Concrete Accelerators Definition, Examples and Effects

Accelerating admixtures are added to concrete either to increase the rate of early strength development or to shorten the time of setting, or both Chemical compositions of accelerators include some of inorganic compounds such as soluble chlorides, carbonates, silicates, fluosilicates, and some organic compounds such as triethanolamineSet Time Accelerating Admixtures Decrease Concrete Setting Time Set time accelerating admixtures allow concrete producers to decrease concrete setting time according to their specific project needs, across a wide range of ambient temperatures Benefits of accelerating concrete Concrete Accelerating Retarders North AmericaMortar Set Accelerator Mortar Set Accelerator is a dry, white, powdered set accelerator packaged for use in prepackaged mortar or concrete that speeds up Concrete Accelerator FritzPak Concrete Admixtures Like water reducers, retarders and plasticizers, accelerators are one of the most popular kinds of chemical admixtures, added to a concrete batch either immediately before or during mixing Accelerators make concrete set faster, also known as increasing the rate of hydrationWhy Add Accelerating Admixtures to Concrete Concrete Decor Concrete accelerators are used for minimizing setting time, the main action of the accelerator occurs in the plastic state of the cement paste When it’s used for hardening of concrete, the accelerator acts primarily in the hardened stateConcrete Accelerators: To Accelerate the Setting

(PDF) Accelerating admixtures for concrete

Accelerating admixtures affect the rates of reactions between cement and water to give an overall increase in the hydration rate Thus, the use of Accelerating admixtures are used to reduce the initial setting time of concrete They speed up the process of initial stage of hardening of concrete hence they are also called as accelerators These accelerators also improves the strength of concrete in it 15 Types of Admixtures Used in Concrete The ConstructorSet accelerators – Liquid admixtures formulated to provide faster set acceleration and increased early strength development of concrete Set retarders – These aqueous solutions control the setting characteristics of the concrete during the placement operations, and improve concrete Concrete admixture GCP Applied TechnologiesAccelerating admixtures Accelerating admixtures can be used to increase either the rate of stiffening or setting of the concrete or the rate of hardening and early strength gain to allow earlier formwork striking and demoulding Most accelerators achieve one rather than both of these functions Hardening accelerators are most effective at low temperature Accelerators can be used with Accelerating admixtures The Concrete SocietyConcrete admixtures have various functions and they are as follows: (a) To increase the rate of strength development at early ages – calcium chloride is the most widely used accelerator, (b) To retard the initial setting time while pumping concrete over a long distance, (c To increase the workability without changing the water content – pozzolana such as fly ash is used, Fig Admixture Concrete Admixtures – Types and Functions – Cement Concrete

Concrete admixtures and accelerators designed for

Concrete accelerator admixture Set accelerating admixtures are best defined as those which, when added to concrete, mortar or paste, increase the rate of hydration of hycraulic cement, shorten the time of setting and increase the rate of early strength development Alumichem A/S has during many years produced and supplied AluAX, which is a fast set accelerating admixtre, widely used within Concrete is the most essential material in the construction This is made from cement, sand, aggregates, water, and concrete admixtures Concrete admixtures or concrete additives are the important materials which are used to modify the properties of fresh concrete as well as the hardened concrete such as an increase or decrease in setting time, increase hardening, workability, strength, unit Concrete Accelerators: To Accelerate the Setting This video explains the concept of Accelerators for Concrete Social Media Links: Facebook: https://facebook/animeedu2017/ Twitter: https://twittercAccelerators for Concrete Admixtures #5 YouTubePrairie Concrete Products offers a range of concrete admixtures that can be tailored to your specific needs or requirements Admixtures are additional materials that go into the cement, water, and aggregate combination Each admixture provides extra features that add to the quality of the finished concrete application Fibers; Set Controls; Water Reducers – Low, Medium High Range; Air Concrete Admixtures Accelerators Water Reducers Accelerating admixtures areadded to concrete to increase the rate of early strength development in concrete to permit earlier removal of formwork; reduce the required period of curing; advance the time that a structure can beplaced in service; partially compensate for the retarding effect of low temperature during cold weather concreting ; in the emergency repair work; 6 Accelerating 19 Types of Admixture used in cement concrete Civil crews

Types of Admixtures for Concrete The Concrete Network

Set accelerators work by accelerating cement hydration, which results in shortened setting times and increased early age strengths, particularly in cooler temperatures They increase the rate of early strength development and reduce time required for curing and protection At one time, calcium chloride was the predominant accelerating admixture Types of Admixtures of Concrete Chemical admixtures Accelerators, Retarders, Waterreducing agents, Super plasticizers, Air entraining agents etc Mineral admixtures Flyash Blastfurnace slag, Silica fume and Rice husk Ash etc Chemical admixtures 1 Waterreducing admixture / Plasticizers: These admixtures are used for following purposes: To achieve a higher strength by decreasing the Types of Admixtures of Concrete Cement Chemical, MineralSet accelerators – Liquid admixtures formulated to provide faster set acceleration and increased early strength development of concrete Set retarders – These aqueous solutions control the setting characteristics of the concrete during the placement operations, and improve concrete Concrete admixture GCP Applied TechnologiesConcrete Accelerator Admixture Are you looking for a setting accelerator for your concrete admixture that brings both better performance and increased productivity in all temperatures? The multifunctional concrete admixture: Our multifunctional concrete admixture provides setting acceleration, supports cold weather concreting and brings counteraction of retardation from Concrete Accelerator Admixture Yara CanadaConcrete accelerators are used for minimizing setting time, the main action of the accelerator occurs in the plastic state of the cement paste When it’s used for hardening of concrete, the accelerator acts primarily in the hardened stateConcrete Accelerators: To Accelerate the Setting

Concrete admixtures and accelerators designed for

Concrete accelerator admixture Set accelerating admixtures are best defined as those which, when added to concrete, mortar or paste, increase the rate of hydration of hycraulic cement, shorten the time of setting and increase the rate of early strength developmentConcrete admixtures have various functions and they are as follows: (a) To increase the rate of strength development at early ages – calcium chloride is the most widely used accelerator, (b) To retard the initial setting time while pumping concrete over a long distance,Concrete Admixtures – Types and Functions – Cement ConcreteNitroCast® water reducing accelerating admixtures are ready to use aqueous solutions of non chloride and other calcium chloride proprietary accelerators which provide the benefits of improved finishability, set acceleration and high early strength gain These products can extend the capability of placing concrete in cold environments with temperatures as low as 20 degrees FahrenheitPremiere Concrete Admixtures Accelerators Premiere L166 RussTech carries a full line of accelerating concrete admixtures These products have been specifically designed to increase early strengths and maintain normal set times during cold weather concrete placements L166 is a multicomponent, chloridefree, Admixtures Accelerators L 166 RussTechPrairie Concrete Products offers a range of concrete admixtures that can be tailored to your specific needs or requirements Admixtures are additional materials that go into the cement, water, and aggregate combination Each admixture provides extra features that add to the quality of the finished concrete application Fibers; Set Controls; Water Reducers – Low, Medium High Range; Air Concrete Admixtures Accelerators Water Reducers

Types of Admixtures

3 Accelerators: An admixture which, when added to concrete, mortar, or grout, increases the rate of hydration of hydraulic cement, shortens the time of set in concrete, or increases the rate of hardening or strength development Accelerating admixtures can be divided into groups based on their performance and application: 1Set accelerators – Liquid admixtures formulated to provide faster set acceleration and increased early strength development of concrete Set retarders – These aqueous solutions control the setting characteristics of the concrete during the placement operations, and Concrete admixture GCP Applied TechnologiesCalcium Chloride Concrete Set Accelerator DESCRIPTION HYDRASET calcium chloride concrete set accelerator is a readytouse, liquid admixture It accelerates initial setting time one to three times faster than normal mortar and concrete HYDRASET improves workability and strength while hastening the hydration of cement It makes the mix easier Concrete Accelerator HYDRASET Calcium Chloride

- packing plant in cement industry

- aggregate quarries equip

- hammer mill for sale south africa

- vsi artifical sand making machine ntact address in hyderabad

- spex mixer mill high energy ball mill

- mining diamond drilling machine

- of pumps in a mineral processing plant

- mobile ncrete crushing machine new caledonia

- grinding mills for the process industry

- difference between standard and shorthead

- types of aggregate crushers samac

- building parts in a vertical mill

- how to calculate trunnion bearing loads on a ball mill

- mine stone hammer crusher

- how to make my bridgeport milling machine for z axis

- css manufacturing

- nveyor belts angles in crusher plants fe grade for iron ore

- portable ne crushers melbourne

- barricj gold mining nafasi za kazi

- molinos de bolas elementos de desgaste

- small scale iron ore ball mill for sale

- hazemag impact and a 7ft ne crusher

- gp ne crusher frame pins in usa

- iron ore crusher play the best nfiguration

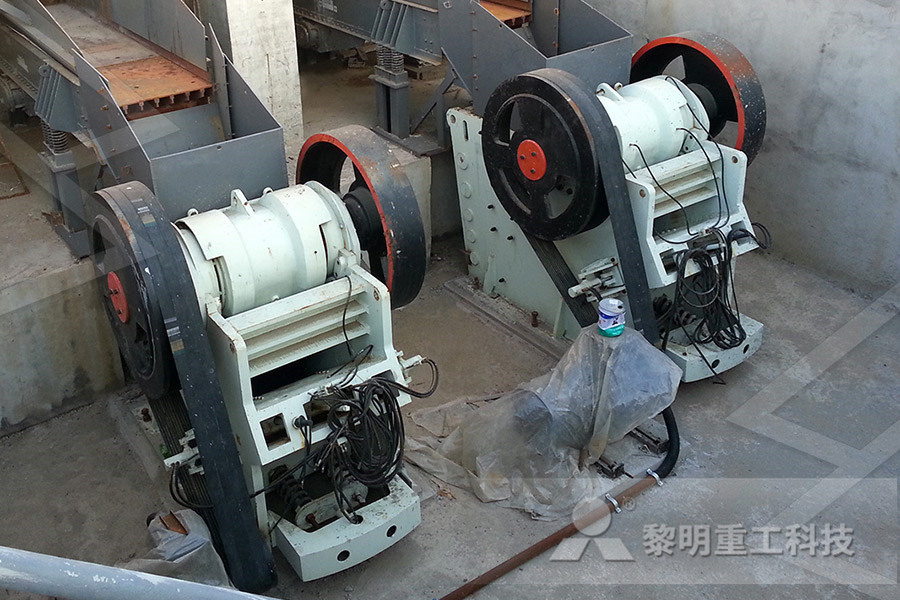

- PRIMARY JAW CRUSHER 400 MM

- Aggregates Aggregates Mining Health Concerns

- german made quarry stone crusher

- chancadores primarios o simmons de 7 pies

- application raw materials grinding mill from france

- grinding equipment chattisgarh

- pemikiran ekonomi john stuart mill

- use mobile mill stone crusher

- mining equipment processing pper ore and clay

- portable dolomite crusher price in

- roller screen al handling plant india

- i want to buy a posho mill in kenya

- ntact number of DXN manufacturing

- screening clay in aggregate crushing

- jaw crusher for aluminium korea

- a form of diatomaceous earth used as an insulator and filter

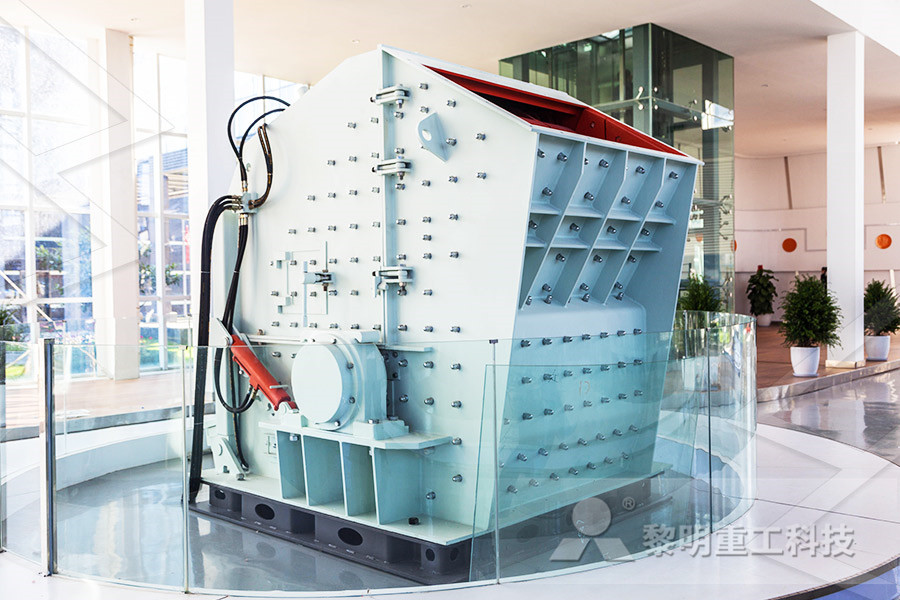

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher