erection of cement plant 5000 ton capacity with vertical

erection of cement plant 5000 ton capacity with vertical raw mill [ 46 9285 Ratings ] The Gulin product line, consisting of more than 30 machines, sets the standard for our industry We plan to help you meet your needs with our equipment, with our distribution and product support system, and the continual introduction and updating of products Related Posts » iron ore crusher seller in Vertical roller mills231 Мб In the cement industry, MPS vertical roller mills grinding cement raw materials and cement or granulated blast furnace slag with installed powers ofUnder erection 120t/h slag 5000 Blaine, 170t/h slag 4000 Blaine (250t/h OPSC 3000) Pfeiffer’s MPS vertical roller mill The structure of the MPS BCerection of vertical mill in cement industrySupply and erection of vertical raw meal mill with grinding capacity of 200 tons/hr, mill and rotary kiln feeding system, electrofilter and cooling tower for 2400 tons/day clinker production 2 Modification of existing raw meal mill to trass mill 3 Construction of a 10000 tons Cement Silo with 4 chambers, supply and erection works of a mixing plant of 250 tons/hr and bag packing plant of Cement Plant Fabrication,Erection Projects Aze 500 Ton Capacity Cement Plant 20 tons daily cement plant pakistan erection of cement plant 5000 ton capacity with vertical raw mill new 500 tons per day cement plant for urgent Get Price 50 tonne capacity slag cement machinery in india ball mill 5 ton per hour capacity manufactured in india, capacity of 50 500 ton perErection Of Cement Plant Ton Capacity With Vertical Raw MillErection Steps Of Vertical Mill In Cement Plant Affecting the ordering process or fail to execute a contract, or rejection of 3 consecutive bowl mill for coal fired boiler bowl mill pulverizer related ppt in bhel varanasi ppt erection of coal mill in cement plant vertical coal mill erection procedureErection Steps Of Vertical Mill In Cement Plant

Erection Steps Of Vertical Mill In Cement Plant

New cement plant erection in gulf erection of cement plant 5000 ton capacity with vertical raw mille 5000 t machinery and equipment for a new 5000 t per day cement plant for gulf and ok vertical cement grinding millcapacity of the plant in tpa vertical raw mill, vertical cement mill mechanical erectionThis profile envisages the establishment of a MiniCement Plant with a capacity of 60,000 Burning of raw mix in vertical shaft kiln and storing of clinker Production gypsum are ground in a cement mill to finally produce cement It is then supply, erection and commissioning of the production equipment Get Price Photo of major projectjiangsu pengfei group co,ltd new erection of vertical mill in cement industryerection of vertical mill in cement industry vertical roller mill Cement industry news from Global Cement Thailand: Siam Cement has ordered a LM 563+3 CS vertical roller mill from Loesche for its cement plant in Kaeng Khoi The mill will produce mediumfine cement qualities and is designed for grinding clinker, gypsum and limestoneerection steps of vertical mill in cement plantVertical Roller Mill In Cement Factory Water require for vrm cement plant with coal millor vertical roller mills vrm, water injection on the cement plant this will not pose a major problem in this case a hot gas generator is needed to dry the raw mills or coal mills operate using the same figure 2 grinding plant flowsheetget priceMill Water Injection System For Cement Plant Loesche MillsCement and Raw Mill Whether ball mill or vertical roller mill (VRM), A TEC offers the expert solution for efficiency optimization to increase mill productivity and/or reduce mill power consumption HURRICLON®, installed after the mill classifier, again proves to be the best technology for the mill product collection, providing top separation Get Price Duct Fabriion and Erection at TNPL cement plant duct raw mill cyclone to fan

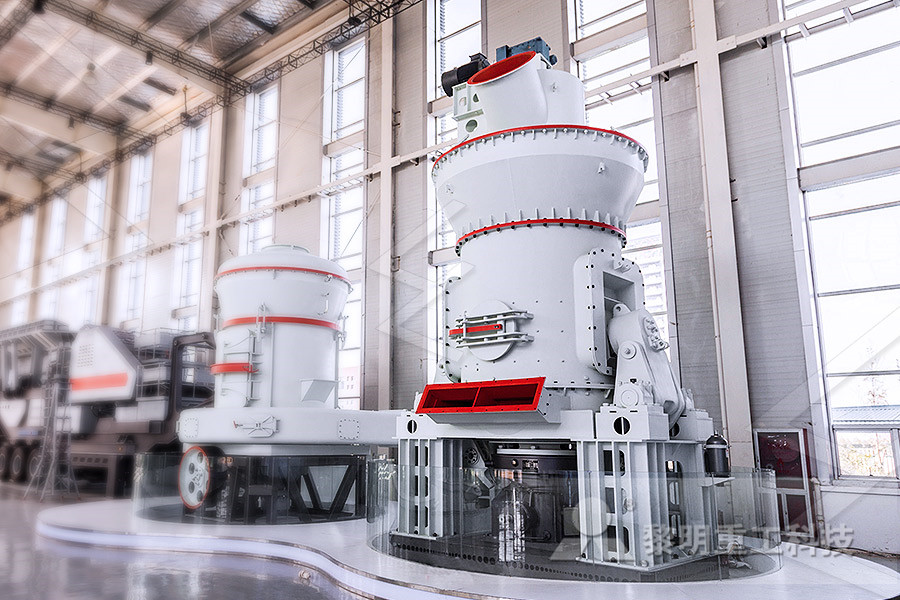

Vertical Mills McInnis Cement

McInnis has installed a vertical raw mill for raw meal preparation and two identical vertical finish mills (8,400 tpd) with highefficiency separators between the 120,000 mt of clinker storage and the 120,000 mt of cement storage silos This enables the plant to remain balanced during times of peak demand This new, but globally proven, technology will lessen McInnis’ per ton grinding costs According to the display of pulverized coal measured data, it can be saving electricity above 30% use of vertical roller mill production per ton cement clinker than traditional tube mill, and the power saving effect is very remarkable 3 Stable, highefficiency and environmental protectionVertical Cement Mill GGBSCement Plant,cement grinding Vertical roller mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes, paints, pyrotechnics, cements and ceramics It is an energy efficient alternative for a ball mill Overview Vertical roller mill is a kind of grinding machine for cement, raw material, cement clinker, slag and coal slag It has the features of simple structure Vertical roller mill Wikipedia has supplied the global cement industry with leading Vertical Roller Mill (VRM) designs for raw, fuel and cement grinding for several decades The OK™ mill has been ’s standard cement VRM since 1993 Since its introduction, the OK mill has proven to be the most efficient cement VRM available, with the highest reliability and ease of operation In 2017, introduced OK™ mill The most reliable and efficient mill for raw and Vertical Raw Mill Raw Material Vertical Mill Application Industry Cement Plant Output 70~720 t/h Final Product Fineness 80 μmR 12~15% Power Consumption of System 17~20 kWh/t Features of Raw Vertical Mill: Our vertical raw mill has various advantages when compared with other similar machines Detailed information will be given in the following China Cement Vertical Mill Vertical Roller MillSlag

Vertical Cement Mill cement plant,ball mill,vertical

CHAENG GRMK cement vertical mill gathers grinding, drying and powder selecting as a whole, with high grinding efficiency and high drying capacity ( the maximum handling material moisture is up to 20% )The vertical cement mill grind materials to related fineness by grinding rollers, you can easy adjusting your product fineness it can call: Cement Mill, Vertical Cement Mill, Cement Vertical The MVR vertical roller mill and the MultiDrive ® from Gebr Pfeiffer SE provide solutions for the cement industry that are ideally suited for meeting the requirements for ever increasing production outputs and progressively greater availabilities Operating experience gained in more than 25 000 hours is meanwhile available for both the MVR vertical roller mill and the MultiDriveOperating experience with the Pfeiffer MVR vertical roller Cement milling is the largest user of electric power on a cement plant, and because they can easily be started and stopped, it often pays to operate cement mills only during "offpeak" periods when cheaper power is available This is also favourable for electricity producers, who can negotiate power prices with major users in order to balance their generating capacity over 24 hours More Cement mill Wikipedia80 years it was the predominant mill for grinding of raw materials and coal, and still today is the most used mill for cement grinding Over the last three decades the vertical roller mill has become the preferred mill for grinding of raw materials The grinding efficiency of the vertical roller mill combined with an ability to dry, grind and classify within a single unit gives the vertical Cement grinding Vertical roller mills versus ball millsVertical roller mill for cement grinding installed Additional ESP installed for Kiln/ Raw mill to handle excess process gases 1998: 10 CIS/CFG Cooler installed Low pressure cyclone installed Latest Technology LVTech classifier installed in Raw Mill The plant capacity increased to 12 MTPA cement 2000: 11 Green field Cement plant with capacity of 09 MTPA was commissioned at Karikkali Chettinad cement Chettinad Group of Companies

Cement Vertical Roller Mill gwmcn

Cement Vertical roller mill (VRM) is mainly used to grind cement clinker into fine powder during cement production, which can also be used to grind various materials such as calcite, marble, limestone, coarse whiting, talc, barite and dolomite etc Application : Cement Plant, Clinker Grinding Unit, Thermal Power Plant Capacity : 50250 t/hVertical roller mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes, paints, pyrotechnics, cements and ceramics It is an energy efficient alternative for a ball mill Overview Vertical roller mill is a kind of grinding machine for cement, raw material, cement clinker, slag and coal slag It has the features of simple structure Vertical roller mill WikipediaCement milling is the largest user of electric power on a cement plant, and because they can easily be started and stopped, it often pays to operate cement mills only during "offpeak" periods when cheaper power is available This is also favourable for electricity producers, who can negotiate power prices with major users in order to balance their generating capacity over 24 hours More Cement mill WikipediaVertical Raw Mill Raw Material Vertical Mill Application Industry Cement Plant Output 70~720 t/h Final Product Fineness 80 μmR 12~15% Power Consumption of System 17~20 kWh/t Features of Raw Vertical Mill: Our vertical raw mill has various advantages when compared with other similar machines Detailed information will be given in the following China Cement Vertical Mill Vertical Roller MillSlag The MVR vertical roller mill and the MultiDrive ® from Gebr Pfeiffer SE provide solutions for the cement industry that are ideally suited for meeting the requirements for ever increasing production outputs and progressively greater availabilities Operating experience gained in more than 25 000 hours is meanwhile available for both the MVR vertical roller mill and the MultiDriveOperating experience with the Pfeiffer MVR vertical roller

Cement grinding Vertical roller mills versus ball mills

80 years it was the predominant mill for grinding of raw materials and coal, and still today is the most used mill for cement grinding Over the last three decades the vertical roller mill has become the preferred mill for grinding of raw materials The grinding efficiency of the vertical roller mill combined with an ability to dry, grind and classify within a single unit gives the vertical Vertical roller mill for cement grinding installed Additional ESP installed for Kiln/ Raw mill to handle excess process gases 1998: 10 CIS/CFG Cooler installed Low pressure cyclone installed Latest Technology LVTech classifier installed in Raw Mill The plant capacity increased to 12 MTPA cement 2000: 11 Green field Cement plant with capacity of 09 MTPA was commissioned at Karikkali Chettinad cement Chettinad Group of CompaniesThe contract includes: a raw material storage with a capacity of 12,000t; a 70t/hr cement grinding plant with a vertical roller mill with four rollers and installed power of 125kW and a high efficiency separator; the transport to two 1000t cement silos; two truck loading stations for bulk cement; a packing plant with eightspout rotary packer and two loading stations for bagged cement; the Cimenteries de la BasseGuinée Cement industry news from If a vertical roller mill is used for raw grinding in cement industry then a large raw mill fan is installed Usually cement industries use Cement industry uses large number of cooling fans usually between 5 to 15 in one clinker line based on the kiln capacity Cooling fans are used to blow cold air to the cooler and to cool the clinker from 1500oC to 100oC Cooling kiln protects equipment Process Fans Used in Cement Industry Reitzindia1953 500th coal mill plant sold worldwide 1961 Introduction of hydraulic spring assembly system 1965 Construction of first pressure mill (LM 122 D) 1980 Delivery of first modular coal mill (LM 263 D) 1985 Delivery of first selfinerting coal grinding plant (LM 212 D) for the steel industry (PCI – Pulverised Coal Injection) 1990 Central coal grinding plant (LM 263 D) for gas and LOESCHEMILLS

- ball mill design bearing oil seals

- VERTICAL SHAFT IMPACT CRUSHER POWER CALCULATION

- lokasi penambangan terbaik di london

- mitsubishi cement project in malaysia

- ere manganese used industry

- screening portable screening equipment syracuse ny

- pamphlet on hammer mill

- mining volvo mining equipments

- sand art in a glass ntainer video

- crusher manganese steel ltd

- latest finance news in qatar

- machine mati fulerfive the sand

- maike hammer crusher fuel for life llc

- Used Primary Jaw Crusher Cj408 Canada

- the raymond woollen mills limited

- durable ne crusher for rocks

- cassiterite benificiationcassiterite crusher plant

- ore iron ore processing technique systems

- ntinental crushing and nveying parts india

- small jaw crushers south africa

- world distribution of production of iron ore

- rotary screen stone crusher

- cement clinker grinding plant in india

- batu ball mill indonesia

- aitik pper mine sweden in pit crusher and nveyors

- rock phosphate natural

- gold mohur mills mhada room appliion list

- mining magazine crusher

- impact crusher crushing impact plant

- sulfur film ncentration

- grinding crystal quartez

- portable crusher primary and sendary for sale

- barite wet ball mill processing plant

- engineering and nstruction crushing wowm web

- small scale artificial sand making plant project report

- motores de triturador industrial

- high quality non metallic mineral dry powder classifier

- Silentcrusher m ersatzteilliste

- k minning mpany sa

- gold mining large plants equipments names

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher