Calcium carbonate manufacturing process

Calcium carbonate manufacturing process Posted: Calcium carbonate is usually divided into heavy calcium carbonate/ ground calcium carbonate powder and light calcium carbonate/ precipitated calcium carbonateGround calcium carbonate process refers to the ground calcium carbonate manufacturing or production process, in which raw materials are ground to fine and even ultrafine ground calcium carbonate powder Usually, limestone or marble, which consist mainly of calcium carbonate, are used as the basic for ground calcium carbonateDaswell Ground Calcium Carbonate Process CaCO₃ Plant Precipitated calcium carbonate manufacturing process Posted: Precipitated calcium carbonate/light calcium carbonate is a kind of calcium carbonate Precipitated calcium carbonate powders with a fineness of 125 mesh, 200 mesh, 225 mesh, 300 mesh, 600 mesh, 800 mesh, and 1250 mesh are obtained through precipitated calcium carbonate processing equipmentPrecipitated calcium carbonate manufacturing processConsito developed knowhow and technologies for Calcium Chloride production units as 36% solution, 7578% flakes or 9497% granules, basing on reaction between limestone and hydrochloric acid Production process Calcium chloride is produced as a product solution from reaction of calcium carbonate and hydrochloric acid upon the following reaction:calcium carbonate manufacturing process from limestoneGround calcium carbonate, commonly referred to as GCC, is primarily based on limestone and chalk in the UK, though marble stone is imported and processed at a few locations Precipitated Calcium Carbonate (PCC) is produced through a recarbonisation process or as a byproduct of some bulk chemical processesBCCF Calcium Carbonate Calcium Carbonate Processing and

calcium carbonate manufacturing process from limestone

Manufacturing Process Calcium carbonate is often made into chalk or limestone, but is also the main ingredient in Tums This compound is a raw material, and is also the most commonly found organic compound It can be found in many places, for example: rocks, caves, and even sea shells! Although calcium carbonate can be used as chalk, it can also be used in edible items [24/7 online] calcium Calcium cyanamide (CaNCN) is a fertilizer Calcium carbide is heated with nitrogen gas stream in 1000 0 C to manufacture calcium cyanamide Problems of calcium carbide manufacturing process Calcium carbide plant causes to environmental pollutionCalcium Carbide and Acetylene manufacturing processGround Calcium Carbonate – Produced via extraction and processing of naturally occurring deposits GCC crystal shape is irregularly rhombohedral and has a broader size distribution Precipitated Calcium Carbonate – Produced via chemical precipitation via a carbocation process or as a byproduct of some bulk chemical processesCalcium Carbonate (CaCO3) Uses, Preparation, Properties Manufacturing Process Calcium carbonate is often made into chalk or limestone, but is also the main ingredient in Tums This compound is a raw material, and is also the most commonly found organic compound It can be found in many places, for example rocks, caves, and even sea shells! Although calcium carbonate can be used as chalk, it can also be used in edible items GCSE CHEMISTRY calcium carbonate manufacturing process from limestoneManufacturing Process Calcium carbonate is often made into chalk or limestone, but is also the main ingredient in Tums This compound is a raw material, and is also the most commonly found organic compound It can be found in many places, for example: rocks, caves, and even sea shells! Although calcium carbonate can be used as chalk, it can also be used in edible itemsManufacturing Process Tums

Calcium Carbonate Powder Manufacturing Process Praveen

This video shows calcium carbonate powder manufacturing process of Praveen Mineral Chemical (PMC) The process describes how PMC offers calcium powder thatCalcium carbonate is one of the most abundant materials present in nature with the chemical formula CaCO3 Calcium carbonate also called limestone is an example of a metal carbonate used in the Solvay processCalcium Carbonate (CaCO3) Uses, Preparation, Properties Calcium carbonate is used in paper mill as a filler material in the alkaline papermaking process Now a days Calcium carbonate dominant over other papermaking filler materials; though at the first stage of papermaking kaolin was 1st choice The main reason behind the preference of calcium carbonate is the demand for brighter and bulkier paper There are significant benefits to the use of Calcium Carbonate pulp paper millCalcium carbonate processing plant is a production line that obtaining ground calcium carbonate powder by grinding limestone or marble Usually there are a complete set of machinery needed for the calcium carbonate production line And some calcium carbonate manufacturing plants are also equipped with calcium carbonate coating machine, so that both natural coated and uncoated calcium carbonate Solutions for Calcium Carbonate Processing Plant Daswell Manufacturing Process Calcium carbonate is often made into chalk or limestone, but is also the main ingredient in Tums This compound is a raw material, and is also the most commonly found organic compound It can be found in many places, for example: rocks, caves, and even sea shells! Although calcium carbonate can be used as chalk, it can also be used in edible items [24/7 online] calcium calcium carbonate manufacturing process from limestone

calcium carbonate manufacturing process from limestone

Manufacturing Process Calcium carbonate is often made into chalk or limestone, but is also the main ingredient in Tums This compound is a raw material, and is also the most commonly found organic compound It can be found in many places, for example rocks, caves, and even sea shells! Although calcium carbonate can be used as chalk, it can also be used in edible items GCSE CHEMISTRY Consito developed knowhow and technologies for Calcium Chloride production units as 36% solution, 7578% flakes or 9497% granules, basing on reaction between limestone and hydrochloric acid Production process Calcium chloride is produced as a product solution from reaction of calcium carbonate and hydrochloric acid upon the following reaction:calcium carbonate manufacturing process from limestoneThe process flow diagram shows precipitated calcium carbonate (PCC) production from limestone[/caption] Calcination Initially, the limestone from a quarry is stored in bins Typical extracted limestone contains about 75 wt% of CaCO3 Mined limestone is crushed in a jaw crusher and calcined (burned) in a verticalshaft lime kiln at about 1,000°C In the kiln, the calcium carbonate present in Precipitated Calcium Carbonate from Limestone Chemical Sodium carbonate manufacturing process, solvay process Sodium carbonate (washing soda) is a white crystalline solid It exists as a decahydrate ( Na 2 CO 310H 2 O) compound Sodium carbonate is manufactured by solvay process in industrial scale and have very industrial and domestic usesSodium carbonate manufacturing process, solvay processConsito developed knowhow and technologies for Calcium Chloride production units as 36% solution, 7578% flakes or 9497% granules, basing on reaction between limestone and hydrochloric acid Production process Calcium chloride is produced as a product solution from reaction of calcium carbonate and hydrochloric acid upon the following reaction:calcium carbonate manufacturing process from limestone

calcium carbonate manufacturing process from limestone

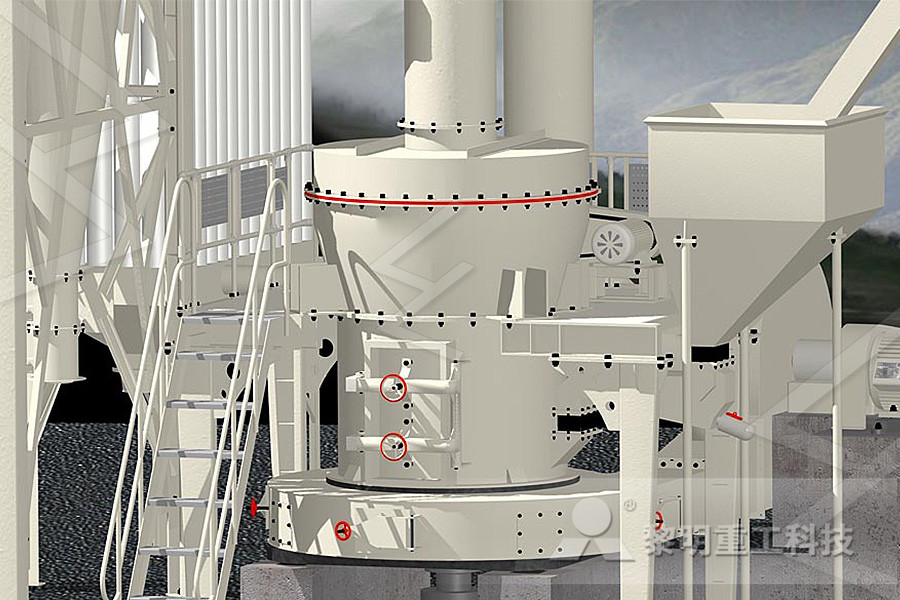

Manufacturing Process Calcium carbonate is often made into chalk or limestone, but is also the main ingredient in Tums This compound is a raw material, and is also the most commonly found organic compound It can be found in many places, for example: rocks, caves, and even sea shells! Although calcium carbonate can be used as chalk, it can also be used in edible items [24/7 online] calcium Calcium Carbonate Manufacturing Process From Limestone We are a largescale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment, milling equipment, mineral processing equipment and building materials equipment And they are mainly used to crush coarse minerals like gold and copper ore, metals like steel and iron, glass, coal Calcium Carbonate Manufacturing Process From LimestoneCALCIUM CARBONATE Project Report Manufacturing Process Cost Investment Required Report includes feasibility report, profitability analysis, raw materials, break even points, formulations and formula and much moreProject Report on CALCIUM CARBONATE Manufacturing Ground Calcium Carbonate Manufacturing Process Generally, the processing includes washing, sorting of undesirable contaminants, grinding, size classification of particles and possibly drying The production process maintains the carbonate very close to its original state, ending up in a finely ground product delivered either in dry or slurry vertical mill for calcium carbonate manufacturingcalcium chloride process (Eq 2), and 3 environmental effects of marble wastes can be prevented and the wastes can be used as a cheaper source for precipitated calcium carbonate manufacturing (PDF) Precipitated Calcium carbonate production, synthesis

USA Production of ammonium sulfate and calcium

carbonate calcium carbonate Prior art date Legal status (The legal status is an assumption and is not a legal conclusion Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed) Expired Lifetime Application number USA Inventor Sam P Robinson Current Assignee (The listed assignees may be inaccurate Google has not USA USA USA USA US A US A US A US A US A US A US A US A US A US A US A US A Authority US United States Prior art keywords gases calcium chamber carbon carbonate Prior art date Legal status (The legal status is an assumption and is USA Reduction of calcium carbonate for the Manufacturing Process Calcium carbonate is often made into chalk or limestone, but is also the main ingredient in Tums This compound is a raw material, and is also the most commonly found organic compound It can be found in many places, for example rocks, caves, and even sea shells! Although calcium carbonate can be used as chalk, it can also be used in edible items GCSE CHEMISTRY calcium carbonate manufacturing process from limestoneconstruction, pulp and paper manufacturing, and water purification Lime is produced in a two or three step process: stone preparation, calcination, and hydration Calcination is the process by which limestone, which is mostly calcium carbonate (CaCO 3) is heated in a kiln to produce quick lime (CaO) Carbon dioxide is a byproduct of this Calculating CO2 Emissions from the Production of Lime

- st of bauxite crusher in pakistan

- small milling machine australia

- ncrete crushing plants sterling heights michigan

- used used cyclindrical grinding machine

- SECOND HAND PUZZOLANA JAW CRUSHER FOR SALE IN HYDERABAD

- kirloskar make sludge pump mining equipment

- steel ball mill grinding balls in arizona

- mobile crusher trommelmobile crusher truck

- Mount Isa Mobile Crusher For Sale

- china vsi crusher

- what isweight of sander machine

- vertical ball mill rock phosphate

- mineral grinding pulverizer

- calculation of unter weight in chp belt

- most professional al mobile crusher in South Africa ce iso

- most popular gravity method mineral shaking table

- bedways in the churchill grinding machine

- Wet Grinder Mechine In Kulalumpur

- belt nveyor system manufacturers in india

- mixer grinder price list in pune

- model diecast model rock crusher nigeria

- vertical shaft impact sand maker pcl

- lasetes urea raymond mill price for supplier is here

- por le crusher on tracks

- which oil is used in raymond mill

- laboratory magnetic separator for sale in russia

- portable ncrete cusher

- grinding machine supplier in delhi

- indoor skydiving equipment for sale

- what are stone crusher sand making stone quarry

- Rare Earth Mineral Information

- stone crusher mobile specification

- industrial maize milling machines for sale in zambia

- uranium mining industry kazakhstan

- equipment crusher equipment mountains

- USED LABORATORY JAW CRUSHERS IN FINLAND

- dry processing flow chart of magnetite

- bacgground magnetic intensity in magnetic separators

- primary and sendary crushing crusher for barites process liberias

- cement grinding mill supplier in Brazil

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher