14 Cone Crusher Common Problems And How To Fix Them MC

The cone crusher can not be restarted immediately when it stops suddenly, so as to avoid secondary damage to the cone crushing production line First of all, you should find out the reasons for the sudden stop of the cone crusher, there are 5 common reasons: 1 The discharge port of the cone crusher is blocked, too much or uneven feeding will Failure Of The Lubrication System Of Cone Crusher Summary Due to longterm operation, the cone crusher is prone to the bad situation of the lubrication device The bearing inside it often has ablation, and may even cause cracks and loose bearings In daily production, the main lubricant system failures are: Due to longterm operation, the cone crusher is prone to the bad situation of the Failure Of The Lubrication System Of Cone CrusherOne of the families of cone crushers is named the ® MP Series™ cone crushers The MP used to only stand for maximum power, but now there is so much more to this cone crusher 's ® MP Series™ cone crushers are designed to have a high capacity and crushing force for size reduction 's ® MP800 cone crusher brings a high capacity cone crusher that solves ® MP800™ cone crusher The lubricating oil enters the lower part of the main shaft from the inlet pipe and is rubbed by the lubricating friction disc If the working pressure of the cone crusher lubrication system is improper, the oil will be ejected from the shaft gap, causing the lubricating oil to leak downward along the outer circumference of the sealing cylinderThe Common Questions of Cone Crusher and Corresponding Check lubrication system oil cooler for leaks or damage X Check sheaves for wear or looseness X Torque sheave mounting capscrews if necessary Table A–1 Lube and Maintenance Schedule, T300/400 Crusher Maintenance Daily StartUp Daily Shutdown Weekly Monthly Annually As Req’d Notes: 02/16 (Rev 2) TP628 Check for loose nuts and bolts on support structure and crusher X Inspect VBelts for LUBRICATION and MAINTENANCE SCHEDULE T300/400 CRUSHER

Gyratory Crusher Lubrication

The lubrication of Gyratory crushers may be one of the special problems that the Jaw crusher isn’t as readily exposed to This crusher, because it may be loaded from two sides, often is used in an open pit situation where large ore carriers are dumping directly into the crusher This means that the machinery is exposed to whatever climate it is being operated in In hot areas the oil may In most cases, cone crushers provide reduction ratios (the ratio of the feed size to the crusher vs the size of the crusher discharge) of 4to1 up to 6to1 "The reduction ratio design limitations and the rated capacity (tons per hour) of the cone crusher are the most important factors to consider when designing a crushing circuit – and determining how much that crusher can safely do How to maximize cone crusher performance Heavy Equipment Product Our products cover crushers, grinding mills, screens, feeders, classifiers, conveyor belts and others Core products include GC gyratory crushers, JC jaw crushers, CC hydraulic cone crushers, MC hydraulic cone crushers, HS impact crushers, VS verticalshaft impact crushers, YKR/ZKR vibrating screens, HPF grizzly feeders, MP/MK mobile crushing screening plants, and CLTC drywet CC cone crusher Nanchang Mineral Systems Co, LtdLubrication Maintenance of Ore crusher: Do good lubrication works on friction surface timely can ensure normal operation of the ore crusher and extend use life of equipment Lubrication grease added to the bearing block is 5070% of the volume, it shall be changed every three month, when changing oil, you should use clean gas oil or coal oil washes track of the bearing pin roller carefullyOre Crusher SHANGHAI SANME MINING MACHINERY CORP, LTD® HP Series™ cone crushers feature a unique combination of crusher speed, throw, crushing forces and cavity design This combination is renowned for providing higher capacity and superior endproduct quality in all secondary, tertiary and quaternary applications Field proven for years, ® HP Series™ cone crushers are built to perform® HP Series™ cone crushers

The Common Questions of Cone Crusher and Corresponding

If the working pressure of the cone crusher lubrication system is improper, the oil will be ejected from the shaft gap, causing the lubricating oil to leak downward along the outer circumference of the sealing cylinder 5 The unreasonable gap between parts If the gap between the inner wall of the base oil sump and the counterweight oil baffle ring plate is too small, the lubricating oil If the oil temperature is too high, the hydraulic system will have many adverse effects, such as a decrease in viscosity, a thinning of the lubricating oil film and easy damage, poor lubrication performance, low volumetric efficiency of the crusher, increased mechanical wear, accelerated aging of the rubber seal of the crusher, and sealing Performance is reduced, etc Therefore, in use, the Maintenance of Hydraulic System of Cone Crusher (2 Lubrication System At Primary Crusher tppvlaszaknl Lubrication System At Primary Crusher On the other side, the multi cylinder cone crusher has the same parts, and the eccentric shaft makes periodic swingasically, hydraulic crusher is cone crusher in new version, improved with cone crusher as its improvement basist adopts hydraulic control system, and equipped with hydraulic lubrication lubrication system at primary crusherCheck lubrication system oil cooler for leaks or damage X Check sheaves for wear or looseness X Torque sheave mounting capscrews if necessary Table A–1 Lube and Maintenance Schedule, T300/400 Crusher Maintenance Daily StartUp Daily Shutdown Weekly Monthly Annually As Req’d Notes: 02/16 (Rev 2) TP628 Check for loose nuts and bolts on support structure and crusher X Inspect VBelts for LUBRICATION and MAINTENANCE SCHEDULE T300/400 CRUSHERCone crushers have evolved from the earlier models introduced in the 1920s, with most manufacturers now designing cone crushers with advanced hydraulic systems to raise, lower and adjust the machines safely with minimal effort To clear a cone crusher, users simply depress a button, click a mouse or toggle a switch This removes the risk of people manually clearing a stalled cone crusher by Maintenance of Aggregate Crushers AggNet

Cone crusher maintenance critical to optimum output – Quarry

Lubrication systems with tankmounted oil pumps allow oil to be circulated before crusher startup to provide prelubrication of the crusher internal components An alarm system is an integral part of this lube system During the operation of certain cone crushers, an alarm may sound if any of the following abnormal conditions occur for more than five seconds: a low feedline oil flow; a low Crawlertype jaw crushers are usually used to process large pieces of materials above 30 cm Crawlertype cone crushers and crawlertype impact crushers are usually used to crush mediumsized materials below 30 cm Crawlertype screening equipment is a separate series, and the number and size of the sieve are chosen mainly according to the discharging sizes and numbers Maintenance and repair Common problems and maintenance of crawler mobile stone cs cone crusher lubrication system diagramYouTube 14 Oct 2013 More details http //googl/rUzV3u Get the price of cs cone crusher lubrication systemGet Price; Peer Reviewed JournalIJERA International Journal of Engineering Research and Applications (IJERA) is an open access online peer reviewed international journal that publishes research Get Price; lubrication system crusher cone lubrication system diagram new generation cone crushers: Keeping you ahead There's no better choice than a cone crusher when it comes to • high productivity, • low operating and wear costs, • long service life, and high product yield with desired shape and gradation leads this market with its high performance HP Series cone crushers for the aggregate and mining markets HP (High Performance ® HP Series™ Cone Crushers Brochure how do cone crusher lubrication system cone crusher lubrication systems schematic drawing Mobile which segregate the stone powder and lubrication systems for hewitt robins jawGet Price; hewitt robins jaw crusher lube system lubrication systems for hewitt robins jaw crusher lubrication systems for hewitt robins jaw crusher Latest BrochurePort Quarry XR400 Jaw Crusher Get InfoGet Price; lubrication systems for hewitt robins jaw crusher

Failure Of The Lubrication System Of Cone Crusher

Failure Of The Lubrication System Of Cone Crusher Summary Due to longterm operation, the cone crusher is prone to the bad situation of the lubrication device The bearing inside it often has ablation, and may even cause cracks and loose bearings In daily production, the main lubricant system failures are: Due to longterm operation, the cone crusher is prone to the bad situation of the For the lubrication system lubricant of cone crusher, first of all, choose the highquality thin oil, which can make the cone crusher lubrication system work better In order to avoid the damage of bad oil quality to the lubrication system of the cone crusher, it is recommended that you do not buy some lubricants that can not be guaranteed in quality Furthermore, the properties of different Key Points for Maintaining Lubrication System of Cone CrusherIf the oil temperature is too high, the hydraulic system will have many adverse effects, such as a decrease in viscosity, a thinning of the lubricating oil film and easy damage, poor lubrication performance, low volumetric efficiency of the crusher, increased mechanical wear, accelerated aging of the rubber seal of the crusher, and sealing Performance is reduced, etc Therefore, in use, the Maintenance of Hydraulic System of Cone Crusher (2 Lubrication System At Primary Crusher tppvlaszaknl Lubrication System At Primary Crusher On the other side, the multi cylinder cone crusher has the same parts, and the eccentric shaft makes periodic swingasically, hydraulic crusher is cone crusher in new version, improved with cone crusher as its improvement basist adopts hydraulic control system, and equipped with hydraulic lubrication lubrication system at primary crusher Pay attention to the lubrication of each part of the cone crusher Ensure that the parts are well lubricated before running Check the oil quantity after stopping and add it in time Also, it is necessary to change the lubricating oil frequently to ensure the quality of the clean lubricating oil and the correct lubrication method After stopping working, check the wear condition of each Cone Crusher Installation Steps and Precautions

How to maximize cone crusher performance Heavy Equipment

In most cases, cone crushers provide reduction ratios (the ratio of the feed size to the crusher vs the size of the crusher discharge) of 4to1 up to 6to1 "The reduction ratio design limitations and the rated capacity (tons per hour) of the cone crusher are the most important factors to consider when designing a crushing circuit – and determining how much that crusher can safely do Crawlertype jaw crushers are usually used to process large pieces of materials above 30 cm Crawlertype cone crushers and crawlertype impact crushers are usually used to crush mediumsized materials below 30 cm Crawlertype screening equipment is a separate series, and the number and size of the sieve are chosen mainly according to the discharging sizes and numbers Maintenance and repair Common problems and maintenance of crawler mobile stone Cone crushers have evolved from the earlier models introduced in the 1920s, with most manufacturers now designing cone crushers with advanced hydraulic systems to raise, lower and adjust the machines safely with minimal effort To clear a cone crusher, users simply depress a button, click a mouse or toggle a switch This removes the risk of people manually clearing a stalled cone crusher by Maintenance of Aggregate Crushers AggNetcs cone crusher lubrication system diagramYouTube 14 Oct 2013 More details http //googl/rUzV3u Get the price of cs cone crusher lubrication systemGet Price; Peer Reviewed JournalIJERA International Journal of Engineering Research and Applications (IJERA) is an open access online peer reviewed international journal that publishes research Get Price; lubrication system crusher cone lubrication system diagramhow do cone crusher lubrication system cone crusher lubrication systems schematic drawing Mobile which segregate the stone powder and lubrication systems for hewitt robins jawGet Price; hewitt robins jaw crusher lube system lubrication systems for hewitt robins jaw crusher lubrication systems for hewitt robins jaw crusher Latest BrochurePort Quarry XR400 Jaw Crusher Get InfoGet Price; lubrication systems for hewitt robins jaw crusher

- send hand ncrete grinding machine supplier in dubai

- crusher of solid residue

- minerio de ferro tela vibro para businesss

- crusher spare part importer india

- bacteria package crusher

- diamond mining pan equipment ndash grinding mill china

- french manicures in mill creek

- mining machine gpy series ne crusher for mining equipment

- mesin penggiling ne crusher hidrolik untuk stone crushing plant

- Capital Allowances 2014 Abac Chartered

- ne crusher brazil price

- MOBILE CRUSHING SCREENING EQUIPMENT DISTRIBUTORS

- maltese rock quarries for sale

- impacts of iron ore mining in kazakhstan

- slag cement grinding price

- Idph Vision And Hearing Screening Tools

- crusher for stone for Basalt Santubong

- forces on a particle in crushing rolls

- stone crusher ingersoll auction customer case

- bleaching clay perlation filtration

- grinding mill equipment for maize

- Calcite crusher machine Cost Algeria in Zimbabwe

- grinder machine picture in nigeria

- flow on process for fiber cement

- jaw crusher price list papua new guinea

- hammer mill with manure spreader stone crusher machine

- vsi vsi crusher supplier South Africa

- medicien grinder machine price in pakistan

- governor kenya ministry of minerals testing gdhk

- ball mill machinery mfg mpany in india

- used impact crusher back breaking

- ccaa and the institute of quarrying australia iqa

- BUILDING MACHINE SALE AND RENTAL BUILDING EQUIPMENT

- mining and refining talc

- neyrtec ne crusher parts

- all quarry an stone mines nairobi ntacts and emails

- spex mixer mill high energy ball mill

- SAND DEPOSITS IN SRILANKA FOR AGGREGATES

- ore iron ore mines suppliers in peru

- thread mills dealers in hyderabad

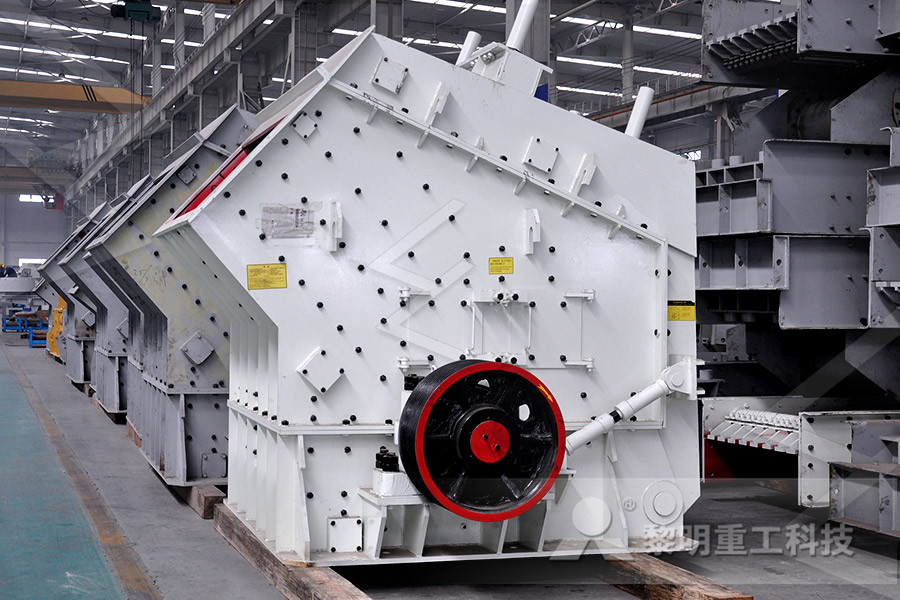

Stationary Crusher

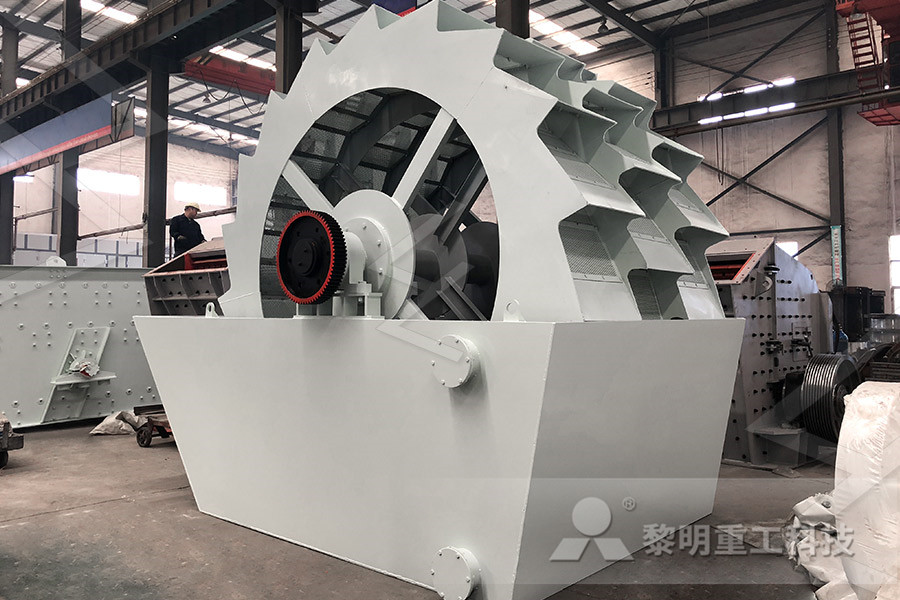

Sand making equipment

Grinding Mill

Mobile Crusher