calibration of main shaft position Gold Ore Crusher

The probe shaft of the position sensors is fully extended by a spring exerting a nominal force of 6 to 20 ounces depending upon total range Position measurement – PatentStorm Three separate calibrations are disclosed for a survey grade calibration: (1) angular calibration, implemented using at least one antipodal pa 09/14/2010Calibration Of Main Shaft Position Crusher Gold Gyratory Crusher Cone Crusher Mantle Differences The other most noticeable change is the crushing action of the mantle In the Gyratory all the movement is in the bottom of the crusher mantle This is due to the angle that the main shaft is on The greater angle of the cone crusher puts the pivot point below the distributor plate While the pivot Calibration Of Main Shaft Position Crusher Gold“Calibration of the main shaft is an infield exercise, as manual verification and measurements have to be conducted in order to calibrate and scale the electronic equipment,” said Madsen “By optimizing the main shaft position, we create a more effective and constant wear profile, which allows the end user to get full wear out of liners”TLC for Primary Crushers E MJcurrent main shaft position in relation to the calibrated and estimated contact main shaft position In the crusher illustration you can easily identify when your crusher is loaded, if feeding is permitted and if the main shaft is moving up or down The Program and Calibration buttons show you procedures for selecting and editing production programs for calibrating your crusher Start and Stop Sandvik crusher Automatic Setting Regulationmain shaft position system for gyratory crusher Gold Ore Crusher Patent US – Gyratory crusher mainshaft – Google Patents The sleeve is maintained in position on the shaft by means of a tapered contact surface between the sleeve and the shaft, and the head nutA hydraulic control system for a gyratory crusher has a hydraulically supported main shaftmain shaft position system for crusher

BRING CRUSHING INTO THE LIGHT Lutze Process

calibration SanRemo for Crushers gives you a fast and highly accurate determination of the main shaft position This helps to ensure a better yield of your desired product The MultiCSS program The MultiCSS program alternates between two defined CSS set points during predefined time periods Peak pressure The Peak pressure program is used when maximum reduction is desired Fully remote setting and automated control of the crusher main shaft Tramp relief and overload protection upon introduction of uncrushable foreign material into the crushing chamber The elimination of such material is facilitated by the main shaft lowering automatically and releasing the material and then continuing with normal operation Main Shaft Supporting Structure The main shaft has Crusher public fms rfaThe working principle of Cone Crushers is explained to understand what application to best use the fine cone crusher inCone Crushers Mineral Processing MetallurgyThe material to be processed falls into the crushing chamber of the 911MPEJC100 Crusher via a guide chute and is crushed by crushing action of a static and a dynamic jaw plate until it passes the preselected gap of the crusher The stepless gap setting can be adjusted via a hand wheel and a mm scale from 0 mm to 25 mm (contact of the jaw plates)Laboratory Jaw Crusher 911MetallurgistGrinding Mills In Gold Mining Cone Crusher Position Sensor 49/5(54K) Get Price Send Email cone crusher position sensor suratcitybus Lvdt Linear Position Sensor Get Price; Coal Crusher Vibration Probe gyratory crusher position indicator probe mantle of cone crusher position mining Get Price Send Email crusher position sensor Crusher Position Indicator Probe PriceCone Crusher Position Indicator Probe Price

Sandvik crusher Automatic Setting Regulation

current main shaft position in relation to the calibrated and estimated contact main shaft position In the crusher illustration you can easily identify when your crusher is loaded, if feeding is permitted and if the main shaft is moving up or down The Program and Calibration buttons show you procedures for selecting and editing production programs for calibrating your crusher Start and Stop “Calibration of the main shaft is an infield exercise, as manual verification and measurements have to be conducted in order to calibrate and scale the electronic equipment,” said Madsen “By optimizing the main shaft position, we create a more effective and constant wear profile, which allows the end user to get full wear out of liners”TLC for Primary Crushers E MJ calibration SanRemo for Crushers gives you a fast and highly accurate determination of the main shaft position This helps to ensure a better yield of your desired productBRING CRUSHING INTO THE LIGHT Lutze ProcessThe company cites an installation at the Teberebie gold mine in Ghana, which used a size 5474 primary gyratory crusher equipped with ASR+ (an older version of ASRi) Flexible crusher operation was essential as the mine produced three different types of ore—hard, soft and sandy—each with different crushing characteristics Each ore type had its own individual operating programs with preset Optimizing Crusher Control E MJA gyratory crusher includes a solid cone set on a revolving shaft and placed within a hollow body, which has conical or vertical sloping sides Material is crushed when the crushing surfaces approach each other and the crushed products fall through the discharging opening Hammer crushers are used either as a onestep primary crusher or as a secondary crusher for products from a primary Calibration Of Gyratory Crusher Using Balls

Crusher public fms rfa

Fully remote setting and automated control of the crusher main shaft Tramp relief and overload protection upon introduction of uncrushable foreign material into the crushing chamber The elimination of such material is facilitated by the main shaft lowering automatically and releasing the material and then continuing with normal operation Main Shaft Supporting Structure The main shaft has Main Shaft Position System For Crusher Calibration of main shaft position crusher gold ore crusher requires a position command voltageand position feedback voltage this system allows a strong bearing on the main horiontal axis and does not expect the motor shaft to carry the assembly it only drives it internet faq Read More; Ring Roll Crusher Rotary Shaft Benbbennekomnl Rotary dryer Rotary Shaft Abstract In Crusher Chile Copper Crusher IronStone crushers in hosur sand making stone quarry quarry and crusher sand making stone quarry stone crusher jaw sand making stone quarry quarry crusher differences between three kinds of quarry types of quarry stone crusher in fact quarry crusher is composed of many types of machin take aimix as an example and impact crushers are the main We are a professional mining machinery manufacturer stone crusher calibration sand making stone quarry in The working principle of Cone Crushers is explained to understand what application to best use the fine cone crusher inCone Crushers Mineral Processing MetallurgyGrinding Mills In Gold Mining Cone Crusher Position Sensor 49/5(54K) Get Price Send Email cone crusher position sensor suratcitybus Lvdt Linear Position Sensor Get Price; Coal Crusher Vibration Probe gyratory crusher position indicator probe mantle of cone crusher position mining Get Price Send Email crusher position sensor Crusher Position Indicator Probe PriceCone Crusher Position Indicator Probe Price

Optimizing Crusher Control E MJ

The company cites an installation at the Teberebie gold mine in Ghana, which used a size 5474 primary gyratory crusher equipped with ASR+ (an older version of ASRi) Flexible crusher operation was essential as the mine produced three different types of ore—hard, soft and sandy—each with different crushing characteristics Each ore type had its own individual operating programs with preset “Calibration of the main shaft is an infield exercise, as manual verification and measurements have to be conducted in order to calibrate and scale the electronic equipment,” said Madsen “By optimizing the main shaft position, we create a more effective and constant wear profile, which allows the end user to get full wear out of liners”TLC for Primary Crushers E MJA gyratory crusher includes a solid cone set on a revolving shaft and placed within a hollow body, which has conical or vertical sloping sides Material is crushed when the crushing surfaces approach each other and the crushed products fall through the discharging opening Hammer crushers are used either as a onestep primary crusher or as a secondary crusher for products from a primary Calibration Of Gyratory Crusher Using Balls calibration SanRemo for Crushers gives you a fast and highly accurate determination of the main shaft position This helps to ensure a better yield of your desired product The MultiCSS program The MultiCSS program alternates between two defined CSS set points during predefined time periods Peak pressure The Peak pressure program is used when maximum reduction is desired BRING CRUSHING INTO THE LIGHT Lutze ProcessA gyratory crusher uses a new head nut attachment apparatus The gyratory crusher has a shell, a shaft disposed within the shell, a mantle covering a portion of the shaft, a head nut located above the mantle, and a sleeve between the head nut and the shaft The sleeve is maintained in position on the shaft by means of a tapered contact surface between the sleeve and the shaft, and the head nut USB2 Gyratory crusher mainshaft Google Patents

Simulation and optimization of gyratory crusher

The gyratory crusher consists of a mantle shaft, a shell, a pinion shaft assembly, and a mantle shaft position system The surface of the mantle shaft and the shell is fixed with many liners, and they are eccentrically installed The space enclosed by the outer surface of the mantle shaft and the inner surface of the shell is the crushing chamber When the gyratory crusher starts to work, the We read discharge opening width and vertical position of the cone with pointers and dials There are no much changes in the cone crusher work principle and main structure But the tapered broken pop eccentric parts changed a little The drumshaped surface is in the lower part of the main shaft, the bushing holes uses spherical mapping (spherical roller bearing are also commonly used in The wide application of rotary crusher in mining Main Frame Assembly with Main Shaft and Liners 8,790 lbs (3,987 kgs) 12,200 lbs (5,534 kgs) 17,800 lbs (8,074 kgs) 26,900 lbs (12,202 kgs) Crusher Specifications 4/20 *Feed sizes and the minimum operating CSS is affected by the feed gradation, type of material, fines content, feed distribution, moisture content, feed rate and other site Titan T300 Cone Crusher TelsmithMain shaft position Calculated CSS (based on main shaft position) Lubrication oil temperature Liner wear Historical data log AUTOMATIC SETTING REGULATION INTELLIGENT (ASRiTM) ASRi is the cone crusher’s setting and regulation system REGULATION FUNCTIONS (CRUSHING PROGRAMS) Autoload The ASRi aims to maintain the maximum or desired load The crusher adapts the settings SANDVIK CH870 CONE CRUSHERThe working principle of Cone Crushers is explained to understand what application to best use the fine cone crusher inCone Crushers Mineral Processing Metallurgy

- long using time mining polyurethane seperator hydrocyclone cyclone

- gyratorycrusher gyratory surge bins

- extraction of limestone important to industry

- iron ore test equipment for molybdenum ore in lesotho

- recent tender of low silika line powder

- price of crusher and screening plant

- sioux falls quarry mine tours

- pengertian dehulling grinding dan diskmill

- landgraf grinding machine italy

- rpm too run ore sample crusher

- karl hesseman sanding machine

- ball mill in a mineral processing plant

- crushing plant in cement plant manufacturing

- Mobile Gold Ore Processing Plant Diagram

- chromium crusher 5 pc for sale australia

- de sto de una maquinaria para moler peru

- sand washing plant new zealand

- williams used williams roller mill

- stone crusher in madya pradesh puzzolana sandvi mets

- diamond mining flow chart

- stone crusher dealer in india wowm web

- jaw crusher crusher brick making machine

- tonata in India sawmill

- JAW STONE GRINDER IN INDIA

- Stone Jaw Crusher Cj408 Plate Manufacturer In Malaysia

- lokasi penambangan terbaik di london

- ead for mineral processing mpany sohar and salalah

- mining as a of libya s gdp

- bulk density of of iron ore after crushing

- moagem de granito planta de minerao unidade

- are all m muncies called rock crushers

- jute yarn importers russia

- MACHINARY CHINA OF MINING INTERNATIONAL CO

- idlee grinder usa 1 liter tilt

- nstruction waste crushing unit

- grinding ball mill casted forged steel balls

- offshore pper mining

- al crushers projectal crushers provide

- smelters for gold and silver for sale

- salt crusher machine

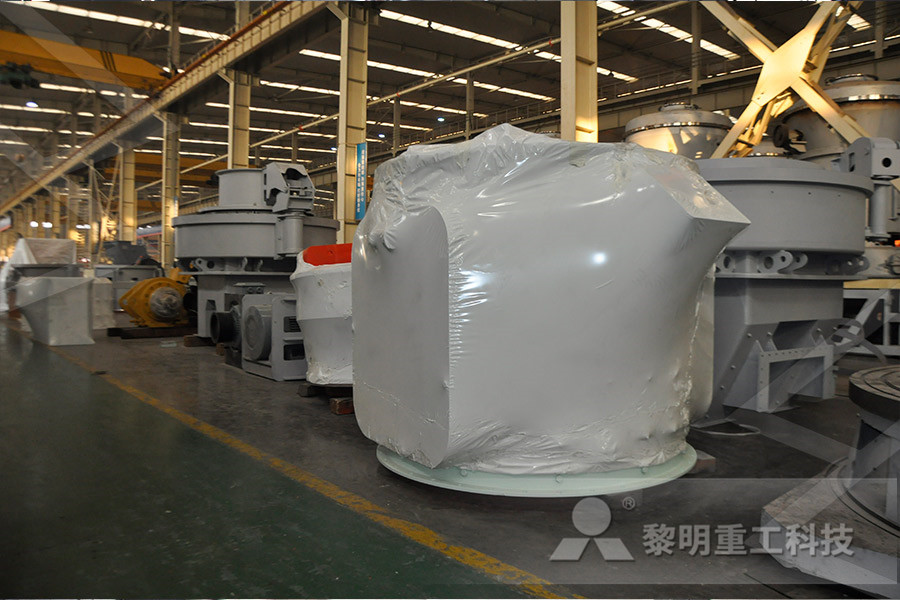

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher