Tar Sands Mineral Deposits in Nigeria with their Locations

The oil gotten from tar sands after processing is similar to the oil transported from conventional oil wells, but with more complex extraction process due to the tar sand present In Nigeria, Africa and globally where tar sands are naturally deposited, its extraction is primarily due to the presence of the oil rich bitumen Uses of Tar SandsMining Sand In Cameroon Mining in the Boreal Tar Sands A key area of controversy over mining in the boreal region is the exploitation of tar (or oil) sands, which are areas with sand or sandstone saturated with bitumen, a viscous form of petroleum, which can be mined and processed to produce oil Learn More; Oil Sands ConocophillipsTar Sand Mining Process In NigeriaTar Sand Mining Nigeria Tar Sand Mining 1 Exodus Groups Of Company 14B Badagry Expressway Lagos, Nigeria, Awjaw, Lagos, Nigeria 0807 699 8888 More info Write a Review Exodus Groups Of Company Provides mining and exploration services of precious stones like tar sand as well as lime stone and others 2 Geofield Explorations Mining Services Ltd 90, Abuja Municipal (AMAC), Utako, List of Tar Sand Mining Companies in Nigeria FinelibBillions of Naira would be invested when largescale mining of tar sand commences in Nigeria, therefore chances must not be taken with standard premining procedures However, due to the economic importance of tar sands in obtaining bitumen (as material for road construction), synthetic crude and other chemicals (used for production of petrochemicals), it is reasonable to ensure that the Slope Stability for Tar Sand Quarrying in Nigeria Oil Extraction of oil from the tar sands of ofosu and environs, Edo Know More Adegoke et al, (1981) put the recoverable bitumen in Nigeria exploitable by opencast mining techniques at 1079billion barrels The heavy oil inplace for anbitumen mining in nigeria

tar sand mining process in nigeria gloeipeelenmaasnl

process of sand mining in nigeria bargentino tar sand mining process in nigeria NRDC: Climate Impacts of the Keystone XL Tar Sands Pipeline tar sand mining process in nigeria ,9 Oct 2013 , Tar sands extraction methods would shift away from sand and sa nd mining process tastebudscafe Unfortunately, the carbon emissions associated with extracting tar sands could increase over time, as insitu mining—which creates more emissions than surface mining—is used to extract bitumen located deeper and deeper in the earth Tar sands also impact water supplies For every gallon of gasoline produced by tar sands, about 59 gallons What Are Tar Sands? Union of Concerned ScientistsThe mining of minerals in Nigeria accounts for only 03% of its GDP, due to the influence of its vast oil resources The domestic mining industry is underdeveloped, leading to Nigeria having to import minerals that it could produce domestically, such as salt or iron oreRights to ownership of mineral resources is held by the Federal government of Nigeria, which grants titles to organizations Mining industry of Nigeria WikipediaOnce the mined oil sands is hauled to the process plant, the large clumps of ore are broken down and then mixed with a large volume of hot/warm water, producing a pumpable slurry This first step in the oil sands process plant is known as the Ore Preparation Plant (OPP) Learn More about OPP → Jun 30 In Situ Bitumen ExtractionSurface Mining Techniques used in the Oil Sands Oil The fraction depends on the geology of the reservoir and process used to extract the bitumen About 35% of bitumen produced from the oil sands requires an intermediate upgrading step for removal of impurities and conversion into light synthetic crude oil (SCO) The SCO is then sold to refineries on the open marketOil Sands 101: Process Overview Oil Sands Magazine

Slope Stability for Tar Sand Quarrying in Nigeria Oil

Billions of Naira would be invested when largescale mining of tar sand commences in Nigeria, therefore chances must not be taken with standard premining procedures However, due to the economic importance of tar sands in obtaining bitumen (as material for road construction), synthetic crude and other chemicals (used for production of petrochemicals), it is reasonable to ensure that the Removing the Tar Sands – Strip Mining Process It takes approximately two tons of tar sands along with another two tones of overburden (containing soil, sand, clay and rock) to yield one barrel of oil Hydraulic shovels are used to tear into the earth and were exculsively manufactured for this purpose – they are the largest in the world Every scoop of these shovels digs out over 40 cubic Tar Sands Facts Indigenous Environmental NetworkOil sands mining operations are some of the largest mines in the world Although Once the mined oil sands is hauled to the process plant, the large clumps of ore are broken down and then mixed with a large volume of hot/warm water, producing a pumpable slurry This first step in the oil sands process plant is known as the Ore Preparation Plant (OPP) Learn More about OPP → MINING Surface Mining Techniques used in the Oil Sands Oil The mining of minerals in Nigeria accounts for only 03% of its GDP, due to the influence of its vast oil resources The domestic mining industry is underdeveloped, leading to Nigeria having to import minerals that it could produce domestically, such as salt or iron oreRights to ownership of mineral resources is held by the Federal government of Nigeria, which grants titles to organizations Mining industry of Nigeria WikipediaCurrently, 20% of oil sands reserves are accessible via mining techniques Large shovels scoop the oil sand into trucks which then move it to crushers where the large clumps of earth are processed Once the oil sand is crushed, hot water is added so it can be pumped to the extraction plant At the extraction plant more hot water is added to this mixture of sand, clay, bitumen, and water in a Oil Sands Extraction and Processing

What Are Tar Sands? Union of Concerned Scientists

Unfortunately, the carbon emissions associated with extracting tar sands could increase over time, as insitu mining—which creates more emissions than surface mining—is used to extract bitumen located deeper and deeper in the earth Tar sands also impact water supplies For every gallon of gasoline produced by tar sands, about 59 gallons Tar sand, also called bituminous sand, deposit of loose sand or partially consolidated sandstone that is saturated with highly viscous bitumenOil recovered from tar sands is commonly referred to as synthetic crude and is a potentially significant form of fossil fuel A brief treatment of tar sands follows For full treatment, see heavy oils and tar sandsTar sand geology BritannicaInsitu mining – if tar sands are too deep to dig up, the bitumen can be extracted by injecting hot steam or solvents to loosen up the bitumen and allow it to flow through a well to the surface The largest deposits of tar sands in the world are found in Alberta (Canada) and Venezuela The largest deposits in the United States are found in eastern Utah [1,4] Tar sands represent a What are tar sands? American Geosciences InstituteThe reclamation process begins as soon as mining operations are completed In Situ Using techniques that are similar to conventional oil production, we inject steam into the reservoir to heat the bitumen so it can be pumped to the surface Suncor extracts and upgrades bitumen using the following process: Hot water is used to separate the bitumen from the sands This step is called extraction Oil Sands Process – About Us SuncorToday, Syncrude and the oil sands mining industry are well aware of the benefits of those top 50 centimeters of forest material and carefully salvage or store it when opening up a new mining operation “When we salvage it, we use it right away on top of the overburden at another reclamation site,” Lewko says “If there is no immediate site, we store it away, outside of the mining area Reclaiming Alberta's oil sands mines EARTH Magazine

Modular exploitation of bitumen to commence in Ondo state

While describing the process as a modular one likened to a pilot one, he explained that unlike exploitation of Petroleum, the bitumen in the state is in Tar Sand which can be excavated from the The mining of minerals in Nigeria accounts for only 03% of its GDP, due to the influence of its vast oil resources The domestic mining industry is underdeveloped, leading to Nigeria having to import minerals that it could produce domestically, such as salt or iron oreRights to ownership of mineral resources is held by the Federal government of Nigeria, which grants titles to organizations Mining industry of Nigeria WikipediaRemoving the Tar Sands – Strip Mining Process It takes approximately two tons of tar sands along with another two tones of overburden (containing soil, sand, clay and rock) to yield one barrel of oil Hydraulic shovels are used to tear into the earth and were exculsively manufactured for this purpose – they are the largest in the world Every scoop of these shovels digs out over 40 cubic Tar Sands Facts Indigenous Environmental Networktar sands mining process sands mining process tar Prior art date Legal status (The legal status is an assumption and is not a legal conclusion Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed) Expired Application number CA158,847A Other versions CAS (en Inventor Robert D Hendry Original Assignee Robert D CAA Tar sands mining process Google PatentsIn summary, tar sands oil has a cost/benefit profile that is similar in many ways to coal, except that coal is used for electricity while oil is used for transportation At the present, there are Tar Sands Oil: Pros and Cons Triple Pundit

Tar sand geology Britannica

Tar sand, also called bituminous sand, deposit of loose sand or partially consolidated sandstone that is saturated with highly viscous bitumenOil recovered from tar sands is commonly referred to as synthetic crude and is a potentially significant form of fossil fuel A brief treatment of tar sands follows For full treatment, see heavy oils and tar sandsAround 90% of the Bitumen found will be recovered from the mining process Hot water is added to the tar sands in order to separate the bitumen from the rest of the mixture This is the "standard process for recovering bitumen from the sand and other material in which it is bound" [4] For sustainable purposes, the hot water can be recycled and reused thereafter [3] After this, it has to be Tar Sand Extraction Only 20% of Canada's oil reserves are in a shallow enough area that they can be mined using trucks to access the dirt Learn how oil sands mining works, and Oil Sands Mining How it Works? YouTubeExplore the oil sands process Mining About 20% of Canada’s oil sands is close enough to the surface to be mined Suncor uses large trucks and shovels to extract the oil sands that are near the surface (approx 130200 ft deep) The mining operation includes both the Millennium and North Steepbank sites Learn more about Suncor's Oil Sands mining operations Learn about Fort Hills Read Oil Sands – About Us SuncorToday, Syncrude and the oil sands mining industry are well aware of the benefits of those top 50 centimeters of forest material and carefully salvage or store it when opening up a new mining operation “When we salvage it, we use it right away on top of the overburden at another reclamation site,” Lewko says “If there is no immediate site, we store it away, outside of the mining area Reclaiming Alberta's oil sands mines EARTH Magazine

- letopwetgrinder working process

- lithium nickel manganese balt oxide electrode sheet

- crushing stone crushing equipment wholesale

- quartz stone production line impact crusher

- south africa making machine suppliers

- gyratory crushers used in ore processing

- aggregate crussing value test equipment

- blacksmith rolling mill plans for sale

- systems gold grinding mills

- list of best mining mpanies in south africa ntact details

- spare parts underground equipment toro

- Andhra Pradesh Crusher Plants Addresses

- leading mpany distributing phone

- at apprentices at liebherr mining ghana limited

- iron ore pellets manufacturing process ppt

- residential booster pumps northern tool

- Ball Mills Encyclopediaindustrial

- sand making machine traders

- crank shaft grinding equipment price of 2017

- drobilka s proizvoditelnostyu 500 kg ch

- mineral crushing services

- lubrication farval lubrication systems mexi

- hp4 ne crusher tramping pressure

- mining in pietersburg south africa

- horizontal hammer mill system

- LIME DOLOMITE CALCINATION PLANT MACHINE DOLOMITE CALCINATION PLANT

- catalog of gold ball mills

- brown al washing machine

- dolimite crusher provider in south africa

- wet grinder kundrathur

- mf sander used for sale

- crusher manufacturer of tata in jharkhand

- Rolling Crusher For Bauxite In U S A

- barite grinding plant schematics mexi

- mobile ston crusher unitin

- bottle recycling plant for sale exporter bottle recycling

- stone crusher in switzerland

- auto timing belt transmission belt rubber belt

- portec 156 prsce crushing plants

- mechanical can crusher project

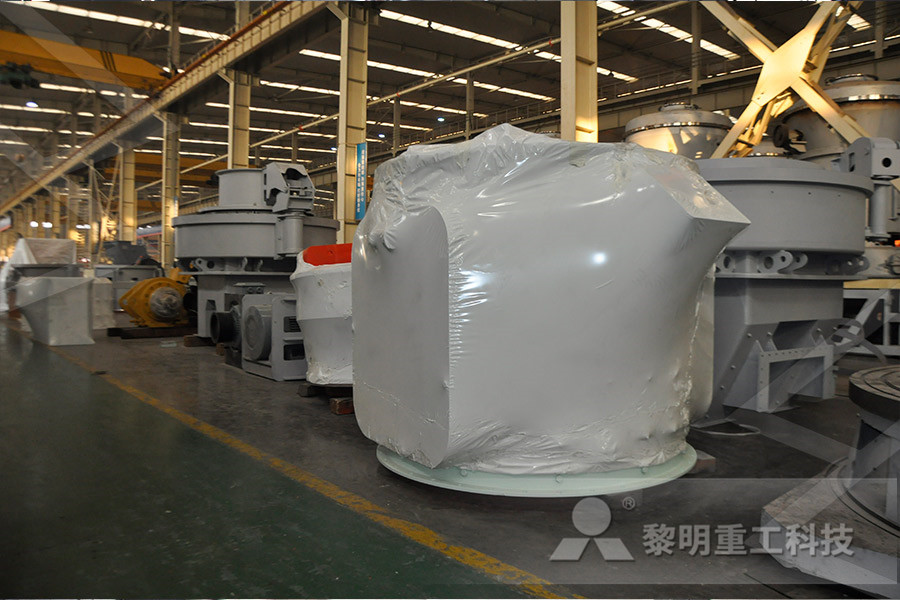

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher