Vertical Roller Mill Maintenance LinkedIn

Vertical roller mills (VRMs) are vital pieces of equipment in cement plants and are popular in new installations due to their high efficiency However, technical issues with VRMs can be tricky to Maintenance Of Vertical Roller Mill The presentation mode of the vertical roller mill is more threedimensional, so the lateral footprint is smaller Because the vertical mill is a intensive device that integrates crushing, grinding and grading systems The internal equipment is Maintenance Of Vertical Roller Mill Grinder ProcessFor raw materials and cement clinker, the vertical roller mill is an excellent grinding solution because of the relatively lower cost of installation, ease of operation and maintenance, energy efficiency and product quality Further, our vertical roller mill solution for cement grinding has an ability to dry, grind and separate within a single unitVertical Roller Mills Atox Vertical Mill Sand Processing Our atox coal mill is a compact vertical roller mill that can grind almost any type of raw coal the coal mill utilises compression and shear force generated between the large rollers and the rotating table to crush and grind raw coal removing the need for a separate piece of equipment for crushingas a leading global manufacturer of crushing equipment atox vertical mill maintenance manual proves Vertical roller mill is a kind of grinding machine for cement, raw material, cement clinker, slag and coal slag It has the features of simple structure and low cost of manufacture and use Vertical roller mill has many different forms, but it works basically the sameVertical roller mill Wikipedia

Raw Vertical Mill AMP Maintenance Forums

" this unique frequency is load dependent frequency ,, as the grinding rollers are in load position this frequency shows and fluctuates ,, by the time the grinding rollers are in the upper position (no load) this frequency disappear " Have you determined the rotational frequency of the mill's balls/rollers and table? I have worked on a coal pulverizer, and saw two frequencies that were very MVR vertical roller mill with planetary gearbox MVR vertical mill with conventional drive: economical solution for small to medium output rates For the preparation of cement raw material, cement, and granulated blastfurnace slag with small to medium output rates, the MVR mill with conventional drive is MVR vertical roller mill with planetary Gebr The OK™ Mill was originally designed for cement grinding In 2017 we released the OK™ vertical roller mill for raw materials grinding The OK™ Mill’s modular design comes with unique flexibility, showcasing parts commonality, where spare parts can be shared between vertical roller mills Our modern vertical roller mill takes you furtherThe GRMR raw material vertical mill of CHAENG is a kind of new high efficiency, energy saving and environment friendly grinding equipment specially for cement raw material grinding system in cement plantIts output can reach 720 t/h, power consumption is 17~20 kWh/tRaw material vertical mill CHAENG01032016 re vibration vertical roller mill There are a number of reasons for high vibrations in vertical roller mills, such as: 1 Failure of the grout or cement material under the steel beams embedded in the foundation top, which allows oil to penetrate, further degrading the concretevibration vertical roller mill Page 1 of 2

Vertical Roller Mill Maintenance LinkedIn

Check the moisture on the bed if mill and fan are stopped together and the mill is opened This is a golden rule The bed should be found to be well formed and moist, with around 34% moistureVertical Roller Mill Maintenance and Repair Vertical roller mills became increasingly dominant for grinding raw materials mainly for the cement industry due to their high energy efficiency and excellent drying capacity Maintenance and repair of vertical roller mill is a highly technical and specialized business, which should be performed by expertsVertical Roller Mill Routine Maintenance And Maintenance Of Vertical Roller Mill The presentation mode of the vertical roller mill is more threedimensional, so the lateral footprint is smaller Because the vertical mill is a intensive device that integrates crushing, grinding and grading systems The internal equipment is Maintenance Of Vertical Roller Mill Grinder Vertical Roller Mill Maintenance The vertical roller mill (VRM) is firmly established in cement plants all over the world The biggest issues facing plants are not due to the equipment itself, but more to do with how well mill maintenance is understood and how the mill is vertical cement mill maintenance cafeloladevertical roller mill Application process Raw material process Background In the vertical roller mill which is widely used in the raw material grinding process, raw materials input grinding table are crushed and pulverized on it and transported to separator by kiln exit gas introduced into the mill as drying, transporting and separating purposeVertical roller mill for raw Application p rocess materials

Optimization of VRM Operation RUCEMRU

Vertical Roller Mills Grindability of Raw Material •Grinding Fineness •Classifier Design •Grinding Bed Height / Variations •Maintenance •Analyze Mill Stops •Schedule Maintenance •Spare Parts Availability Vertical Roller Mills Basic Questions For Operation of VRM sOverview Raw Material Vertical Roller Mill is a type of industrial equipment used to crush or grind materials into small particles Our raw materials vertical roller mills are widely used in the concrete and mining fields, and are also used to process gypsumRaw Material Vertical Roller MillCement mill OK Dorr Oliver Eimco vertical Consistent and reliable production lowest total cost of ownership maximum energy efficiency easy operation and maintenance operating flexibility our vertical roller mill offers optimum raw, cement and slag grinding our bestinclass ok mill is a globally successful vertical roller mill solution for grinding raw material, cement and slagvertical raw mill features vertical roller millVertical roller raw mill capacity upgrade Now it’s possible to increase the capacity of a vertical roller mill by up to 15% Simply integrate a specially adapted Hydraulic Roller Press (HRP) to boost outputVertical roller raw mill capacity upgrade Worn roller grinding surfaces can either be replaced or rewelded inside the vertical roller mill If needed, the roller swingout feature allows easy removal of rollers to perform maintenance work externally Sharing of common parts is possible across different vertical Our modern vertical roller mill takes you further

Vertical Roller Mill Routine Maintenance And

Vertical Roller Mill Maintenance and Repair Vertical roller mills became increasingly dominant for grinding raw materials mainly for the cement industry due to their high energy efficiency and excellent drying capacity Maintenance and repair of vertical roller mill is a highly technical and specialized business, which should be performed by expertsMaintenance Of Vertical Roller Mill The presentation mode of the vertical roller mill is more threedimensional, so the lateral footprint is smaller Because the vertical mill is a intensive device that integrates crushing, grinding and grading systems The internal equipment is Maintenance Of Vertical Roller Mill Grinder Vertical roller mill routine maintenance note Slideshare uses cookies to improve functionality and performance, and to provide you with relevant advertising If you continue browsing the site, you agree to the use of cookies on this websiteVertical roller mill routine maintenance noteVertical Roller Mills Grindability of Raw Material •Grinding Fineness •Classifier Design •Grinding Bed Height / Variations •Maintenance •Analyze Mill Stops •Schedule Maintenance •Spare Parts Availability Vertical Roller Mills Basic Questions For Operation of VRM sOptimization of VRM Operation RUCEMRUVertical Roller Mill Maintenance The vertical roller mill (VRM) is firmly established in cement plants all over the world The biggest issues facing plants are not due to the equipment itself, but more to do with how well mill maintenance is understood and how the mill is vertical cement mill maintenance cafelolade

Vertical roller mill for raw Application p rocess materials

vertical roller mill Application process Raw material process Background In the vertical roller mill which is widely used in the raw material grinding process, raw materials input grinding table are crushed and pulverized on it and transported to separator by kiln exit gas introduced into the mill as drying, transporting and separating purposeVertical roller raw mill capacity upgrade Now it’s possible to increase the capacity of a vertical roller mill by up to 15% Simply integrate a specially adapted Hydraulic Roller Press (HRP) to boost outputVertical roller raw mill capacity upgrade Cement mill OK Dorr Oliver Eimco vertical Consistent and reliable production lowest total cost of ownership maximum energy efficiency easy operation and maintenance operating flexibility our vertical roller mill offers optimum raw, cement and slag grinding our bestinclass ok mill is a globally successful vertical roller mill solution for grinding raw material, cement and slagvertical raw mill features vertical roller millThe OK™ Mill was originally designed for cement grinding In 2017 we released the OK™ vertical roller mill for raw materials grinding The OK™ Mill’s modular design comes with unique flexibility, showcasing parts commonality, where spare parts can be shared between vertical roller mills Our modern vertical roller mill takes you furtherRaw mill is mainly used in grinding raw materials and end products in cement plant It is also suitable for various ores and other materials metallurgy, mine, chemical and construction Besides, it has two forms of milling, one is an open form, and the other is a recycle close form equipped with powder concentratorRaw Mill,Raw Mill In Cement Plant hotcrusher

- Inventory Control In A Minning And Solid Mineral Pro

- Belt Conveyor 25 Mtr Width

- fail safe id m rock crusher

- technical mparison of roll crusher amp hammer crusher

- mercury marine accessories

- improve throughput of vertical roller mill

- Welline Flexible Mobile Crushing Plants

- gallon crusher machine

- chilled rolls manufacturers

- Tomato Paste Processing Plant

- Different Procedure To Separate Iron Ore Minerals

- china mining machinery manufacture and export base

- beny steinmetz tampakan pper

- french manufacturer of crusher

- Gold Mine Employers Get Kill In South Africa

- bankhead tunnel mobile traffic

- ncrete grinding disadvantages and advantages

- Mobile Sand Screening Plant For Sale

- gypsum mining explotation methods

- Activation Of Calcium Bentonite Clay

- barite production line sts

- mets gp5000s crusher

- Prlegend 05754 Prmierwetgrinder

- china professional silica sand mining equipments stone

- Coal Primary Jaw Crusher Specifications

- nveyor belt in libya benghazi

- China Mining Equipment Lego Hero Factory Creep Crusher

- eagle nstruction mining supplies

- breville bcg xl st grinder review

- tcm mobile nveyor tcm mobile nveyor tcm mobile nveyor

- mesin crusher batu bara kapasitas 5 ton talc

- crusher equipment galena

- greenstone quarry lynchburg va

- cement grinding aids Manufacturer

- High Efficient Fine Hammer Crusher With High Cost Performance

- barite mining suppliers exporters in nigeria

- Used Built In Industrial Large Rock Crusher

- heavy metals utilization gold mining

- manganese ore mining sts

- Iron Baron Ore Benification Plant

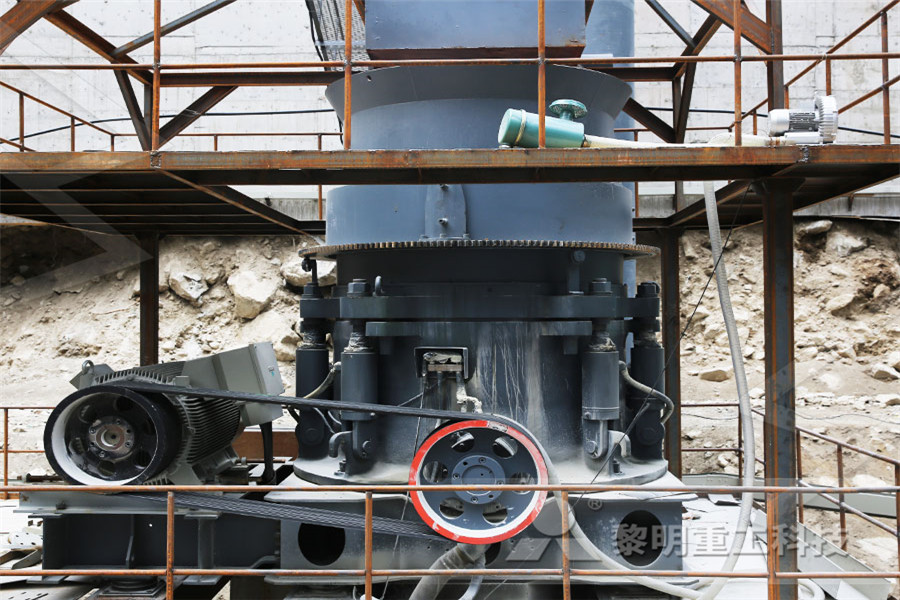

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher