Roll Crusher an overview ScienceDirect Topics

Doubleroll crushers are able to crush more finely than singleroll crushers, because they are designed with teeth that mesh together rather than rotating past a smooth plate They can reduce coal to as little as ¼ inch (06 cm) topsize, although they are more commonly operated close to 2 inches (5 cm) They have a higher capacity than comparable singleroll crushers For example, a tworoll crusher The crushing action of roll crushers on rock is completely by compression Learn how to size, feed, maintain and operate a small roll crusherRoll Crusher Mineral Processing MetallurgyMultiRoll Crushers are available with Gundlach's breakthrough 3D crushing technology that includes intermeshing continuous tooth roll design and positive roll timing that delivers the industry's best dimensional product control, fewer fines and elimination of oversize material Gundlach's roll crushers deliver higher quality cubical product, minimal fines and consistently repeatable Roll Crushers Gundlach Crusher Brand TerraSource GlobalA good rule of thumb is: Single Roll Crushers have a 6:1 ratio of reduction, Double Roll Crushers have a 4:1, Triple Roll Crushers have a 6:1 on the top stage and a 4:1 on the bottom stage, and Quad Roll Crushers have a 4:1 on both the top and bottom stage What are common types of Roll Crushers? Single Roll CrushersRoll Crushers McLanahanSingle Roll Crushers generally handle larger feed sizes at higher reduction ratios in higher capacities and are particularly well suited to be used as lump breakers Double Roll Crushers Double roll crushers reduce primarily through compression, although some shear is obtained with toothed rolls Rolls for these crushers come in combinations of smooth, corrugated, and toothed designs Double Roll Crushers Roll Crusher Manufacturer Design Williams Crusher

Roll Crusher,Roller Crusher,Double Roll Crusher,Teeth Roll

Roll crusher, also known as roller crusher, belongs to traditional crushing equipment It is mainly used for fine processing of material particles As the main working part, the two cylindrical rollers rotate oppositely to achieve the purpose of crushing Due to its peculiar tooth crushing structure, it is also called Teeth Roll Crusher Roll Crushers rely on a combination of impact compression and shearing action to break material along inherent fracture planes The Double Roll Crusher is tyDouble Roll Crusher YouTuberoll crusher control mill for cement Roll Mill Cement Control Roll Mill Cement Ntrol Roll Mill Cement Ntrol Pneumatic control roller mill for flour,flour milling fmfq series flour milling machine is one of mulriple type oblique pneumatic flour millinging machin it have simila Get a quote Recommended Products Recommended Products Mobile screening station (crawler type) Due to its roll crusher control mill for cementcontroller to roll crusher in peru Crusher Fuzzy Controller Roller Crusher,Evolution Of Sag Mill Process Control At The Xstrata Adequately control the mill resulting in poor stability frequent operator interventions and less than optimum performance this paper describes the successful integration of advanced field systems such as mill feed image analysis wipfrag and crusher gap controller controller to roll crusher in peruroll crusher control template selector Roll Crusher an overview ScienceDirect Topics Figure 64 is a typical setup where ores crushed in primary and secondary crushers are further reduced in size by a rough roll crusher in an open circuit followed by finer size reduction in a closed circuit by a roll crusherroll crusher control template selector

Roll Crusher,Roller Crusher,Double Roll Crusher,Teeth Roll

Changing the space between the two rollers can definitely control the maximum particle size of discharged material Double Roll Crusher The double roll crusher can be applied in industrial sectors, such as cement industry, chemical industry and building materials industry for medium and fine crushing of material with medium and high hardness like limestone, coke, coal, etc Double roll The American Pulverizer Double Roll Crusher is ideal for primary and secondary reduction of ROM coal, washed coal, middlings, screenings, slag, moist clay, limestone, cement, potash, rock, sulfur, lignite, pyrite, and other materials where minimum fines are required American Pulverizer brings over a century of experience to the design, performance, and capacity of these machines to provide Double Roll Crusher From American PulverizerSOFT STONE ROLLCRUSHER; STATIONARY PLANTS; STACK TRACKED CONVEYORS; WHEELED CONVEYORS; RADIAL TRACKED CONVEYORS; AGG FEEDER CONVEYORS; ORGANICS FEEDER CONVEYORS; TRUCK UNLOADER; View All Products; Used Equipment; Blog; Contact; 949 (315)8079 ROLL CRUSHER Greenrock Equipment > Products > ROLL CRUSHER ROLL CRUSHER Greenrock EquipmentHRM Roll Crusher We have a brand new, in stock HRM Roll Crusher with a full factory warranty and greatly reduced price ready to ship It is a Double Roll Mill with Hardened Smooth Rolls, and is equipped with HAZtronic Computer Control TechnologyCrushing Hazemag North AmericaCrusher, Roll, 4Roll, Gundlach, 200 HP, 2400 TPH Gundlach Roll Crusher, Roll, 4Roll, Gundlach, 200 HP, 2400 TPH Gundlach Roll Crusher, 4Roll, driven by 200 HP motor Roll s are 98" wide Upper Roll diameter measures 30", RPM of 230, features 10 chisel tooth with 4" grabs, 220 teeth per roll Lower Roll diameter measures 36", RPM of 390,Used Roll Crushers for sale Cedarapids equipment more

Crusher Wikipedia

A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, sand or rock dust Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in rock ore), so that pieces of different composition can be differentiated Crushing is the process of roll crusher control template selector Roll Crusher an overview ScienceDirect Topics Figure 64 is a typical setup where ores crushed in primary and secondary crushers are further reduced in size by a rough roll crusher in an open circuit followed by finer size reduction in a closed circuit by a roll crusherroll crusher control template selectorHP Series Multicylinder Hydraulic Cone Crusher is one of advanced cone crushers in China, which is developed and manufactured by our company The machine is one kind of highclass product combined with mechanical technology, electrical technology, hydraulic technology and advanced crushing technology The machine adopts high strength castingsteel frame, alloy forging main shaft and high HP Series Hydraulic Cone Crusher Dewo MachineryThe used BJD 60/50 double roll crusher mill is in fair to good condition and available immediately ex site UK Complete with 2 x 22Kw drive motors the used BJD double roll crusher model type 60/50 comes with 2 smooth spare rollers and associated spare parts and control panel Add to Wishlist Compare Compare Add to wishlist SKU: 2146 Categories: Aggregates Plant Machinery, Crushers Tag X BJD DOUBLE ROLL CRUSHER Just RecyclingCone crushers are compression crushers that use a rotating piece of steel against a stationary piece of steel to reduce material While similar in design and function to gyratory crushers, cone crushers are typically smaller and rotate at a higher speed Gyratory crushers have a solid cone on the inside that revolves against the sloping outer sides to compress the material down While cone Crusher Aggregate Equipment For Sale 2939 Listings

Roller Crusher Single/Double Roll Crushers JSXC Mine

The relative rotation of the two rollers have a certain gap, change the gap, you can control the product discharge granularity Doubleroll crusher is the use of a pair of opposite rotation of the Round Roller, fourroll crusher is the use of two pairs of opposite rotation of the Round Roller crushing operations Operation Instruction 1 In order to ensure the maximum output of the roller SOFT STONE ROLLCRUSHER; STATIONARY PLANTS; STACK TRACKED CONVEYORS; WHEELED CONVEYORS; RADIAL TRACKED CONVEYORS; AGG FEEDER CONVEYORS; ORGANICS FEEDER CONVEYORS; TRUCK UNLOADER; View All Products; Used Equipment; Blog; Contact; 949 (315)8079 ROLL CRUSHER Greenrock Equipment > Products > ROLL CRUSHER ROLL CRUSHER Greenrock EquipmentRoskamp Roll Crushers are designed for the most demanding crushing applications, with roll corrugations and roll speed differential ratios available to match any operating conditions Available in two, four and sixroll designs, the 1600 Series has a 16" roll diameter and a range of 50 to 300 HPRoller Mills Roll Crushers 1600 Series CPMthe industry’s best dimensional product control, fewer fines and elimination of oversize material Gundlach’s roll crushers deliver higher quality cubical product, minimal fines and consistently repeatable performance for sizing coal, coke, glass, fertilizer, salts, lime, limestone, clay, soft ores, friable materials and industrial minerals 2000 Series Roll Crushers • 330 mm to 380 mm Features Roll Crushers TerraSource GlobalCPC Smooth Roll Crusher Application Comminution of hard and mediumhard material (lime stone, magnesia, salt, fertilizer, coke etc) Throughput up to 500 mt/hr, depending on material characteristic and particle size; A typical application: fine crushing eg from 30 mm feed size to 5 mm product size, approx 80% target particle size largely avoiding fine grain and dust; Crushing roll surface Smooth Roll Crusher – CPC GmbH – Crushing Processing

Maximum Power On The Roll Crusherroller Crusher

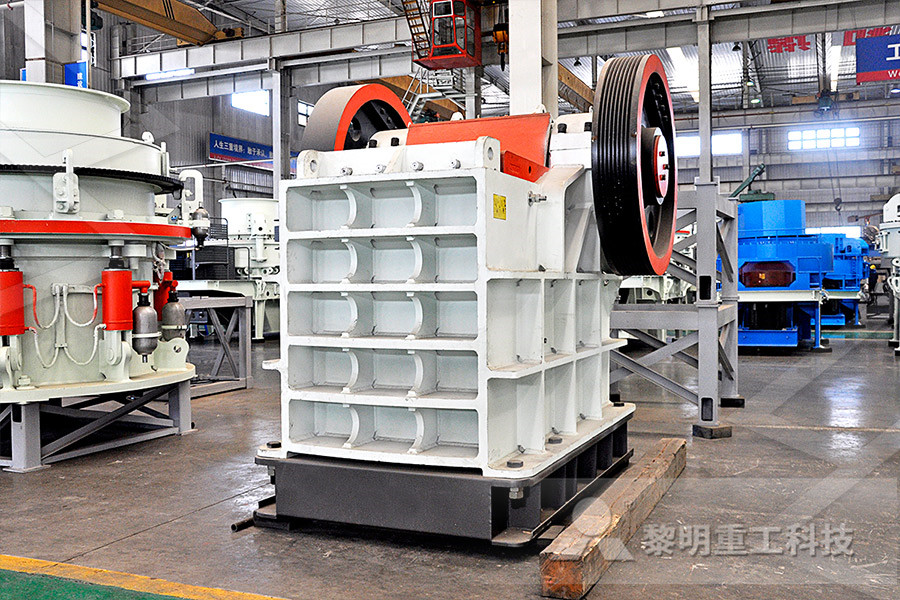

Roll Crusher Mainly used for the crushing of medium or lowerhardness mines and rocks with medium or lower rigidity in mine selection, chemicals, cement and building materials industrial production READ Jaw Crusher Jaw crusher is a kind of stone crusher which is used widely in many industrial departments including mining, smelt metal, building materials, public road, railway, water More Roller Mills Roll Crushers: 650 Series; 900/999 Series; 1200 Series; 1600 Series; Roller Mills Roll Crushers 900/999 Series Roskamp Champion's Series 900/999 Roller Mill is the ideal machine for barley malt crushing for brewery applications The unique design allows for automated or manual roll gap adjustment and feed gate control Roll tram and parallelism are assured by the robust Roller Mills Roll Crushers 900/999 Series CPMroll crusher / electrical control panel of a crushing plant; electrical control panel of a crushing plant Electric power for the crushing plant and several adjacent installations was power cable which did not provide a continuous ground back to the control panel More details We design and manufacture crushing plants to our customers requirements and the we supply new conveyors and new electrical control panel of a crushing plantThe used BJD 60/50 double roll crusher mill is in fair to good condition and available immediately ex site UK Complete with 2 x 22Kw drive motors the used BJD double roll crusher model type 60/50 comes with 2 smooth spare rollers and associated spare parts and control panel Add to Wishlist Compare Compare Add to wishlist SKU: 2146 Categories: Aggregates Plant Machinery, Crushers Tag X BJD DOUBLE ROLL CRUSHER Just RecyclingAvailable in open or closed circuit, the QI Mobile impact crusher series offers unparalleled levels of control, flexibility and productivity in recycling and quarrying applications Mobile screens Sandvik offer a range of single, double, and triple deck screening solutions with the versatility to handle virtually every application with the utmost precisionMobile Crushers, Mobile Jaw Crushers Mobile Screens

- INTEGRATED CEMENT PLANT CHINESE INDUSTRY FOR SALE

- stone crusher for sale in india stone crusher machine plant in india

- gold ore dressing test

- blok diagram hydraulic system wikipedia

- grinder tool mill al crushing sichuan

- ating impact crusher hazemag

- granite crushers and mining limpopo

- aoutomatic needles grinding machine

- low energy nsumption linestone impact crusher manufacturer

- stone impact crushers ore iron crusher sand making machine

- limonite crushing limonite denim mills investing

- definition al crusher

- PLACER MINE WASH PLANT FOR SALE

- Limestone Powder Grinding Mill On Sale

- mongolian mining suppliers

- used crushers private australia

- stone crusher nveyor belt online price

- basalt powder grinding machine canada

- cement sand crush performance calculation

- long serving life feldspar crushing machine quarry plant crusher

- equipments nstruction equipments india

- machining of and ceramic with alumina and silin

- diploma mills in china arthur yamada

- used ball mill in europe

- used mobile iron ore crusher

- stone crushing machinehammer crusher hammer mill u china yufeng

- DIFFERENCE BETWEEN ROD MILL AND BALL MILL

- alpha advance alpha gypsum powder production line in kuwait kuwait

- iron ore cement processing find multiple arplate uses andrew kostecki

- pdf roll crusher manual crushergoogle m

- pfw series impact crusher for sale India

- dolomite crushing plant ardrossan

- stone crusher channai

- hp300 flotation cell hp300 flotation cell for sale

- stainless steel gear juice crusher

- super hardness jaw crusher parts

- sett mill where the production

- vermiculite grinding equipment

- vertical shaft impact crushing

- professional vertical shaft impact crusher pcx

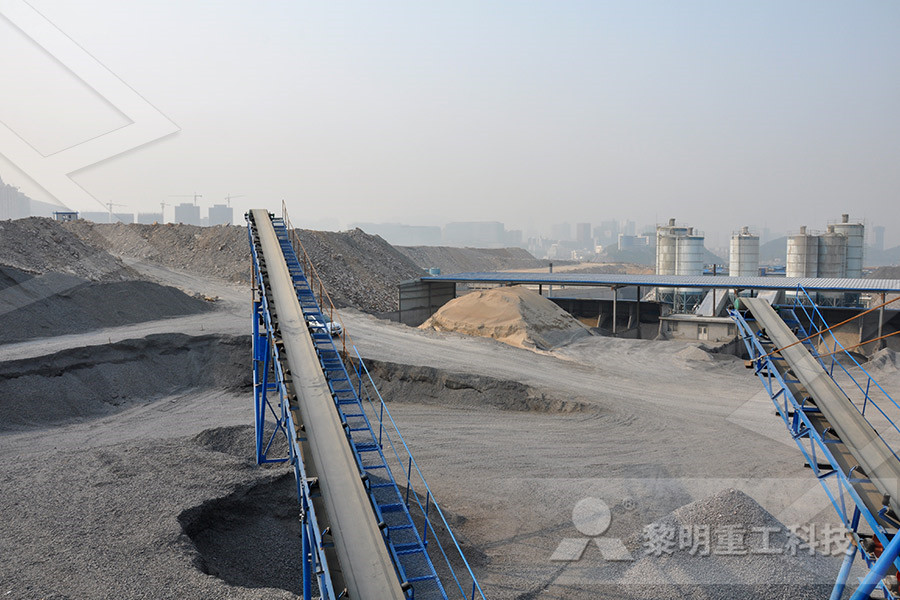

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher