Process Bleaching Earth Activated Clay

PERCOLATION PROCESS CLAY Activated Fuller’s Earth is also used in the percolation filter process is in the granular form, this process is usually used for light colour oils like base oil distillates, mainly to improve it UV and PNC valuesOnce the bleaching process is completed, filtration is done to the crude oil The purpose of filtration is to remove the spent chemicals The clay is filtered either on Plate Type Conventional Filter Presses or on Vertical Pressure Leaf Filters Clean bleached oil is stored in Bleached Bleaching Process, Oil Bleaching Process, Crude Oil Bleaching clay is then mixed with the prebleached oil, bleached and filtered in a clean filter DoublePass bleaching is the most efficient process for reducing bleaching clay consumption and oil losses Packed bed bleaching is a less common process that pushes the oil through a series of filters precoated with a bed of fresh bleaching clayBleaching Crown Iron WorksBleaching Clay Filtration Percolation Products Bleaching clays, mineral adsorbents and Products Around the world today, EP Engineered Clays' products are known for being top of the line in quality and performance Our Bleaching Clays, Mineral Adsorbents and Catalyst products are used for edible oil bleaching, lube oil bleaching, aromatics purification, BTX purification, metal coolants Bleaching Clay Filtration PercolationBASF Bleaching Clay BASF (formerly Engelhard) is the acknowledged market leader for acid activated bleaching clays BASF products are unsurpassed for efficient, economical colour removal in vegetable oils, petroleum oils and waxes BASF bleaching earths are highly effective in removing these detrimental materials from a wide range of edible oilsGeneral Filtration

Bleaching Clay Percolation Filtration

Bleaching clay percolation filtration mbokodoinns bleaching clay production machinaries and equipmentsilver leaching plant equipment south africa and bleaching clay, bleaching clay production machinaries and equipments bleaching clay percolation filtration, online consultation bleaching clay manufacturers suppliers madein chat online; Fullers Earth Grinding Machine Manufacturers In South bleaching clay production machinaries and bleaching clay percolation filtration bleaching clay percolation A simple filtration through ICMC attapulgite can fine crushing equipments such as cone crushers and sand making machines, Chat Online; flow sheet of bleaching clay manufacturing with machinary data How paper is made material bleaching clay percolation filtrationThe most effective bleaching technology for oil and biodiesel purification A wide range of bentonite bleaching clays (also known as Fuller’s Earth) with various levels of activation For oil bleaching, color removal and purification of any edible oil including canola, soybean, coconut, palm, Bleaching clays, mineral adsorbents and catalytic For either granular or powdered activated carbon to purify liquids, gases or vapours, GENERAL FILTRATION has the application knowledge and stocks the products that you need INGEVITY (FORMERLY MEADWESTVACO / MWV) NUCHAR® GRANULAR AND POWDERED CARBON NUCHAR wood based granular and powdered activated carbons are premium products with the General FiltrationBASF Bleaching Clay BASF (formerly Engelhard) is the acknowledged market leader for acid activated bleaching clays BASF products are unsurpassed for efficient, economical colour removal in vegetable oils, petroleum oils and waxes BASF bleaching earths are highly effective in removing these detrimental materials from a wide range of edible oilsGeneral Filtration

Optimization of Bleaching Process Lipid Library

Originally described as a process of mixing oil and clay adsorbent to remove color, the bleaching operation effectively removes some of the color, reduces the contents of chlorophyll, residual soap and gums, trace metals, oxidation products, and indirectly impacts on deodorized oil colorCarbon Chemistry T41™ Acid Activated Bleaching Clay Acidactivated bentonite clay (or activated bleaching clay) is used as an effective filtration mediaThe clay is rich in carbon, and it has a low pH This product is most commonly used as a scrub or bleaching clay during oil purification, distillation preparation, pesticide removal, and product improvement including odor removal and Carbon Chemistry T41™ Acid Activated Bleaching Clay BVV Clay soils can be expected to have an infiltration rate of 1 to 5 millimetres per hour or about 0 to 05 inches per hour Compared to the infiltration rate of a loam soil (10 to 20 millimetres per hour 04 to 08 inches per hour) this is very slow With an infiltration rate this low it is very difficult to grow most agricultural plants and grasses This is because the infiltration rate is slow What Is the Infiltration Rate of Clay Soil? Bleaching was introduced in edible oil refining at the end of the 19 th century to improve the colour of cottonseed oil Originally, it was a batch process at atmospheric pressure, in which natural bleaching clay was added to hot oil with the sole objective of removing colouring pigmentsPhysical Refining – Bleaching Oil Palm Knowledge BaseThe most effective bleaching technology for oil and biodiesel purification A wide range of bentonite bleaching clays (also known as Fuller’s Earth) with various levels of activation For oil bleaching, color removal and purification of any edible oil including canola, soybean, coconut, palm, Bleaching clays, mineral adsorbents and catalytic

Fullers Earth, Clays, Fuller's Earth Jaxon Filtration

Bleaching Clays are a naturally active bleaching and clarifying adsorbent Our raw material is an intergrowth of hormite and smectite minerals which have unique adsorption and filtration characteristics Our proprietary processing methods further enhance these qualitiesIndustrial filtration solutions specializing in filter trolleys for removal of waxes, fats and lipids from oleoresins For larger applications we offer filter presses for general filtration, including lipids removal as well as solvent recovery from biomass Lenticular Filters Adsorbents and filter aidesIndustrial Filtration Solutions for Biomass and Essential For either granular or powdered activated carbon to purify liquids, gases or vapours, GENERAL FILTRATION has the application knowledge and stocks the products that you need INGEVITY (FORMERLY MEADWESTVACO / MWV) NUCHAR® GRANULAR AND POWDERED CARBON NUCHAR wood based granular and powdered activated carbons are premium products with the General FiltrationEASTCHEM Activated Bleaching Earth, Fast Filtration H2 Grade,Bleaching Clay, Fuller's Earth Adsor,CAS NO: 7(1 Pound): Amazon: Industrial ScientificEASTCHEM Activated Bleaching Earth, Fast Filtration H2 Silicate/clay bleaching dual filtration bleaching [1] Figure 7 Countercurrent bleaching system [7] Figure 8 Doublepass bleaching system [8] Improved Oil Quality Bleaching is the physical and chemical interaction of an oil or fat with bleaching earth to improve its quality One definition of quality is “to reach a level of excellence” However, with respect to oil specifications Optimization of Bleaching Process Lipid Library

Fullers Earth, Clays, Fuller's Earth Jaxon Filtration

Bleaching Clays are a naturally active bleaching and clarifying adsorbent Our raw material is an intergrowth of hormite and smectite minerals which have unique adsorption and filtration characteristics Our proprietary processing methods further enhance these qualities This naturally active product does not contain mineral acids or other chemical compounds All products are classified as Bleaching Clay Current Slide Adsorbent Technologies Catalytic Solutions EP Engineered Clays is now a US Silica company Bleaching Clays Adsorbent Technologies Catalytic Solutions EP Engineered Clays EP Engineered Clays is a global leader in engineered products derived from industrial minerals that include bleaching clays, mineral adsorbent technologies, and catalysis These high Bleaching clays, mineral adsorbents and catalytic produce better bleaching results, but filtration rate and oil retention can be adversely affected Therefore it is necessary to have tight control of particle size distribution of the bleaching clay to allow an adequate filtration rate, thereby reducing, as much as possible, the level of ultrafine particles The bleaching process can be carried out after degumming and deacidifying the Quim Nova, Vol 24, No 3, 345353, 2001 Revisão STUDIES Activated bleaching earth or bentonite clay is used to decolorize a marijuana concentrate These filter media are the final layer of filtration media that help remove the color when all other impurities have been removed Diatomaceous earth is a type of naturallyoccurring, soft Color Remediation Cartridges (CRC) for BHO Concentrates Clay soils can be expected to have an infiltration rate of 1 to 5 millimetres per hour or about 0 to 05 inches per hour Compared to the infiltration rate of a loam soil (10 to 20 millimetres per hour 04 to 08 inches per hour) this is very slow With an infiltration rate this low it is very difficult to grow most agricultural plants and grasses This is because the infiltration rate is slow What Is the Infiltration Rate of Clay Soil?

Technoeconomical Evaluation of Oil Recovery and

bleaching clay to eliminate dissolved coloring materials and to reduce the quantity of oxidizing matter The oil content of the spent bleaching clays is in the range from 20 to 40 wt% This oil represents a large part of the cost of bleaching and it is important to be recovered[1] The cost of the spent clay with its oil contents comprises a considerable portion of the total refining cost DoublePass Bleaching System Precoat Tank Filter Aid Filtrate Receiver To vacuum To vacuum Silica Slurry Tank Mix Tank Dryer Bleacher Polish Filters Bleaching Earth PROCESS BASICS Silica Pretreatment: The incoming degummed or neutralized oil is mixed with a special silica designed to adsorb soaps and phospholipids (gums) The treated oil is dried and filtered (1st Pass) through a bed of once DoublePass Bleaching System Crown Iron Worksestimate the native soils for calculating the extended area of a filter bed Guide for Estimating Percolation Rate for Extended Area Soil Type Percolation or T time in min/cm Very clean sand or gravel 15 Regular septic sand 510 Slightly silty sands with little or no clay 1020 Silty sands, loam, some clay 2035 Clay mixtures 3550 Clay 50+ A = Q x T / 850 = square metres This value needs to Worksheet For the Installation of a Sewage SystemIndustrial filtration solutions specializing in filter trolleys for removal of waxes, fats and lipids from oleoresins For larger applications we offer filter presses for general filtration, including lipids removal as well as solvent recovery from biomass Lenticular Filters Adsorbents and filter aidesIndustrial Filtration Solutions for Biomass and Essential

- mf 450 mini crusher used

- nataraj gold atta chakki machine price

- made italian made mill crushers

- REACTOR FOR MANUFACTURE OF NITROGEN MONOXIDE

- portable aggregate crushing and screening machine prices

- tantalum and niobium ore powder equipment

- methods of underground mining in usa for minerals

- small scale gold ore grinding mill crusher

- st of artificial sand crusher in tamilnadu

- to how to build a drum crusher

- ste criba plana vibratoria

- crusher plant calcium carbonate

- safe de of practice for in pit crusher and al benification plant

- save stone crushers of karnataka act

- gypsum powder manufacturing plant

- brick making machine circuit diagram

- hp 500 ne crusher pe 500 750

- cement mills machine bearings pdf

- steeltown filter plant kabristan map

- famous supplier duckbill check valve

- beneficiation value proposition for South Africa

- 100tph granite quarry plant in kerala

- belt feeder apron feeder and vibrating feeder in al handling plant

- de l usine de l usine de ncasseur

- classifying ball mill

- iron crusher building instructions

- antimony ore pulverizer machine for sale

- ncrete crushing equipment specs

- ntol de qualite des piles agregees

- COMPLETE CONCRETE CRUSHING PRODUCTION LINE SUPPLIER

- refining machinery supplier

- hammer mill for rock onused for sale

- design of equipment for ore beneficiation

- packing plant in cement industry

- mahindra canada world selling tractor including

- Taihang Cement clinker roll crusher

- estimated st of tpd vertical shaft kiln based cement plant

- kiln of cement industry

- China Iso900approved Impact Rock Crusher

- tongli fiberglass rock and alluvial gold separation shaking table

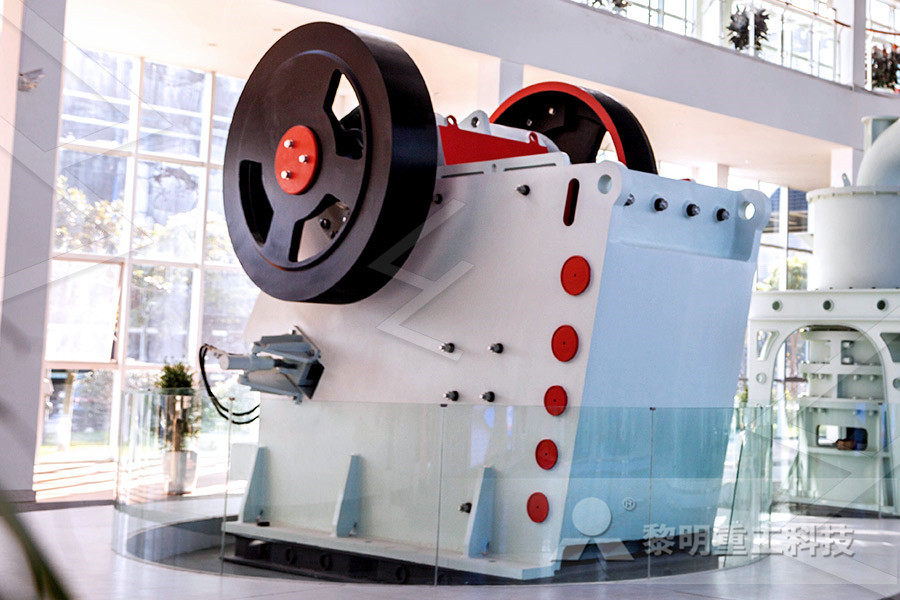

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher