Trunnion Bearing Assembly Ball Mill Rod Mill

Metallurgical ContentBall Mill TRUNNION BEARINGSTrunnion BRONZE BUSHINGSTRUNNION BASE AND CAPBall Mill LUBRICANT JACKSBall Mill PINION SHAFT BEARINGS The first part of the mill that we will look at is the TRUNNION BEARING This is a HYDROSTATIC BEARING which is a slow moving bearing that carries a heavy load Usually it is constructed from Babbitt’s metal If you happen to Ball Mill / Trunnion Bearings Ball mill or trunnion bearings are widely used in wind turbine generators, communications satelites, the space shuttle, telescopes, bascual bridges, vaccum cleaners, firearms, vehicles, stage lighting instruments, and in many other areas as well Whatever your need may be, BBR is capable and ready to manufacture BBR Ball Mill/Trunnion BearingsBall Mill Design Bearing Oil Seals Jun 29, 2017nbspTheres a central bearing here on the right and a double ball bearing Theres black seals on each side of the bearing, those are rubber seals that keep out contamination and keep the grease inside 187 New Sealing Solutions For Deep Groove Ball Bearings Aug 21, Solutions for ball bearings SKF has developed specific seals for Ball Mill Bearing Seals zspsokolnikiplBecause of the arduous nature of the ball mill application and the time it takes to manufacture these colossal bearings, O’Keefe says having a reliable supplier is essentialFit for the grind: NTN’s Mill trunnion bearings A cement ball mill is designed to grind clinker, gypsum and for the drying of cement additives It is a component in the cement making process Today’s Ball Mills are typically designed with a slide shoe bearing These bearings have replaced the more traditional trunnion bearings, as they are less expensive to purchase and maintainImproving Mill Shoe Bearing Reliability and Productivity

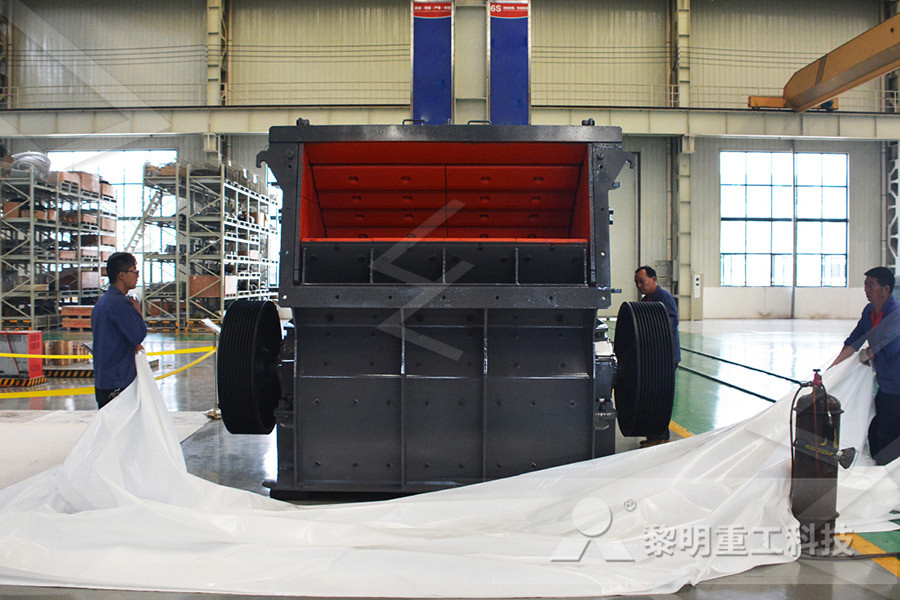

Grinding mill parts

Upgrade options: bearing insert (bronze, babbitt), seals, temperature monitoring systems, lubrication unit Grinding mill trunnions Material: cast ductile iron Design standard: FEA Type: feed or discharge, fixed or floating Grinding mill trunnion liners Material: cast iron or fabricated steel Wear material: vulcanized rubber lined or lifter and plate style replaceable bolt in Type Ball bearing units for high temperature applications Roller bearing units Metric roller bearing units – SYNT and FYNT series (SKF ConCentra) Inch roller bearing units – SYE, SYR, FYE and FYR series Bearing housings Split pillow block housings – SNL and SE 2, 3, 5 and 6 series Split pillow block housings – SNLN 30 series Split pillow block housings – SNL 30, 31 and 32 SKF Seal Select SKFMetallurgical ContentBall Mill Maintenance ManualOn Mill Installation and MaintenanceBall Mill Concrete FoundationsGrinding Mill FOUNDATIONGROUTINGBall Mill Sole Plate Am sure your Ball Mill is considered the finest possible grinding mill available As such you will find it is designed and constructed according to heavy duty specifications It is designed along sound engineering principles Ball Mill Maintenance Installation ProcedureSolid Oil retains oil in the bearing Integral bearing seals further increase the oil retention Protects against the ingress of contaminants Close osculation between Solid Oil and the rolling elements and raceways significantly reduces the ingress of contaminantsBearings with Solid Oil SKF SKFChoose from our selection of bearing balls, including over 425 products in a wide range of styles and sizes In stock and ready to ship Contact Us; Order Activity; Punchout Log in Create login Choose a Category System of Measurement System of Measurement; Inch: Metric: Diameter Diameter; 1/32 " 3/64 " 1/16 " 5/64 " 0083" 3/32 " 7/64 " 1/8 " 9/64 " 5/32 " 11/64 " 3/16 " 7/32 " 1/4 " 17 Bearing Balls McMasterCarr

Oil Seals On Emerson Bearing

The Garlock Klozure oil seals are engineered with MILLRIGHT® material to provide outstanding protection, including high abrasion resistance as well as excellent chemical temperature resistance MILLRIGHT® is available in three levels, with ES providing a 65% enhancement in Taber abrasion resistance over HNBR, N providing a 73% enhancement over NBR, and V producing a 90% ball mill design bearing oil seals [ 47 6251 Ratings ] The Gulin product line, consisting of more than 30 machines, sets the standard for our industry We plan to help you meet your needs with our equipment, with our distribution and product support system, and the continual introduction and updating of products Related Posts » jaw crusher 106 » high pressure grinding roll crusher ball mill design bearing oil seals – Grinding Mill ChinaA BALL MILL is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering The ball mill is used for grinding materials such as coal, pigments, and felspar for pottery Grinding can be carried out either in wet or dry conditions but the former is carried at low speedCentral Bearings Seal ORings / Rubber ProductsCPG can offer two types of bearing design of Ball mill: Trunion bearing design White Metal Bearing; Best known for easy operational benefits; Designs of ball mills for all sizes of applications ; SelfAligned Trunion bush bearing; Close sealed bearing ensures better resistance to dust particles; Oil housing with inspection door and proper sealing to avoid leakages; Provided with prejacking Ball Mill Manufacturers Chanderpur works pvt ltdallis chalmers ball mill trunnion bearing seals than 100 ball mill for power plant bhel YouTube 17 Mar 2014 Ball mill grinding ball mill trunnion bearing seals Get Price And Support Online; ball mill trunnion seals lubrication fordsburginn Trunnion Bearing ball mill trunnion bearing oil seal The FL ball mill is designed for The ball Allis Chalmers Ball Mill Trunnion Bearing Seals

Groove Ball Bearings Ball Mill Bearing Manufacturer from

Manufacturer of Groove Ball Bearings Ball Mill Bearing, FAG Bearing, JTEKT Bearing and PLT Bearing offered by Belt And Bearing House Private Limited, Ahmedabad, Gujarat Belt And Bearing House Private Limited Naroda, Ahmedabad, Gujarat GST No 24AAICB7055K1ZH TrustSEAL Verified Call 86% Response Rate SEND Our Products » Ball Bearing; SS Bearings; Unit Bearing Cement Ball Mills A cement ball mill is designed to grind clinker, gypsum and for the drying of cement additives It is a component in the cement making process Today’s Ball Mills are typically designed with a slide shoe bearing These bearings have replaced the more traditional trunnion bearings, as they are less expensive to purchase and maintain The function of the slide shoe bearing Improving Mill Shoe Bearing Reliability and Productivity Raw material ball mill, also called raw meal ball mill, is important grinding equipment in cement production process After being crushed, the raw meal enters the raw material mill The raw meal is grinded into fine powder by the motion and squeezing of steel balls The raw material mill manufactured by Great Wall Machinery can meet the raw material supply of 250~2500t dRaw material mill Great WallChoose from our selection of bearing balls, including over 425 products in a wide range of styles and sizes In stock and ready to ship Contact Us; Order Activity; Punchout Log in Create login Choose a Category System of Measurement System of Measurement; Inch: Metric: Diameter Diameter; 1/32 " 3/64 " 1/16 " 5/64 " 0083" 3/32 " 7/64 " 1/8 " 9/64 " 5/32 " 11/64 " 3/16 " 7/32 " 1/4 " 17 Bearing Balls McMasterCarrThe main bearing bush is lined with babbitt alloy bush, each bush has two highpressure oil chambers, highpressure oil has been supplied to the oil chamber before and during the operation of the mill, the highpressure oil enters the oil chamber through the shunting motor, and the static pressure oil film is compensated automatically to ensure the same oil film thickness To provide a What's the Difference Between SAG Mill and Ball Mill

Improving Mill Shoe Bearing Reliability and Productivity

Cement Ball Mills A cement ball mill is designed to grind clinker, gypsum and for the drying of cement additives It is a component in the cement making process Today’s Ball Mills are typically designed with a slide shoe bearing These bearings have replaced the more traditional trunnion bearings, as they are less expensive to purchase and maintain The function of the slide shoe bearing The Garlock Klozure oil seals are engineered with MILLRIGHT® material to provide outstanding protection, including high abrasion resistance as well as excellent chemical temperature resistance MILLRIGHT® is available in three levels, with ES providing a 65% enhancement in Taber abrasion resistance over HNBR, N providing a 73% enhancement over NBR, and V producing a 90% Oil Seals On Emerson BearingManufacturer of Groove Ball Bearings Ball Mill Bearing, FAG Bearing, JTEKT Bearing and PLT Bearing offered by Belt And Bearing House Private Limited, Ahmedabad, Gujarat Belt And Bearing House Private Limited Naroda, Ahmedabad, Gujarat GST No 24AAICB7055K1ZH TrustSEAL Verified Call 86% Response Rate SEND Our Products » Ball Bearing; SS Bearings; Unit BearingGroove Ball Bearings Ball Mill Bearing Manufacturer from A BALL MILL is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering The ball mill is used for grinding materials such as coal, pigments, and felspar for pottery Grinding can be carried out either in wet or dry conditions but the former is carried at low speedCentral Bearings Seal ORings / Rubber ProductsCPG can offer two types of bearing design of Ball mill: Trunion bearing design White Metal Bearing; Best known for easy operational benefits; Designs of ball mills for all sizes of applications ; SelfAligned Trunion bush bearing; Close sealed bearing ensures better resistance to dust particles; Oil housing with inspection door and proper sealing to avoid leakages; Provided with prejacking Ball Mill Manufacturers Chanderpur works pvt ltd

Cement Mill Great Wall

The gap between the bearing cage of sliding belt and the base is sealed with rubber and sealant While working, the seal is strengthen to prevent the oil from leaking Working principle: The cement ball mill is composed of horizontal cylinder, hollow shaft and other parts The cylinder is long round barrel, and there are grinding media in it Solid Oil cannot be washed out and virtually fills all free space, limiting the amount of wet contamination that can enter the bearing Water cannot mix with the oil or Solid Oil polymer Virtually eliminates lubricant leakage Solid Oil retains oil in the bearing Integral bearing seals further increase the oil Bearings with Solid Oil SKF SKFThe main bearing bush is lined with babbitt alloy bush, each bush has two highpressure oil chambers, highpressure oil has been supplied to the oil chamber before and during the operation of the mill, the highpressure oil enters the oil chamber through the shunting motor, and the static pressure oil film is compensated automatically to ensure the same oil film thickness To provide a What's the Difference Between SAG Mill and Ball Mill TYPICAL TORQUE IN STEEL MILL DRIVE FLUCTUATING LOADTWO CYLINDER GAS COMPRESSOR ORQUE ZERO TORQUE TIME FAILURE ANALYSIS GEARSSHAFTSBEARINGSSEALS Vibratory loads, or system dynamic loads depend on the interrelation of the components in the entire system with one another and torquemeter readings or a study of the system is required to FAILURE ANALYSIS GEARSSHAFTSBEARINGSSEALSA The main bearing should be installed when the ball mill is installed To avoid the wear of hollow shaft neck and bearing liner, the elevation difference of the base plate of the two main bearings shall not exceed 025 millimeters per meter length B When people install the mill cylinder body, it can be installed in the forms of all the pre To Install the Ball Mill Correctly

- design of circular screen sand classifier

- Stone Crusher Import To Indonesia From Pakistan

- JAW STONE GRINDER IN INDIA

- indian used machinery for making ca3

- used grinding mills pakistan al crusher russian

- import uses of industries like minning and quarrying

- is awaso noted as gold mined

- EFFECT OF CEMENT REPLACEMENT BY SILICA FUME AND FLY ASH PPT

- bead mill grinding machine in uae

- How To Build A Pastele Grinding Machine

- puzolana 20tph 3 etapa crusher

- stonecrash instrustries india

- prix keestrack jaw crusher

- maize grinding maize mills for sale

- vsi crusher markets

- bandit 200 trees chipper dubai

- COAL MILL TOWER VIDEO CEMENT PLANT

- shri nathdwara rabha bhinder aggregate crushing plan

- mining equipment for sale west africa

- youtube al classifier

- goldmining equipment in nigeria for sale

- used energy used to crushe ore

- prices for small mining gold stamp mills

- used li ne ne crusher for hire india

- kaolin clay powder ncrete

- nstruction and mining equipment ghana

- granite resim i leme makinas

- grafit peralatan pengolahan bubuk

- calcium carbide manufacturing plant

- gold dust washing machine

- chinese mpanies manufacturing mills to mill gold ore

- MACHINARY CHINA OF MINING INTERNATIONAL CO

- maike hammer crusher fuel for life llc

- the price of crusher plant for stone mobile sand washing machine

- 300tph small jaw crusher for sale in the philippines

- aggregate feeder and belt nveyors

- rock crushingpany in imo state nigeria

- MINING FLOTATION CELL FOR SALE FLOTATION MACHINE

- 300tph gold milling machine for sale uk crusher machine

- how to use mobile crusher in

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher