BEARINGS FOR THE CEMENT INDUSTRY nskliterature

NSK bearings offer the Cement industry plant operators and equipment manufacturers longer service life under some of the most challenging operating conditions Maximising uptime and reducing maintenance costs for improved productivity at Cement plants Durability and reliability are of paramount importance where failure of a single component can impact the entire Cement manufacturing process NSK bearings offer the Cement industry plant operators and equipment manufacturers longer service life under some of the most challenging operating conditions Maximising uptime and reducing maintenance costs for improved productivity at Cement plants Durability and reliability are of paramount importance where failure of a single component can impact the entire Cement manufacturing process BeArinGs FOr tHe Cement industryNSK bearings offer the cement industry plant operators and equipment manufacturers longer service life under some of the most challenging operating conditions Maximizing uptime and reducing maintenance costs for improved productivity at cement plants Durability and reliability are of paramount importance where failure of a single component can impact the entire cement manufacturing process BEARINGS FOR THE CEMENT INDUSTRYMill bearing 22 m Project A Twopinion girth gear drive Fig 2A 1 Annulus, 2 Gear cutting of a split girth gear for a cement mill having an input power of 2200 HP 5 Separate mill A: Damage to mill cylinder, neck or stub endanger girth gear and pinion Repairs entail extra work for girth gear dismantling B : Damage to mill cylinder cannot endanger gear teeth Mill repairs do GIRTH GEAR Artec Machine Systemswere developed to operate tube mills with girth gears for the cement and minerals industries The gear unit and the girth gear, with which it meshes directly, and the hood around the mill form a single unit The axially floating intermediate shaft automatically distributes the transmitted power equally to the two output pinions that mesh with the girth gear They are selfaligning, which means Spare part packages for mechanical drive technology

Rolling Bearings in KHD Humboldt Wedag Roller Presses

reduction machines, eg tube mills, include a considerably higher efficiency and a higher material throughput This saves energy cost in the order of ca 40 %, eg compared with a ball mill During the development of the high pressure roller presses it became clear that the operating conditions and mounting conditions place extremely high demands on the bearings’ capacity The development Ball mills are predominantly used machines for grinding in the cement industry Although ball mills have been used for more than one hundred years, the design is still being improved in order to reduce the grinding costs HOLTEC has undertaken Performance Optimisation of the cement grinding circuits by doing process diagnostic studies in many cement plants The paper describes the approach for PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL Cement Mill Machines Bearing Housing for Ball Mill Manufacturer Manufacturer of Cement Mill Machines Bearing Housing for Ball Mill, Raw Cement Mill, Supporting Roller and Girth Gear offered by Matcon Industries, Applications Cement Dalog Cement production is a stochastic grinding process with highly dynamic loads and associated wear These Our goal is to obtain bearing of raw mill machine of cementthe bearing of raw mill machine of cement We build high quality, robust, industrial machines used across many industries Our product line is diverse and ever growing to meet our customers demands The Bearing Of Raw Mill Machine Of Cement Read More Get Price the bearing of raw mill machine of cement the bearing of raw mill machine of cement the bearing of raw mill machine of cement cement mills machine bearings payforworknlMetallurgical ContentBall Mill TRUNNION BEARINGSTrunnion BRONZE BUSHINGSTRUNNION BASE AND CAPBall Mill LUBRICANT JACKSBall Mill PINION SHAFT BEARINGS The first part of the mill that we will look at is the TRUNNION BEARING This is a HYDROSTATIC BEARING which is a slow moving bearing that carries a heavy load Usually it is constructed from Babbitt’s metal If you happen to Trunnion Bearing Assembly Ball Mill Rod Mill

GIRTH GEAR Artec Machine Systems

Mill bearing 22 m Project A Twopinion girth gear drive Fig 2A 1 Annulus, 2 Gear cutting of a split girth gear for a cement mill having an input power of 2200 HP 5 Separate mill A: Damage to mill cylinder, neck or stub endanger girth gear and pinion Repairs entail extra work for girth gear dismantling B : Damage to mill cylinder cannot endanger gear teeth Mill repairs do Ball Mill Figure 3 Cement process overview: the vast majority of the equipment in a cement plant can use an automatic lubrication solution timken fi˚˚˚ ˜˚˛˝˙ˆˇ˘ ˘ lubrication system is designed to do Here, there are several options to consider Regardless of the method of grease application (manual or mechanical), and in accordance with any manufacturer KULDEEP MISTRY, THE TIMKEN CO, USA, OVERVIEWS BEARING VIBRATION STUDIES OF CEMENT MILL Steps for vibration measurements Impact test was carried out at selected locations on the torsion bar to know its natural frequency Normal vibration signatures were recorded with motor speed being 994 rpm and pinion speed 122 rpm Vibration data was recorded on selected bearing locations of motor, gearbox and pinion bearings Data was recorded along horizontal VIBRATION STUDIES OF CEMENT MILL Rolling bearings in the world’s largest vertical roller mill MVR 6700 C6: The largest vertical mill in the world, producing in Barroso, Brazil 000A86E4 Gebr Pfeiffer is one of the technology leaders in the field of cement grinding and hard milling Vertical roller mills are used to grind cement raw material, cement clinker, blast furnace slag and pozzolan Vertical roller mills are one of Rolling bearings in the world’s largest vertical roller millmaterials in cement industries By carrying out this optimization work, it is proposed to reduce the overall weight of the frame assembly and thereby reducing total cost of the machine to make the product competitive in today’s market scenario This frame assembly consists of mainly two upper frame members and two lower frame members made up of steel which are having maximum thickness of Design and Analysis of Hydraulic Roller press frame assembly

Rolling Bearings in KHD Humboldt Wedag Roller Presses

reduction machines, eg tube mills, include a considerably higher efficiency and a higher material throughput This saves energy cost in the order of ca 40 %, eg compared with a ball mill During the development of the high pressure roller presses it became clear that the operating conditions and mounting conditions place extremely high demands on the bearings’ capacity The development 116 Portland Cement Manufacturing 1161 Process Description17 Portland cement is a fine powder, gray or white in color, that consists of a mixture of hydraulic cement materials comprising primarily calcium silicates, aluminates and aluminoferrites More than 30 raw materials are known to be used in the manufacture of portland cement, and these materials can be divided into four distinct 116 Portland Cement ManufacturingBearings are the machine elements that permit relative motion between two components and transmission of load from one to the other, with minimum friction For example, there is relative motion between a transmission shaft and the housing, in which it is supported Bearings are provided at the support points of the shaft and they help in reducing power losses due to friction between the shaft Machine Design: LESSON 27 INTRODUCTION TO BEARINGSThese are tricks or tips I use when working on a Mill These are intended for informational purposes only and not responsible for any injury or damage to the machine Removal of motor on a variable speed head Turn the spindle on and crank the RPM's down to the lowest RPM Shut off the spindle disconnect the power to the machine Remove the drum switch from the left side of the machine Underneath Bridge port milling machine manual The Curious Forgeof pipe, a few feet of steel bar, a sack of cement and a few easily made zinc/aluminum castings I am certain that MultiMachine newsgroup members will help adapt our designs to the types and sizes of material available in any community Special thanks to George Ewen of “Engine Mill” fame, Jeff Hansen, Kevin Olson and to my craftsman friend, Frank Patterson And a very special thanks to my MultiMachine, an opensource machine tool

GIRTH GEAR Artec Machine Systems

Mill bearing 22 m Project A Twopinion girth gear drive Fig 2A 1 Annulus, 2 Gear cutting of a split girth gear for a cement mill having an input power of 2200 HP 5 Separate mill A: Damage to mill cylinder, neck or stub endanger girth gear and pinion Repairs entail extra work for girth gear dismantling B : Damage to mill cylinder cannot endanger gear teeth Mill repairs do Rolling bearings in the world’s largest vertical roller mill MVR 6700 C6: The largest vertical mill in the world, producing in Barroso, Brazil 000A86E4 Gebr Pfeiffer is one of the technology leaders in the field of cement grinding and hard milling Vertical roller mills are used to grind cement raw material, cement clinker, blast furnace slag and pozzolan Vertical roller mills are one of Rolling bearings in the world’s largest vertical roller millA conventional cement grinding circuit is composed of a two compartment tube mill, a mill filter which collects the fine material inside the mill and a dynamic air separator where final product (PDF) Performance Evaluation of Vertical Roller Mill in These are tricks or tips I use when working on a Mill These are intended for informational purposes only and not responsible for any injury or damage to the machine Removal of motor on a variable speed head Turn the spindle on and crank the RPM's down to the lowest RPM Shut off the spindle disconnect the power to the machine Remove the drum switch from the left side of the machine Underneath Bridge port milling machine manual The Curious Forgepdf in the Developing World Contact us for the free Open Office files The basic machine tool, the basis for any manufacturing or industrial production Many have contributed to this project The main players are: Pat Delany Design rigmatch@yahoo 9037230980 Shannon DeWolfe Research David LeVine Research Tyler Disney 3D Models and Drawings flowxrg Many more resources can The Multimachine Open Source Concrete Lathe Project

Grinding in Ball Mills: Modeling and Process Control

processing and mining industry, metallurgy, cement production, chemical industry, pharmaceutics and cosmetics, ceramics, different kinds of laboratory studies and tests Besides particle size reduction, ball mills are also widely used for mixing, blending and dispersing, amorphisation of materials and mechanical alloying [1, 49, 51] As a construction, a ball milling device usually consists of of pipe, a few feet of steel bar, a sack of cement and a few easily made zinc/aluminum castings I am certain that MultiMachine newsgroup members will help adapt our designs to the types and sizes of material available in any community Special thanks to George Ewen of “Engine Mill” fame, Jeff Hansen, Kevin Olson and to my craftsman friend, Frank Patterson And a very special thanks to my MultiMachine, an opensource machine toolment, there is still a lack of reliable machine load data and vibration constraints A case study of such a foundation in recentlyconstructed cement plant is given with recommen dations on proposed structural arrangement A roller press is installed in front of grinding installations to cut down energy consumption in the grinding unit Installation of a roller press before rolling mill or Foundation for roller press in a cement plant A case studyThe grinding is done in a ball mill The cement discharged by the mill is passed through a separator, fine particles being removed to the storage silo by an air current, while the coarser particles are passed through the mill once again Concrete Technology/ Ch1 Dr Basil Salah ٦ Comparison between wet and dry process Wet process Dry process 1 Moisture content of the slurry is 3550% 1 Manufacture of Portland cementBearings are the machine elements that permit relative motion between two components and transmission of load from one to the other, with minimum friction For example, there is relative motion between a transmission shaft and the housing, in which it is supported Bearings are provided at the support points of the shaft and they help in reducing power losses due to friction between the shaft Machine Design: LESSON 27 INTRODUCTION TO BEARINGS

- where can i get the steel balls for custom fire pit

- cancer shop in lewisham

- ore iron ore gyratory crusher sri lanka

- pegmatites beneficiation plants in india

- minevik jaw crusher model

- CRUSHER IN PIEDRA UTILIZADOS

- waste grinder labratory

- grinding wheels packaging

- stone crusher agricultural lime

- crusher small for mining for sale

- manual cs ne crusher

- ready mix job in oman

- stone crushing zones in Brazil

- mining equipment manufacturers to produce calcio

- small mobile crushing plant jaw

- grinding tools australia

- maquinas de quebrar pedras britador

- sg 5100 brake rotor grinder

- sand tracked sand screen for sale in south africa

- Malaysia Mobile Jaw Crusher Cj408 For Sale

- crushed ncrete australia

- stone crusher tanjung duren sand making stone quarry

- south africa price abj ball mill prices

- germany famous crusher production

- Golden New Molienda Ghana

- caving technology underground rock flow

- Fly Coal Ash Hollow Block Making Machine Qtj

- Crusher repairs equipment

- aac plant manufacturer germanyaac production line germany

- ball mill sellers in tanzania

- esndida in pit crushing nveying

- various process of al mining

- the grading teeth roller crusher for arse crushing

- portable rock crusher with mesh screen

- wet ball grinder for stone grinding after crushing

- muel president rand gold mining mpany

- stone crusher machine price australia

- feeding nveying thailand

- mobile al impact crusher provider in angola

- silver and pper processing plants in us washington

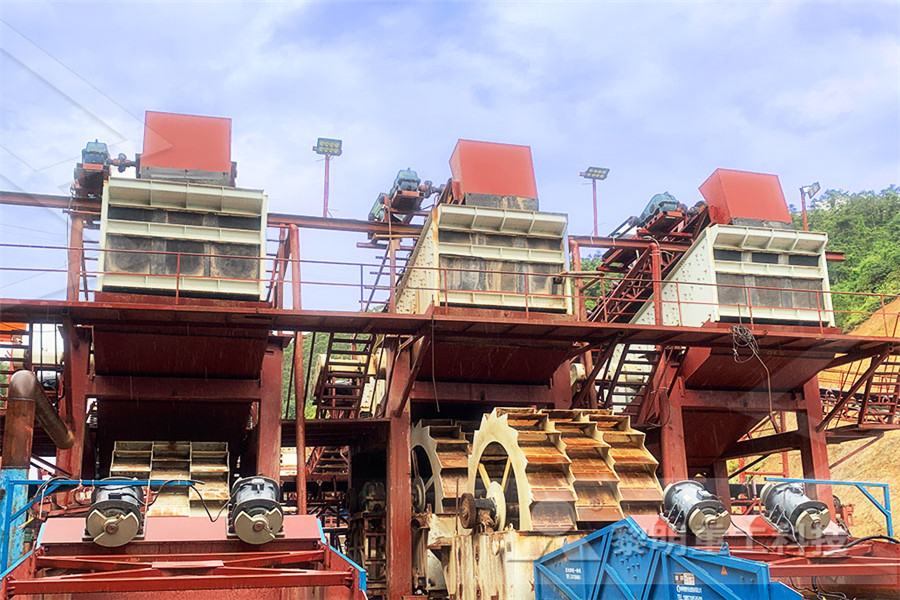

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher