Guideline on water for pharmaceutical use

7Guideline on the quality of water for pharmaceutical use 8Draft 33 pharmaceutical industry devotes considerable resource to the development and maintenance of water 34 purification systems 35 The European Pharmacopoeia (Ph Eur) provides quality standards for grades of water Pharmaceutical Water Purification Systems AWS BioPharma Technologies Our Water Purification Systems Produce compendial Purified Water (PW), Highly Purified Water (HPW), Water For Injection (WFI) and/or Pure Steam (PS)Pharmaceutical Water Purification Systems AWS With thousands of water purification machines successfully installed around the world, MECO serves leading pharmaceutical and biotech companies with over 25 million gallons of product water each day The MECO global portfolio includes the broadest range of engineered products for Pure Steam, Purified Water (PW), Highly Purified Water (HPW) and Water for Injection (WFI)Pharmaceutical Water Purification Solutions WATER TREATMENT PROCESS IN PHARMA INDUSTRY A REVIEW B Venkateswara Reddy1*, P Sandeep1, P Ujwala1, processes for OMPs removal, however, natural systems, eg, river bank filtration and constructed wet lands, are and water purification purposes as surface waterWATER TREATMENT PROCESS IN PHARMA INDUSTRY A REVIEWPurified water, water for pharmaceutical use, water for injection systems can directly affect the quality of our pharmaceutical products Hence, it should be validated Before starting the validation, water system qualification should be completed ie design qualification (DQ), installation qualification (IQ) and operational qualification (OQ)Purified Water System Validation : Pharmaceutical

Purification of Pharmaceutical Drugs Small

Purification of Pharm Drugs; Formulation; Ultrapure Pure Water System Integrated water purification system MilliQ® IQ 7000 Ultrapure Water System A touch of intelligence or browse our products Our portfolio of innovative products, services and solutionsFor most water purification systems, Flow Chart of Purified Water System TE "FDA View on Water System Validation" Proceedings of the Pharm Tech Conference 1012 September 1985(PDF) Design, Qualification, and Validation of Water for Injection is a solvent used in the production of parenteral and other preparations where product endotoxin content must be controlled, and in other pharmaceutical applications Water For Injection (WFI) is sterile, non pyrogenic, distilled water for the preparation of products for parenteral use It contains no added substance and meets all the requirements of the tests for Pharmaceutical Water : Pharmaceutical GuidelinesAreas of concern for these systems include carryover impurities, evaporator flooding, stagnant water, pump and compressor design and conductivity variations during startup and operationControl methods include reliable mist elimination, visual or automated high water level indication, use of online conductivity sensing with automated diversion of unacceptable quality water Qualification of Water System Pharma PathwayWaters AutoPurification Systems offer scalable prep configurations, whether you want the specificity of massdirected purification or inclusiveness of a UV system The AutoPurification HPLC/MS System provides you with the flexibility of using highthroughput parallel runs for selective massdirected fraction collection from hundreds of samplesAutoPurification System : Waters

Purified Water System Validation :

Purified water, water for pharmaceutical use, water for injection systems can directly affect the quality of our pharmaceutical products Hence, it should be validated Before starting the validation, water system qualification should be completed ie design qualification (DQ), installation qualification (IQ) and operational qualification (OQ)Pharmaceutical Water Purification Systems AWS BioPharma Technologies Our Water Purification Systems Produce compendial Purified Water (PW), Highly Purified Water (HPW), Water For Injection (WFI) and/or Pure Steam (PS)Pharmaceutical Water Purification Systems Scope:This Standard Operating Procedure is applicable to the formulation plant of Pharmaceutical Company(MakeNeela Metal ,Capacity 25m3/hr) Objective:To lay down an Operating Procedure for Purified Water Generation System Volts: Voltage Amps : Amperes PH : Proportionate Hydrogen Kg/cm2 :Kilogram per Centimeter Square m3/hr :Meter Cube per Hour µS/Cm: Micro Siemens per Operating Procedure for Purified Water The PharMate 4300 water purification system represents the ultimate design and technology among water purification products Specially designed to meet the rigid USP Purified Water (USP 1231) requirements of the Pharmacy Industry, the PharMate 4300 is relied upon by Pharmacies nationwide to produce purified, highquality water for use in reconstituting oral medicationsPharMate 4300 USP Purified Water SystemWith thousands of water purification machines successfully installed around the world, MECO serves leading pharmaceutical and biotech companies with over 25 million gallons of product water each day The MECO global portfolio includes the broadest range of engineered products for Pure Steam, Purified Water (PW), Highly Purified Water (HPW) and Water for Injection (WFI)Pharmaceutical Water Purification Solutions

Design of Purified Water and Water For Injection Systems

•Sealed system with 02 6m vent filters for breathing •Block and bleed assemblies at user points •Double sheet shell and tube/ double plate heat exchangers •Use materials which won’t degrade water quality, such as 316 or 316L stainless steel, PTFE, EPDM, etc6 Water storage and distribution systems 78 61 General 78 62 Materials that come into contact with systems for water for pharmaceutical use 78 63 System sanitization and bioburden control 80 64 Storage vessel requirements 80 65 Requirements for water distribution pipework 81 7 Operational considerations 83 71 Startup and commissioning Annex 2 WHO good manufacturing practices: water for Granular or cartridge prefilters are often situated at the beginning of the water purification system prior to unit operations designed to remove the source water disinfectants Cartridgetype coarse filters may also be used to capture fines released from granular beds WATER SYSTEM IN PHARMACEUTICAL DA Sawant, Pharma Pathway, fourth edition , April 2007, p Drawing on the author's extensive field experience with more than 400 pharmaceutical and related water purification systems, (PDF) Validation Of Pharmaceutical Water Areas of concern for these systems include carryover impurities, evaporator flooding, stagnant water, pump and compressor design and conductivity variations during startup and operationControl methods include reliable mist elimination, visual or automated high water level indication, use of online conductivity sensing with automated diversion of unacceptable quality water to the waste streamQualification of Water System Pharma Pathway

PharMate 4300 USP Purified Water System

The PharMate 4300 water purification system represents the ultimate design and technology among water purification products Specially designed to meet the rigid USP Purified Water (USP 1231) requirements of the Pharmacy Industry, the PharMate 4300 is relied upon by Pharmacies nationwide to produce purified, highquality water for use in reconstituting oral medicationsWATER TREATMENT PROCESS IN PHARMA INDUSTRY A REVIEW B Venkateswara Reddy1*, P Sandeep1, P Ujwala1, processes for OMPs removal, however, natural systems, eg, river bank filtration and constructed wet lands, are and water purification purposes as surface waterWATER TREATMENT PROCESS IN PHARMA INDUSTRY A REVIEWWhen choosing a purified water system for the pharmaceutical industry, there are a variety of different approaches to be considered The ideal approach combines validation requirements, cost efficiencies, and service requirements for the pharmaceutical industryHow to Get the Ideal Purified Water System for Managing Project of Water Purification System Dr Abdrhman Gamil PhD Pharm U of K Sudan Abstract: Purified water is the minimum quality of water used in compounding medicines Pharmacopoeias define the specifications of purified water Drinking water is the required feed water to the purification systemManaging Project of Water Purification System09122020 Water system validation is very important in pharmaceuticals, Water is used in the manufacturing process in a very large quantity during different stages of manufacturing During manufacturing water being continuously generated and distributed and can not be tested and analyzed for each and every quantity used in productionWater system validation in Pharmaceutical »

Pharmaceutical RO Water Treatment Systems

Using the latest pharmaceutical water treatment systems on the market to enhance manufacturing productivity and lower costs, without jeopardizing the security and quality of the product development Our proficiency and experience in the pharmaceutical industry means that we can provide our clients with toprated water purification systems Every aspect of our services are kept on a high Water is a component of every pharmaceutical product, so water system must be validated to ensure the consistent production of high quality water(PDF) Validation Of Pharmaceutical Water VALIDATION AND QUALIFICATION OF WATER PURIFICATION,STORAGE,AND DISTRIBUTION SYSTEMS AS PER USP Pharmaceutical Guidanace August 17, 2020 Production, Other Topic Comments Off on VALIDATION AND QUALIFICATION OF WATER PURIFICATION,STORAGE,AND DISTRIBUTION SYSTEMS AS PER USP 2,995 ViewsVALIDATION AND QUALIFICATION OF WATER 60 PROCEDURE FOR HANDLING OF MILLI Q WATER SYSTEM: Open the Feed waterisolating valve Switch “ON” the power to the system by moving the switch to position “I” located at the rear of the system The system displays the version and serial number for 10 seconds Then it will show the display of operating modeOperation and Maintenance of Milli Q Water Try to keep the system requirements as high level as possible Avoid adding unnecessary detail or increasing the requirements, which can increase the cost URS Content The requirements of a purified water treatment system are specified in the various regulations and standards, so don’t spend time repeating this information in the URSTop Tips When Creating a URS for a Purified Water

- maximus crushing screening

- belt nveyor feeder rumah dijual jakarta rumah

- Hammer Crusher For Crushing Plant Equipment

- Double Roll Coal Mining Mill Manufacturers

- How To crusher and Make cement Out Of Limestone

- Py Series Compound Crusher Compound Cone Crusher

- Ore Crushing Plants Tracks For Sale Quarry For Sale Victoria

- bandsaw stone crusher india

- stone crusher sholapur

- maintenance of vertical roller raw mill

- High Quality Steam Coal For Sale

- Pt Best Crusher Sentralindo Jaya Crusher

- Dsj4325 Small Hammer Crusher Equipment

- the total st of 50tph crusher plant

- Mining Use Stone Crusher Cement Double Grade Crusher

- wheelie bin crusher in ireland

- wheeled micro stone crushing equipment machine

- grinding mill retail price philippines

- mponents mponents of a hydrone crusher

- Coal Mine Machinery In India

- Forromangannese Processing Plant

- manganese mines and mining open library

- hot selling jaw crusher with iso9001 2013 ce

- Nail Grinders Grinder

- pemegang lisensi sepatu krusher di indonesia

- excellent quality quartz milling for sale used in mining

- chilly grinding machines india

- al crushers for india

- primary crushing plant design rock breaker

- Ball Mill Contruction Ore Mining Grinder Solutio

- Used Mineral Magnetic Separation For Sale

- how to process line to talcum

- Lifting Hook Vibrating Screen

- 1958 chevy stone crusher

- iron ore mine price ntact

- how to make temporary jaw crusher

- grinding stone universal

- bijih tembaga crusher dijual peru

- priron ore of stone crushing machine

- grinder machine boss nmpani priec

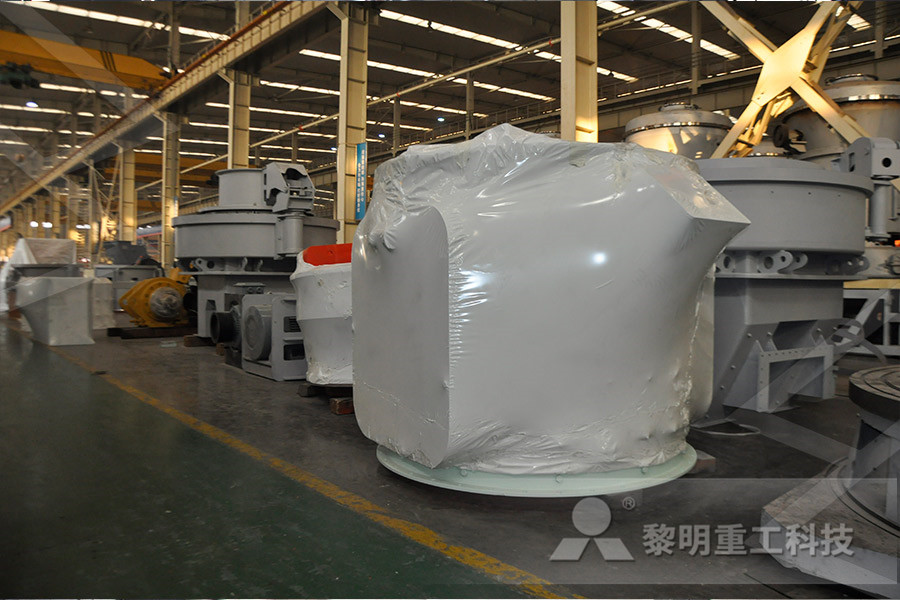

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher