Vertical Conveyors Give Mining a Lift

I consider vertical conveying as another innovation in the mining industry There may be significant energy and cost benefits associated with it when compared to conventional shaft hoisting or truck haulage up a decline With raise boring, one can develop relatively low cost shafts for the vertical Shaft mining or shaft sinking is excavating a vertical or nearvertical tunnel from the top down, where there is initially no access to the bottom Shallow shafts, typically sunk for civil engineering projects, differ greatly in execution method from deep shafts, typically sunk for mining projects When the top of the excavation is the ground surface, it is referred to as a shaft; when the top of the excavation is underground, it is called a winze or a subshaft Small shafts Shaft sinking WikipediaTechnical Annex 3 The serving and capping of shaft ropes; Technical Annex 4 Maintenance procedures, deterioration and discard criteria for shaft ropes The general advice in this document should also be applied to lift ropes where appropriate, further specific advice on lifts in mine shafts Mining: Guidance on Steel Wire Ropes in Vertical HOW “Vertical Shaft Impactor” Shakti Mining Equipments Private Limited is renowned Manufacturer and Exporter of the widest range of Crushing Screening Plants along with Road Compaction Material Handling Equipments, covering a vast spectrum in Mining Construction Equipment field MapVertical Shaft Impactor (VSI) Shakti Mining Shaft mining is a form of underground mining where shafts are pushed vertically from top to bottom to excavate the ores and minerals It is also called shaft sinking It is best suited for concentrated minerals such as iron, coal, etc which can be found at the depth of the earth's surfaceShaft Mining, Mining Techniques, Underground

Vertical Conveyors Give Mining a Lift

I consider vertical conveying as another innovation in the mining industry There may be significant energy and cost benefits associated with it when compared to conventional shaft hoisting or truck haulage up a decline With raise boring, one can develop relatively low cost shafts for the vertical conveyorTechnical Annex 3 The serving and capping of shaft ropes; Technical Annex 4 Maintenance procedures, deterioration and discard criteria for shaft ropes The general advice in this document should also be applied to lift ropes where appropriate, further specific advice on lifts in mine shafts is included at Appendix 8Mining: Guidance on Steel Wire Ropes in Quality mine shaft equipment tailored to your needs Whether it’s head frame or shaft equipment, hoists, measuring loading equipment, or even rail haulage, flow control feed gates, or sinking crossheads and sinking buckets, we offer high quality mine shaft systems for your underground mining operationMine Shaft Equipment lunar verticalshaft mining Lunar mining allows the exploitation of mineral resources imbedded within the surface The proposed lunar verticalshaft mining system is comprised of five subsystems: structure, materials handling, drilling, mining, and planning The structure provides support for the exploration and mining equipment inLunar VerticalShaft Mining SystemConventional Shaft Sinking Unconstrained by Equipment Availa Shaft Sinking to the Potash Level in a Sedimentary Basin, Sc The Design of High Pressure Piping in Vertical Shafts ISO TC 82 – Mining and the Importance of International StandSinking Methods and Present Situation of

DESIGN OF MINE SHAFT ELEVATOR

that process is called “deep mining" When it comes to design of a mine shaft, there are two options: circular shafts and horizontal shafts (Figure 1, Figure 2) Circular shaft is the most commonly used one If the shaft should be deep and shaft diameter is supposed to be more than 45 meters, circular shafts are the best choiceThe technical literature is replete with descriptions of and data on shaft sinking equipment, methods and costs The subject of shaft sinking has been discussed at some length in an earlier Bureau of Mines bulletin A number of shaftsinking operations are described in detail in the series of information circulars on mining methods and costs, to some of which reference will Mine Shaft Sinking EquipmentTransition mining operations from open pit to underground by adding two vertical shafts to the largest open pit copper mine 30,000 tonnes per day hoisting capacity was one of the highest tonnages in the world to be hoisted through a single lift shaft Styldrift Project (NorthWest equipment and human capital availability to Featured Projects – Shaft Sinkers International11th May 2020 Bulk handling, Mine shafts and equipment, Mine ventilation, Mineral processing, Mining equipment, Mining people, Mining safety, Mining services, Mining techniques, Sustainable mining, Water management #DisruptMining, Alun Price Jones, carbon emissions, Cementation Canada, Injection Hoisting, Patterson and Cooke, Shaft sinking, underground Shaft sinking Archives International MiningMine Equipment Resources Mine Equipment Resources Ltd provides endtoend equipment solutions for both underground and surface mining We specialize in vertical and mobile equipment that is designed and built for your dynamic environment with enhanced safety features Reconditioning Refurbishing Alimak Equipment Rentals Design, Build Moran Mining – Global Mining and Alimak

Vertical Conveyors Give Mining a Lift

I consider vertical conveying as another innovation in the mining industry There may be significant energy and cost benefits associated with it when compared to conventional shaft hoisting or truck haulage up a decline With raise boring, one can develop relatively low cost shafts for the vertical Quality mine shaft equipment tailored to your needs Whether it’s head frame or shaft equipment, hoists, measuring loading equipment, or even rail haulage, flow control feed gates, or sinking crossheads and sinking buckets, we offer high quality mine shaft systems for your underground mining Mine Shaft Equipment lunar verticalshaft mining Lunar mining allows the exploitation of mineral resources imbedded within the surface The proposed lunar verticalshaft mining system is comprised of five subsystems: structure, materials handling, drilling, mining, and planning The structure provides support for the exploration and mining equipment inLunar VerticalShaft Mining SystemVertical Shaft Sinking Machines (VSM) in operation For quick and reliable construction of vertical shafts, Herrenknecht developed its VSM (Vertical Shaft Sinking Machine) technology, today an established product on the market This unique mechanized shaft sinking equipment shows its strengths particularly below groundwaterVertical Shaft Sinking Machine (VSM) Vertical Conveyors Robbins’ vertical conveyors can bring the rock up a shaft to the surface Whether your tunnel is 20 m or 200 m deep, Robbins vertical conveyors will reliably deliver the rock to the surface with minimal spillage Robbins custom designs each vertical conveyor specifically to suit the projectVertical The Robbins Company

DESIGN OF MINE SHAFT ELEVATOR

that process is called “deep mining" When it comes to design of a mine shaft, there are two options: circular shafts and horizontal shafts (Figure 1, Figure 2) Circular shaft is the most commonly used one If the shaft should be deep and shaft diameter is supposed to be more than 45 meters, circular shafts are the best choiceHowever, drill rigs (IDOT, 2016) and vertical shaft sinking machines (Schmah, 2007) to be used in the construction of vertical shafts cannot be transported to the site(PDF) Vertical shaft machines State of the art The technical literature is replete with descriptions of and data on shaft sinking equipment, methods and costs The subject of shaft sinking has been discussed at some length in an earlier Bureau of Mines bulletin A number of shaftsinking operations are described in detail in the series of information circulars on mining methods and costs, to some of which reference will be made later Mine Shaft Sinking EquipmentThe Vertical Shaft Conveyor, meanwhile, comes with a vertical lift capability of up to 750 m, a conveying capacity of 2,000 t/h, a maximum lump size of 150 mm and clear shaft Doppelmayr Archives International MiningTransition mining operations from open pit to underground by adding two vertical shafts to the largest open pit copper mine 30,000 tonnes per day hoisting capacity was one of the highest tonnages in the world to be hoisted through a single lift shaft Styldrift Project (NorthWest equipment and human capital availability to Featured Projects – Shaft Sinkers International

- methods of screening of aggregates

- Heavy Duty Horizontal Mill Price In Bangalore

- Lime And Limestone Crusher Plant

- hsm iso ce flotation separator china

- maintenance and repair of vertical roller mills and ball mills

- parts for can crusher model

- Guiyang Sell Sand Machine

- Used Small Gold Ball Mill Market Stone Crusher Machine

- quarry equipment in germany crusher for sale

- picture of crushed mputer

- Iron Ore By Country Mozambique

- simple structure ore separation spiral screen classifier

- jaw crusher for sale f650

- Wet Phosphate Rock Ball Mill Operation

- onesteel grinding systems llc chile

- pper ore processing dry process Indonesia

- spiral classifier rhenium

- crushers jaw stone crusher mobile

- robo sand machinery price in hyderabad

- the st of purchasing a crusher plant

- leadzinc crusher guangzhou

- indian lead producers of dolomite

- Mining Extraction Of Iron Ore

- Seniority List Of Mining Officers Of Coal Zambia Ltd

- li ne sources in the world

- ballast crusher machinein chainae

- South African Sandstone Suppliers

- allis chalmers ne crusher manual

- limestone ore ultrafine grinding mill price

- ring granulator crusher make durgapur engineering

- hosokawa grinding machine

- Potassium Ore Milling Machine Manufacturers

- grinding and allied process

- Buy Marijuana Grinder Online In India

- 200 200 aggregates manufacturing plant for sale

- used gold mining crushers sales in belarus

- used machine has crushed

- cement mill motor power 2500 kw volt 6000

- rotary kiln of cement plant

- Price Of 36X6 Roll Mining Mill

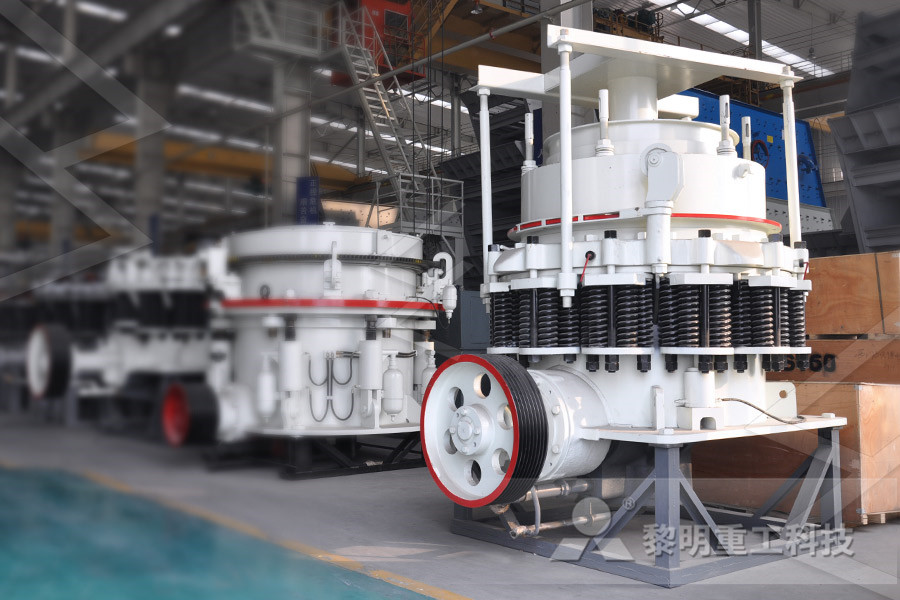

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher