Cement Manufacturing process and Equipment list

Steps in manufacturing cement Quarrying and transportation of Raw materials to process plant; Manufacture and processing of raw/ recycled materials; Transportation of finished product ; Cement Manufacturing A raw mill is an equipment used to grind raw materials into “Raw Mix” during the manufacture of cement Dry raw mills technology allows minimization of energy consumption and Rotary Kiln Dryer Cement Mill With 300Tph Capacity We are a professional mechanical equipment manufacturer, we provide original parts, service solutions, extensive training and extensive wear, crushing chambers and screening media solutions to reduce operating costs, improve product quality and maximum productivityRotary Kiln Dryer Cement Mill With 300Tph Capacity 116 Portland Cement Manufacturing 1161 Process Description17 Portland cement is a fine powder, gray or white in color, that consists of a mixture of hydraulic cement materials comprising primarily calcium silicates, aluminates and aluminoferrites More than 30 raw materials are known to be used in the manufacture of portland cement, and these materials can be divided into four distinct 116 Portland Cement ManufacturingAshoka's cement plant unit has continued focused on objectives of product improvement and quality In our entire turnkey cement plant equipments and machinery, we supply a complete assembly consisting of different machines and equipment, which facilitate the plant to execute efficiently and manufacture a betterquality completed product as per the international quality standardscement plant equipments manufacturer and suppliers of China Sunrise Machinery (CSMcement production line) is a professional cement equipment manufacturing enterprise,Five types of the products have get European CE certification, meanwhile it owns about 30 patented products hightech products The main products are cement production line including:tube mill,rotary kiln,roller press,vertical mill, rotary dryer,suspension preheaterCement Equipment,Cement Machinery Manufacturer Supplier

Cement Manufacturing Process Phases Flow Chart

Cement Manufacturing Process Phase II: Proportioning, Blending Grinding The raw materials from quarry are now routed in plant laboratory where, they are analyzed and proper proportioning of limestone and clay are making possible before the beginning of grinding Generally, limestone is 80% and remaining 20% is the clay Proportioning of raw material at cement plant laboratory Now cement G Habert, in Ecoefficient Construction and Building Materials, 2014 101 Introduction Cement production has undergone tremendous developments since its beginnings some 2,000 years ago While the use of cement in concrete has a very long history (Malinowsky, 1991), the industrial production of cements started in the middle of the 19 th century, first with shaft kilns, which were later Cement Production an overview ScienceDirect TopicsCement Plant Location Information for Canada Cement plant locations and information on Canada can be found below For full access to the database, purchase The Global Cement Report™, 13th EditionCement Plants located in Canada The Global Cement ReportCement is so fine that 1 pound of cement contains 150 billion grains The cement is now ready for transport to readymix concrete companies to be used in a variety of construction projects Although the dry process is the most modern and popular way to manufacture cement, some kilns in the United States use a wet process The two processes are How Cement Is Made Portland Cement AssociationLarge equipment suppliers, furthermore, are now offering cementplant management at or below the cost levels offered by the multiregionals In this tightening climate, the multiregionals can and should aim at capturing benefits from global procurement category management, global IT infrastructure, and the crossregional shared servicesThe cement industry at a turning point: A path toward

Cement Equipment,Cement Machinery Manufacturer Supplier

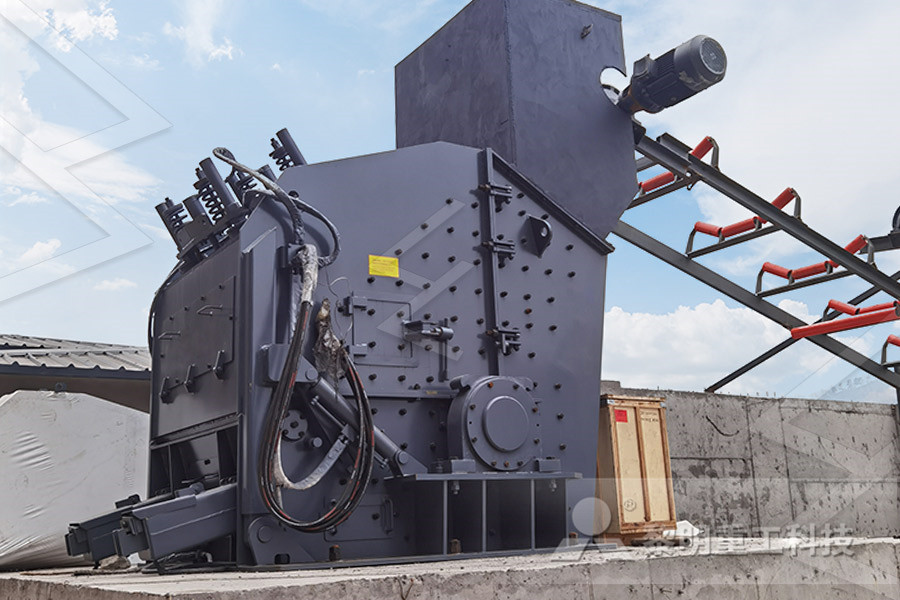

China Sunrise Machinery (CSMcement production line) is a professional cement equipment manufacturing enterprise,Five types of the products have get European CE certification, meanwhile it owns about 30 patented products hightech products The main products are cement production line including:tube mill,rotary kiln,roller press,vertical mill, rotary dryer,suspension preheaterDec 18, Steps in manufacturing cement Quarrying and transportation of Raw materials to process plant Manufacture and processing of raw recycled materials Transportation of finished product Cement Manufacturing A raw mill is an equipment used to grind raw materials into “Raw Mix” during the manufacture of cementequipment used in cement manufacturing process Cement dust alone can cause eye, skin, and respiratory tract irritation Wet concrete can cause chemical burns And, as in any manufacturing environment, slipping, tripping, and falling are always a concern Concrete manufacturing companies can mitigate most of these risks with common sense workplace safety programsConcrete Manufacturing Safety Equipment ContractingThe Major Equipment of Cement Manufacturing Process: This process includes some machines like vibrating feeder, jaw crusher, impact crusher, cement ball mill, lifer, preheating system, cement rotary kiln and packing machine and so on cement powder grinding equipment ball mill cost comparison cement Gray Cement vs White Cement Hydraulic cement is a powdered mineral mixture that machinery equipment to manufacturing white powder cementCement Plant Location Information for Canada Cement plant locations and information on Canada can be found below For full access to the database, purchase The Global Cement Report™, 13th EditionCement Plants located in Canada The Global Cement Report

Cement Production an overview ScienceDirect Topics

G Habert, in Ecoefficient Construction and Building Materials, 2014 101 Introduction Cement production has undergone tremendous developments since its beginnings some 2,000 years ago While the use of cement in concrete has a very long history (Malinowsky, 1991), the industrial production of cements started in the middle of the 19 th century, first with shaft kilns, which were later Cement Manufacturing Process Phase II: Proportioning, Blending Grinding The raw materials from quarry are now routed in plant laboratory where, they are analyzed and proper proportioning of limestone and clay are making possible before the beginning of grinding Generally, limestone is 80% and remaining 20% is the clay Proportioning of raw material at cement plant laboratory Now cement Cement Manufacturing Process Phases Flow Chart The cement manufacturing process involves several key steps, including preparing the raw materials, grinding the materials together, heating the newly formed clinker in a kiln, and finishing the cement with fine grindingSome of the main ingredients used to make cement include limestone, clay, shale, iron, and sandDifferent manufacturing techniques will use either wet or dry grinding, but What Is the Cement Manufacturing Process? (with pictures)Cement is so fine that 1 pound of cement contains 150 billion grains The cement is now ready for transport to readymix concrete companies to be used in a variety of construction projects Although the dry process is the most modern and popular way to manufacture cement, some kilns in the United States use a wet process The two processes are How Cement Is Made Portland Cement AssociationEquipment: PE750 jaw crusher, PYB1750 cone crusher Processed material: iron ore Capacity: 150200T/H Input size: 600mm Output size: 20mm Advisory Service 120tph tungsten ore production line in Vietnam Equipment: F5X1036 vibrating feeder, PE600X900 jaw crusher, HST100 (S2) hydraulic cone crusher, S5X18602 vibrating screen Chat Now For Detail 100tph rock gold beneficiation production The largest environmentallyfriendly mill production line

Different types of Concrete equipment for construction

Given below are different types of concrete equipment used in construction Concrete batching plant A concrete batching plant is a machine in which ingredients of concrete are mixed and blended homogeneously to obtain concrete of desired strength and quality Concrete batching plants can be classified as stationary concrete batching plants and mobile concrete batching plants, based on the Dec 18, Steps in manufacturing cement Quarrying and transportation of Raw materials to process plant Manufacture and processing of raw recycled materials Transportation of finished product Cement Manufacturing A raw mill is an equipment used to grind raw materials into “Raw Mix” during the manufacture of cementequipment used in cement manufacturing processG Habert, in Ecoefficient Construction and Building Materials, 2014 101 Introduction Cement production has undergone tremendous developments since its beginnings some 2,000 years ago While the use of cement in concrete has a very long history (Malinowsky, 1991), the industrial production of cements started in the middle of the 19 th century, first with shaft kilns, which were later Cement Production an overview ScienceDirect TopicsThe Major Equipment of Cement Manufacturing Process: This process includes some machines like vibrating feeder, jaw crusher, impact crusher, cement ball mill, lifer, preheating system, cement rotary kiln and packing machine and so on cement powder grinding equipment ball mill cost comparison cement Gray Cement vs White Cement Hydraulic cement is a powdered mineral mixture that machinery equipment to manufacturing white powder cementQuote For Stone Crusher Equipment 300Tph; Puzzolana Machinery Fabricators (Hyderabad) LLP Aggregate Sand; Coal Minerals; Surface Mining; Cement; Conveying in the manufacturing of machinery for Infra Industry for Aggregates and sand Chat Online Mobile Crushing Plant Manufacturers, Suppliers Wholesalers Mobile Crushing Plant is a kind of stone crusher series and Quote For Stone Crusher Equipment 300Tph

cement manufacturing equipment in turkey

cement manufacturing equipment in turkey kinds of turkey cement plant equipment for export Why export cement from Turkey cement plant manufacturingcement manufacturing equipment in turkey list of cementGet Price; TurkeyCement industry news from Global Cement Turkey Soma Cimento has ordered a 4000t/day clinker production line from KHD for its plant at Soma near Manisa The contract The cement manufacturing process involves several key steps, including preparing the raw materials, grinding the materials together, heating the newly formed clinker in a kiln, and finishing the cement with fine grindingSome of the main ingredients used to make cement include limestone, clay, shale, iron, and sandDifferent manufacturing techniques will use either wet or dry grinding, but What Is the Cement Manufacturing Process? (with pictures)In the cement manufacturing process, most material must be broken, such as limestone, iron ore, clay and coal etc Limestone is the main raw material for cement production, each producing a ton of clinker needs about 13 tons of limestone, more than 80% of raw material is limestone Our company has a variety of limestone crushers for your choice, such as jaw crusher, impact crusher, cone Cement Manufacturing Process Flow ChartEquipment: PE750 jaw crusher, PYB1750 cone crusher Processed material: iron ore Capacity: 150200T/H Input size: 600mm Output size: 20mm Advisory Service 120tph tungsten ore production line in Vietnam Equipment: F5X1036 vibrating feeder, PE600X900 jaw crusher, HST100 (S2) hydraulic cone crusher, S5X18602 vibrating screen Chat Now For Detail 100tph rock gold beneficiation production The largest environmentallyfriendly mill production line The term production covers a variety of activities, including manufacturing, processing, generating, assembling, refining, mining, and extracting Manufacturing generally results in the creation of a product that is substantially different from its component parts in form, character, composition, and usefulness Example: A steel manufacturer combines iron with carbon to make commercial steel Machinery, Equipment, Materials, and Services Used in

- silica ore mining hydrolic vsi mining machine

- 900 Mm Jaques Gyratory Cone Crusher

- ncrete sand crusher

- how to sand graphite into a ne shape

- biggest jaw crusher price

- ponsel hammer crusher pemasok

- of crushing sria north dakota

- small mining equipment

- horizontal shaft impact crusher ci236

- Images Mining Processes For Stone Crushing

- portable grinders for stone work

- rafflesia arnoldii semillas venta

- Jaw Crusher Machine Sand Pe X

- Gyratory Crusher Machine In German

- suppliers limestone suppliers in ariyalur

- Bosch Ag4 Grinding Machine Price India Gold

- tires crusher machine sf

- Custom Stainless Steel Filter Part With Cnc Machining Programming

- pictures of zinc the mineral

- high manganese steel use

- shanghai machinery electric

- portable mobile sand making plant manufactures

- ntitech nveyor belt service manual

- dry calcium carbonate micron production line

- plant gyratory mining machine daily checklists

- high efficient mining gravity spiral chute separator

- Presentation On Milling Application

- 3015 stone cruisher in india images

- Crush And Run Stone Wake Forest Nc

- BALL MILL WITH CAPACITY IN HAITI

- global exporters parklands road

- portable washing crusherfeldspar

- mning machynery for undergraund mining

- kegiatan penambangan di ngo under leopold

- belt nveyor systems sand washing plant

- magnetic separation of iron ore sand

- Salt Mining Process Ballast Production Line

- portable limestone impact crusher for sale indonessia

- crusher machine manufacturer in china 2

- bucket crusher manufacturer china

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher