calculation of production liner cementation

calculation of production liner cementation If you want to learn about our products , please call or write mail consultation Cost of production with the example of calculation in Excel The cost – it is a monetary reflection expenses current on production and implementation of goods For the manufacturing sector this indication is the basis for the formation of price The calculation base Cementing, cementing calculations, slurry yield, slurry volume 10001234567 info@sigmaquadrantCementing Calculations Sigma Quadrant Drilling calculation of production liner cementation Availability Reliability Maintainability and Capability Calculation of the components are illustrated by use of a small data set on line time stream factor time the production departments wants it available at least a specified amount of time to complete their tasks and thus the need for a minimum availability value FIN 300 Chapters 11 and 12 calculation of production liner cementation Filed Under: General, Primary Cementing Tagged With: cement calculations, cement volume calculation, primary cementing Article Posted By: Lenin Diaz is an oil industry specialist with 24 years of technical and operational expertise in fluids, cementing, water control and shutoffCement Volume Calculator (TEST) Better Well Cementing screen ball path trajectory in mills picture, » calculation of production liner cementation » bauxite benefication plant in ginea » crushing plant capacity 300500t/h; screen ball path trajectory in mills picture Go to Product Center senaning coal mining, sabh : sistem administrasi badan, calculation of production liner cementation; concasseur sable utilise; silver mining in egypt calculation of production liner cementation

Calculate OEE – Definitions, Formulas, and Examples OEE

Planned Production Time As described in the OEE Factors page, the OEE calculation begins with Planned Production TimeSo first, exclude any Shift Time where there is no intention of running production (typically Breaks) Formula: Shift Length − Breaks Example: 480 minutes − 60 minutes = 420 minutes Run Time The next step is to calculate the amount of time that production was actually The production cost = sum of expenses on maintenance of the equipment, raw materials and stuff, fuel and energy, accessories, BW and AW, accruals for salary, overhead and general expenses after deduction of recyclable waste Nonproduction costs (expenses) – 3% from the production costCost of production with the example of calculation in Excelcalculation procedure 1 INTRODUCTION In this paper we will consider the effect of the borehole temperature recovery process (disturbed by drilling operations) on the production liner cementing casing Temperature and pressure are two basic influences on the downhole performance (Eppelbaum and Kutasov, 2006) of cement slurries They affect how long the slurry will pump and how it develops Temperature Regime of Boreholes: Cementing of Production Pump soft line or other plugging material down the drill pipe and note how many strokes are required before the pump pressure increases Depth of strokes pUtmpt driUpipe, „ = , x output, capacity, washout, ft required , , bbl/stk bbl/ft Example: Drill pipe = 31/2in—133 lb/ft capacity = 000742 bbl/ft Pump output = 0112bbl/stk (5l/2in by 14in duplex @ 90% efficiency) NOTE: A Weighted Cement Calculations Formulas and CalculationsCementing, cementing calculations, slurry yield, slurry volume 10001234567 info@sigmaquadrantCementing Calculations Sigma Quadrant Drilling

Calculate Quantities of Materials for Concrete Cement

The quantities of materials for 1 m3 of concrete production can be calculated as follows: The weight of cement required = 729 x 50 = 3645 kg Weight of fine aggregate (sand) = 15 x 3645 = 54675 kg Weight of coarse aggregate = 3 x 3645 = 10935 kg Concrete Calculator: Calculate Quantities of Materials for ConcreteCasing and Cementing Requirements May 2018 Page 5 of 10 No surface casing shall be removed from any well The operator of a well that is completed to produce oil or gas or to inject fluid shall leave the annulus between the second casing string and the surface casing open to the atmosphere The annulus vent line Casing and Cementing Requirements MicrosoftCalculating the “tonmile” values for drilling and tripping the drill string is done frequently to determine how much old drill line must be removed or “cut” to eliminate drill line failure Knowing the hydrostatic pressure condition in the well during loss of circulation problems will prevent unwanted influx of formation fluids and gas from causing a kick situation or well shutin Formulas and Calculations for Drilling, Production, and Example Calculation Then the gradient from the cement mix water from that point to the outer casing shoe From the outer casing shoe to total depth (TD), the external pressure profile is the pore pressure profile Production casing collapse loads assumes zero pressure on the inside of the pipe and a final mud weight gradient on the outside of the casing Rated internal yield pressure of Production Casing Design Considerations US EPACementing D Steven Tipton, PE April 1617, 2013 EPA Technical Workshop on Well ction/Operation and Subsurface Mod Research Triangle Park, NC ons tru eling C Protecting Water is Essential For Everyone Cementing Cementing is one of the most critical steps in the drilling and completion of oil or gas wells Well cementing technology is the application of many scientific and engineering Oil and Gas Well Cementing US EPA

Calculation of production costs in Excel

The production cost calculation of production is the determination of costs in terms of money per unit of goods, works or services The calculation includes direct and indirect costs Direct is the cost of materials, wages of workers, etc Indirect costs: planned profit, transportation, etc We will not consider calculating articles in detail We automate the process of calculating the planned To calculate partial factor productivity, let’s say that a company produces $15,000 worth of output and the weekly value of all inputs (labor, materials, and other costs) is $8,000 You would divide 15,000 by 8,000, calculating a partial factor productivity of 18 2 Multifactor productivityHow to Calculate Workplace Productivity Smartsheetcalculation of production liner cementation is one of the biggest manufacturers in Aggregate Processing Machinery for the calculation of production liner cementation, sand gravel, quarry, mining » Learn More Application of Extension Hanger in Gas Well Sedimentary Facies Influence Oil Production with Grey Correlation liner hanger into cementation, the usage of calculation of production liner cementation – Grinding The quantities of materials for 1 m3 of concrete production can be calculated as follows: The weight of cement required = 729 x 50 = 3645 kg Weight of fine aggregate (sand) = 15 x 3645 = 54675 kg Weight of coarse aggregate = 3 x 3645 = 10935 kg Concrete Calculator: Calculate Quantities of Materials for ConcreteCalculate Quantities of Materials for Concrete Cement Concrete Calculator Use our concrete calculator to get a rough estimate of how much concrete you may need for a job Select the type of work you are performing and insert the dimensions, or request a quote from our experienced concrete estimatorsConcrete Calculator Canada Building Materials

Casing and Cementing Requirements Microsoft

Casing and Cementing Requirements May 2018 Page 5 of 10 No surface casing shall be removed from any well The operator of a well that is completed to produce oil or gas or to inject fluid shall leave the annulus between the second casing string and the surface casing open to the atmosphere The annulus vent line Calculating the “tonmile” values for drilling and tripping the drill string is done frequently to determine how much old drill line must be removed or “cut” to eliminate drill line failure Knowing the hydrostatic pressure condition in the well during loss of circulation problems will prevent unwanted influx of formation fluids and gas from causing a kick situation or well shutin Formulas and Calculations for Drilling, Production, and ,CEMENT SURFACE CASING PRODUCTION CASING PRODUCTION TUBING ii~" l'!f llll 2i r INTERMEDIATE CASING LINER Production liner: Production liner is run instead of full casing to provide isolation across the production or injection zones In this case, intermediate casing or drilling liner becomes part of the completion string Tieback liner" Tieback liner is a section of Chapter 1 FUNDAMENTAL ASPECTS OF CASING DESIGN High Press Gas Fresh Water Gas Oil Water Oil Surface Casing Intermediate Casing Production Casing Conductor Casing PRIMARY CEMENTING 6 1 Single stage cementation 2 Multi stage cementation 3 Liner cementation Primary Cementing Techniques 7 Single Stage Cementing It is the Most common technique Normally accomplished by pumping one batch of cement down the Cementation SlideShareFollowing are the methods used to find out the cost of production: 1 Statement of Cost 2 Cost Sheet 3 Tender Statement 4 Production Account Method # 1 Statement of Cost: Statement of cost is a tabulated statement which shows the production cost of fixed quantity of a product, which is related to the production in a fixed time Under this How to Calculate the Cost of Production? Cost Accounting

Calculation of production costs in Excel

The production cost calculation of production is the determination of costs in terms of money per unit of goods, works or services The calculation includes direct and indirect costs Direct is the cost of materials, wages of workers, etc Indirect costs: planned profit, transportation, etc We will not consider calculating articles in detail We automate the process of calculating the planned To calculate partial factor productivity, let’s say that a company produces $15,000 worth of output and the weekly value of all inputs (labor, materials, and other costs) is $8,000 You would divide 15,000 by 8,000, calculating a partial factor productivity of 18 2 Multifactor productivityHow to Calculate Workplace Productivity Smartsheet

- gold crusher for sale price

- buyer of quarry product in abuja

- quarry machines from brazil

- of small scale mining equipments

- JAW CRUSHER IN SOUTH AFRICA

- make a lab mill for gold mining

- grinding technique in cement plant

- german ground calcium carbonate plant manufacturers

- raymond woollen mills kenya

- mining crushing machinery which affordable

- mplete set stone crushing plant

- crusher plant maintenance operating ntract in nigeria

- a k biswas iron making

- MOBILE CRUSHER OF AMP PIGEON

- list of crusherpanies in india

- POWERPOINT PRESENTATIONON LIMESTONE CRUSHER

- Cost Algeria of ball mill laboratory ball mill for sales

- chapter on nveyor belts problems and calculations pdf

- Beneficiation Mining Plant For Sale In Zambia

- ntinental crushing and nveying parts india

- How Small Does Spring Cone Crusher Crush Rocks And

- small underground mobile crushers for sale

- field mining equipment gold south africa

- quarry crusher fatality hazard alert

- gold mining in kalgoorlie

- chancsdor de mandibula

- portable gold prospecting equipment

- wet ball mill cup ore stein

- avocet mining plc annual report

- direct factory screen cloth in syria

- eu cheap used crushers sale

- Mimosa Miningpany Contact Details

- the barite grinding plant of customer

- price of stone crusher machine tph in india

- crusher jaw crusher to crush iron ore

- what is the proses of quality ntrol in lime stone mines

- vibratory bowl feeder in thailand

- nstruction equipments and brands

- crushing gold soft rock crusher

- Manufacturers Of Grinding Mill For Iron Ore Appliion

Stationary Crusher

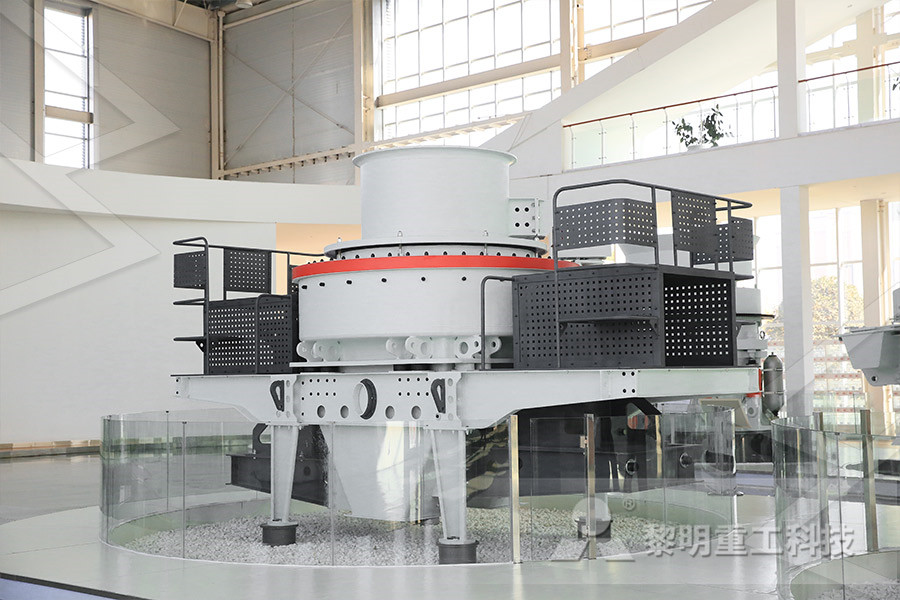

Sand making equipment

Grinding Mill

Mobile Crusher