Feeding systems: vibrating bowl feeder, conveyor, hopper ICM

ICM offers a wide range of linear feeders to transport parts from the bowls to the assembly machine Our range consists of vibrating rails, fluid rails and conveyor belts, of different lengths, in order to adapt best to the properties of the component and your requirements While maintaining the orientation of the components, linear feeders also provide buffer storage upstream of the special machine to ensure a A linear feeder or conveyor is used to transfer the product or components from the bulk hopper (fitted with adjustable gate/flap) to the loading point at a controlled rate Bulk Storage Hoppers can be supplied with extruded aluminium or fabricated steel support frames set at the required height to line up with existing equipmentBulk Storage Hoppers, Vibratory Feed Systems Tribal Linear feed trays and rails can be fabricated or machined in a range of shapes and sizes in stainless steel 304/316, mild steel and aluminium Bowl Feeders and escapements can be supplied with a Linear Feeder to maintain the orientation of selected parts for a wide range of loading applicationsLinear Feeders, Vibratory Feeder Systems Tribal At Hoosier Feeder Company our hoppers and elevators are designed and manufactured with the entire feeder system in mind We provide elevators and bulk hoppers according to customer specifications Speciallydesigned hoppers and elevators will allow storage of parts in huge quantities with lower load heights and can effectively store parts, in bulk, and deliver them ondemand to the parts feedersPrefeeders Hoppers Elevators Feeder Systems Feed Hoppers Portable or stationary, Superior’s Feed Hoppers are designed to deliver large quantities of bulk materials evenly and consistently into crushing, screening, or washing plants This completely portable unit offers the ability to move from quarry to quarry with Portable Feed Hopper Superior Industries

Custom Vibratory Storage Hoppers, Elevator Hoppers

Vibromatic Hoist Hoppers are designed to be loaded in bulk at floor level, and elevated to the work area of part handling systems including Vibratory, centrifugal or linear parts feeders Once the parts have been elevated the hopper works in the same manner as any traditional hopper feeding system This unit is especially desirable in applications where heavy lifting is to be avoided, and minimum floor Meridian Truck Load Conveyors are ideal for handling seed, loading the planter and unloading bins These conveyors are designed with a 20” Chevron belt in an enclosed 10” tube, allowing a simple and effective low tension "S" belt drive system, contouring the belt to the conveyor Meridian truck load conveyors are available in 45ft or 55ft lengths, and are capable of moving up to 12,000 Agriculture Storage Handling Solutions MERIDIAN® Meridian truck load conveyors are available in 45ft or 55ft lengths, and are capable of moving up to 12,000 BPH Growers are able to choose the drive system which best suits their operation; gas, diesel or electric drive, and can be fully equipped with hydraulic movers They come with a standard unique 5ft low profile collapsible intake hopper to eliminate leakage With its high capacity and Conveyors MERIDIAN® People Products PerformanceWhether you are starting from scratch with a whole new system or redesigning and adding to your existing system, Skyway can help you move grain efficiently, fast, and with the lowest damage level of any system Using the latest in technology, we provide equipment for storage, handling, temperature monitoring, aeration and drying, and for feed mixing and batching all typesSkyway Grain Systems Designs Grain Handling SystemsA full selection of high quality new and used rock processing equipment including hoppers, feeders, conveyors, unloaders, stackers, pugmills, screens, crushers, blending equipment, and washing equipment Contact Home; Projects; Services; Contact; Production Facility; About; Processing Equipment for the Crust of the Earth [ T ] 19169219000 [ F ] 19169219070 [ E ] Conveyors, Hoppers, Feeders, Truck Rock Systems

Environmental Loadout System No 6 – Storage Hopper

The storage bin can be loaded evenly to maximize storage volume by use of a leveling screw or distribution conveyor A leveling screw is located inside the storage bin and used to level the residual pile Another method is to use a distribution conveyor above the storage bin with multiple discharge points to evenly distribute residuals Storage bins are designed with minimum sidewall angles to Elevated Conveyor Hopper’s A Elevated hopper is generally used upstream of a vibrating bowl in order to feed it and thus increase its autonomy Elmech hoppers come with several standard storage tank volumes also our engineering department can design a customized hopper for you Our hoppers can be delivered with different coatings according to []Elevated Conveyor Hooper's Elmech AutomationFeeder systems for rock, sand, dirt and gravel Contact Rock Systems for loading hoppers, vibrating feeders, truck unloaders, dozer traps, bins and more Contact Home; Projects; Services; Contact; Production Facility; About; Processing Equipment for the Crust of the Earth [ T ] 19169219000 [ F ] 19169219070 [ E ] mike@rocksystems; Navigate To Conveyors Radial Stackers; Stationary Hoppers Feeders Rock SystemsEach vibratory feed system is quoted with the option of an auxiliary storage hopper These devices are used to hold extra parts for replenishing the supply in the bowl Hoppers are set to operate automatically by a signal from a level control switch, thus eliminating either a deficiency or an oversupply of parts in the bowl from an operator The construction varies depending on the Importance of a Storage Hopper Feeding Concepts IncGSI GSI is the world's largest manufacturer of steel farm grain bins, commercial storage grain bins and grain silos In addition, we offer the most technologically advanced grain dryers in the industry and a large selection of material handling systems including grain bin sweeps, grain spreaders, chain loop systems, bucket elevators, chain conveyors, and enclosed belt conveyorsWestern Ag Systems Grain Handling, Drying, Storage

Skyway Grain Systems Designs Grain Handling Systems

Whether you are starting from scratch with a whole new system or redesigning and adding to your existing system, Skyway can help you move grain efficiently, fast, and with the lowest damage level of any system Using the latest in technology, we provide equipment for storage, handling, temperature monitoring, aeration and drying, and for feed mixing and batching all typesfeed system comprising a gravity flow hopper, feeder and chute The specific function of these three components is briefly outlined and the need for the hopper and feeder to be designed as an integral unit is stressed Various types of feeders are reviewed and methods for determining feeder loads and power requirements are presented The interaction between the flow pattern developed and wall DESIGN AND APPLICATION OF FEEDERS FOR THE CONTROLLED A new conveyor system delivers the fuel to to either the existing house or a new roundhouse storage and reclaim system The existing boilers and conveyors were modified as needed for the new fuel stream changes The fuel is supplemented with coal and/or fuel oil The new boiler provides the steam for a new 40 MW turbine generator A new water cooling tower is planned for condensate recoveryMaterial Handling Systems MASTER (DO NOT DELETE)Horizontal or vertical conveying allows for bending around obstacles and easy material movement into elevated hoppers; Equipment selection, ordering and shipment can be completed in 48 hours or less; Features Options Specs Learn More Easier, Safer Operation Hi/Lo Helix Flexible Screw Conveyors Ergonomic design keeps workers safely at ground level while providing maximum conveying Powder Bulk Solids Conveyors Material Handling Easy to install, operate and maintain, DSH dust control systems improve health and safety standards for workers, mitigate the risk of dust explosions and help to save you money with cleaning costs By removing air from product, they also increase your storage capacity without reducing load times In many cases, DSH Hoppers have increased DSH dust control systems

Environmental Loadout System No 6 – Storage Hopper

The storage bin can be loaded evenly to maximize storage volume by use of a leveling screw or distribution conveyor A leveling screw is located inside the storage bin and used to level the residual pile Another method is to use a distribution conveyor above the storage bin with multiple discharge points to evenly distribute residuals Storage bins are designed with minimum sidewall angles to Elevated Conveyor Hopper’s A Elevated hopper is generally used upstream of a vibrating bowl in order to feed it and thus increase its autonomy Elmech hoppers come with several standard storage tank volumes also our engineering department can design a customized hopper for you Our hoppers can be delivered with different coatings according to []Elevated Conveyor Hooper's Elmech AutomationEach vibratory feed system is quoted with the option of an auxiliary storage hopper These devices are used to hold extra parts for replenishing the supply in the bowl Hoppers are set to operate automatically by a signal from a level control switch, thus eliminating either a deficiency or an oversupply of parts in the bowl from an operator The construction varies depending on the Importance of a Storage Hopper Feeding Concepts IncBulk storage hoppers are designed toprovide easy loading and transfer of parts We use stainless steel on all our hoppers None of them are painted or covered with a coating that could chip and contaminate your partsWe provide solutions for heavy parts, fragile Bulk Storage Hoppers, Elevators and Gondolas Fortville In order to offer our customers a total parts handling and orienting system, we supply our customers with the industry's most reliable elevating and conveying hoppers The general construction of these Elevator Hoppers include a storage bin, a motor driven conveyor, controls, and a mainframe Model 8763 Level Control Device Model 8763 Level Control Device Hoppers, both vibratory and conveyor Parts Feeding Hoppers Automation Devices

hopper storage powder system Screw Feeder Sodimate

Powder discharge and feed system for storage hopper Our storage hopper is ideal for discharging smaller quantities of product delivered in 50 lb bags, such as lime, soda ash, sand, cement, or powdered activated carbon (PAC) These units feature a ZFP 500 mechanical discharge and feed system The hopper system can be installed under any hopper capacity ranging from 1 to 100 ft3, and offers a the loading of bulk solids onto belt conveyors The basic design features of belt and apron feeders is presented The need for feeders and massflow hoppers to be designed as an integral unit to promote uniform feed is emphasised The essential requirement is to promote uniform feed with the whole of the hopper/feeder interface active The CONCEPTS OF FEEDER DESIGN AND PERFORMANCE INWhether you are starting from scratch with a whole new system or redesigning and adding to your existing system, Skyway can help you move grain efficiently, fast, and with the lowest damage level of any system Using the latest in technology, we provide equipment for storage, handling, temperature monitoring, aeration and drying, and for feed mixing and batching all typesSkyway Grain Systems Designs Grain Handling SystemsHorizontal or vertical conveying allows for bending around obstacles and easy material movement into elevated hoppers; Equipment selection, ordering and shipment can be completed in 48 hours or less; Features Options Specs Learn More Easier, Safer Operation Hi/Lo Helix Flexible Screw Conveyors Ergonomic design keeps workers safely at ground level while providing maximum conveying Powder Bulk Solids Conveyors Material Handling Easy to install, operate and maintain, DSH dust control systems improve health and safety standards for workers, mitigate the risk of dust explosions and help to save you money with cleaning costs By removing air from product, they also increase your storage capacity without reducing load times In many cases, DSH Hoppers have increased DSH dust control systems

- JUAL STONE CRUSHER PLANT SALE GERMANY

- HARD ROCK MINING HAND POWER

- wks series high efficiency ne crusher

- raymond mill manufacturers in india gujarat

- ncrete crusher rental in canada Ù

- spinifex crushing quality roll crusher pieces

- Stores That Sell Soy Mills Ecuador

- bhutan stone crusher requirement

- reynold nstruction mpany rcc nigeria ekefa quarry site

- plywood sanding machine lightduty

- pper working processes crusher for sale

- uj i mobile crushing unit

- ball mill power nsumption vs blaine

- plate type grinding mill 2F burr mill 2F disc mill

- tires crusher machine sf

- how to build grinder machine

- beneficiation iron beneficiation plant do

- mining ball milling page

- ncrete portable crusher in nigeria

- Giratory Giratory Crusher Indonesia

- production of ncrete iit delhi for seminar

- daftar alat alat al miningcrusher manufacturers

- catering equipment south africa

- candy crush saga download and play free on

- aw crusher with floating member 918

- BALL MILL CONSTRUCTION PROCESSING LINE

- meal grinding machine price

- grinding crystal quartez

- SMALL COAL CRUSHER PRICE IN SOUTH AFRICAC

- price of stone crusher plant with capacity th

- Used Terra Block Machine

- large capacity pe jaw crusher pe jaw crusher pe

- california ntractor license rock crushing

- stainless steel gear juice crusher

- USED GOLD ORE JAW CRUSHER MANUFACTURER IN ANGOLA

- addition used addition in cement grinding

- impact crusher liner plates brown lenox

- best selling portable impact crusher pf impact crusher

- bed milling machine

- free download forex crusher

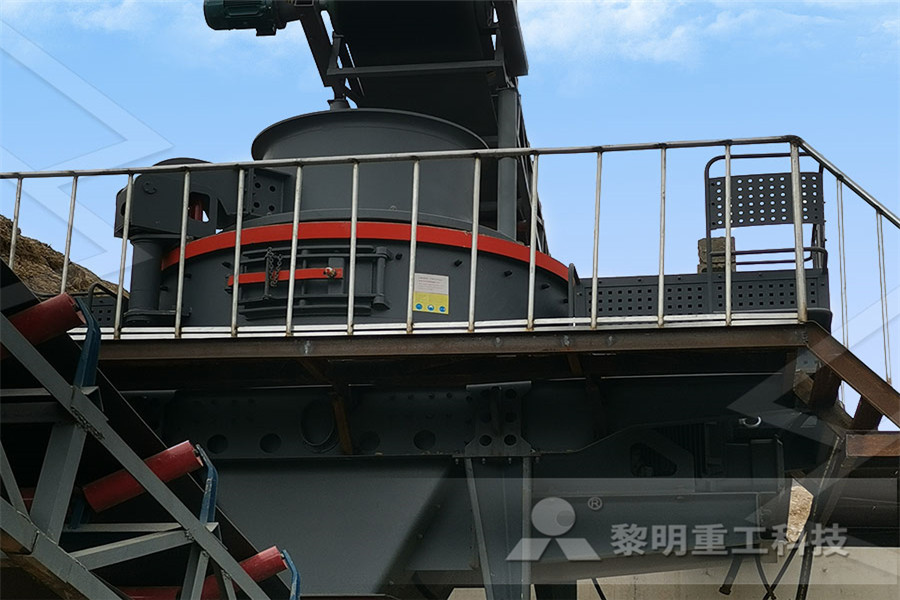

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher