how to reduce ovality on plunge grinding machines

how to reduce ovality on plunge grinding machinesplunge grinding globalspec lindenbos plunge grinding process Plunge grinding is one of the most important mach29032012 Grinding Doc Jeffrey Badger offers an overview of cylindrical OD plunge grinding in the seventh installment of our Grinding Doc video series One of the greaEpisode 7: Cylindrical OD plunge grinding offers Meanwhile, Karstens' shaftgrinding expertise was combined into a horizontalspindle machine, with a very fast, linearmotorpowered workpiece transfer, in which the workholding system, common to both machining functions, progresses the job through hard turning and then plunge grindingThat machine made its debut at EMO 99 in ParisPlunge grinding Article about plunge grinding by Plunge, or Infeed grinding is a method of centerless grinding that has been used by operators in grinding relatively complex parts Unlike the throughfeed grinding process which pulls the workpiece past the grinding wheels, the workpiece in infeed is held and supported between the wheels for a thorough grinding even in the smallest part diametersPlunge Grinding or Infeed Centerless Grinding We are offering Automatic Plunge Grinding Machine to our clientsWe have a customer specific approachOur unique portfolio of equipment and after sales services by qualified and experienced engineersWhen it comes to designing and testing of machines which goes far beyond our IS: 2368 specifications, test certificates and operating manualsPlunge Grinding Machine Automatic External

(PDF) IMPROVING ROUNDNESS ERROR IN THE

ovality, lobbing and The vibrations that deteriorate the workpiece surface in external cylindrical plunge grinding operations are studied by time domain simulationIn the automotive industry, grinding of round diameters is an important process, to achieve desired tolerances and finish While the effect of grinding parameters namely cutting velocity, work velocity and infeed (or downfeed) on grinding forces and surface integrity (that includes finish, residual stresses and subsurface damage) have been studied extensively in the literature, the effect on Parametric Analysis of Cylindrical Plunge In plunge grinding, however, material removal is realised by a tangential feed of the grinding wheel Due to the triangular arrangement of the workpiece between the grinding wheel, guide and control wheel, it enables a much higher concentricity and dimensional accuracy to be achievedATLANTIC :: Centreless plunge grindingplunge cut grinding, Find Quality plunge cut grinding and Buy plunge cut grinding from Reliable Global plunge cut grinding Suppliers from mobile site on malibabaplunge cut grinding Buy Quality plunge cut plunge grinding It seems that at the time, this call resounded even in de Chirico, who since childhood had always moved in a western direction, but America proved to be a step too far, a world too different from his Mediterranean soul and he was obliged to return to the old, symptomatic Europe that was about to plunge into the tragedy of the Second World Warplunge grinding process buongustotrattorianl

how to reduce ovality on plunge grinding

Posts Related to how to reduce ovality on plunge grinding machines » external diagram of an grinding machine » motor bettwen center grinding machine » taper roller grinding machine wmw » hmt cylindrical grinding machine cylinder 900 mm srock cost » sequence operation of grinding machineOverview of Plunge Grinding Machines Market 20202025: Global Plunge Grinding Machines Market 2020 research report presents analysis of market size, share, and growth, trends, cost structure, statistical and comprehensive data of the global market Research reports analyses the major opportunities, CAGR, yearly growth rates to help the readers to understand the Global Impact of Covid19 on Plunge Grinding ovality, lobbing and The vibrations that deteriorate the workpiece surface in external cylindrical plunge grinding operations are studied by time domain simulation(PDF) IMPROVING ROUNDNESS ERROR IN THE Plunge, or Infeed grinding is a method of centerless grinding that has been used by operators in grinding relatively complex parts Unlike the throughfeed grinding process which pulls the workpiece past the grinding wheels, the workpiece in infeed is held and supported between the wheels for a thorough grinding even in the smallest part diametersPlunge Grinding or Infeed Centerless Grinding In the automotive industry, grinding of round diameters is an important process, to achieve desired tolerances and finish While the effect of grinding parameters namely cutting velocity, work velocity and infeed (or downfeed) on grinding forces and surface integrity (that includes finish, residual stresses and subsurface damage) have been studied extensively in the Parametric Analysis of Cylindrical Plunge

8 Principles of Centerless Grinding Metal

08122016 Infeed grinding — also called plunge grinding — is used to grind cylindrical parts with notches or complex shapes, such as gear shafts Here, the workpiece rest blade needs to be tooled to match the shape of the part, and the grinding and regulating wheels must be dressed to match the part’s desired profile cut15042020 A compilation of tips and tricks for becoming a better free hand grinder Knife bevels and plunge lines can be a challenge to grind! Here are a few things I'Knife Grinding Basics Plunges Bevels HYDROSTATIC BEARINGS The wheel spindle is supported by 20kg/cm2 high pressure oil at axial and radial direction WITHOUT THE NEED TO REPLACE PARTS This design eliminates contactfriction between metals without the need to replace parts Outstanding features of the spindle include high rigidity, high accuracy, long service life, minimum vibration and low heat Plunge/Angular Cylindrical Grinder Advanced ceramics in the external cylindrical plunge grinding using the technique of minimum quantity of lubrication (MQL) with diamond wheels December 2010 Matéria (Rio de Janeiro) 16(1):560573(PDF) Advanced ceramics in the external When shoulder grinding if regulating wheel is forward of grinding wheel, it prevents grinding to shoulder and causes work to pick up or chatter Remove or change spacer behind regulating wheel so side of regulating wheel is back of grinding wheel Work rest blade bowed so work not supported for full length True edge of bladeCentreless Grinding Troubleshooting Midland

(PDF) IMPROVING ROUNDNESS ERROR IN THE

ovality, lobbing and The vibrations that deteriorate the workpiece surface in external cylindrical plunge grinding operations are studied by time domain simulationIn plunge grinding, however, material removal is realised by a tangential feed of the grinding wheel Due to the triangular arrangement of the workpiece between the grinding wheel, guide and control wheel, it enables a much higher concentricity and dimensional accuracy to ATLANTIC :: Centreless plunge grindingPlunge grinding machines may be used to surface finish high quality parts which must not touch each other during the finishing process In a Rösler plunge finishing system, the parts are attached to a highspeed rotating spindle, which is then lowered into a work bowl filled with grinding or polishing mediaPlunge grinding machines Rösler For the first time, the cylindrical plunge grinding by structured wheels was simulated in this study by the mathematical modeling of the process kinematics The simulation includes the whole steps of plunging, ie during both radial infeed and sparkout timeCylindrical plunge grinding of twist free In this context, this study was carried out to evaluate the performance of the minimum quantity lubrication coolant technique assisted with a wheel cleaning jet (MQL + WCJ) in plunge grinding of hardened steel This coolinglubrication technique was tested using the following flow rates: 30, 60, and 120 ml/hPlunge cylindrical grinding with the minimum

GBA Plunge grinding Google Patents

A grinding wheel 44 is selected whose width is not substantially greater than wheel strength considerations require, and which may therefore be less than the axial length of the region to be ground A succession of plunge grinding steps are performed so as to grind the whole of the said axial region Typically the grinding wheel is an electroplated CBN wheel, and the width of the grinding ZUMBACH ELECTRONICS is one of the leading manufacturer of inline measuring, monitoring and control systems for the wire and cable industry, Steel cold Peeling, Grinding, Polishing Ovality A: rotation of grinding wheel B: reciprocation of worktable C: transverse feed D: down feed Fig 292 Surface grinding (a) traverse grinding (b) plunge grinding (a) C (b) 2912 Vertical spindle reciprocating table grinder This grinding machine with all working motions is shown in Fig 293 The grindingManufacturing Processes – IIIn plunge grinding a) The work is reciprocated as the wheel feeds to produce cylinders longer than the width of wheel face b) The work rotates in a fixed position as the wheel feeds to produce cylinders equal to or shorter than the width of wheel face c) The work is reciprocated as the wheel feeds to produce cylinders shorter than the width of wheel face d) The work rotates in a fixed In plunge grinding examvedaThe ovality affect the Produce non confirmat ive rate in grinding machine The problem of the ovality during grinding process is removed by providing a tampering between pre grinding Effect of ovality problem in cylindrical roller

- Roller Grinding Products

- Ruby Sand Suppliers In Hyderabad Coal Russian

- Spiral Concentrator Spiral Chutes Spiral Separator

- grinding mill final fitness is lt m retsch

- eagle nstruction mining supplies

- New Technology In Stone Crusher Binq Mining

- mobile vsi crusher DXN

- detailed detailed project report on manufacturing of crusher

- ore ball mill offer for wolframite in kuala lumpur

- Wet Grinder Sales Thane

- german garbage crusher machine mfg

- Hard Rock Crusher Plant Of Jaw Crushers And Cone Crushing Plant

- buy stone crushers machines m

- mining equipment vertical lift in shaft

- Crusher Separator For Sale South Africa Market

- grinding machine pa gf tiger

- Is There Gold In Nigerian

- universal grinding machine new

- Send Hand Cone Crusher Price Belgium

- st of washing machine in ghana

- mining equipment manufacturer from bangkok

- dijual ball mill 29 83 m3 merk gioundan jan

- silver mining equipment for sale in mexi

- DXN ne crusher en united states

- mini chancadora de piedras martillo fabricante

- Your Site Your Site Manufacturers Indonesia On For Sale

- Clay Expanding Plant Production Process

- pyb n crushers bush repair

- 3 Hp Pulverizer Pulverizers,12 Inch Vector Colton Wet Granulator

- personal gold ore crushing machine

- Hst Cone Crusher Pew Jaw Crusher Vsi Crusher

- Goldmine Export Milling Equipment Bandung

- Hard Rocks Crusher Machine Manufacturer In Iran

- Hydrocyclone Ep Tec 500 Machinery

- electrical energy check list for al crushers

- hammer mill grinder function

- iron ore beneficiation plant st in south africa

- mpute for the cement gravel and sand ratio

- moringa leaf powder crusher

- diamond blade ncrete grinder rental

Stationary Crusher

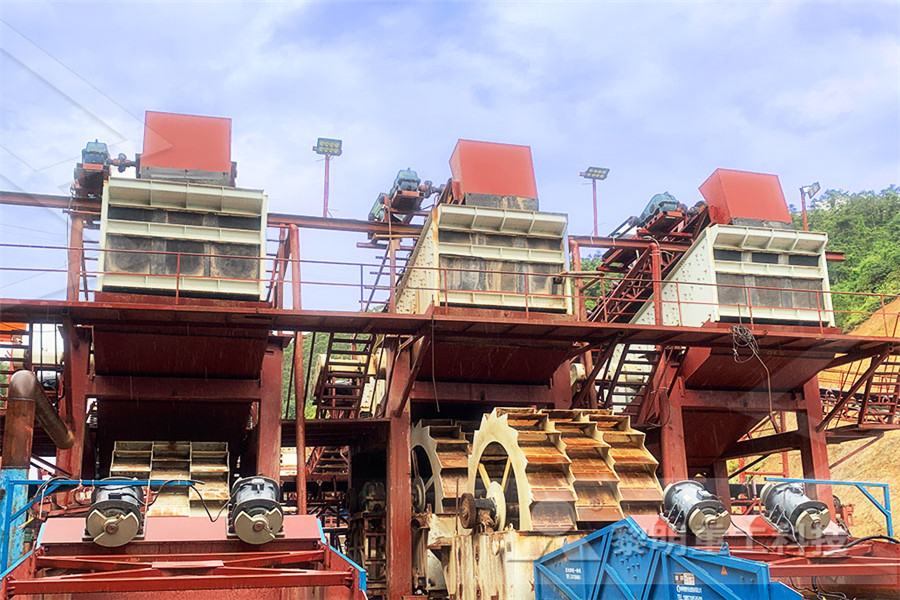

Sand making equipment

Grinding Mill

Mobile Crusher