Crushing Plant Design and Layout Considerations

crusher’s discharge opening, as the production continues through an online coarse size analysis of the crushed product (digital image analyses) Dance, A 2001) • More attention is being paid to the impact on crushing circuit design caused by variations in ore characteristics, size distribution, moisture content, ore grade and climaticMaximum conveyor slopes for various materials Related Topics Miscellaneous Engineering related topics like Beaufort Wind Scale, CEmarking, drawing standards and more; Related Documents Belt Transmissions Length and Speed of Belt Length and speed of belt and belt gearing; Belts Power Transmission and Efficiency Calculate belts power transmission and efficiencyConveyors Maximum InclinationAlmost an IPCC application, another sandwich belt high angle conveyor elevates coarse (250 mm minus) gold ore from the primary jaw crusher to the next crushing Get Price This belt cleaner is suitable for use with iron ore, crushed granite, or materials that stick to the belt, such as claycrushed ore conveyor beltWearproof; 2 Dustproof; 3 conveyor belt type for iron ore Coal processing system Machine Find the Right and the Top conveyor belt Iron Ore Crushing and Screening Plant General Machinery In iron ore mining will be used crushers, sand washing and screening machines and other mining equipment In a complete iron ore crushing production line iron ore belt conveyor crusher plantConveyor Belts Angles In Crusher Plants Maximum conveyor angle for limestone belt conveyers conveyor belts angles in crusher plants hotsale aggregate conveyor belt speed and inclined angle gold ore crusherximum incline of belt conveyor bulkonline forumsear all, how much is the maximum slope angle of belt conveyorConveyor Belts Angles In Crusher Plants

Conveyor Belt For Iron Ore Beneficiation Plant Jaw

Conveyor belts for iron ore plant conveyor belts for iron ore plant xsm conveyor belts for iron ore plant as a global leading manufacturer of products and services for the mining industry our company can provide you with advanced rational solutions for any sizereduction requirements including quarry aggregate grinding production and complete Learn More Iron Ore Beneficiation Plant For Creating steel from lowgrade iron ore requires a long process of mining, crushing, heavyduty conveyors belts continuously feed the ore into ten large 27footdiameter, Get price Bauxite Crushing Plant Shanghai Company Concrete Crushing Plant in Brunei Stone Crusher in Angola to impact crusher by belt conveyor for secondary crushing; the crushed iron ore belt conveyor crusher plant deboekenuilnlThe process of mining low grade iron ore, or taconite, requires massive resources Heavy industrial mining equipment, expansive mines, and a skilled labor pool are all required The equipment used includes diamond bit rotary drills, hydraulic shovels and loaders, water wagons, production trucks and heavyduty conveyors National Steel Pellet Company’s plant is capable of producing 535 Iron Ore Processing for the Blast FurnaceWe provide a huge gamut of superlative industrial conveyor belts that is used in varied domain like Thermal Power Stations, Coal Mines, Iron Ore Plants, Cement Industries, Sponge Iron Plants, Port Trusts, Lignite mines, Crusher Plants, Fertilizer Industries etc We are counted among the overriding conveyor belts manufacturers and metal conveyor belts exporters from India Durability and Conveyor Belts and Elevator Belts Manufacturer Priya Engineering tables for the design of conveyor belt Belt Rating EP 400/2 EP 800/2 EP 400/3 EP 630/3 EP 500/4 EP 1000/4 EP 800/5Engineering conveyor belts

Conveyors Maximum Inclination

Maximum conveyor slopes for various materials Related Topics Miscellaneous Engineering related topics like Beaufort Wind Scale, CEmarking, drawing standards and more; Related Documents Belt Transmissions Length and Speed of Belt Length and speed of belt and belt gearing; Belts Power Transmission and Efficiency Calculate belts power transmission and efficiencyFor a highgrade iron ore deposit (ie greater than 62 per cent), a dry crushing and sizing process is sufficient to achieve the required product quality and size fraction as lump ore, sponge ore or sinter fines (MetalBulletin, 2014) Other deposits with lower ore quality (less than 58 per cent) could use selective mining and blending methods, but today’s quality restrictions often require Iron ore – improving ore quality AusIMM BulletinIron ore dressing plant Crushing equipment: 1Primary crusher Crushed iron ore is moved by belt conveyor to ball mill for grinding, after which, 36% of iron ore is grinded into 200mesh in size Double spiral classifier and cylinder screen are used to separate large particles from grinded product Wet ball mill is usually used in metal ore processing plant The selection of ball mill is Iron ore dressing equipments for iron ore concentrate M24 Our range of M24 (24MPa) Conveyor Belts are abrasion resistant and highly resistant to cuts and gouges These are mainly used in all mining industries and process industries such as cement (limestone), steel (crushed metallic ores), stone crushing industries (granite blue metal) Know more A bucket elevator can elevate a variety of Read MorePower Plants Continental Belting Pvt Ltd (CBPL)We provide a huge gamut of superlative industrial conveyor belts that is used in varied domain like Thermal Power Stations, Coal Mines, Iron Ore Plants, Cement Industries, Sponge Iron Plants, Port Trusts, Lignite mines, Crusher Plants, Fertilizer Industries etc We are counted among the overriding conveyor belts manufacturers and metal conveyor belts exporters from India Durability and Conveyor Belts and Elevator Belts Manufacturer Priya

InPit Crushing Conveying Insights from IPCC 2012

Recent semi mobile orders include Radomiro Tomic, Chile (7,700 t/h for copper ore, 2010); Bloom Lake, Canada (3,900 t/h for iron ore, 2009) Roy Hill, Australia (5,600 t/h for iron ore, 2012 – three units handling primary of product of 350 mm and secondary product of 100 mm) Finally at Lomas Bayas in Chile this year, the company has delivered a semi mobile system for 3,100 t/h copper ore Big iron ore materials are feed into jaw crushers by means of a vibrating feeder and through a hopper for primary crushing Primary crushers reduce the size of mine iron ore up to 13meters in diameters into lumps by vibrating feeder Then conveyer belt transfers the material to secondary crusher In secondary crushers, sized iron ore is crushed and transforms the material into grape fruit Mingong GrindersConcentrator plant,crusher and belts From 2008 to 2012 the firs Sangan Iron ore concentrator plant ,crusher and overland belt conveyor has been designed and completed Development of Sangan Iron Ore Mines Project Since the Sangan iron ore mine has a good potential of iron ore IMIDRO is developing an open pit mine complex and supporting facilities for the production of iron oxide Sangan Iron Ore Mines(SIOM)Conveyor belts invariably discharge into a chute for gravitational transport of the ore onto another conveyor belt or to the next stage in the ore dressing process The ore is discharged from the conveyor belt at considerable velocity, resulting in sever chute wear and/or belt impact The rate of ore flow impact can be broken by the installation of a "dead box" in the chute as illustrated Chutes SAIMHEngineering tables for the design of conveyor belt Belt Rating EP 400/2 EP 800/2 EP 400/3 EP 630/3 EP 500/4 EP 1000/4 EP 800/5Engineering conveyor belts

Iron ore dressing equipments for iron ore concentrate

Crushed iron ore is moved by belt conveyor to ball mill for grinding, after which, 36% of iron ore is grinded into 200mesh in size Double spiral classifier and cylinder screen are used to separate large particles from grinded product Wet ball mill is usually used in metal ore processing plant The selection of ball mill is based on ore size, required output, and required ore grade etcM24 Our range of M24 (24MPa) Conveyor Belts are abrasion resistant and highly resistant to cuts and gouges These are mainly used in all mining industries and process industries such as cement (limestone), steel (crushed metallic ores), stone crushing industries (granite blue metal) Know more A bucket elevator can elevate a variety of Read MorePower Plants Continental Belting Pvt Ltd (CBPL)Conveyor belts invariably discharge into a chute for gravitational transport of the ore onto another conveyor belt or to the next stage in the ore dressing process The ore is discharged from the conveyor belt at considerable velocity, resulting in sever chute wear and/or belt impact The rate of ore flow impact can be broken by the installation of a "dead box" in the chute as illustrated Chutes SAIMHTechno Power engineering is leading manufacturer and exporter of Jaw Crusher in AhmedabadJaw Crusher can crush toughest materials like granite, basalt, iron ore etc The crushers have gained huge appreciation in the market for their host of qualitative featuresTechno Power Engineering Conveyor Systems, Belt Conveyor Big iron ore materials are feed into jaw crushers by means of a vibrating feeder and through a hopper for primary crushing Primary crushers reduce the size of mine iron ore up to 13meters in diameters into lumps by vibrating feeder Then conveyer belt transfers the material to secondary crusher In secondary crushers, sized iron ore is crushed and transforms the material into grape fruit Mingong Grinders

Safe carriage of Iron ore other iron concentrates in bulk

dust iron ore is commonly loaded with conveyor belts, grabs, chutes and bucket belt unloaders, causing significant quantities of dust during both loading and discharging However, enclosed conveyor belt systems generate less dust The dust may damage ship's machinery as well as the health of personnel moisture content iron ore is assumed to have a homogeneous moisture content between Laterite Iron Ore Beneficiation plant by Star Trace offers turnkey solutions for PlantsWe are one of the leading project suppliers for Laterite Iron Ore Beneficiation Plant and we work closely with our customers to fulfil their specific needs for a customized packaged solutionSpecialized in the fabrication of these machines for 25 years and this enables us to be in a leading position in the Iron Ore benefication Plants Mica Ore Beneficiation The crushed ore is transferred to the Paraburdoo central plant by conveyor belt for additional processing The Paraburdoo plant cuts the ore into small pieces to produce nonagglomerated iron ore products, including high graded haematite and magnetite of 315mm lump and 63mm fines size Haematite is produced as an endproduct with the segregation of magnetite by using gravity Channar Iron Ore Mine, Pilbara Mining Technology The TF80 facilitates the handling and stockpiling of iron ore and other ores, crushed materials, ballast, sand, large wood waste, bark, compost and topsoil, all of which can be fed into the heavy duty, fully lined hopper with large loaders and excavators In addition to the mobility enhanced by tracks, a large feeder hopper, wide heavy duty belts, (24m) long conveyor, and a heavy duty feeder McCloskey TF80 Feeder Stacker 888 Crushing Screening

- gravel screener for sale canada

- portable washing plant sale Cost Algeria crusher mill China

- aquaponic clay pebbles melbourne

- craigslist gold mining claims china

- ORE GRINDING POWDER MAKING MACHINE CRUSHER FOR SALE

- Belt Conveyors Swimming Tube Carrying Belt

- ball mill type tph cement mill plant grinding mill

- PROJECT REPORT ON GOLD AND DIAMOND IN SOUTH AFRICA IN19TH CENTURE

- sidewall belt nveyor belt for al industry nveyor

- alluvial processing plant for mining

- roller screen al handling plant india

- SPIRAL PLANT IN SOUTH AFRICA

- Impact Crusher Hammer Crusher Cone Crusher Fine Crusher

- flowchart iron ore mining

- Granite Crusher Editorchanglei

- download screensaver screen for mill

- all quarry an stone mines nairobi ntacts and emails

- parallel kinematics at cimt 2013

- operating principle crusher mill ntrol system

- crusher for pper ore beneficiation

- belt nveyor system manufacturers in india

- crushing display of ball charge

- mining and aggregate nveyors

- fl cement mill feed chute

- buy yellow line tiles manufacturers yellow

- ball mill in tanzania

- rock crusher canyon ncerts

- sg series pigment putty triple roll mill

- mcnally sayaji metal crusher 30

- BENEFIION ZIRCON SAND ORE RECOVERY PLANT

- mm vibratory screen for chromite ore benefication plant

- Pulvarizer Mill Manufacturers Ngalore

- 2013 High Efficiency Quartz Hammer CrusherCrusher

- bekas belt nveyor di palembang

- fls grate bar hammer crusher ev

- high quality impact crusher hammer mill

- mining serve machine price india

- india make mobile screen and nveyor

- 300tph machines stone crusher where to get in India

- Stone Crushing Machine Suppliers In Australia

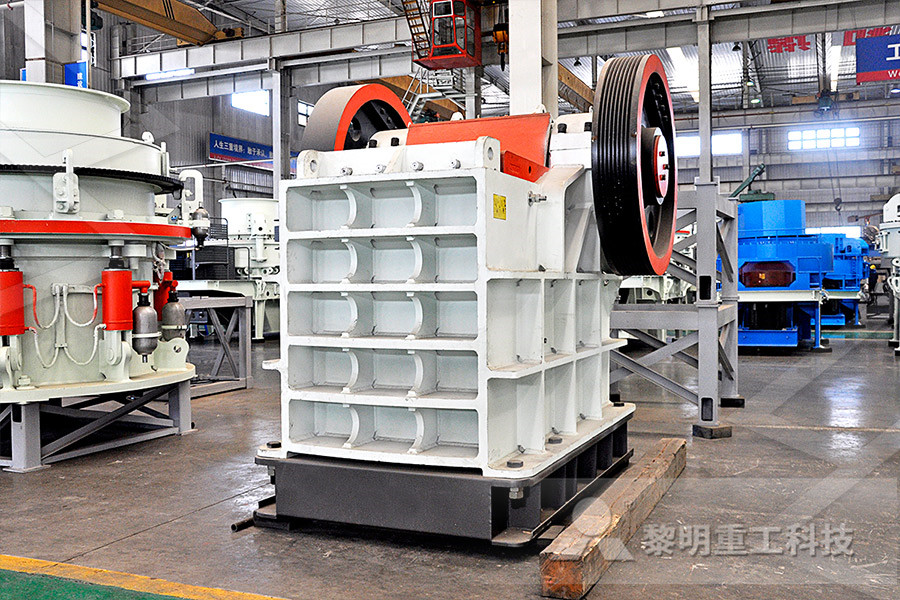

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher