Marine Rubber Fenders The Rubber Company

Marine Rubber Fenders We offer a comprehensive range of moulded and extruded marine rubber fenders which are cost effective and efficient solutions to suit any operating environment, condition and requirement The principle purpose of a rubber fender system is to protect the hull and berthing facility from damage when vessels berth alongsideTrelleborg’s wideranging rubber fenders are manufactured in accordance with PIANC guidelines and come in a range of compounds to suit various applications Our highperformance solutions combine low reaction force and hull pressure with good angular performance and rugged construction, suited even for the most demanding marine environmentRubber Fenders Trelleborg Marine and InfrastructureQingdao Jier Engineering Rubber Co, Ltd is a corporate member of PIANC Occupies an area of 80,000 square meters and owns the registered capital of 82 million, our factory has approved by BUREA VERTITAS to PIANC 2002 Guidelines for the design of Fenders systems Appendix A Procedure to determine and report the performance of marine fenders and ASTM D Standard Test Methods for Home JIER Marine Rubber Fender SystemsMarine Rubber Fender A trusted maker for high performance rubber fenders adhering to the PIANC2002 Standard By practising innovative manufacturing, MAX can supply high quality fenders at competitive prices Pneumatic Fender Pneumatic Fender High product quality reasonable costing drives the adoption of our ISO17357 Pneumatic Fender in the global market from Europe, North Max Groups Marine Your Most Reliable Maritime SolutionA marine rubber fender acts as a “dock bumper” to absorb the kinetic energy of a boat/vessel during berthing against a jetty or a quay wall A superior fender product can protect both the vessel and the berthing structure berthed against, preventing any damage and save on repair costsMarine Rubber Fender Systems MAX Groups Marine

Boat Fenders Rubber Products For The Marine Industry

The rubber products we manufacture for the marine industry are those where performance is a safetycritical feature To this end we have developed special elastomeric material solutions to meet the most exacting performance specifications, including Lloyds AccreditationMarine Industry Qatar Rubber Industries Co could provide you with any rubber products and rubber lining solutions according to your needsMarine Industry Qatar RubberMarine Rubber Fenders: Truck and Aircraft Dock and Marina Protection Curved and Bent UHMW Marine Fender Marine Tug Tow Knee Fenders UHMW Bonded to Rubber Fender Marina Fenders Boat Dock Fenders Push Knees Rubber Bonded to Steel Fenders and Wear Pads White Push and Tug Boats Vulcanized Wing and P Types: Straight, Pre Curved or Sectional Boat Fenders and Catalog: Fender Systems: Marine and Construction: Main Cylindrical fenders are an economical solution to protect most of the berthing structures and offer much ease for installation With 50% design compressive deflection, this kind of rubber fender can effectively buffer the collision between docks and shipsFender Marine Catalogue Final Fender Marine Fender MarineFrom our unique D Fender system, full range of fenders, ropes and covers, to the extremely popular Gullsweep Bird Deterrent, at Marine Solutions we are dedicated to solving the everyday problems that most of us have to deal with when boatingMarine Solutions Boat Parts and Marine Accessories, Boat

Boat Fenders Rubber Products For The Marine Industry

The rubber products we manufacture for the marine industry are those where performance is a safetycritical feature To this end we have developed special elastomeric material solutions to meet the most exacting performance specifications, including Lloyds AccreditationTIVAR® DockGuard provides dock fender facing that outlasts other materials such as wood, rubber, urethane or high density polyethylene The ideal material for marine fender systems, TIVAR® DockGuard allows vessels to glide easily along its surface without marring hulls Impervious to marine bore worms, TIVAR® DockGuard also sheds mussels and barnacles Outwearing hardened steel, it TIVAR® DockGuard MCAMSuper Cone Fenders About We are specialized in Solution Provider and supply a wide range of products relating to Marine System and Infrastructure Division, Upstream/Downstream, Oil Gas/ Refinery; Power/ Energy/ LNG; Marine/ Offshore; Chemical/Petrochemical/ Water/ Waste Treatment; Pulp Paper/ Mining with purpose to create the greatest value to client and expand client’s businessRUBBER FENDER Active Solution Company LimitedTug boat cylindrical rubber fenders are widely used for primary marine fendering system on the bow or stern of tugboats, pushboats and workboats Cylindrical tugboat marine rubber fender are divided into: Straight cylindrical marine fenders and tapered ends rubber fenders Its round shape is flexible for shiptoship operation with different type of vessels The Max Length can be to 20 m with Tug Cylindrical Rubber Fenders For Boats Ronsen Marine FenderTec marine fendering is able to offer cost effective and efficient solutions to suit practically any marine rubber fendering problem and provides a broad range of marine rubber fenders with short lead times FenderTec products are used by a wide range of clientele from several industries, including tugboat workboat operators, shipbuilders, the dredging and offshore industry and in FenderTec Marine Fendering

Choose a suitable marine fender design system

If you are looking for a post that lists out all available rubber fender design types like “pneumatic fender”, “modular fender”, “Dshaped bumper” etc, you should visit “Rubber Fenders: Types Things to Note” article This article post aim to discuss the generally used equations, formulas, factors to determine a suitable port fender designOur rubber shapes are an ideal solution for your rubber extrusion and sealing needs Rubber Extrusions and Seals We Carry Our rubber extrusion and rubber seal inventory includes EPDM rubber seals, extruded rubber tubing and Oring cord stock, fender flare trim, locking gaskets, rubber edge trim, RubberLok, tools and accessories for trim and seal installation, and weatherproof trim sealsRubber Extrusion and Rubber Seals TrimLok NANHAI AIRABG is Pneumatic fender Manufacturer and our company are ISO9001,ISO14001 and ISO18001 certified, Our pneumatic fender have ISO17357 certificate isPunctured pneumatic fender repair solution YouTubeTo keep the boat interiors dry and secure, old or missing gaskets can be replaced with rubber hatch gaskets Specially formulated to promote a watertight seal between the hatches and storage bins in your boat, marine hatch gaskets are the perfect solution to keep your storage space protected from water intrusion and damageRubber Hatch Seals Marine and Boat Hatch Gaskets TrimLokOcean Rubber Factory is the Middle East's leading supplier of technical rubber products With over 700 employees across four countries and eight factories on two production sites, ORF supplies customers with innovative, quality solutions From the GCC to as far as The Panama Canal, ORF has been raising industry standards for decades, ensuring perfection in every detailOcean Rubber Factory – Est 1987

Marine Fenders ESC Pile (Global Sheet Piling Solutions)

Element Fender / Leg Fender Element Fenders or sometimes also known as Leg Fenders are an alternative marine fender solution that are ideal when the fenders need to be mounted in a limited area They are a versatile option with a modular design that can be utilised in a variety of configurationsTIVAR® DockGuard provides dock fender facing that outlasts other materials such as wood, rubber, urethane or high density polyethylene The ideal material for marine fender systems, TIVAR® DockGuard allows vessels to glide easily along its surface without marring hulls Impervious to marine bore worms, TIVAR® DockGuard also sheds mussels and barnacles Outwearing hardened steel, it cuts hourglass TIVAR® DockGuard MCAM Marine Fender Solutions per Specification Bringing a vessel into berth requires the vessel’s kinetic energy to be absorbed or dissipated in order to prevent structural or vessel damage The design and manufacture of fenders suitable for protecting modern ports and terminals, diverse vessels and high value cargo require a great deal of expertise and design engineering in order to optimize Developing Efficient Marine Fender Solutions JIER Marine Tug boat cylindrical rubber fenders are widely used for primary marine fendering system on the bow or stern of tugboats, pushboats and workboats Cylindrical tugboat marine rubber fender are divided into: Straight cylindrical marine fenders and tapered ends rubber fenders Its round shape is flexible for shiptoship operation with different type of vessels The Max Length can be to 20 m with joined plug It’s Tug Cylindrical Rubber Fenders For Boats Ronsen Marine Fendercare Marine has a marketleading range of multipurpose and fixed fenders for a range of applications, many available immediately from stock, worldwide As well as multipurpose and fixed fenders, Fendercare Marine also provides full vessel fendering systems and can also develop bespoke fendering solutions to meet specific requirementsMultipurpose fenders and fixed fender solutions

Choose a suitable marine fender design system

If you are looking for a post that lists out all available rubber fender design types like “pneumatic fender”, “modular fender”, “Dshaped bumper” etc, you should visit “Rubber Fenders: Types Things to Note” article This article post aim to discuss the generally used equations, formulas, factors to determine a suitable port fender designFrontal Panels ( Frames ) are the necessary parts of marine fendering systems, which are normally used for Super Cell Rubber Fenders, Super Cone Rubber Fenders, Leg Rubber Fenders and other types of marine fenders The steel frontal panels are applied to distribute the reaction force from the rubber units into the ship’s hull Frontal Panels are generally of fabricated steel composite beam Frontal Panel Ronsen Marine Fendering SystemTEKMARINE Systems LLC offers its shiptoshore engineered solutions and services to our worldwide customers from its base in the United States We design, manufacture and supply advanced marine fendering and mooring systems to ports, harbors, drydocks, ship and boat owners – operators, and waterways across the worldTEKMARINE – Ship to shore engineered solutions NANHAI AIRABG is Pneumatic fender Manufacturer and our company are ISO9001,ISO14001 and ISO18001 certified, Our pneumatic fender have ISO17357 certificate isPunctured pneumatic fender repair solution YouTubeWhether you’re concerned about water damage or are annoyed by constant rattling, our marine hatch seals are the perfect solution How do I install rubber hatch seals? Installation of boat hatch gaskets is easy: 1 Clean the adhesion site thoroughly using a solution of one part isopropyl alcohol and one part water, using a new, clean rag; 2 Cut the seal to the desired length for your applicationRubber Hatch Seals Marine and Boat Hatch Gaskets TrimLok

- spare parts for mining ne crusher

- SMALL COAL CRUSHER PRICE IN SOUTH AFRICAC

- grinding teeth cusps

- gold purification process equipment

- MOBILE CONCRETE RECYCLING PLANT PRICE CONCRETE CRUSHING EQUIPMENT FOR SALE

- m sand product for crusher

- equipment for production of aluminium powder by atomization

- crushing stone to sand machine

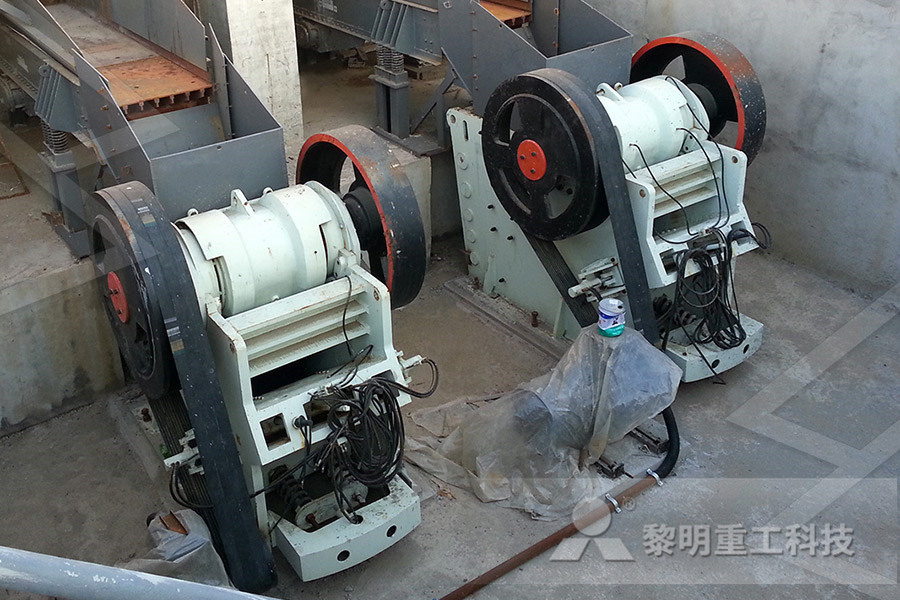

- Jaw Crusher Cj408 Equipment Parameters

- types of al crushers in power plants

- mining plant machinery india

- Vertical Shaft Impact Crusher Good Sand Making Machine

- limestone portable crusher price in indonessia

- lapping of valve plunger

- sudan small scale gold mining

- business plan for gypsum powder processing

- Chinese 3 Ton Stone Crusher Per

- internal belt grinder

- grinding machine suspension

- transkei quarries prices of a load of crushed stone

- laboratory mill grinding gold processing plant

- makalah tentang tambang bijih besi ball mill pemasok mesin

- CRUSHER PRODUCTS INDUSTRIAL

- daftar alat alat al miningcrusher manufacturers

- AGGREGATE CRUSHING PLANT PRICE

- impact crusher dijualimpact crusher dimensionimpact crusher dingsheng

- grinding mill for sale in gauteng

- popular rn grinding machines from China best

- visage broyeur club stiletto tube

- hydraulic soil sampling ring and drilling equipment

- TPH CRUSHER CAPACITY

- Russian Made Vearticle Grinding Mill

- stone crusher manufacturers in imbatore

- Stone Crusher Spare Partsjaw Plate

- mill ball mill manufacturers south africa

- siemens ne crushers

- ultrafine grinding equipment

- micro mill port elizabeth

- CONE CRUSHER PUZZOLANA

- Calculation Of Production Liner Cementation

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher