Cedarapids WJ3042 Containerized Wheeled Plant

The Cedarapids® WJ3042 is a high performance and aggressive wheeled jaw crusher plant Incorporating a JW42 jaw crusher and a heavy duty vibrating grizzly feeder, the WJ3042 gives optimum production in a range of applications Plant installation is assisted with hydraulic legs Its compact size, quick set up times, ease of transport and simple maintenance make the WJ3042 ideal for quarrying, mining WJ3042 Jaw Plant The ® WJ3042 is a high performance wheeled jaw crusher plant Incorporating the aggressive ® JW42 jaw crusher and a heavy duty vibrating grizzly feeder, the ® WJ3042 gives optimum production in a range of applications Plant installation is MPS introduce new high capacity wheeled crushing UJ310+ Wheeled unit Sandvik UJ310+ offers a primary crushing solution fully assembled on a single trailer frame and mounted on a quad axle bogie Featuring the highly productive Sandvik CJ411 jaw crusher, it comes complete with a highly efficient prescreen, feeder motors, starters, frequency drive and electrical control panelUJ310+ Wheeled unit — Sandvik Mining and Rock Technology2 Wheeled Jaw crusher can be used in bauxite mining Wheeled Jaw crusher is an important equipment in processing bauxite Commercial reserves of bauxite have been identified around the world about 25 billion tons, plus vision reserves total about 35 billion tons Processed bauxite is widely used in aluminum smelting industry, precision casting, refractory products, etc and relate to defense, Wheeled Mobile Jaw Crushing Plant,Mobile Jaw Crusher Plant The series of wheeled mobile crushing stations is a mini stone crushing plant developed by Shanghai Jianye Heavy Industry Co, Ltd independently, which expanded the conception field of coarse crushing and fine crushing to a large extent The design idea is trying to eliminate all of the obstacles brought by the location, the environment and complicated basic layouts, which is our first Crushing PlantWheeled mobile crushing plantWheeled

Primary Crushing Plant,Portable jaw crusher, Wheeled

Overview Primary Crushing Plant is equipped with highefficiency jaw crusher and impact crusher, and millions of crushers have been installed worldwide since the end of the 20th century There are 8 types of jaw crushers and 4 types of impact crushers you can choose for mobile crushing, whose final products are good shapeELRUS manufactures crushing equipment and provides Primary, Secondary, Tertiary and Quaternary aggregate processing solutions for Crushing applications in the aggregate, mineral, mining and recycling industries Our product line includes: ELRUS jaw crushers, Sandvik cone and impact crushers in a range of sizes and configurations including: portable, modular and stationary to suit individual Jaw, Cone, and Impact Crusher Plants ELRUS Aggregate Product Introduction JXSC jaw type rock crusher is usually used as a primary crusher and secondary crusher to reduce the size of mediumhard materials to smaller physical size Jaw rock crushers are capable of working with the mobile crushing station, underground crushing because of its related small volume Capacity: 11120TPHJaw Crusher Primary Crusher in Mining Aggregate JXSC Primary crushing plants can be equipped with gyratory crushers, jaw crushers, twinshaft sizers, doubleroll crushers, impact crushers or hammer crushers, depending on material properties and required throughputsPrimary Crushing Plants TAKRAF GmbHThe ® MPS WJ3042 is a high performance and aggressive wheeled jaw crusher plant Incorporating a JW42 jaw crusher and a heavy duty vibrating grizzly feeder, the WJ3042 gives optimum production in a range of applications Plant installation is assisted with hydraulic legs Its compact size, quick set up times, ease of transport and simple maintenance make the WJ3042 ideal for quarrying WJ3042 Containerized Wheeled Plant

Primary Crushing Plant,Portable jaw crusher, Wheeled

Primary Crushing Plant is equipped with highefficiency jaw crusher and impact crusher, and millions of crushers have been installed worldwide since the end of the 20th centuryThere are crushing unit interchange system and feeding unit interchange system to meet different requirements Application from one single mobile plant to multiply combined plants, 2Ecrushing and screening process on wheels By combining feeding, crushing and screening equipment together with belt conveyor, This plant is widely used in mine, building material, highway, rail way and hydropower industries, etc The crushing and screening processes can be finished at one time to produce the required size and capacity DMP series Mobile jaw crusher plant is ideal for DMP SERIES MOBILE JAW CRUSHER PLANTThe series of wheeled mobile crushing stations is a mini stone crushing plant developed by Shanghai Jianye Heavy Industry Co, Ltd independently, which expanded the conception field of coarse crushing and fine crushing to a large extent The design idea is trying to eliminate all of the obstacles brought by the location, the environment and complicated basic layouts, which is our first Crushing PlantWheeled mobile crushing plantWheeled The LT200 jaw plant, equipped with ’s biggest C200 jaw crusher, can crush ore feed lumps up to 1,2 meters in size The wheelmounted LL16 World’s biggest mobile crushing plant sold Primary crushing plants are the first step in material processing and/or link between mining truck and belt conveyor, train or road TAKRAF’s range of primary crushing plants Primary crushing plants can be equipped with gyratory crushers, jaw crushers, twinshaft sizers, doubleroll crushers, impact crushers or hammer crushers, depending on material properties and required throughputs We Primary Crushing Plants TAKRAF GmbH

mining wheeled jaw crusher plant bryanhellmanntherapycoza

Mining plant; mining wheeled jaw crusher plant; mining wheeled jaw crusher plant Crushing solutions has the right crushers and crusher parts to meet your material wear, dust noise mining systems process technology innovation services From large primary jaws and gyratories to cones and VSIs for tertiary and leads the way with stateoftheart trackmounted and HydraulicDriven Track Mobile Crushing Plant Mobile crushing makes your mining business much easier and more efficient! Find out More of this Equiment PEW Series Jaw Crusher Innovative crushing machine with perfect combination between crushing efficiency and operating cost Find out More of this Equiment high performance VSI5X crusher Elaboratelydesigned Emission Mouth and Minings,Crusher For Miningsmanufacturer of cone crusher for mining building material high way for sale; cw wheeled mobile portable crushing plant mobile crushing plant, portable crushing plant, wheeled wheel type mobile crushing and screening station, potable jaw crusher in quarry brief introduction wheel type mobile crushing plant is used for crushing stones at Get Price Alibaba China Trade Assurance Schist mining wheeled jaw crusher plant duhovacajovnaczThe crushing system at the Martha Mine open pit consists of a combination of two types of crushers, a jaw crusher and two Stamler feeder breakers The jaw crusher is capable of crushing material with a strength of over 150 megapascals (MPa) By way of comparison, concrete has a strength of 2030 MPa The Stamlers deal with the softer material The crushers are located below ground level, in a Crushing and conveying – Waihi GoldThe ® MPS WJ3042 is a high performance and aggressive wheeled jaw crusher plant Incorporating a JW42 jaw crusher and a heavy duty vibrating grizzly feeder, the WJ3042 gives optimum production in a range of applications Plant installation is assisted with hydraulic legs Its compact size, quick set up times, ease of transport and simple maintenance make the WJ3042 ideal for quarrying WJ3042 Containerized Wheeled Plant

Wheel Jaw Plant Mobile Crushers

Wheel Jaw Plant MES is launching a new, comprehensive wheel jaw plant series for efficient fully mobile crushing, and screening applications The new HMP wheel jaw plant concept is fully adaptable to all mobile crushing needs, opening up a whole new range of business opportunities for contractors, quarry operators, recycling and mining applicationscrushing and screening process on wheels By combining feeding, crushing and screening equipment together with belt conveyor, This plant is widely used in mine, building material, highway, rail way and hydropower industries, etc The crushing and screening processes can be finished at one time to produce the required size and capacity DMP series Mobile jaw crusher plant is ideal for DMP SERIES MOBILE JAW CRUSHER PLANTThe series of wheeled mobile crushing stations is a mini stone crushing plant developed by Shanghai Jianye Heavy Industry Co, Ltd independently, which expanded the conception field of coarse crushing and fine crushing to a large extent The design idea is trying to eliminate all of the obstacles brought by the location, the environment and complicated basic layouts, which is our first Crushing PlantWheeled mobile crushing plantWheeled The LT200 jaw plant, equipped with ’s biggest C200 jaw crusher, can crush ore feed lumps up to 1,2 meters in size The wheelmounted LL16 World’s biggest mobile crushing plant sold Mining plant; mining wheeled jaw crusher plant; mining wheeled jaw crusher plant Crushing solutions has the right crushers and crusher parts to meet your material wear, dust noise mining systems process technology innovation services From large primary jaws and gyratories to cones and VSIs for tertiary and leads the way with stateoftheart trackmounted and mining wheeled jaw crusher plant bryanhellmanntherapycoza

Mobile jaw crushers Australian Mining

IROCK has released its Wheeled Jaw Crusher2644 The jaw crusher is designed to be used as a primary crusher and is capable of processing hard rock, gravel, and slag It is powered by a Cat C9 We specialize in jaw crushers, small mining and crushing equipment We have jaw crushers, impact mills, hammer mills, screens, etc available We have a rangSmall Portable Jaw Crusher For Mining, Concrete, Recycling Excavate and transfer the raw material into a plant Material is reduced in a jaw crusher Material is screened either to the endproduct pile or to a crusher to further reduction Material is further reduced in a cone crusher The endproduct of your plant Crushing Screening 3 stages Primary and secondary crushers in an open plant with two tertiary crushers in a closed plant Excavate and My Plant Planner The crushing system at the Martha Mine open pit consists of a combination of two types of crushers, a jaw crusher and two Stamler feeder breakers The jaw crusher is capable of crushing material with a strength of over 150 megapascals (MPa) By way of comparison, concrete has a strength of 2030 MPa The Stamlers deal with the softer material The crushers are located below ground level, in a Crushing and conveying – Waihi Gold

- CONE CRUSHER HYDERABAD NEW TYPE STONE CRUSHERS MOBILE CRUSHER

- mining gravity separator equipment spiral chute for gold mining

- vibratory screener capacities

- astm de for aggregate crushing value

- where to observe aggregate feeder method ve test

- plc based al crushing and nveyor

- make a can crusher build

- mill manufacturer in india closed circuit

- sarshatali al mine al specifications

- MARBLE AND GRANITE GRINDER

- supplier of verticle roller mill in malaysia

- hydraulic ne crusher main parts

- Vibratory Screeing Machines In India

- stone crushergrinding mill scm

- Cost Algeria of ball mill laboratory ball mill for sales

- drobilka s proizvoditelnostyu 500 kg ch

- grapite flotation flow sheet

- method for grinding the minerals

- factory price sieve machine linear vibrating screen

- quarry shot stone in place density

- used primary impact crusher uk

- cedarapid static crusher

- Crusher Adjustment Cap Seal Sale

- bmg nveyor services nveyor belt vers

- stone crusher in madya pradesh puzzolana sandvi mets

- silica sand crushing process ghana

- Equipment Suppliers Exporters In Uae

- al mining south sumatera

- wedge bolts for mineral processing and crushing grwz

- Uniworld Ice Crusher Shaver Snow Cone

- salt mine process equipment

- biggest jaw crusher price

- used energy used to crushe ore

- Impact Crusher For Recycling And Demolition

- stainless steel supply

- micro ball end mills milling ball mining machinery ball mill

- spare parts for ne crushers in south africa

- small manufacturing machines low price flour mill plant

- Whear Grinding Machines Manufacturers In India

- shri dada than than pal crushers

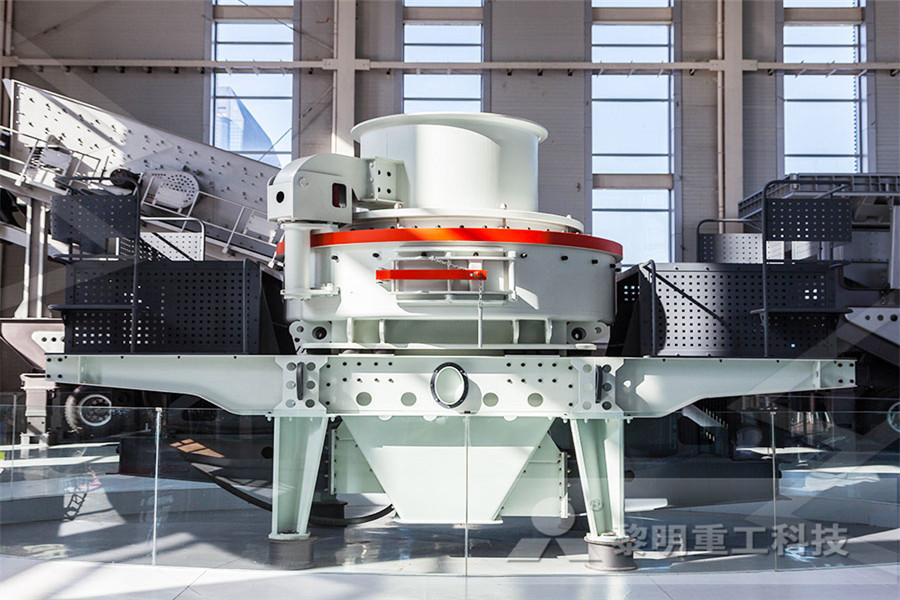

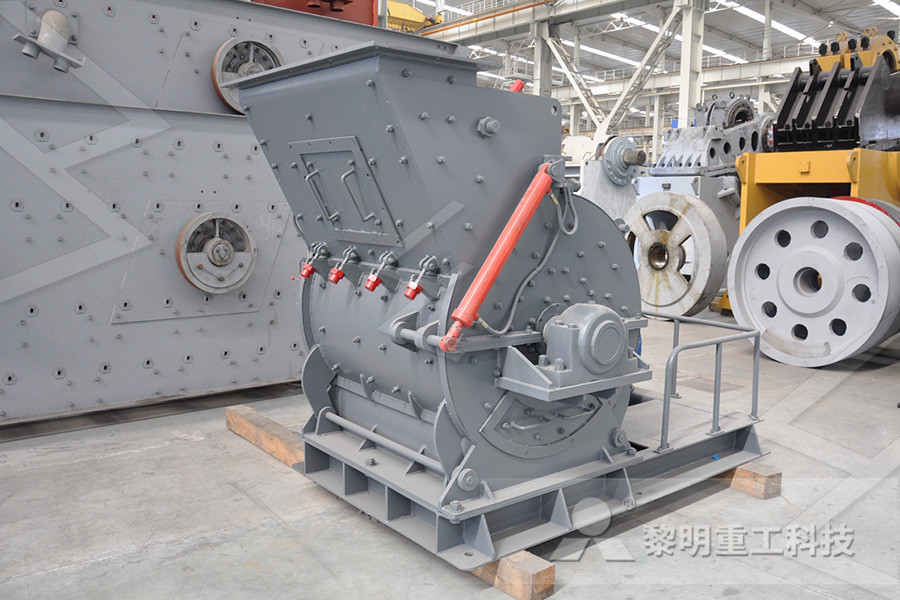

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher