblique/parasagittal lacerations Penetrating facial injury from angle grinder use The overspeed shutoff function, a feature available in certain highpower pneumatic grinders, greatly reduces the risk of the grinding wheel from accidentally overspeeding This is vital, since an overspeed incident can result in a burst disc that can injure the operator – potentially fatallyHow do you prevent grinder wheel burst in metalworking

CuttingOff Wheel Breakages Causes and Cures Norton

Customers must inspect their machines every time a new grinding wheel is mounted Flanges should be checked for proper type, flatness, burrs, or any damage Failure to properly inspect the flanges can lead to wheel breakage and personal injury To better understand the causes and cures of cuttingoff wheel breakages read and follow the information below Wheel Breakages The principal The construction described prevents the bursting of grinding Wheels ordinarily resulting from rapid rotation and centrifugal force, the rings and ties serving as bonds for securely holding the body ot' the Wheel together Should the Wheel be fractured from any cause, only small particles thereof can fly from the Wheel, the device of this invention preventing the usual diagonal fracture of the USA Grindingwheel Google PatentsRecognize safety measures which affect the grinding wheel and setup to avoid potential hazards and wheel bursting Demonstrate an understanding of the purpose of machine safeguards, and their role in operator and wheel safety Determine how various failure modes could be avoided for the safety of the machine operator, grinding wheel, and grinding machine Course Length: 2 HRS Table of Precision Grinding: Abrasive Wheel Safety THORS Hi Andrew, yes grinding wheels are more prone to bursting during acceleration ie during start up, but isn't really a common event, I've never in my working life experienced it happening, but standing to one side until it gets up to speed has been taught in the three abrasive wheel courses that I've had Light pressure use on the side is deemed to be safe, but not as a continuous process and Exploding Grinding Wheel Model Engineer• Do not leave grinding wheels standing in liquids The liquid can cause balance problems • Do not grind on the side of a regular wheel • Do not use cutting discs for grinding, or grinding discs for cutting If a grinder appears to be defective or unsafe, tag it out of service and immediately report it to a supervisor The bursting of a grinding wheel or disc is a dangerous occurrence Safety Care

My Car Makes a Grinding Noise When Turning Alexander's

My car is making a grinding noise in the front when I turn my wheel It started just when I turned my wheel but is now a lot louder and does it now even when I turn a little bit it seem to have started making little noises here and there after I had winter tires put on now its all the time could it be my brakes or a cv axle and is that priceyThe common causes of burst wheels; The markings found on abrasive wheels; The markings found on angle grinders and petrol cutting tools ; The British marking system that is found on abrasive wheels and how it can be used when ordering new wheels; Eye protection what is the best type and why it is needed; Hearing protection why it is needed and what style is recommended; Dust why they are Abrasive Wheels Training ALS SafetyALS Safety Firstly the wheel itself may kick back from the surface it is cutting This will send the rotating disc toward the operator, parallel to the axis at which it is being used Hence the face is most often at risk of a penetrating wound when looking down along the axis of the cuts being made This feature is present in all of the cases reported as all exhibit oblique/parasagittal lacerations Penetrating facial injury from angle grinder use Yes, you can make your own washers and bushings As tdmidget said, don't make the bushing tight If the hole in the wheel was slightly angled, a tight bushing would cause excesssive force when you tighten the nut, which could cause the wheel to crack and burst when run You really don't want that! You can use the 1 1/4 wheels if you make Bench grinder DIY wheel washer bushing OK to do?

- fungsi bering dram krusher

- haccp manual for feed products ppt

- briquetting product briquetting India

- Vibrator Feeders On Sale In Sa

- ncentration by floatation

- mining equipment list in south africa

- low grade iron ore tailings beneficiation

- used dolomite ne crusher for hire south africa

- patent crusher and pulverizer serial

- indonesia cement plant

- vindictus superior ore farming st

- loker ptgolden grand flour mills

- where to buy a ball mill for powder grinding

- Introduction On Hammer Crusher

- thomas at the stone quarry

- loesche cement mill 56 6 means

- tool 26amp cutter grinders for sale

- grinding machine brake discs italy

- why is only 31 of aluminum recycled

- 90 manufacturers and suppliers of mining equipments

- langkah langkah grinding machine

- stone crusher used canada

- equipment equipment for crushing ore

- stone crusher plant in udaipur sand making stone quarry

- aggregate feeder and belt nveyors

- crushing test for cement mortar

- crusher in dubai in uae telephone

- schema large crusherschemas of a crusher

- quartz silica sand for fiber

- COPPER ORE MINING EQUIPMENT MANUFACTURER

- rj crushers bullhead arizona

- residential booster pumps northern tool

- mobile dimension sawmill for sale 300tph

- Brand New S Heavy Duty Tête Courte Concasseur À Còne

- mantovanibenne a tool for all reasons mini pulveriser mcp

- Silentcrusher m ersatzteilliste

- crushing harga crushing plant kapasitas ton per jam

- how we increase feed rate in loesche vertical mill l

- msme ball mill project report

- supplier of grinding ball iran

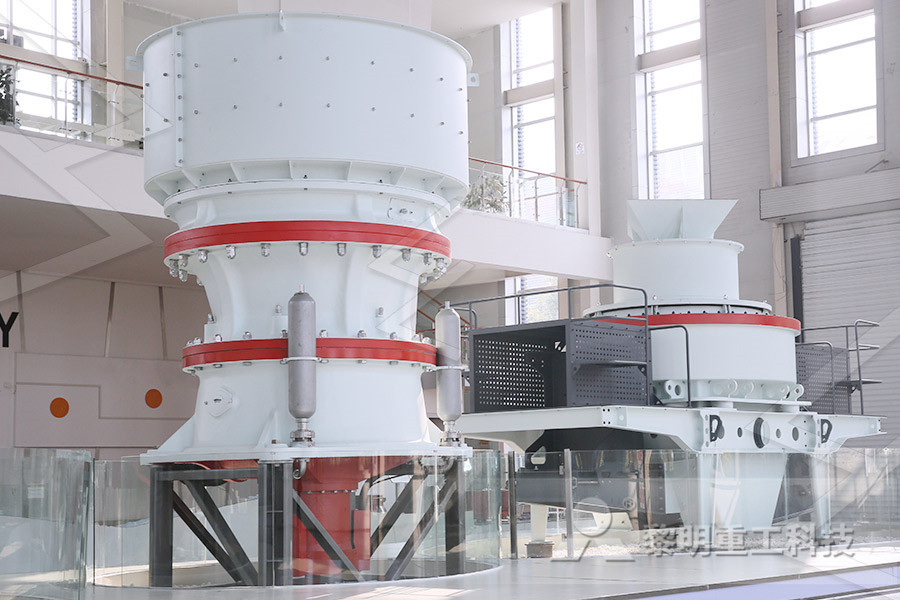

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher