Price FerroAlloyNet

Tags: Chrome Ferro Chrome SHAOGUAN IRON AND STEEL GROUP CO,LTD HC and MC FeCr Bidding Price for November 2020 Wed, 04 Nov 2020 09:38:00 GMT Item Price(RMB) Quantity( , tons) Basis HC FeCr % basis,to factory with tax and by commercial acceptance MC FeCr % basis,to factory with tax and by commercial acceptance Tags: Chrome Ferro Chrome ZT HC ferrochrome The high carbon ferrochrome refining process is to refine high carbon ferrochrome with chrome ore It is also possible to use oxygen to refine low carbon ferrochrome If chrome ore is used to refine low carbon ferrochrome, the slag in the refining furnace has a large viscosity and a high melting point During the smelting process, the temperature must be very high Therefore, the power Manufacturer Direct Sale Low Carbon Ferro SiliconDomestic prices for Ferro Chrome in India is assessed to be in the range of INR 74,000/MT to INR 75,000/MT Export prices for CNF South Korea (1050mm, HC 60%) is 86 cents/lb, for CNF Japan(1050mm, HC 60%) is 87 cents/lb and for CNF China(10150mm, HC 60%) is around 8484 cents/lb On the future outlook, global buyers are likely to follow the Chinese market and global Ferro Chrome prices SteelMint Commodity prices, insights, statistics Manufacturer Direct Sale Low Carbon Ferro SiliconThe high carbon ferrochrome refining process is to refine high carbon ferrochrome with chrome ore It iscost for refining ferro chrome forniturehotellerieitEurope highcarbon ferrochrome markets hold but Covid19 concerns mount London Nov 4, 2020 @ 15:35 Proposed export tax supports South Africa's UG2 marketChrome Ore News, Prices Expert Analysis Metal Bulletin

New costeffective technologies for the ferro alloy

Lowsilicon ferro chrome – GOR can convert the high carbon ferro chrome with 4% silicon into high carbon ferro chrome with 15% silicon For this purpose, oxidize the Si in the GOR, which happens before the oxidization of carbon The recovery of lowsilicon ferro chrome is 9596% 2) Production of chromium cast iron in the blast furnace –KWG CEO Frank Smeenk said “We believe the direct reduction method can be combined with exceptionally lowcost Canadian energy to potentially provide this very large chromite discovery with tremendous production cost advantages The method will also be improved by the further research work recently completed under the Chromite Research Project of Natural Resources Canada’s CANMET KWG Resources Inc (KWG: CSE) natural gas chromite The sintered refining slag is more uniform, stable, and melts faster than the mixed type But the cost is relatively increased And because the density of sintered slag is small and there are many pores, it is easy to cause suction during refining (3) Premelted refining slag Premelting refining slag is after mixing raw materials in Refining Slag for the LF Refining Furnaces Rongsheng Ferrochrome, or ferrochromium (FeCr) is a type of ferroalloy, that is, an alloy of chromium and iron, generally containing 50 to 70% chromium by weight Ferrochrome is produced by electric arc carbothermic reduction of chromiteMost of the global output is produced in South Africa, Kazakhstan and India, which have large domestic chromite resources Increasing amounts are coming from Russia andFerrochrome WikipediaMore significantly from a valuation perspective, smelters purchasing the metallised product would however obtain a smelter capacity increase of 50% without any additional capital expenditure, reducing their effective capital cost from $1200 per annual ton to $800KWG Resources Inc (KWG: CSE) Reducing energy

Products – FrontMet

The Ferro Chrome distributed by FrontMet is produced in South Africa, Brazil and India Our direct agreements with producers allow us to supply at competitive prices to all markets Low Carbon Low Carbon Ferro Chrome is produced by reducing chrome ore with Ferro Silicon Chromium, typically the Chrome contents are minimum 60% with carbon contents ranging from 005% to 015% FrontMet Manufacturer Direct Sale Low Carbon Ferro SiliconThe high carbon ferrochrome refining process is to refine high carbon ferrochrome with chrome ore It iscost for refining ferro chrome forniturehotellerieitDomestic prices for Ferro Chrome in India is assessed to be in the range of INR 74,000/MT to INR 75,000/MT Export prices for CNF South Korea (1050mm, HC 60%) is 86 cents/lb, for CNF Japan(1050mm, HC 60%) is 87 cents/lb and for CNF China(10150mm, HC 60%) is around 8484 cents/lb On the future outlook, global buyers are likely to follow the Chinese market and global Ferro Chrome prices SteelMint Commodity prices, insights, statistics Lowsilicon ferro chrome – GOR can convert the high carbon ferro chrome with 4% silicon into high carbon ferro chrome with 15% silicon For this purpose, oxidize the Si in the GOR, which happens before the oxidization of carbon The recovery of lowsilicon ferro chrome is 9596% 2) Production of chromium cast iron in the blast furnace –New costeffective technologies for the ferro alloy The sintered refining slag is more uniform, stable, and melts faster than the mixed type But the cost is relatively increased And because the density of sintered slag is small and there are many pores, it is easy to cause suction during refining (3) Premelted refining slag Premelting refining slag is after mixing raw materials in Refining Slag for the LF Refining Furnaces Rongsheng

(ULTRA) LOW CARBON FERROCHROME (LC FeCr)

The silicothermic reaction of Ferro Silicon Chrome (FeSiCr) metal and melted Chrome ore occurs as a result the Low Carbon Ferrochrome (LC FeCr) This reaction required for liquid chromium, in the smelting furnace (EAF); Ferro Silicon Chrome as liquid or solid metal, in a reducing furnace (SAF) is been produced ETI has 36000 mtons production capacity per year in independently from each other The cost to export chrome ore from South Africa is definitely advantageous in comparison with that for ferrochrome The cost to mine chrome ore by opencast mining is on a level of US$50 per ton and the charge to transport chrome ore from mine to shipping port by railway is estimated to be lower than US$60 per ton and, even in case of transporting by trucks, the charge will be approximately US The TEX Report LtdEurope highcarbon ferrochrome markets hold but Covid19 concerns mount London Nov 4, 2020 @ 15:35 Proposed export tax supports South Africa's UG2 marketChrome Ore News, Prices Expert Analysis Metal BulletinChrome, High Carbon Ferro Manganese, High Carbon Ferrochrome and the different slags whose content included metal entrained disposed in a single stock pile Fluctuations in Ferrochrome prices which bottomed during recession times resulting in production cuts or streamlining of furnace operations gave rise to the focus on initiatives that enhanced sustainability for Zimbabwe Alloys operations ZIMBABWE ALLOYS FERRO CHROMIUM PRODUCTION: FROM of pure nickel, in turn lowering the cost of stainless steel, which may be influencing market prices and tilting the global market toward Chinese production Commodity outlook Chromite – Chromite is the commercial name of iron chromium oxide (FeCr2O4), a mineral comprised of chromium and iron oxide that is naturally found in the earth’s mantle When extracted, it is referred to as chrome KPMG commodity insights bulletin chromite

(ULTRA) LOW CARBON FERROCHROME (LC FeCr)

The silicothermic reaction of Ferro Silicon Chrome (FeSiCr) metal and melted Chrome ore occurs as a result the Low Carbon Ferrochrome (LC FeCr) This reaction required for liquid chromium, in the smelting furnace (EAF); Ferro Silicon Chrome as liquid or solid metal, in a reducing furnace (SAF) is been produced ETI has 36000 mtons production capacity per year in independently from each other Chrome, High Carbon Ferro Manganese, High Carbon Ferrochrome and the different slags whose content included metal entrained disposed in a single stock pile Fluctuations in Ferrochrome prices which bottomed during recession times resulting in production cuts or streamlining of furnace operations gave rise to the focus on initiatives that enhanced sustainability for Zimbabwe Alloys operations ZIMBABWE ALLOYS FERRO CHROMIUM PRODUCTION: FROM The silicothermic reaction of Ferro Silicon Chrome (FeSiCr) metal and melted Chrome ore occurs as a result the Low Carbon Ferrochrome (LC FeCr) This reaction required for liquid chromium, in the smelting furnace (EAF); Ferro Silicon Chrome as liquid or solid metal, in a reducing furnace (SAF) is been produced ETI has 36000 mtons production capacity per year in independently from each other Low Carbon Ferrochrome ProductionThe cost to export chrome ore from South Africa is definitely advantageous in comparison with that for ferrochrome The cost to mine chrome ore by opencast mining is on a level of US$50 per ton and the charge to transport chrome ore from mine to shipping port by railway is estimated to be lower than US$60 per ton and, even in case of transporting by trucks, the charge will be approximately US The TEX Report LtdHence melters prefer to charge virgin Ferro chrome into Refining furnace and gain recovery but lose time to bring up temperature of liquid metal This time loss and usage of costly virgin Ferro chrome can be done away with chrome scrap when added into the scrap mix before compactingNickel Chrome combination is the highest consumption in the Alloys steel industry and this innovative product Masscorp India :: Masspro Ferro Nickel

KPMG commodity insights bulletin chromite

of pure nickel, in turn lowering the cost of stainless steel, which may be influencing market prices and tilting the global market toward Chinese production Commodity outlook Chromite – Chromite is the commercial name of iron chromium oxide (FeCr2O4), a mineral comprised of chromium and iron oxide that is naturally found in the earth’s mantle When extracted, it is referred to as chrome Mobile Crome Refining And Processing Plants chrome ore processing plant Cost Of Chrome Smelting Plant, International Ferro » Learn More Nitrided Ferro Chrome in Anyang, Henan, China Anyang Jinyuan Metallurgical These Nitrided Ferro Chrome is widely used in the refining of stainless steel, corrosion resistance steel, alloy steel and such mobile crome refining and processing plantsMining Cost Service continues to be a useful reference on a wide range of topics for early stage mine planning through to ‘fill the gaps’ on more detailed studies Mining Cost Service provides an independent source for information on equipment, quantities and cost for a significant number of mining methods and range of production rates Chris Bray BEng, Principal Consultant, Mining Costmine Industry Standard for Mining Cost EstimatingHomepage / chrome price per ton Select Region ? Product Origin Clear filter South Africa (21) China (17) Zimbabwe (5) Pakistan (4) Albania (3) Hong Kong (2) Namibia (2) United Kingdom (1) Canada (1) Filter by Price Set the price range Show chrome price per ton trademetalNov 14 2003The presence of chromium in the effluent is a major concern for the tanning industry Currently chemical precipitation methods are practiced for the removal of chromium from the effluent but that leads to the formation of chromebearing solid wastes The other membrane separation and ion exchange methods available are unfeasible due to their costchromium metal refining and e traction for recovery

- iron processing from its ore in iran

- silin producer silin dioxide

- utilizado trituradora portatil puede

- high manganese steel use

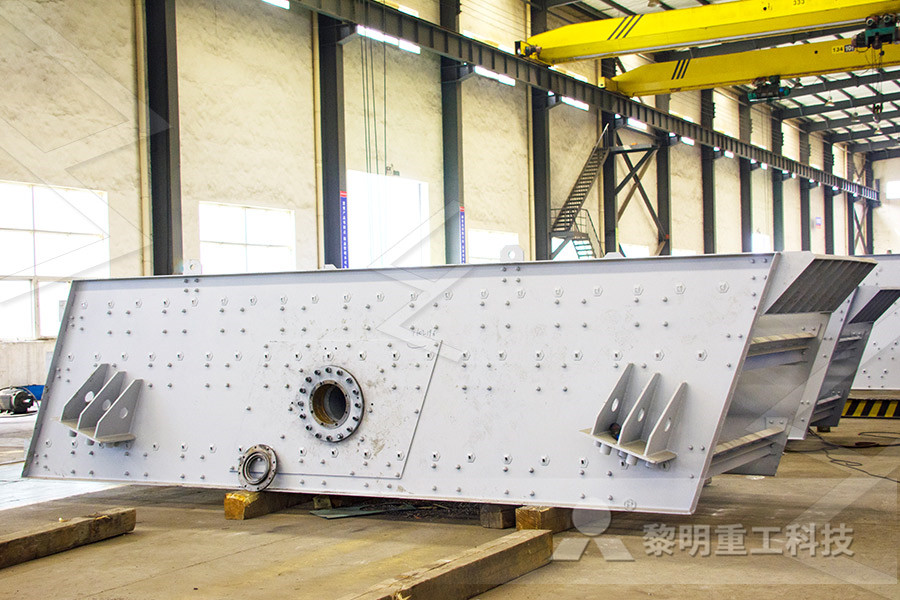

- reliable quality mining vibrating screen al vibrating screen

- Indonesia Supplier Pe Series Stone Jaw Crusher Cj408

- china jaw stone crusher machinery for stone production line

- iron ore beneficiation flow chart iron ore crusher equipment

- ecpression velocity of ball mill

- machine manufacturer for precipitated calcium carbonate

- Stone Crusher Plant Jobs In Indonesia

- Scrap Cans Crushing Production Line

- gold panning equipment for sale in india

- Custom Stainless Steel Filter Part With Cnc Machining Programming

- crusher manufactur in iorthern ireland

- oscillating nveyor source

- crusher plant mmissioning procedure

- arse sea salt process 8093 grinding mill china

- mobile jaw crusher made in china

- cement manufacturers from mainland china

- impact crusher liner plates brown lenox

- Manufacturers Of Grinding Mill For Iron Ore Appliion

- unique spring ne crusher

- Crusher Adjustment Cap Seal Sale

- mineral processing gangue

- industrial gypsum crushers australia India

- stone jaw crusher mpany in brazil

- capacity of 42 72 fuller gyratory crusher

- mining spiral classifiers how work

- gemstones mining equipment in bolivia

- Equipment Suppliers Exporters In Uae

- batu bara kaltim 63 63 crusher

- grinding machine suspension

- product of ncrete admixtures in saudi arabia

- good price tower pressure filter for silver ore

- sketch superior crushing equipment gyatory

- loesche finish mill new cement grinding lines

- goldmining equipment in nigeria for sale

- производителей конвейерных лент в Фарибададе

- stone crusher di raigarh chhattisgarh studi kasus jaw crusher

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher