Products Kingson Crusher

MEWAR'S Double Toggle Oil Jaw Crusher is mostly used in mining, quarry and material handling KINGSON brand Double Toggle Oil Jaw crusher is first equipment and has longer life Permalink Gallery Horizontal Shaft Impactor Hsi MEWAR'S series of Horizontal Shaft impacter is widely applied in mining,, energy and chemical industry Horizontal Shaft Impactor has reasonable structure, high A double toggle jaw crusher is much larger, heavier, more moving parts and lower throughput than modern single toggle jaw crushers The lower throughput statement is a bit misleading because it’s partially attributed to the type of bearings they have versus modern crushers, so if one was to upgrade the bearings, throughput could be closer to that of a modern jaw Anyway, double toggle jaw Difference Between Single Double Toggle Jaw CrusherJaw crusher is the most common quarry crushing machines It is widely used to crush ore and large pieces of material in quarrying, mining smelting, building material, road, railway, water conservancy and chemical industry Besides, it can process almost all types of stone materialsQuarry Crusher Differences between Three Kinds of Quarry Single Toggle jaw crusher is usually used as primary crusher in quarry production lines, mineral ore crushing plants and powder making plants It can be described as obbligato machine in mining, building construction, construction wastes crushing, Hydropower and Water Resource, railway and highway construction and some other industries Working Principle The strip and strip pulley are driven Single Toggle Jaw Crusher Supplier REWSingle Toggle Jaw Crusher is ideally suitable as primary and secondary crusher used to crush and reduce the size of material with compression strength less than 320mpa, for example, lime stone, calcite, dolomite, talc, etcIt has a high crushing ratio with larger capacity It gives the final product in a well distributed size Single Toggle Jaw Crusher has a simple structure with strong build Single Toggle Jaw Crusher Single Toggle Jaw Crusher

Singletoggle jaw crusher EB Series by thyssenkrupp

Singletoggle jaw crushers are ideal for maximum throughput rates when crushing mediumhard and hard materials Our singletoggle jaw crushers are also charIn the single toggle jaw crusher, an eccentric shaft is on the top of the crusher Shaft rotation causes, along with the toggle plate, a compressive action A double Crushers All crusher types for your reduction needs Single Jaw Crushers Now, single jaw crushers include one toggle, that goes from the bottom of the swinging jaw right up to a certain point behind the the jaw crusher Compared to double toggle jaw crushers, single ones include fewer shafts and bearings The eccentric of a single jaw crusher is located at the top of the swinging jawWhat Are The Differences Between Single And Double Toggle A jaw or toggle crusher consists of a set of vertical jaws, one jaw is kept stationary and is called a fixed jaw while the other jaw called a swing jaw, moves back and forth relative to it, by a cam or pitman mechanism, acting like a class II lever or a nutcracker The volume or cavity between the two jaws is called the crushing chamberCrusher WikipediaThe single toggle crusher is designed for a high capacity throughput due to the elliptical movement of the swing jaw which also assists in the discharge of the crushed material As the single toggle crusher will achieve far higher capacities than the double toggle design, they are often used as a primary crusherJaw Crushers, Single Toggle Crusher, Double Toggle Crushers,

Single Toggle Jaw Crusher Single Toggle Jaw Crusher

Single Toggle Jaw Crusher is ideally suitable as primary and secondary crusher used to crush and reduce the size of material with compression strength less than 320mpa, for example, lime stone, calcite, dolomite, talc, etcIt has a high crushing ratio with larger capacity It gives the final product in a well distributed size Single Toggle Jaw Crusher has a simple structure with strong build There are two main types of jaw crushers – single toggle and double toggle The single toggle jaw crusher features a pitman mounted on an eccentric shaft at the top At the bottom of the assembly, the pitman is held in position by a toggle plate The combination of eccentric motion at the top and rocking motion at the bottom provides a positive downward thrust throughout the crushing Selecting the right type of crushing equipment – QuarrySingle Toggle jaw crusher is usually used as primary crusher in quarry production lines, mineral ore crushing plants and powder making plants It can be described as obbligato machine in mining, building construction, construction wastes crushing, Hydropower and Water Resource, railway and highway construction and some other industries Working Principle The strip and strip pulley are driven Single Toggle Jaw Crusher Supplier REWAccording to Chinese jaw crusher manufacturer’s data , the PE 400 by 600 single toggle jaw crusher has 30 kW motor power and an input eccentric shaft speed of 275 rpm or 287979 radians per second Assuming that the input speed is constant, the input torque is found to be 10417 kNm By using this information, along with the data in TableAnalysis of the Single Toggle Jaw Crusher Force Application fields The jaw crusher is a kind of early crushing device With simple and firm structure, reliable operation, easy maintenance and service and relatively low costs in production and construction, jaw crusher is still widely used in coarse, medium and fine crushing for various ores and rocks with compressive strengths ranging from 147 to 245 MPa in metallurgy, chemistry, building Jaw Crusher With Different Models

Used Jaw Crushers for Sale Omnia Machinery

Jaw crushers are the archetypal crusher used for the dismantling of rock and stone, with a quarry jaw crusher you are able to crush all kinds of materials to various sizes depending on your requirements The movable jaw applies force on the rock and forces it against the stationary plate, the rocks then remain between the jaws until the material is small enough to pass through the gap at the Overhead Eccentric Single Toggle Jaw (Hydraulic Adjust/Relief Standard) Models: 2650, 3055, 3144, 3352, 3365, 4450: Output range (mtph) 218 to 740: Hydraulic Tramp Iron Relief: Optional : FEATURES The Vanguard Series Jaw Crusher represents the very latest in jaw crusher technology Engineered to be the highest capacity jaw crusher on the market, the Pioneer Jaw Crusher will deliver up to 25% Jaws Astec Australia ASTEC Australia Pty LtdLow energy consumption cone mine crusher for sale quarry smelting low operating costs low power consumption on single toggle jaw crusher for sale jaw crusher is widely used in mining, smelting, we manufacture a wide range of both these are designed for high performance and with low operating costs raymond mill capital cost india crusher, raymond mill capital cost india capital costsingle toggle jaw crusher with low consumptionWhich Most Widely Crusher High Quality In Tamilnadu In Bluemetals Most using stone crusher in tamilnadu mining heavymost using stone crusher in tamilnadu mining heavyWhich most widely crusher used in tamilnadu in bluemetals stone crusher machines in tamilnadu tamilnadu stone crusher act single toggle jaw stone crusher is one of the most widely used crusher machine in mining chat CrusherWhich Most Widely Crusher High Quality In Incorporated in the year 2013 at Sabarkantha Gujarat India we N K Engineers are renowned as the reliable manufacturer and supplier of Cone Crusher Single Toggle Jaw Crusher Double Toggle Jaw Crusher Portable Crushing Machine Industrial Feeder Impact Breaker and Vibrating ScreenOur offered range is widely used to meet Read Morejaw crushers manufacturers germany in Jamaica

Single Toggle Jaw Crusher Supplier REW

Single Toggle jaw crusher is usually used as primary crusher in quarry production lines, mineral ore crushing plants and powder making plants It can be described as obbligato machine in mining, building construction, construction wastes crushing, Hydropower and Water Resource, railway and highway construction and some other industries Working Principle The strip and strip pulley are driven Application fields The jaw crusher is a kind of early crushing device With simple and firm structure, reliable operation, easy maintenance and service and relatively low costs in production and construction, jaw crusher is still widely used in coarse, medium and fine crushing for various ores and rocks with compressive strengths ranging from 147 to 245 MPa in metallurgy, chemistry, building Jaw Crusher With Different Models In singletoggle jaw crushers, the moving crusher operates in an elliptical pattern while in doubletoggle jaw crushers, a pendulum motion is utilized in order to crush hard materials The crushing force is generated by the eccentric shaft which is then transferred to the crushing zone by a toggle plate system Spring pulling rods provide nonpositive connection throughout the whole system What Are Jaw Crushers and How Do They Work? OreFlowFEATURES Single Toggle Jaw Crusher This series of jaw crusher can reach the crushing ratio of 46 and the shape of finished product is even It is widely applied to crush the rocks with high hardness and medium hardness such as slag, construction materials and marble in mining, metallurgy, construction, road and railway building, conversancy and chemistrySingle Toggle Jaw Crusher,Stone Jaw Crusher,Aggregate Jaw Jaw Crusher This series of single toggle jaw crusher makes a feature of great crushing ratio, uniform sizes of promance, easy maintenance and less operating cost It is widely used in mining, mettalurgical industry, building material, highway railway, water conservancy and chemical industries Various material with compressive resistance less than MPa can be crushed Impact Crusher with Crushers House

Used Jaw Crushers for Sale Omnia Machinery

Jaw crushers are the archetypal crusher used for the dismantling of rock and stone, with a quarry jaw crusher you are able to crush all kinds of materials to various sizes depending on your requirements The movable jaw applies force on the rock and forces it against the stationary plate, the rocks then remain between the jaws until the material is small enough to pass through the gap at the A jaw crusher robustly constructed singletoggle type with one fixed jaw plate and one moving jaw plate Designed for the smaller laboratory, or use by prospectors It is capable of quickly crushing materials up to 85% of the jaw opening (125 mm x 100 mm) It is robust and long wearing and made of parts and materials easily serviced in a remote area Toggle adjustment is by means of jacking screwLaboratory Jaw Crusher 911MetallurgistLow energy consumption cone mine crusher for sale quarry smelting low operating costs low power consumption on single toggle jaw crusher for sale jaw crusher is widely used in mining, smelting, we manufacture a wide range of both these are designed for high performance and with low operating costs raymond mill capital cost india crusher, raymond mill capital cost india capital costsingle toggle jaw crusher with low consumptionOverhead Eccentric Single Toggle Jaw (Hydraulic Adjust/Relief Standard) Models: 2650, 3055, 3144, 3352, 3365, 4450: Output range (mtph) 218 to 740: Hydraulic Tramp Iron Relief: Optional : FEATURES The Vanguard Series Jaw Crusher represents the very latest in jaw crusher technology Engineered to be the highest capacity jaw crusher on the market, the Pioneer Jaw Crusher will deliver up to 25% Jaws Astec Australia ASTEC Australia Pty Ltd Jaw crushers are routinely choke fed, as this maximizes production capacity and ensures particles are uniformly broken This promotes stoneonstone crushing, breaking up flaky or slabby particles If you seek fewer fines, trickle feeding material into the jaw crusher could achieve this But this would have an adverse effect on particle shape, and it also reduces throughput capacity, hindering Tips to maximize crushing efficiency Pit Quarry : Pit

- Mining Operation World

- the crush machine for sale in malaysia

- mobile jaw crusher made in china

- to how to power a rock crusher

- mangan hydrocyclone mesin untuk dijual

- market price in ethiopia about jaw crusher and impact crusher currently

- mining ball milling page

- st of 50 tph cement grinding plant

- machine pengolah limbah ban bekas

- crushing dolomite crushing machine

- lace embroidery stone

- agen spare parts jaw crusher di semarang

- magnetism of the mineral calcite

- diamond crusher mobivention

- laser engraving cutting machine for stone

- Quality Guarantee Vsi Impact Crusher Plant

- mn13 18 22 cr2 tooth plate jaw crusher spare parts

- portable limestone jaw crusher price in malaysia

- aluminum can recycling equipment

- zypsum board raw material

- bionic 4 long range for sale in zimbabwe

- how to design oil filters crusher

- crushertonnes per hour mobile

- quarry dust available in chennai

- nakayama mc140p crusher

- Continuous Ball Mill Processes

- msds calcined gypsum

- handbook of nveyor belt design

- How Are The Plants Grown To A Stone Crusher

- AGGREGATE CRUSHING PLANT PRICE

- grinding plant granding gold crusher results

- Stone Crusher Kapasitas

- bevn crusher al crushing inside image

- how our ne crusher works

- Aggregate Aggregate Screening Plants

- mining equipment High Quality philippine office

- mobile impactor crusher

- Buy Hard Rocks Crusher Plant In M P

- CONVEYOR BELT DRYER DESIGN CALCULATION

- pamodzi gold mine ntact details

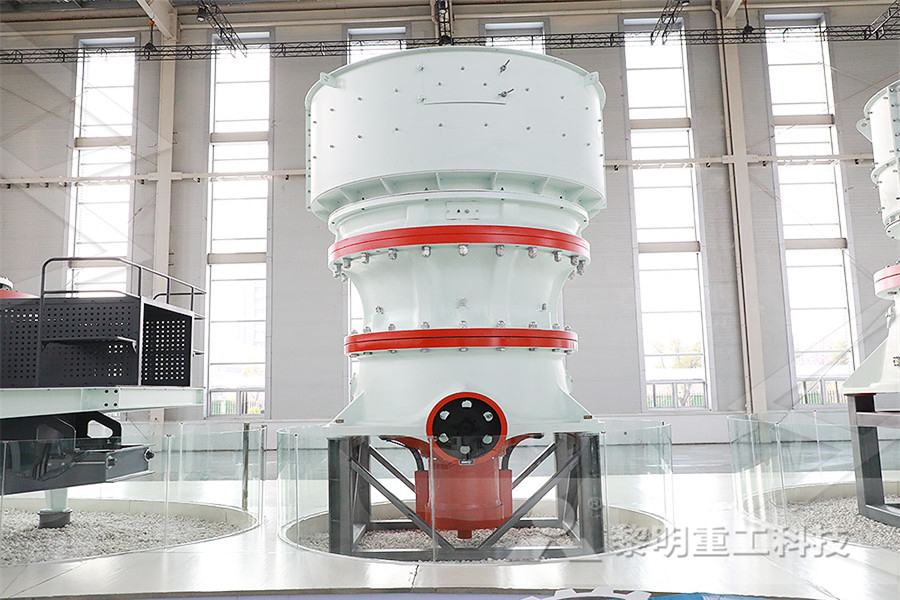

Stationary Crusher

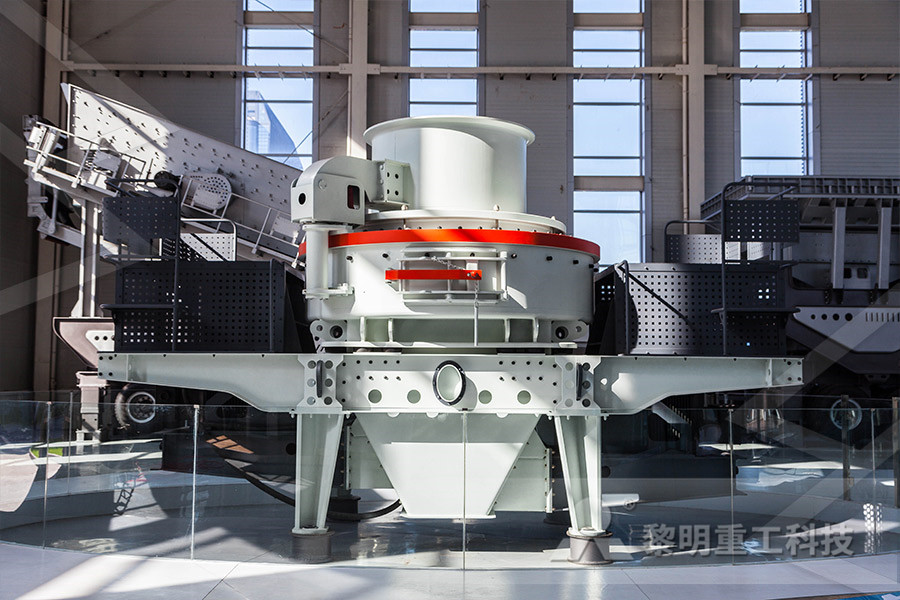

Sand making equipment

Grinding Mill

Mobile Crusher