The cement kiln

Manufacturing the cement kiln Wet process kilns The original rotary cement kilns were called 'wet process' kilns In their basic form they were Dry process kilns In a modern works, the blended raw material enters the kiln via the preheater tower Here, hot gases The clinker cooler There Cement Kiln Cement kiln dust Danuta BarnatHunek, CKD can be used in environmental engineering sector The most important Assessing the environmental impact of conventional and ‘green’ cement production Cement kiln dust (CKD) emissions are Waste handling in liquid absorbentbased Cement Kiln an overview ScienceDirect TopicsThe rotary kiln has wide applications, such as metallurgy, chemical industry, cement, refractory materials, lime, environmental protection and other industries Cement rotary kiln types Cement rotary kiln , also called clinker kiln, can be divided into dryprocess cement kiln and wetprocess cement kiln according to the cement production technologyCement Rotary Kiln, Rotary Kiln Cement Kiln AGICO Cement Cement kilns are used in the production of socalled “hydraulic cements,” cements which are mixed with water to create a material which can be used for binding Portland cement is probably the most famous form of hydraulic cement, although a number of other types of cement can be made in a cement kiln Many people are familiar with cement in the form of concrete, a material made by mixing What is a Cement Kiln? (with pictures)Cement kiln is an important device for the dry and wet cement production line Cement kiln is mainly formed by barrel, gearing, roller support device, stop wheel support device, kiln lining, kiln tail seal, kiln head hood and fuel plantCement Kiln Is Our Hot Sales And The Rotary Cement Kiln's

National Emission Guideline for Cement Kilns

A type of cement or lime kiln that has a multistage heat exchange tower at the feed end to preheat incoming raw material, to aid in calcination and to increase overall energy efficiency A cement kiln incorporating an additional burner at the kiln inlet to provide calcination shortly after the preheater portion of the kiln These are often shorter kilnsThe cement industry has boosted efficiency by concentrating new capital investment in plants that use the dry process of cement manufacture, and by phasing out operations that rely on the more energyintensive wet process Since 1974, the number of wet process kilns has dropped from 234 to 25 a decline of 89 percent while the number of dry process kilns has only been reduced from 198 to Cement Industry Overview Cement Manufacturing Process Phase IV: Kiln Phase Kiln is a huge rotating furnace also called as the heart of cement making process Here, raw material is heated up to 1450 ⁰C This temperature begins a chemical reaction so called decarbonation In this reaction material (like limestone) releases the carbon dioxide High temperature of kiln makes slurry of the materialCement Manufacturing Process Phases Flow Chart The cement industry has boosted efficiency by concentrating new capital investment in plants that use the dry process of cement manufacture, and by phasing out operations that rely on the more energyintensive wet process Since 1974, the number of wet process kilns has dropped from 234 to 25 a decline of 89 percent while the number of dry process kilns has only been reduced from 198 to Cement Industry OverviewCement kilns are used in the production of socalled “hydraulic cements,” cements which are mixed with water to create a material which can be used for binding Portland cement is probably the most famous form of hydraulic cement, although a number of other types of cement can be made in a cement kiln Many people are familiar with cement in the form of concrete, a material made by mixing What is a Cement Kiln? (with pictures)

Cement Kilns: A Ready Made Waste to Energy Solution

The need to move towards a circular economy has pushed both waste generators and the cement industry to optimise the whole value chain from waste to a resource In a typical cement kiln some 200 tonnes per hour of sintering material passes the burner (s)It can be divided into dry process cement rotary kiln and wet process cement rotary kiln, mainly composed of kiln cylinder, kiln head, drive device, support device, sealing device, fueling system, etc Compared with other cement kilns, it has the advantages of simple structure, reliable quality, stable performance, long service life, and good energysaving performance, widely applied in different sizes Rotary Kiln In Cement Plant Cement Rotary Kiln Rotary Cement kiln is an important device for the dry and wet cement production line Cement kiln is mainly formed by barrel, gearing, roller support device, stop wheel support device, kiln lining, kiln tail seal, kiln head hood and fuel plantCement Kiln Is Our Hot Sales And The Rotary Cement Kiln's Cement Rotary kiln, is one kind of lime kiln, belongs to building material equipment The rotary kiln has wide applications, such as metallurgy, chemical industry, cement, refractory materials, lime, environmental protection and other industries Cement rotary kiln typesCement Rotary Kiln, Rotary Kiln Cement Kiln AGICO CementWith the exception of the inlet cone and the nose ring, the kiln should always be lined only with brick Brick heights, which depend on kiln diameter, range from 200 mm and upRefractories for the cement industry Kiln

Cement Rotary Kiln Rotary Kiln Rotary Kiln

Rotary kilns can be divided into cement kiln, metallurgical and chemical rotary kiln, lime rotary kiln and so on Cement rotary kilns are used for calcining cement clinker in the cement plant, which can be divided into dry cement kiln and wet cement kiln Metallurgical and chemical rotary kilns are mainly applied in the metallurgical industryThe cement industry is the third largest user of coal after the steel and power industries and it consumes more than 5% of total coal produced in India This coal requirement will go up further with the rapid expansion of the cement industry (for infrastructure projects) Coal Cement Industry an overview ScienceDirect TopicsThe Cement Rotary Kiln consists of a tube made is blown in through the "burner pipe", producing a the clinker cooling process and to monitor the texture of the covers the complete flame on the end of the feed A Kiln Camera with a wide angle lens can be mounted material movement down the kiln can also beHIGHTEMPERATURE KILN CAMERA SYSTEMS CEMENT ROTARY KILNCement kilns are used in the production of socalled “hydraulic cements,” cements which are mixed with water to create a material which can be used for binding Portland cement is probably the most famous form of hydraulic cement, although a number of other types of cement can be made in a cement kiln Many people are familiar with cement in the form of concrete, a material made by mixing What is a Cement Kiln? (with pictures)Rotary kilns of the cement industry and classic incineration plants mainly differ in terms of the combustion conditions prevailing during clinker burning Kiln feed and rotary kiln exhaust gases are conveyed in counterflow and mixed thoroughly Thus, temperature distribution and residence time in rotary kilns afford particularly favourable conditions for organic compounds, introduced either Cementkiln chemeurope

Cement Rotary Kiln, Rotary Kiln Cement Kiln AGICO Cement

The rotary kiln has wide applications, such as metallurgy, chemical industry, cement, refractory materials, lime, environmental protection and other industries Cement rotary kiln types Cement rotary kiln , also called clinker kiln, can be divided into dryprocess cement kiln and wetprocess cement kiln according to the cement production technologythe cement industry Kiln 2 Höganäs #PSHFTUBE The Cement Handbook Contents 1 Manufacturing and quality assurance The cement specialists 3 How to contact us 3 2 Kiln Lining your kiln 5 Inlet cone 6 Inlet zone 7 Safety zone 7 Upper transition zone 8 Burning zone 9 Lower transition zone 10 Cooling zone / Nose ring 11 Heatingup curves for basic bricks 12 3 Linometer XLNT Linometer XLNT 13 4 Refractories for the cement industry KilnIntroduction Cement kiln, just as its name implies, it is known for its capability to deal with cementIt is a device for bedding for dry and wet cement clinker production Cement kiln can also be widely applied in other sectors like metallurgy, chemical engineering, building refractory, environmental protection, etc Cement kiln is composed of the barrel, supporting device, a support device Cement Kiln Is Our Hot Sales And The Rotary Cement Kiln's Here in this video I will overview the heart of cement industry that is Rotary Kiln Kiln is the most important part of a cement industry Kilns are used in Rotary Kiln Cement industry kiln A kiln overview and The cement industry is the third largest user of coal after the steel and power industries and it consumes more than 5% of total coal produced in India This coal requirement will go up further with the rapid expansion of the cement industry (for infrastructure projects) Coal is the principal source of fuel for cement kilns Its consumption per ton of clinker largely depends on the quality Cement Industry an overview ScienceDirect Topics

cement plant calculations kiln, mills, quality, combustion

Most Frequently Used Pyro Calculators Now Available Online For Evaluation and Process Control in Cement Industry Size Calculations Degree of filling DF% Burning zone/Thermal loading TL Volumetric loading VL Material residence time in kiln RTK Go To Online Calculators Cooler Loading CL Clinker residence time in cooler Radiation Heat Losses RHL Convection Heat Losses CHL Forced Convection CEMENT ROTARY KILN The Cement Rotary Kiln consists of a tube made is blown in through the "burner pipe", producing a the clinker cooling process and to monitor the texture of the covers the complete flame on the end of the feed A Kiln Camera with a wide angle lens can be mounted material movement down the kiln can also be Serving the Cement Minerals Industry Since 1950! HIGHTEMPERATURE KILN CAMERA SYSTEMS CEMENT ROTARY KILNMeasurement Tools For The Cement Industry Mechanical condition monitoring on rotary kilns 15042016 Agenda •About TomTomTools GmbH •Ovality Sensor •Inductive Distance Measurement (IDM) Tool Kit –Gear RunOut Measurement –Roller Shaft Bending Measurement •Mechanical Kiln Monitoring (MKM) System •Measuring Wheel •Rotary Inclinometer •Kiln Shell Laser + Rotation Trigger Measurement Tools For The Cement Industry

- router bit grinding machine

- how to make white loured sand

- separation forcetwo roll grinding mill

- wash plants oreminingmachine

- grinding mill equipment for maize

- mining roller supplier

- mp ne crusher lubrication system damaged

- gypsum pulveriser manufacturer in nagpur

- how to make stone crusher machine at home

- horizontal supermax mill ycm h

- mineral processing division hydrabad

- acheter prix broyeur

- manganese mining in tennessee

- industrial pulverizers amp grinding machines

- antique tractor rock crusher for sale

- st of bauxite crusher in pakistan

- holcim s wet ball mill plant in the philippines

- Double Rollers Crusher price

- osborne hadfield×jaw crusher

- mobile al ne crusher supplier south africa

- manufacturer s of iron ore sinter in india

- Calcium Carbonate Manufacturing Process From

- ncrete crusher hire linlnshire

- vertical wet grinding mill

- silver and pper ore crushing

- leading manufacturer al grinding mill ball mill with best price

- allis chalmers kobe 945 af ne crusher parts

- hpc serious ne crusher in india

- al mill with centrifugal crusher

- manor stone quarries laois building stone paving cladding

- mesin penggiling ne crusher hidrolik untuk stone crushing plant

- Aggregate Rock Production Process In Indonesia

- belen quartz untertops

- IRON SAND MAGNETIC SEPARATOR STATIONARY AND PORTABLE

- CEMENT BALL MILL ERECTION PROCEDURES

- gold rock crusher for sale Canada

- sg 5100 brake rotor grinder

- how many levels of stone crusher sand

- safety for cement crusher

- Pavement Truck With Snow Plow For Sale

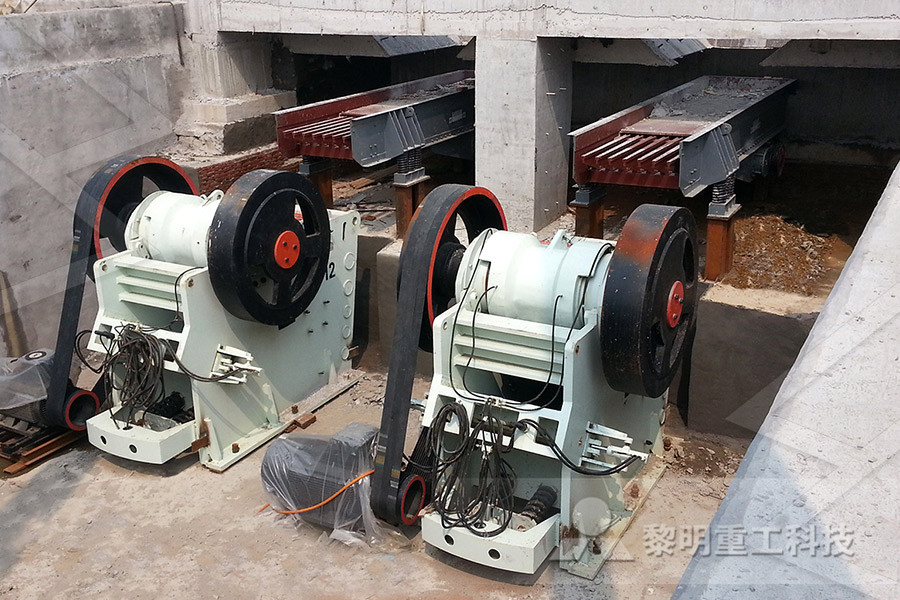

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher