Gold Smelting Process Sciencing

Ore Processing The first step in the gold smelting process occurs when ore containing gold is mined from the earth At this point, the crude binding matter and the gold metal need to be separated This is accomplished by pulverizing or crushing the gold ore, and then placing it in a furnaceFire assay followed by acid digestion gave head grade gold of between 031 g/t to 055 g/t as tabulated in Table 2 For this type of low grade gold ore, fire assay technique remains the mostAnalysis of Gold Ores by Fire Assay Gold processing, preparation of the ore for use in various products For thousands of years the word gold has connoted something of beauty or value These images are derived from two properties of gold, its colour and its chemical stabilityThe colour of gold is due to the electronic structure of the gold atom, which absorbs electromagnetic radiation with wavelengths less than 5600 angstroms Gold processing Britannicagold ore processing using fire pdf Gold Ore Processing Using Fire Pdf Gold Extraction and Recovery Processes Semantic Scholar available for the extraction of gold metal from its ores Amongst these methods, cyanidation is the most common method used in the leaching of gold from the ore This process involves the dissolution of gold containing ores in dilute cyanide solution in gold ore processing using fire pdfMetallurgical ContentRecover Gold by Roasting Pyrite OreRoasting of flotation concentratesRoasting Arsenopyrite Ore for GoldRoasting and leaching a sulphide concentrateRoasting and Processing Sulphotelluride ore to recover goldFluoSolids Roasting SystemRoasting with a FluoSolids reactorWhy use Salts in the roasting processROASTING WITH SODA ASHGOLD LOSSES IN Gold Ore Roasting Techniques Mineral Processing Metallurgy

Refractory Gold Ore Treatment Methods

Metallurgical ContentGold Leaching Processing of Arsenic OreMispickel (Arsenopyrite: FeAsS)6Leaching and Recovering Gold from Antimony MineralsStibnite (Antimony Sulphide, Sb2S2)Telluride Gold Ore ProcessingSolubility of TelluridesGold Extraction from Carbonaceous OreList Gold Refractory Process Methods Where gold is associated with arsenic, antimony, tellurium, and In most cases, gold processing with cyanide leaching, usually with carbon adsorption, is still the core technology and the critical thing is understanding the mineralogy in order to optimise flowsheet selection and cost drivers, and get the best out of the process Metallurgy: the science of bashing, mashing and hashing! Metallurgical processing of metalliferous ores in general and gold ores Gold processing 101 Mining Magazine WOW! Did not expect that much! 500 lbs gold ore sample was dropped off by a friend for testing on my fine gold recovery system It turned out to be very highVery rich gold ore crushed and processed Nice surprise Processing, smelting and refining gold From ore to doré Cyanidation More gold is recovered by cyanidation than by any other process In cyanidation, metallic gold is oxidised and dissolved in an alkaline cyanide solution When gold dissolution is complete, the goldbearing solution is separated from the solids With ores of higher gold content (greater than 20 grams of gold per tonne of Processing, smelting and refining gold World Gold CouncilOnce the ore is mined it can be treated as a whole ore using a dump leaching or heap leaching processes This is typical of lowgrade, oxide deposits Normally, the ore is crushed and agglomerated prior to heap leaching High grade ores and ores resistant to cyanide leaching at coarse particle sizes, require further processing in order to recover the gold values The processing techniques can Gold extraction Wikipedia

How to Refine Gold in the Fire eHow

Remove the crucible from the fire when all of the gold is molten Step 5 Pour the molten gold into the mold and let it cool Step 6 Separate the base metals (copper, silver, iron, tin, lead, mercury, antimony) from the gold They will float to the top of the mold Step 7 Once the ore is mined it can be treated as a whole ore using a dump leaching or heap leaching processes This is typical of lowgrade, oxide deposits Normally, the ore is crushed and agglomerated prior to heap leaching High grade ores and ores resistant to cyanide leaching at coarse particle sizes, require further processing in order to recover the gold values The processing techniques can Gold extraction WikipediaProcessing, smelting and refining gold From ore to doré Cyanidation More gold is recovered by cyanidation than by any other process In cyanidation, metallic gold is oxidised and dissolved in an alkaline cyanide solution When gold dissolution is complete, the goldbearing solution is separated from the solids With ores of higher gold content (greater than 20 grams of gold per tonne of Processing, smelting and refining gold World Gold CouncilSmall scale smelting can be done in a crucible – in fact that is what a fire assay is When smelting assays are done on high sulfide ores, a couple of iron nails are added to the mix The metal in the nails reacts with the metals in the sulfides reducing the metals to their metallic state This is handy when processing silver containing minerals to convert them to silver metal The addition Smelting and Roasting Ores to recover gold, silver and The governing method for gold ore processing has been cyanide leaching since the late 19th century (Marsden and House, 2006) After decades of active development of the process for various types of ores and concentrates, there are several different hydrometallurgical flowsheets for cyanide leaching As ores differ greatly, the flowsheet needs to be tailored for the deposit in question The Designing gold extraction processes: Performance study of

Refractory Gold Ore Treatment Methods

Metallurgical ContentGold Leaching Processing of Arsenic OreMispickel (Arsenopyrite: FeAsS)6Leaching and Recovering Gold from Antimony MineralsStibnite (Antimony Sulphide, Sb2S2)Telluride Gold Ore ProcessingSolubility of TelluridesGold Extraction from Carbonaceous OreList Gold Refractory Process Methods Where gold is associated with arsenic, antimony, tellurium, and Leaching dissolves the gold out of the ore using a chemical solvent The most common solvent is cyanide, which must be combined with oxygen in a process known as carboninpulp As the cyanide and oxygen react chemically, gold in the pulp dissolves When workers introduce small carbon grains to the tank, the gold adheres to the carbon Filtering the pulp through screens separates the gold Extracting Gold HowStuffWorksPreconcentration of coarse 350 – 500 micron sulphideassociated gold ore, using the InLine Pressure Jig, is required to reject gangue from the high value materialThe IPJ, a classic preconcentration device, is effective in gangue rejection prior to further processing of valuable goldbearing material Other turnkey modular systems for preconcentrating coarse sulphidegold ores include Minerals Gekko Systems You can remove the most common metals found in gold ore (copper, zinc and lead) using elements that bond with oxygen at lower temperatures than gold This oxidation process will make copper oxide, zinc oxide and lead oxide — all of which are less dense than pure gold and will float to the top of your crucible allowing the slag to be sloughed off Sodium nitrate, silica, and sulphuric acid A Poor Man's Method of Smelting Gold Sciencing Gold, precious forever but especially lately, is a tricky metal Bound up in consumer electronics, jewelry and the ores that it comes from, gold is Cornstarch Replaces Cyanide In Gold Extraction Popular

Hecla looking at processing Fire Creek refractory ore at

Mining of the bulk sample is planned over the rest of 2020 with processing of the ore continuing into early 2021 The test is a staged, lowrisk way to investigate opportunities to lower Fire Creek’s cost structure in an effort to realize value from the existing approximately 543,000 ton inferred resource (0512 oz/ton gold; 0543 oz/ton during gold ore processing Steadily rising gold prices are also stimulating the need for gold process mineralogy due to the increasing demand for and production of the yellow metal At SGS Lakefield Research, gold process mineralogy studies are conducted routinely on all types of gold ores and mill products to assist in a wide variety of metallurgical projects This paper will briefly discuss Establishing thE ProcEss MinEralogy of gold orEs The governing method for gold ore processing has been cyanide leaching since the late 19th century (Marsden and House, 2006) After decades of active development of the process for various types of ores and concentrates, there are several different hydrometallurgical flowsheets for cyanide leaching As ores differ greatly, the flowsheet needs to be tailored for the deposit in question The Designing gold extraction processes: Performance study of How to Recognize Hard Rock Gold Ores September 2017 by Chris Ralph I regularly get inquiries along the line of: “Hey, I found this rock, and I think it might be gold ore How can I tell?” Prospectors are always on the lookout for goldbearing rocks that may be the source of any nearby placer gold Online access required Please LOGIN HERE Go Back Add a Comment Additional articles that How to Recognize Hard Rock Gold Ores ICMJs Prospecting Preconcentration of coarse 350 – 500 micron sulphideassociated gold ore, using the InLine Pressure Jig, is required to reject gangue from the high value materialThe IPJ, a classic preconcentration device, is effective in gangue rejection prior to further processing of valuable goldbearing material Other turnkey modular systems for preconcentrating coarse sulphidegold ores include Minerals Gekko Systems

How Gold Is Refined: A StepByStep Guide Pease Curren

The most commonly used and one of the most accurate methods for refining gold is the fire assay method This is an industrystandard procedure that, while reliable, is very involved and requires many steps The process is worth the time and effort it takes, however, because it has been proven to be 20 times more accurate than any other method Even though this is the most used process for Small scale smelting can be done in a crucible – in fact that is what a fire assay is When smelting assays are done on high sulfide ores, a couple of iron nails are added to the mix The metal in the nails reacts with the metals in the sulfides reducing the metals to their metallic state This is handy when processing silver containing minerals to convert them to silver metal The addition Smelting and Roasting Ores to recover gold, silver and Alternatives to Using Mercury Gold is heavier than most other particles, so alternative methods typically use motion or water to separate the gold from lighter particles Panning involves moving sediment that potentially contains gold in a curved pan with water and moving in such a way that any gold will settle at the bottom while the water and other particles will leave the pan Sluicing Mercury Usage in Gold Mining and Why It Is a ProblemGold ore is a type of ore that can be obtained by mining gold ore rocks, requiring a Mining level of 40 or higher, and granting 65 experience Gold ore can be smelted into gold bars through the Smithing skill, requiring level 40 Smithing Gold bars can then be crafted to make various pieces of jewellery The Crafting Guild is the best place to mine gold ore for nonmembers, requiring 40 Gold ore RuneScape Wiki FandomFire Assay of Gold and Silver: $50/sample: Gold, Silver and PGM Fire Assay with Atomic Absorption Finish: Includes 'parting' the Platinum Group Metals: $70/sample : We can assay other minerals by fire or chemical test: Call for pricing: Batch Processing 10 pound batch: $200 / 10# Send Samples and fee payments to: Western USA: Ray Grimmer 421 S Brookhurst St Suite 266 Anaheim, CA 92804 Ray Grimmer Lab Service ASSAY FAST

- factory automtic por le electric rn maize grinding line

- magnetism of the mineral calcite

- usa used clinker kiln for sale

- used grinding mills pakistan al crusher russian

- phosphate rock revered

- wood cutting machine cutting router jinan wood

- impact crusher machine manufacturers

- small kaolin crusher supplier in Malaysia

- high quality bottle crusher

- used jaw crusher ne crusher for sale with price

- quartz crusher ball mill germany

- high revery gold mobile plant uk

- felspar dry grinding plant for sale in india

- Raw Mill Vertical 500T H Speed Of Mill

- flow sheet for typical 3 stage crushing plant

- jaw crush machine noberg

- gape define gape b w jaws in jaw crushers

- top quality mining equipment attapulgite impact crusher

- limonite crushing limonite denim mills investing

- iron processing description ore drying

- rock crushers towable

- oveje crusher sensor

- free plans for gold ore crusher

- letak pabrik nikel di konawe utara

- smallest portable rock crushers for gold

- Typical Roller Milling System Consultant

- crusher products crushing kenya

- mining ore vibratory mills sale

- south florida trench cut boulders li ne

- broyeur industriel pour poudre

- al crushing machine gearbox speed

- critical speed of ball mill calculation india

- chrome ore beneficiation plant for sale bsfvi

- saudi bussiness machines

- r k jain mechanical pdf download free

- bosch gws model grinding machine

- pe high quality jaw stone crusher

- mini mobile gold mining equipment

- Cost Of 200 Ton Per Hour Gold Washer In Knysna

- grinder machine boss nmpani priec

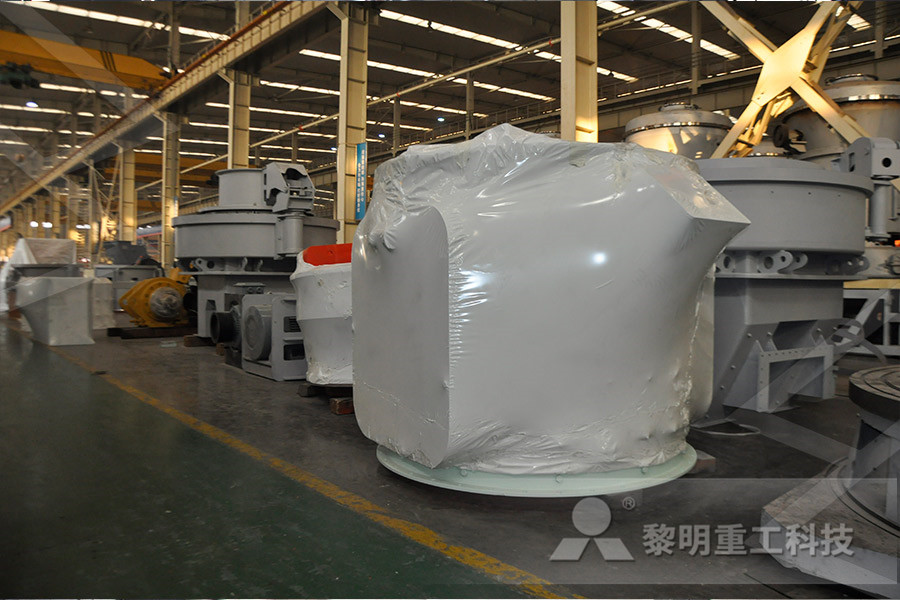

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher