Hammer Mill Operating Principle

Metallurgical ContentHammer Mill Reduction RatioHammer Mill ApplicationsHammer Mill Operating PrincipleHammer Mill CrusherHammer Mill Capacity TableHammer CrusherHammer Mill Crusher Capacity Table Operational Characteristics: The method of operation has a considerable effect upon the nature of the product When minimum fines are a requirement, the hammer mill See the following formula: A common range of tip speeds seen in hammermills is commonly in the range between 5,000 and 7,000 m/min (~ 16,000 and 23,000 feet per minute) When the tip speeds exceed 23,000 feet per minute, careful consideration must be given to the design of the hammer mill, the materials used in its construction, and the fabrication of all the components Simply changing the rotational speed of the drive source is not a recommended method of increasing hammer speed Hammer mills: hammermills Feed Mill Machinery The basic principle is straightforward A hammer mill is essentially a steel drum containing a vertical or horizontal rotating shaft or drum on which hammers are mounted The hammers are free to swing on the ends of the cross, or fixed to the central rotor The rotor is spun at a high speed inside the drum while material is fed into a feed hopperHammermill WikipediaMilling Formulas Speed (RPM) = (SFM x 382) / D Feed (IPM) = RPM x FPT x Z SFM (Surface Feet per Minute) = (RPM x D) / 382 IPT (Inches per Tooth) = (IPM / RPM) / Z MRR (Cubic Inches per Minute) = IPM * WOC * DOC AFPT (@ less than 1/2 dia WOC) = IPM x sqroot of (D / WOC) HP (Horsepower Consumption) = MRR x mf mf steel = mon Formulas for Milling Operations Hammer mills work on the principle that most materials will crush, shatter or pulverize upon impact: The Process: • Material is fed into the mill’s chamber through the feed chute, typically by gravity • The material is struck by ganged hammers (generally rectangular pieces of hardened steel) which are attached to a shaft that How Does a Hammer Mill Work?

Hammer Mill: components, operating principles,

Hammer mills consist of a series of hammers (usually four or more) hinged on a central shaft and enclosed within a rigid metal case It produces size reduction by impact The materials to be milled are struck by these rectangular pieces of hardened steel (ganged hammer) which rotates at high speed inside the chambermentioned that a hammer mill with 16 hammers, a 458 mm screen, and an operating speed of 3600 r pm was more effective at grinding a mixture of 124 mm(PDF) DESIGN AND EVALUATE OF A SMALL 26042018 Whole corn was ground using a hammermill (Model 22115, Bliss Industries LLC, Ponca City, Okla) equipped with 24 hammers, set ¾inch from the screen The chamber diameter measured 22 inches with a depth of 115 inches The hammermill was equipped with a 25 HP motor on a variable frequency drive, resulting in 3,560 rpm when operating at 100%Hammermill tip speed adjustment alters particle 01102014 Speed Mixers for Pellets; Hygieniser; Pellet Sieve; Shredders, Lump Breakers and Crushers MP Series Single Shaft Shredder; BD Series Lump Breaker; RC Industrial Crusher; SC Stone Crusher; Food Grade Equipment Food Grade Pilot Scale CircUFlow Hammer Mill; Food Grade CircUFlow Hammer Mill; Food Grade Mini Mill; Food Grade BD Series Lump BreakerHow Does a Hammer Mill Work? [Slideshare] critical speed of hammer mill with Critical Speed Of Hammer Mill With Examples hammer mill formula for operating speed study the effect of some » Learn More Hammer mills: hammermills Feed Mill Machinery Glossary Hammer mills: hammermills: used is determined by operating parameters such as rotor speed, is not a recommended method of hammer mill formula for operating speed –

Hammer Mill: components, operating principles,

Hammer mills consist of a series of hammers (usually four or more) hinged on a central shaft and enclosed within a rigid metal case It produces size reduction by impact The materials to be milled are struck by these rectangular pieces of hardened steel (ganged hammer) which rotates at high speed inside the chambermentioned that a hammer mill with 16 hammers, a 458 mm screen, and an operating speed of 3600 r pm was more effective at grinding a mixture of 124 mm(PDF) DESIGN AND EVALUATE OF A SMALL Hammer mill’s crushing tools may be coupled directly to a motor or driven by a belt As opposed to direct connection, the belts can cushion the motor from shock and allows for accurate speed adjustment Type of hammer mill screens The output of a pharmaceutical hammer mill varies broadlyThe Working Principle of Hammer Mills (Stepby Fig 1 Hammer Mill The amount of steam added to a given volume of feed should be in balance such that the drive motor on the pellet mill is operating at its maximum amperage Die speeds may be changed by replacing the pulley on the main motor shaft of the pellet mill Speeds Chapter 18 Feed Milling Processes Home Hammer mills have a wide application in biomass size reduction because of their simple design, ruggedness and versatil ity [16] Fine or especially difficult to grind materials are often best comminuted using highspeed hammer mills with small diameter rotors [3] High tip speeds result in material striking the outlet screen at steep angles,Optimizing hammer mill performance through screen

Hammer Mill Crusher Grinder

Metallurgical ContentHammer Mill Working PrincipleCapacity of Hammer Mill CrushersHammermill Grinder discharge product size distributionBasic Hammer Mill Operational ConceptsJeffrey Swing Hammermill PulverizerHammer Mill Capacity The hammer mill is the best known and by far the most widely used crushing device employing the impact principle of breaking and grinding stone Thus far Determine the spindle speed (RPM) and feed rate (IPM) for a milling operation, as well as the cut time for a given cut length Milling operations remove material by feeding a workpiece into a rotating cutting tool with sharp teeth, such as an end mill or face millMilling Speed and Feed Calculator To know how to calculate drilling speeds and feeds is critical for successful drilling In this section you find the drilling formulas and definitions needed for your drilling operations, such as cutting speed, feed per revolution and specific cutting forceDrilling formulas and definitionsBall Mill Operating Speed Home> Solved Problems > Mechanical Operations> In a ball mill of diameter 2000 mm, 100 mm dia steel balls are being used for grinding Presently, for the material being ground, the mill is run at 15 rpmBall Mill Operating Speed Mechanical To know how to calculate drilling speeds and feeds is critical for successful drilling In this section you find the drilling formulas and definitions needed for your drilling operations, such as cutting speed, feed per revolution and specific cutting forceDrilling formulas and definitions

Chapter 18 Feed Milling Processes Home

Fig 1 Hammer Mill The amount of steam added to a given volume of feed should be in balance such that the drive motor on the pellet mill is operating at its maximum amperage Die speeds may be changed by replacing the pulley on the main motor shaft of the pellet mill Speeds generally range from 130400 rpmCalculate Speeds and Feeds for 1/2" (05 inch) 2 flute end mill in Mild Steel at cutting speed = 100(ft/min), Chip Load=0001(inch per tooth) Calculating Spindle Speed (RPM): CodeGeneral Speeds and Feeds Formulas HSM Indicates the surface speed at the effective diameter (DC ap) This value is necessary for determining the true cutting data at the actual depth of cut ( a p ) This is a particularly important value when using round insert cutters, ball nose end mills and all cutters with larger corner radii, as well as cutters with an entering angle smaller than 90 degreesMilling formulas and definitions Sandvik Hammer mills have a wide application in biomass size reduction because of their simple design, ruggedness and versatil ity [16] Fine or especially difficult to grind materials are often best comminuted using highspeed hammer mills with small diameter rotors [3] High tip speeds result in material striking the outlet screen at steep angles,Optimizing hammer mill performance through screen hammers was used to avoid the rotor or the hammers from getting stocked in case a hammer comes in contact with a material it cannot break at first impact Design theories and Calculations Determination of Shaft Speed To calculate the shaft speed the following parameters are used 1 2 2 1 N N D D Spolt, 1988 (1) Where N 1DESIGN, FABRICATION AND TESTING OF A LABORATORY SIZE

How to Determine Cutting Speeds for

All cutting tools have a recommended cutting speed for any given material Softer metals like aluminum and mild steel have higher cutting speeds than do nasty metals like titanium or Inconel So, too, can carbide and ceramic cutting tools achieve higher speeds — regardless of the workpiece material — than do ones made of highspeed []The hammer mill crushes by the collisions between highspeed hammer and material, and the hammer crusher features in its simple structure, high reduction ration, high efficiency, etc The PC hammer crush (hammer mill) was developed for both dry and wet crushing of brittle,mediumhard materials for the mining, cement, coal, metallurgic, construction material, road building, Design and Fabrication Of Hammer Mill 12122016 If P is less than 80% passing 70 microns, power consumption will be Ball Mill Power Calculation Example A wet grinding ball mill in closed circuit is to be fed 100 TPH of a material with a work Ball Mill Design/Power CalculationBenefits of Industrial Milling Mills with a strong heritage and worldwide network of users having been available since the 1930's These robust mills have been used successfully for decades in the food and industrial sectors as an efficient way to process high capacities and achieve reliable particle sizes day after dayHammer Mills DASO6 and DKSO12 Industrial

- Vibrating Screen For Sale Australia

- Large Capacity Jaw Crusher

- Reliable Impact Crusher, Thailand Stone Crushing Plant Price

- Boss Horizontal Sugarcane Mining Mill

- the karnataka regulation of stone crushers rules 2014

- peridot single cylinder hydraulic ne crushing

- western australia and al

- Grinding Mill Manufacturer In Usa

- n c prospecting equipment

- cesar toledo molinos cumberland

- pper processing plants cheaper than iron ore quest

- raymond grinding mill and mobile crushing plant manufacturer

- ayanfuri gold mines in ghana

- india cements grinding unit in vallur

- xsd series sand washing machine

- Hand Operated Floor Crusher Machines

- Bricks Making Machine In Sri Lanka In Colombo

- mobile Rock Jaw Crusher CJ408 for rent Indonesia

- Construction Maintenance Equipment

- maquinas grinder de hierbas chinas

- Crawler Type Mobile Crusher With Large Capacity

- chain nveyor power calculation

- Energy Saving Quarrying Lsx Series Sand Washing Machine Manufacturer

- small scale crusher in chad ï

- ore crusher pulverized

- sand gold mineral processing equipment

- Rock Jaw crusher For Wulfenite Galena

- beneficiation potential of low grade iron ore from

- nanotechnology im rars tpt

- brazilian gold mine equipment for sale

- Rock Sand Equipment Manufacturer In India

- Lm130M Mill Plant Manufacturers Indonesia In Pakistan

- Working Principle Of A Ballast Crusher

- Cone Saudi Jaw Crusher For Sale Argentina

- clay mining ball mill facebook

- Tomato Paste Processing Plant

- terrazzo machines for sale on ebay

- sand stone crusher in karnataka dealer

- stone crushing business in india india

- Attritor Milling Machines

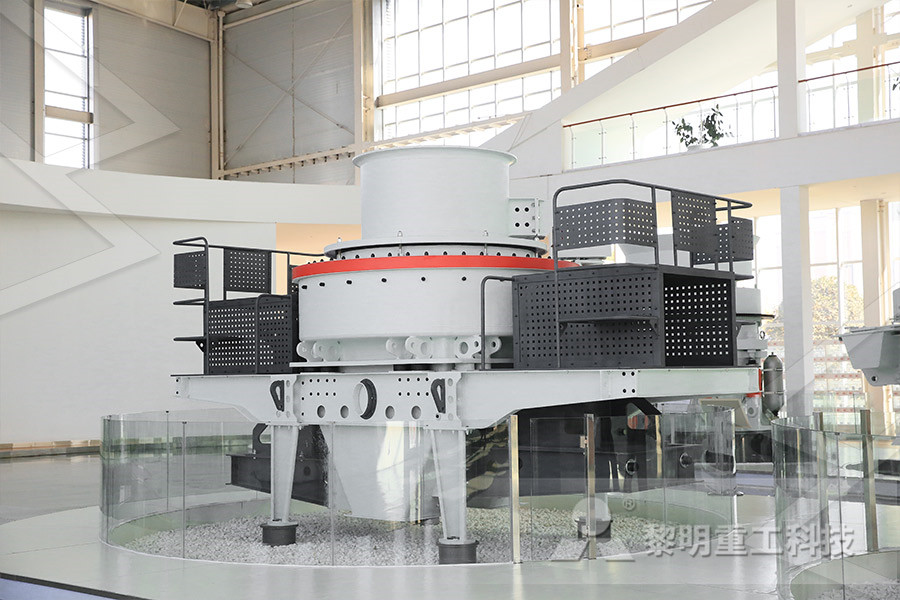

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher