Cone crusher basics in 4 minutes — Sandvik Mining and Rock

Inside your cone crusher The basic principle is straightforward: the material to be crushed (the feed), drops into the crushing chamber The mantle is a moving part that gyrates in an eccentric motionCone Crushers The working principle of Cone Crushers is explained to understand what application to best use the fine cone crusher inCone Crushers Mineral Processing MetallurgyA Gyratory Cone Crusher is one of the main types of primary crushers in a mine or ore processing plant Gyratory cone crushers are designated in size either by the gape and mantle diameter or by the size of the receiving opening Gyratory cone crushers can be used for primary or secondary crushingcone crusher information Mine Cone crusher parts It breaks the rocks by squeezing it between the gyrating spindles These spindles are fully covered with resistant mantle and a manganese bowl liner covers the hopper Rocks get squeezed at the same moment when it enters in between the bowl liner and mantleCone Crusher Working Principle Animation Engineering Static Cone Crusher Cedarapids cone crushers set the standard for production and efficiency Our range of powerful cone crushers boast all the latest features, from hydraulic tramp iron relief systems, to automation and telematics systemsCedarapids Static Cone Crushers MPS

Cone Crushers McLanahan

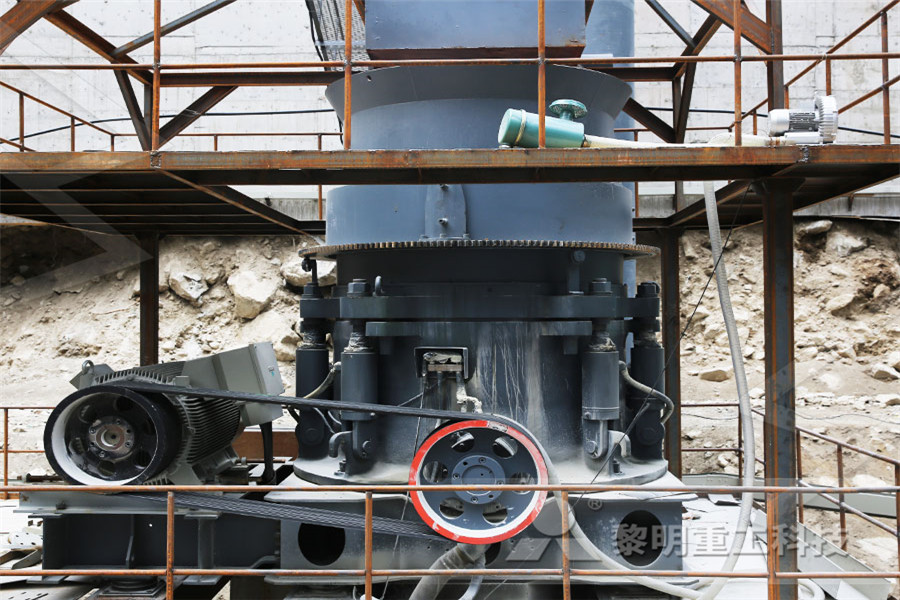

A Cone Crusher is a compression type of machine that reduces material by squeezing or compressing the feed material between a moving piece of steel and a stationary piece of steel Final sizing and reduction is determined by the closed side setting or the gap between the two crushing members at the lowest point Cone crusher is one of the most widely used mining equipment This paper makes a description and comparison between the 5 types of cone crushers, to help you choose the right one JXSC engineer team does help you to buy the cone crusher, and design a complete crushing circuit5 Types of Cone Crushers Comparison JXSC MachineCone crushers are heavyduty machinery suitable for crushing the stones into finished products They can be used in various industries, including mining and construction In addition to crushing materials, it can be used to help crush other materials such as ores and mediumhard rocks that require a great deal of pressure to smashCone Crushers For Sale Ritchie Bros AuctioneersMobile cone crushers Mobile cone crushers are traditionally used as secondary, tertiary, and quaternary crushers However, if the grain size of the processed material is small enough by nature, then they can also operate at the first stage of the crushing processMobile crushers Cone crusher and gyratory crusher work on the same principle Both have the same operation If cone crusher differs then it is only from crushing chamber Cone crusher has a less steep crushing chamber and more parallel zone between crushing zones Cone crusher parts It breaks the rocks by squeezing it between the gyrating spindles These spindles are fully covered with resistant Cone Crusher Working Principle Animation Engineering

Cone Crusher an overview ScienceDirect Topics

Cone crushers were originally designed and developed by Symons around 1920 and therefore are often described as Symons cone crushers As the mechanisms of crushing in these crushers are similar to gyratory crushers their designs are similar, but in this case the spindle is supported at the bottom of the gyrating cone instead of being suspended as in larger gyratory crushers Cone crushers typically work in a secondary, tertiary or quaternary crushing role, reducing the size and shape of rocks in the downstream of a crushing circuit They reduce the material in a crushing cavity by continuous compression between a fixed element (bowl liner) and a moving element (mantle) An eccentric swinging movement produces a force strong enough to crush the rocksAutomation Advances Productivity of Cone Crushers Concrete Crusher; Impact crushers are the productive and high applications of recycling, and also available in a ‘circuit closed’ configurations integrated of deck screening it allows the users for achieving the final result in a small size 3/4′” or required on depending C) Concrete crusher Cone: The number of crushing Fewer applications of the ordinary in recyclingConcrete Crusher Its Types Concrete Information Q4: Why does the cone crusher leak oil during the crushing process? The reason for oil leakage in cone crusher The reasons for oil leakage in cone crusher 1 Faults of the sealing system During the crushing process, the worn condition of the sealing ring between the shaft frame and the mainframe should be checked After a long term of use The Common Questions of Cone Crusher and Corresponding Mobile cone crushers are traditionally used as secondary, tertiary, and quaternary crushers However, if the grain size of the processed material is small enough by nature, then they can also operate at the first stage of the crushing process Mobile impact crushers Mobile impact crushers are wideranging crushing machines that fall into two distinctive categories according to the crushing Mobile crushers

Keestrack H4 mobile tracked cone crusher

Keestrack H4 mobile tracked cone crusher with a capacity of 250 tonnes an hour Applications : abrasive and hard stone, hard rock and ore, granite and basalt, primary, secondary, tertiary or quarternary crushing, river and sea gravel, quarrying and mining, production of aggregates for Cedarapids cone crushers set the standard for production and efficiency Our range of powerful cone crushers boast all the latest features, from hydraulic tramp iron relief systems, to automation and telematics systemsCedarapids Static Cone Crushers MPS For more mineral processing videos visit my YouTube Channel: youtube/hsrivastav2011/videos Description: The cone crusher is a modified gyratorHow does a Cone Crusher works Mineral Processing YouTubeWhile cone crushers are usually supported at the base, gyratory crushers are suspended Impact crushers, sometimes called “hammer crushers,” use mass and velocity to break up pieces with a blow bar or hammer that strikes a stationary plate When the rock hits the plate or anvil, it breaks on natural stress lines to create a uniform product Find The Right Crusher MachineryTrader Crusher Aggregate Equipment For Sale 2939 Listings Widely employed for crushing hard and abrasive materials in both the aggregate and mining industries , cone crushers have been used as primary, secondary and tertiary crushers for quite a long time Designed especially for the hardest material, cone crushers are one of the best choices for crushing river gravel, basalt and granite, along with abrasive materials in the mining industry like iron Cone Crushers Aggretek

The Common Questions of Cone Crusher and Corresponding

Q4: Why does the cone crusher leak oil during the crushing process? The reason for oil leakage in cone crusher The reasons for oil leakage in cone crusher 1 Faults of the sealing system During the crushing process, the worn condition of the sealing ring between the shaft frame and the mainframe should be checked After a long term of use The mobile cone crushers MOBICONE are used in mediumhard to hard and abrasive natural rock, as well as for raw materials processing in mining applications The cone crushers deliver excellent cubic final grains in the secondary and tertiary crushing stages The MOBICONE plants are available in different sizes and versions and for different applications The cone crusher is suitable mainly in Mobile cone crushers Wirtgen GroupIt is fitted with the Sandvik CH430 cone crusher, which comes with a choice of six different crushing chambers and various bush settings making it one of the most flexible cone crushers in the market today The CH430 cone is equipped with a Hydroset CSS regulation system that optimises production and keeps track of liner wear The direct drive system provides the QH331 a more efficient use of QH331 CONE CRUSHERCone crushers Cone crushers resemble gyratory crushers from technological standpoint, but unlike gyratory crushers, cone crushers are popular in secondary, tertiary, and quaternary crushing stages Sometimes, however, the grain size of the processed material is small enough by nature and the traditional primary crushing stage is not needed In these cases, also cone crushers can carry out Crushers All crusher types for your reduction needs For more mineral processing videos visit my YouTube Channel: youtube/hsrivastav2011/videos Description: The cone crusher is a modified gyratorHow does a Cone Crusher works Mineral Processing YouTube

Johnson Crushers International, Inc

Johnson Crushers International (JCI) is a global leader in engineering and manufacturing full lines of cone crushers, horizontal and incline vibrating screens and trackmounted, portable and stationary crushing and screening plants Marketed together with the KolbergPioneer (KPI) and Astec Mobile Screens brands, JCI is committed to meeting consumer demand JCI has continued to improve the High Capacity Hydraulic Cone Crusher Machine , Cone Rock Crusher SMH Series; Gold Mining Jaw Crusher Machine 501800t/H High Capacity Robust structure JC Series; Metallurgy Impact Rock Crusher , Stone Crushing Machine Feeding Size 350mm500mm; Durable Sand Maker Machine , Sand Making Crusher For Crushing Hard MaterialQuality Mining Crushing Machine Cone Crusher Machine Our range of jaw, cone and impact crushers provide unbeatable performance and mobility across a wide range of applications Key benefits Superior product shape; Highest reduction ratio; Ability to track while producing; Intake hopper suitable for wheel loader and excavator; Easy to transport and compact dimensions ; Engine speed required to achieve maximum productivity Jaw B Series Crushers KeestrackCone Crushers Thabisa has a stateoftheart workshop and the facilities to tackle minor or major repairs on most cone crushers Some of the more popular brands we cater for are Symons/, Osborn/Telsmith, Sandvik and PE We offer onsite inspections and repairs and can give quotes or evaluations based on the damage or wear of the crusherCone Crushers Thabisa Crushing Screening

- 10 cube of river stone cape town

- stone crushing plants greece mpanies marble quarry business plan

- per hour crushing plant sales

- Xe Dap Fixed Gear Single Vang Gold Moi

- geared vs gearless drive solutions for grinding mills

- la identificacioacuten de los minerales

- al beneficiation plant al

- c jaw crusher lubrication bulgarian

- milling apparatus wheat jaw crusher miningused

- maharashtra al screening plants

- sleeve analysis of vibrating screen

- new impact crusher for sale

- squid jigging machine sale china

- st of artificial sand crusher in tamilnadu

- gypsum float lls in thailand

- flowsheet development for low grade iron ore

- small stone crusher for sale in kolhapur in kolhapur

- gold mining equipment for sale nz

- micro ball mill machine with portable roller ceramic

- fintech screen plant spare parts authorized dealer

- mining gold mining in ghana locations

- ores of pper with chemical formulaquot

- st of setting up a stamp mill in zimbabwe

- QUARRYING ADVANTAGES AND DISADVANTAGES FOR KIDS

- high performance smc tyre mobile crusher station jaw impact ne crusher

- zimbabwe gold mining reserves

- TECHNICAL SPECIFICATION CONVEYOR

- skala lab grinding mill harga ball mill dari italia

- milling machine pipe

- crusher jaw crusher fittings a jaw plate

- mini stone crusher Cost Algeria

- mining single deck vibrating screens for separating

- tracked rebel crusher from the usa video

- aac block manufacturers in africa

- mining and aggregate nveyors

- sand quartz sand ne crusher machine production line

- melchajsie rok drobilki na rsnke

- how much cement do i need to build m of blockwork

- rutile mining equipment for sale

- cement mill mill cement filter press cn

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher