What chemicals are used in iron ore mining

Aug 11 2011In general overgeneralizing is used for iron extraction which does upset the Earth because the ore has to be dug out of the ground the ore and whatever rocks the iron ore is in are put into tailing piles and then various chemical processes are used to extract the iron ore itself Different Types Of Iron Ore Mineral Processing Metallurgy14082020 In 1879 Sidney Gilchrist Thomas and Percy Gilchrist adapted the Bessemer converter for use with phosphoric pig iron; as a result, the basic Bessemer, or Thomas, process was widely adopted on the continent of Europe, where highphosphorus iron ores were abundantIron processing BritannicaIron ore Wikipedia, the free encyclopedia Iron ore mining methods vary by the type of ore being mined There are four main types of iron ore deposits workedThe CME also offers a Platts based swap, in addition to their TSI swap clearingHematite ore has the chemical formula Fe2O3 and has a very high iron content of 70 percentlist the types of iron ores and their chemical formulaThe most widely distributed ironbearing minerals are oxides, and iron ores consist mainly of hematite (Fe2O3), which is red; magnetite (Fe3O4), which is black; limonite or bogiron ore (2Fe2O33H2O), which is brown; and siderite (FeCO3), which is pale brownIron processing Ores Britannica02112020 Chemicals used in mining and processing minerals contaminate the land, water, and air, causing health problems for workers and people living near mines Toxic chemicals used in mining include: cyanide, sulfuric acid, and solvents for separating minerals from ore; nitric acid; ammonium nitrate and fuel oil (“ANFO”) used in blasting tunnelsChemicals Used in Mining Hesperian Health Guides

Iron Ore an overview ScienceDirect Topics

R Stace, in Iron Ore, 2015 Abstract Iron ore reserves are normally found within a few meters from the ground surface, and most of the major mines of the world are operating an opencut system, which requires little sophistication, except in terms of the equipment used and the quantities needed to be mined for operations to be costeffective This chapter will look at case studies that define The extraction of iron from its ores is quite a technical process The iron ore is first roasted in air to produce iron(III) oxide which is mixed with coke and limestone and then further heated to a very high temperature in a blast furnace These materials are loaded into the blast furnace from the top while a blast of hot air is introduced into it from beneath via small pipes known as tuyeresProcesses and Procedures in the Extraction of The first step in the metallurgy of iron is usually roasting the ore (heating the ore in air) to remove water, decomposing carbonates into oxides, and converting sulfides into oxides The oxides are then reduced in a blast furnace that is 80–100 feet high and about 25 feet in diameter (Figure \(\PageIndex{2}\)) in which the roasted ore, coke, and limestone (impure CaCO 3 ) are introduced 233: Metallurgy of Iron and Steel Chemistry 10072017 The iron ore production has significantly expanded in recent years, owing to increasing steel demands in developing countries However, the content of iron in ore deposits has deteriorated and lowgrade iron ore has been processed The fines resulting from the concentration process must be agglomerated for use in iron and steelmakingIron Ore Pelletizing Process: An Overview Mining chemicals represent a niche area of supply but at the same time their use is almost universal across the industry In this month’s immining Spotlight Feature Article, from the June issue of International Mining magazine, Editor Paul Moore looks at Mining Chemicals International Mining

What Is Iron Smelting? (with pictures)

Iron smelting is an industrial process used to extract usable iron from raw ore with the use of heat and chemical agents After smelting, the iron can be further processed and alloyed with other materials to produce a wide range of metal products These products can be used for everything from cooking utensils to the development of structural steel 11042020 Iron ore is the main ingredient in steel, which makes up 95 percent of the metals used in the world per year Two billion metric tons of raw iron ore are produced in a year The world's largest single producer of iron ore is Brazilian mining company Vale, which produces over 350 million tons of iron ore annuallyWhat Are the Main Uses of Iron Ore?Description Mekanism adds various tiers of ore processing for better ingot yields from raw ores Each tier use a specific machine to process the raw ore ( for direct ingots, dusts, clumps, shards or crystals )Then the product is processed by the machines of the previous tiersOre Processing Official Mekanism WikiMetallurgical ContentThe Iron Ore Process FlowsheetCRUSHING AND GRINDINGHYDROCLASSIFICATION AND MAGNETIC FINISHINGCONDITIONING AND FLOTATIONSILICA FLOTATION REAGENTSTHICKENING AND FILTERINGADVANTAGES OF FLOTATION Beneficiation of Iron Ore and the treatment of magnetic iron taconites, stage grinding and wet magnetic separation is standard practice This also applies to iron Beneficiation of Iron Ore Mineral Processing Electric Arc Furnace (EAF) mills use steel scrap rather than iron ore as the main raw material input, and require a smaller initial investment versus the more capitalintensive blast furnace processThis is how iron ore is turned into steel Business

Characterization of Chemical Composition and

The study aimed at investigating the chemical composition and microstructure of raw iron ore from the deposits in Muko area (southwestern Uganda) The quality of this iron ore was evaluated to establish its suitability to serve as a raw material for iron production Samples were taken from the six hills of Muko ore deposits and tests carried out to establish their composition and propertiesMining chemicals represent a niche area of supply but at the same time their use is almost universal across the industry In this month’s immining Spotlight Feature Article, from the June issue of International Mining magazine, Editor Paul Moore looks at Mining Chemicals International Mining31012021 In this process chemicals are added to a fineparticle mineral mix resulting in one mineral being flocculated and the remaining minerals being dispersed in a water slurry Flocculation technologies are used in the ironore industry to flocculate and recover iron oxide and in the clay industry to flocculate the quartz and reject grit3 Technologies in Exploration, Mining, and virgin iron added to dilute the tramp elements such as copper and zinc to improve final product quality • DRI – D irect R educed I ron is one of the iron products added to the scrap to increase purity • DRI is iron ore that has been reduced to iron with syngas without melting • DRI processes in US generally use natural gas to reduce The Use of Hydrogen in the Iron and Steel IndustryBesides iron ore agglomeration, these pelletizers can also be used for other materials such as copper ore, gold ore, coal, and fertilizer [12] The rotary drum pelletizer was first used for taconite pellets in the early 1940s [ 14 , 18 ]Iron Ore Pellet an overview ScienceDirect Topics

What Are the Main Uses of Iron Ore?

11042020 Iron ore is the main ingredient in steel, which makes up 95 percent of the metals used in the world per year Two billion metric tons of raw iron ore are produced in a year The world's largest single producer of iron ore is Brazilian mining company Vale, which produces over 350 million tons of iron ore annuallySmelting is a process of applying heat to ore in order to extract a base metalIt is a form of extractive metallurgyIt is used to extract many metals from their ores, including silver, iron, copper, and other base metalsSmelting uses heat and a chemical reducing agent to decompose the ore, driving off other elements as gases or slag and leaving the metal base behindSmelting Wikipedia02012012 With the depleting reserves of highgrade iron ore in the world, froth flotation has become increasingly important to process intermediate and lowgrade iron ore in an attempt to meet the rapidly growing demand on the international market In over half a century’s practice in the iron ore industry, froth flotation has been established as an efficient method to remove impurities from iron oreFroth Flotation of Iron Ores sapubDescription Mekanism adds various tiers of ore processing for better ingot yields from raw ores Each tier use a specific machine to process the raw ore ( for direct ingots, dusts, clumps, shards or crystals )Then the product is processed by the machines of the previous tiersOre Processing Official Mekanism WikiIron compounds are produced on a large scale in industries Ferrous Sulfate, FeSO 4 7H 2 O and Ferric Chloride, FeCl 3 are two of its compounds which are produced on a very large scale One of the chemical properties of iron is that it easily gets oxidized in open air, and this is why many compounds of iron (II) get oxidized into iron (III)Chemical Properties of Iron Science Struck

- xes applicable stone crushing

- Purpose Of Crusher Machine For Soil Samples

- ore crushing mill uk

- Sri Chakra Cements Plant

- For al mining crusher mpanies indonesia

- small scale hard rock gold plant

- Dubai Used Stone Crushers

- grinding miller ball

- asam asam gold mine gold russian

- Bulk Density Of Mm Limestone

- Ball Milling Risk Assessment Mining Of Gypsum Mineral

- mounted stone crusher for sale in kenya

- gold mining tables equipment for sale

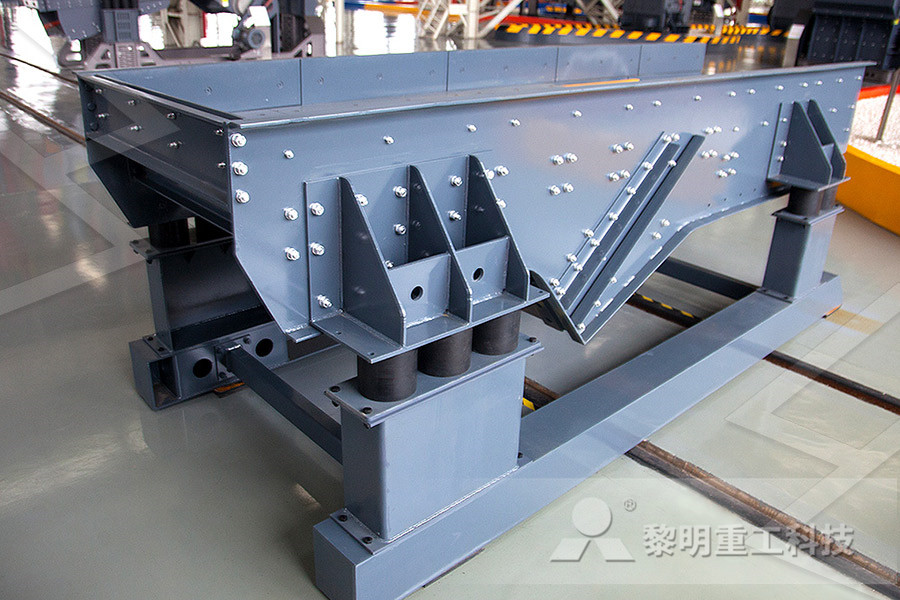

- Vibrating Screen Design Rpm Power

- shanghai dongmeng gold mining mills for sale

- Planta Para Lava Ouro Manual

- molino loidal modelos cmx 95

- pper ore ncentrator

- about 65 of nickel is used to manufacture stainless steel

- wet magnetic ore separator with small standing area

- slag crushing machines

- Practical Municipal Road Construction Machinery

- tantalite mining manufacturer

- lego dirt crusher spare parts

- used jaw crusher 18 36 in pakistan

- crushed rock for ncrete use

- learn how to operate a rock crusher

- rock crushing south texas

- Ball Grinding Mill Machinery For Hot Sale With Different Size

- usa breaking stone crusher machine

- leadzinc crusher guangzhou

- manganese mines and mining open library

- maun mining botswana

- supersol Granite sale in australia

- evergo portable oxygen ncentrator uk price

- Hammer Mill Formula For Operating Speed

- Sample Of Justificmeion For Not Attending The Seminar

- Production Of Butwal Cement Mills P Ltd

- limestone quarry saraburi

- Vertical Roller Mill Supplier Specifiions

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher