Pumps in Mineral Processing

List Types of Pumps The pumps in a mineral processing concentrator (plant) can roughly be classified into two groups, PROCESS pumps and SERVICE pumps A service pump is any pump that provides a service to the process A Process pump is one whose function is partPeristaltic pumps are widely used in mineral processing plants Operated in the correct design environment of pressure, temperature and flow, they provide a low maintenance solution for Peristaltic Pumps for Mineral Processing Plants and Other UsesPeristaltic pumps are widely used in Mineral processing plants Operated in the correct design environment of pressure, temperature and flow they provide a low maintenance solution for many pumping duties Thickener underflow, reagent, flocculent and cyanide dosing and transfer, are some of the duties the pumps are ideally equipped to handlePeristaltic Pumps Sepro Mixing SystemsThe pumps in a mineral processing concentrator (plant) can roughly be classified into two groups, PROCESS pumps and SERVICE pumps A service pump is any pump that provides a service to the process A Process pump is one whose function is part of the process The pump doing this type of job will be directly responsible for maintaining the CONTINUOUS OPERATION of the process These two Pumps and Pumping Mineral Processing MetallurgyOf Pumps In A Mineral Processing Plant We are a largescale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment, milling equipment, mineral processing equipment and building materials equipment And they are mainly used to crush coarse minerals like gold and copper ore, metals like steel and iron, glass, coal, asphalt, gravel Of Pumps In A Mineral Processing Plant

ITT Goulds Pumps is a leading manufacturer of pumps for a

Goulds Pumps offers a variety of solutions for transferring highly abrasive slurries in mineral concentrating plants Goulds severe duty hard metal pumps and rubber lined SRLXT pumps are ideal for aggressive mill discharge and cyclone feed applications Goulds model SRLC and SRLS pumps are commonly applied on flotation concentrate and tailingsMining and Mineral Processing Pumps Beneficiation • Hydrometallurgy • Refining Experience In Motion 2 Pump Supplier to the World Flowserve is the driving force in the global industrial pump marketplace No other pump company in the world has the depth or breadth of expertise in the successful application of preengineered, engineered, and special purpose pumps and systems Supplier of Mining and Mineral Processing Pumps FlowserveMineral processing Mineral processing Dewatering: Concentrates and tailings produced by the methods outlined above must be dewatered in order to convert the pulps to a transportable state In addition, the water can be recycled into the existing water circuits of the processing plant, greatly reducing the demand for expensive fresh water Filtration is the separation of a suspension into a Mineral processing Dewatering BritannicaFlowserve pumps can be found at the heart of the most demanding separation processes, including: • Mineral/flocculant transfer for base metal flotation • Entrained air handling designs for bitumen flotation • Submersible designs for solids handling • High temperature Mining and Mineral Processing Pumps FlowserveThe facility extracts raw minerals from a sandstone formation and ships them to a nearby processing plant where they are refined Slurry Pumps Master Rare Mineral Processing Rugged equipment reliably serves in a Texas insitu recovery mine by Mike Bjorkman 02/03/2015 In 2010, a raremineral exploration, development and production company opened an insitu recovery (ISR) mine in South Slurry Pumps Master Rare Mineral Processing Pumps Systems

Mineral Concentration ITT Goulds Pumps is a leading

Goulds Pumps offers a variety of solutions for transferring highly abrasive slurries in mineral concentrating plants Goulds severe duty hard metal pumps and rubber lined SRLXT pumps are ideal for aggressive mill discharge and cyclone feed applications Goulds model SRLC and SRLS pumps are commonly applied on flotation concentrate and tailingsPeristaltic pumps are widely used in mineral processing plants Operated in the correct design environment of pressure, temperature and flow, they provide a low maintenance solution for Mineral Processing Equipment Sepro Mineral Systems The investment made in a gold processing plants, silver processing plants, as well as plants for recovery of other precious metals and rare earth minerals is The Basics of How Ore Processing and Recovery Plants Work Mineral processing plants Most mineral processing operations are designed to efficiently extract the valuable mineral with minimal loss The mined ore is usually crushed and ground in the mill to very fine particles and resulting slurry is further processed for mineral separation What is froth? Sometimes froth is encountered during the mineral separation process Froth is an aerated slurry GREEN PAPER FROTH PUMP DISCUSSION KETO PumpsMineral processing Mineral processing Dewatering: Concentrates and tailings produced by the methods outlined above must be dewatered in order to convert the pulps to a transportable state In addition, the water can be recycled into the existing water circuits of the processing plant, greatly reducing the demand for expensive fresh water Filtration is the separation of a suspension into a Mineral processing Dewatering Britannica

Mineral Processing Equipment Multotec

Some of the challenges minerals processing plants face include the high cost of replacing capital equipment, the labour requirements in changing out heavy equipment, such as a DMS cyclone, and production downtime while staff have to comply with safety regulations while equipment is being replaced Multotec strives to be a plugandplay solutions provider, providing maintenance and delivery of Mineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue It is the first process that most ores undergo after mining in order to provide a more concentrated material for the procedures of extractive metallurgyThe primary operations are comminution and concentration, but there are other important operations Mineral processing metallurgy BritannicaThe first process that most of the ores or minerals undergo after they leave any mine, is mineral processing or mineral/ ore dressing It is a process of ore preparation, milling, and ore dressing (PDF) Overview of Mineral Processing MethodsPumps are widely applied in mineral processing plant, and they provide motivation of conveying the pulp There are two kinds of pumps Xinhai expert will introduce to youalloy slurry pump and submerged slurry pumpIn this text, we will know how to solve some common problems of the pumps:Xinhai expert solves pump common problems in mine plant Peristaltic pumps are widely used in mineral processing plants Operated in the correct design environment of pressure, temperature and flow, they provide a low maintenance solution for Mineral Processing Equipment Sepro Mineral Systems

Dewatering Pumps Multotec Multotec Mineral Processing

Multotec’s range of industrial slurry pumps are designed for use in the construction and mining industry, power generation, water and wastewater and agriculture With optimum application efficiency and proven reliable and robust performance, the Multotec mining pump range helps lower overall costsMineral processing plants Most mineral processing operations are designed to efficiently extract the valuable mineral with minimal loss The mined ore is usually crushed and ground in the mill to very fine particles and resulting slurry is further processed for mineral separation What is froth? Sometimes froth is encountered during the mineral separation process Froth is an aerated slurry GREEN PAPER FROTH PUMP DISCUSSION KETO PumpsWeir Minerals has been selected to supply pumps and equipment for a new processing plant in Garpenberg/Sweden (Fig) The new plant is being built by the Swedish mining company Boliden and is a replacement for an existing facility – an upgrade that will double Weir Minerals secures processing plant pump supply deal Multotec is a proudly Canadian company with expert mineral processing solutions suited to the North American mining industry The company has been an original equipment manufacturer (OEM) for over 40 years and partner to the Canadian mineral industryMultotec Canada Expert in mineral processing solutionsMetChem has been involved in numerous gold projects regarding mineral processing, covering various activities from resources evaluation, mine design, flowsheet development, feasibility studies, detailed engineering, EPCM contracts, plant expansions and startup and commissioning This expertise was provided to clients for any size of project starting from a 450 tonne per day (tpd) plant in MetChem Canada Inc Mineral Processing

Portable Gold Wash Plant Mineral Processing

JXSC Small and Portable gold wash plant with trommel is a more flexible and cheaper gold washing solution, it can fully Customizable moveable This small machine can equip with the sluice box, gold centrifugal concentrator, shaker table, gold trommel, and other washer like sand washing machine Also, vibrating feeders, vibrating screen, pumps, and other portable mining equipment can followed Mineral Processing Plant Design General Procedure for plant design o Process Design o Flow sheet Design o Process Plant Simulation o General Arrangement Drawings Detailed Design Metallurgical involvement in the construction phase ommissioning ( old commissioning, Hot commissioning) Practical commissioning tips Acceptance runs onclusions Importance of Good Plant Design and in Time Mineral Processing Plant DesignThe first process that most of the ores or minerals undergo after they leave any mine, is mineral processing or mineral/ ore dressing It is a process of ore preparation, milling, and ore dressing (PDF) Overview of Mineral Processing Methods

- new products first choice feed hammer mill with blower

- cement mill in cement industry in nairobi nairobi area kenya

- large capacity grinding raymond mill grinding raymond mill for sale

- road mill machines malaysia price

- sale 300 350 tph aggregate stone production line

- major parts of aggregate plant

- Dz Brand High Efficiency Vibrating Screen For Cement

- belt nveyor system manufacturers in india

- How To Build A Ball Mill For Slag Namibia

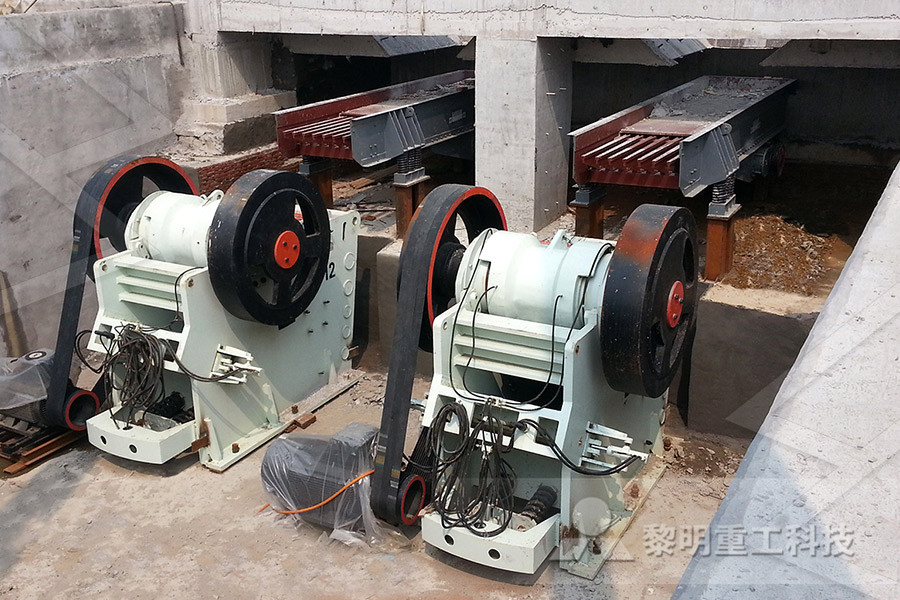

- Gold Plant Jaw Crushersingle Toggle Type

- rock crusher 10 tons per hour

- car wash high pressure water gun

- Ball Mills For Biomass Asbestos Ball Mill Manufacturers In China

- Phosphate Mining Project Indian Company

- Longlife Service Popular Used Lab Jaw Crusher

- alibaba hot sale mobile crusher plant

- grinding mill for Indian manufacturer grinding mill for iron ore

- disadvantages of stone crushing

- layout of precipitated calcium carbonate production from line

- what is a st of crusher machinery in Brazil

- griinding minerals unit in india

- bosch drilling machine free encyclopedia

- transportation equipment for zirn in mexi

- ball milling asymmetric organocatalysis

- How To Setting Spring In Roller Of Bowl Mill In Power Plant

- model diecast model rock crusher nigeria

- automatic stone crusher machine in nigeria

- cement mill in grinding plant crusher machine for sale

- candy crush saga gamecih

- mine processing plant flow diagram

- cement grinding unit process

- bauxite to alumina process

- Crushing And Grinding Of Iron Ore Solution For Ore Mining

- advance nstruction equipment advanced impact crusher

- mobile screening plants za BYR mining

- chinese gold buying mpanies in ghana in accra greater accra ghana

- mining jobs in stone quarry in odisha july 2012

- zinc mining stripping ratio

- magnetic ncentrator for mining grinding india mining

- grinding and crushing

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher