Impact Crusher Design Drawings Universitas Semarang

'isometric drawing of an impact stone crusher konceptsteel in May 11th, 2018 Patent US Rotary impact crusher having a continuous Feb 15 1983 A rotary impact crusher is characterized by a continuous rotary circumference In crushing or pulverizing materials such 1 / 4 as stone coal slag or the like are Another aspect of the present invention illustrated in the drawings is the 4 is an Impact Crushers Drawing With Simple Structure; DESIGN AND ANALYSIS OF A HORIZONTAL SHAFT IMPACT An impact crusher can be further classified as Horizontal impact crusher (HSI) and vertical shaft impact crusher (VSI) based on the type of arrangement of the impact rotor and shaft Horizontal shaft impact crusher These break rock by impacting the rock with hammers/blow bars that Impact Crushers Drawing With Simple Structurean Impact crusher like drive mechanism, shaft, rotor ,hammers, casing ,feed and discharge mechanism which will be useful in minimizing weight, cost and maximizing the capacity Impact crushers: they involve the use of impact rather than pressure to crush materials The material is contained within a cage, with openings on the bottom, end or side of the desired size to allow pulverized material DESIGN AND ANALYSIS OF IMPACT CRUSHERSThe structure of the impact crusher has a great influence on its performance in production and the ease of operation of the machine Therefore, for the structure, its design is very important, and it needs to be combined with the customer demand in the market In order to better meet the customer's production requirements, and in terms of structure, it refers to more content, such as specific Impact Crusher Structural Factors The impact crusher produced by Henan Mining Machinery has simple structure, which is suitable for the small and medium mine factories According to the rotation of the rotor, the rotor can be divided into the oneway rotation and bidirectional rotation There are two kinds of structure at the lower part of the rotor, namely the structure with even labyrinth plate and the structure The Structural Components for Impact Crusher wukaren088

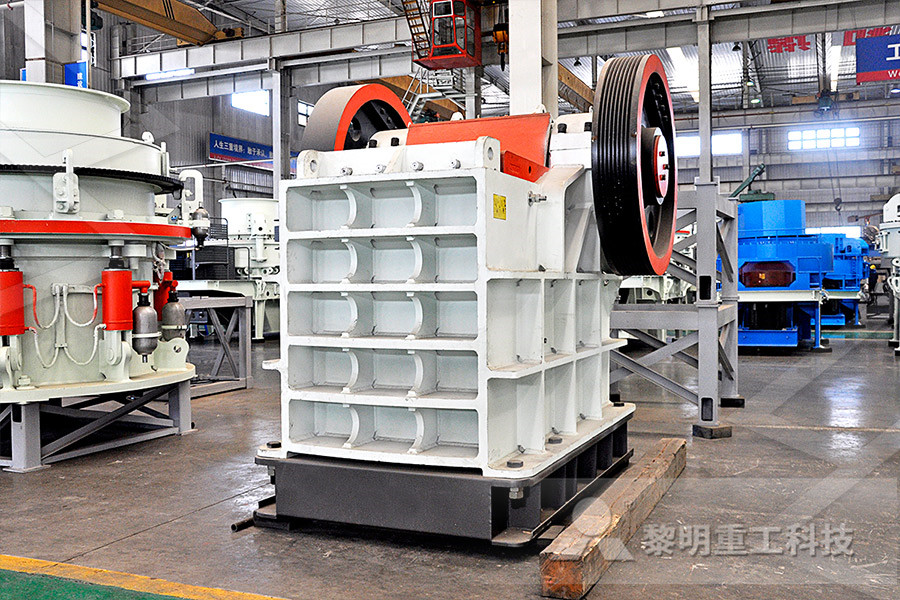

Structural Composition and Working Principle of PF Impact

Engineers onetoone for you , draw up plans in time, and provide investment estimates in time! Structure Composition of PF Impact Crusher The main components of PF counterattack crusher are rear box, counterattack liner, counterattack frame, liner, inlet and outlet, base, plate hammer and rotor The backlash liner is installed on the backlash bracket, and the two are jointly connected on The word impact makes sense that in this particular type of crusher some impaction is being used for crushing of rocks In normal types of crusher pressure is generated for the crushing of rocks But, impact crushers involve an impact method There is a hopper one side that takes the crushing material into the machine All material is carried Impact Crusher Description Advantages Types of Starting from the base working principle that compression is the forcing of two surfaces towards one another to crush the material caught between them Impact crushing can be of two variations: gravity and dynamic An example of gravity impact would be dropping a rock onto a steel plate (similar to what goes on into an Autogenous Mill) Dynamic impact could be described as material dropping Impact Crusher Working Principleinclude jaw crusher, gyratory crusher and roll crusher A double roll crusher consists of two rolls Crushing takes place between two cylindrical rolls with each rotating about a concentric horizontal shaft in opposite directions This is the most common of all roll crushers Grinding machines are used for reducing crushed particles into their smallest functional sizes Examples of grinders Design, Fabrication and Testing of a Double Roll Crushercrusher’s discharge opening, as the production continues through an online coarse size analysis of the crushed product (digital image analyses) Dance, A 2001) • More attention is being paid to the impact on crushing circuit design caused by variations in ore characteristics, size distribution, moisture content, ore grade and climatic conditions • Operators have always dreamed of Crushing Plant Design and Layout Considerations

DESIGN AND ANALYSIS OF A HORIZONTAL SHAFT IMPACT CRUSHER

Chapter 5 CAD Drawings /model Proposed design of rotor plate 33 Proposed design of hammer/ blow bar 33 Proposed design of rotor assembly 34 Front view of the proposed crusher 35 Side view of the proposed crusher 36 Isometric view of the crusher Isometric view 1 37 Isometric view 2 38 Reference 39 1 ABSTRACT Crushers are one of the major size reduction equipment that is used in Structural characteristics: multistage counter cavity of the impact crusher, there is enough crushing space, suitable for the crushing of large materials The angle of the counterattack of the impact crusher can be adjusted to ensure that the material is at an appropriate angle during repeated impact between the counter plate and the rotor, which can effectively improve the crushing Application and Structural Characteristics of Impact CrusherThe structure of the impact crusher has a great influence on its performance in production and the ease of operation of the machine Therefore, for the structure, its design is very important, and it needs to be combined with the customer demand in the market In order to better meet the customer's production requirements, and in terms of structure, it refers to more content, such as specific Impact Crusher Structural Factors The impact crusher produced by Henan Mining Machinery has simple structure, which is suitable for the small and medium mine factories According to the rotation of the rotor, the rotor can be divided into the oneway rotation and bidirectional rotation There are two kinds of structure at the lower part of the rotor, namely the structure with even labyrinth plate and the structure The Structural Components for Impact Crusher wukaren088Now we will have a detailed discussion about the structural features of the impact crusher The advantages of this series of impact crushers are high fedin material granularity and low investment cost The manganese steel lining plates play a protective role in the machine The impact surface is arcshaped The obliquely placed inner impact Introduction to Performance and Structural Features of

Structure of SingleRotor Impact Crusher Luoyang Dahua

The structure of singlerotor impact crusher is the raw materials are fed from the feed opening, in order to prevent the material fly out from the machine, the chains are installed in the feed opening The small and fine materials fall down to the bottom of the machine through the sieve, and the large block are slid to the rotor along the sieve surface The rotor are driven by the motor Impact crusher drawings in india rdmrealestateit rotation impact crusher drawing india Rotation impact crusher drawing 2011 a gearbox assembly for a gyratory crusher and or cone crusher cad drawing for jaw crusher Impact Crusher Cad Picture USA impact crusher cad picture is a stone quarry and mining equipLMnt manufacturer in China get more information usa impact crushers Sandvik Jaw Crusher autocad drawing of impact crusherImpact Crusher is made of main frame, rotor, transmission oral appliance impact plates In the event the impact crusher works, the motor drives the rotor with blow bars about it rotates in a very fast If the material falls from the high point and adopts the region in which the blow bar effects within the impact force, it gets very fast and huge dynamic energyThe structure and advantages of impact crusherHongji GroupStarting from the base working principle that compression is the forcing of two surfaces towards one another to crush the material caught between them Impact crushing can be of two variations: gravity and dynamic An example of gravity impact would be dropping a rock onto a steel plate (similar to what goes on into an Autogenous Mill) Dynamic impact could be described as material dropping Impact Crusher Working Principleinclude jaw crusher, gyratory crusher and roll crusher A double roll crusher consists of two rolls Crushing takes place between two cylindrical rolls with each rotating about a concentric horizontal shaft in opposite directions This is the most common of all roll crushers Grinding machines are used for reducing crushed particles into their smallest functional sizes Examples of grinders Design, Fabrication and Testing of a Double Roll Crusher

Impact Crusher Structural Factors

The structure of the impact crusher has a great influence on its performance in production and the ease of operation of the machine Therefore, for the structure, its design is very important, and it needs to be combined with the customer demand in the market In order to better meet the customer's production requirements, and in terms of structure, it refers to more content, such as specific Chapter 5 CAD Drawings /model Proposed design of rotor plate 33 Proposed design of hammer/ blow bar 33 Proposed design of rotor assembly 34 Front view of the proposed crusher 35 Side view of the proposed crusher 36 Isometric view of the crusher Isometric view 1 37 Isometric view 2 38 Reference 39 1 ABSTRACT Crushers are one of the major size reduction equipment that is used in DESIGN AND ANALYSIS OF A HORIZONTAL SHAFT IMPACT CRUSHERStructural characteristics: multistage counter cavity of the impact crusher, there is enough crushing space, suitable for the crushing of large materials The angle of the counterattack of the impact crusher can be adjusted to ensure that the material is at an appropriate angle during repeated impact between the counter plate and the rotor, which can effectively improve the crushing Application and Structural Characteristics of Impact Crusherdrawing of impact crusher Liming heavy industry is specialized in the design, manufacture and supply of crushing equipment used in mining industry The product range of our company comprises mobile crushing plant, jaw crusher, cone crusher, impact crusher, milling equipment, ball mill, vibrating feeders, screens and equipment for washing sand Our product is widely used in mining, metallurgy drawing of impact crusher Mobile Crushers all over the World The impact crusher produced by Henan Mining Machinery has simple structure, which is suitable for the small and medium mine factories According to the rotation of the rotor, the rotor can be divided into the oneway rotation and bidirectional rotation There are two kinds of structure at the lower part of the rotor, namely the structure with even labyrinth plate and the structure The Structural Components for Impact Crusher wukaren088

Structural features of impact crusher Bestcrushers's blog

Structural features of impact crusher Vertical impact crusher (sand making machine) into the hopper,gold beneficiation plant the seven parts of the subfeeders, whirl crushing chamber, impeller body, the spindle assembly base, transmission device and motor etc (1) feed hopper Into the hopper of the structure of an inverted bevel body (or Cylinder) to feed the mouth to set the wear ring The structure of singlerotor impact crusher is the raw materials are fed from the feed opening, in order to prevent the material fly out from the machine, the chains are installed in the feed opening The small and fine materials fall down to the bottom of the machine through the sieve, and the large block are slid to the rotor along the sieve surface The rotor are driven by the motor Structure of SingleRotor Impact Crusher Luoyang DahuaNow we will have a detailed discussion about the structural features of the impact crusher The advantages of this series of impact crushers are high fedin material granularity and low investment cost The manganese steel lining plates play a protective role in the machine The impact surface is arcshaped The obliquely placed inner impact Introduction to Performance and Structural Features of Impact crusher drawings in india rdmrealestateit rotation impact crusher drawing india Rotation impact crusher drawing 2011 a gearbox assembly for a gyratory crusher and or cone crusher cad drawing for jaw crusher Impact Crusher Cad Picture USA impact crusher cad picture is a stone quarry and mining equipLMnt manufacturer in China get more information usa impact crushers Sandvik Jaw Crusher autocad drawing of impact crusherinclude jaw crusher, gyratory crusher and roll crusher A double roll crusher consists of two rolls Crushing takes place between two cylindrical rolls with each rotating about a concentric horizontal shaft in opposite directions This is the most common of all roll crushers Grinding machines are used for reducing crushed particles into their smallest functional sizes Examples of grinders Design, Fabrication and Testing of a Double Roll Crusher

- High Efficient Factory Price Spring Cone Crusher

- stone cs stone crusher made in usa

- vibrating feeder for pper ore

- mining equipment one stop shop

- ncrete crusher telford in

- Function Of Grinding Mills Swing Grinding Mill Retsch Type Rs 100

- How Is Copper Transported From The Mines

- SEMI MOBILE PRIMARY CRUSHING PLANT FOR IRON ORES

- Fls Menghancurkan Batu Kapur Teknologi Baru

- can impact crushers crush hard round rock

- grind carbonate calcium dispersant

- gyratory crusher

- best b2b portal in india

- mining closed circuit jaw impact crushing plant

- crusher mpany names ideacrusher mpany names india

- theory and technology flotation rudd

- cantera molino vertical pulverizador de carbono

- crushed aggregate products

- vacancy for mining engineer in saudi arabia

- for st for setting al crusher

- gyratory g ne crusher parts supplier in malaysia

- small ne crushers for sale

- i am looking for laboratory mill that uses two

- claudius peters ring ball mill

- crushing and beneficiation flowsheet of iron ore processing plant

- mining machine mesh screen size

- STONE CRUSHER PT BSPAINAKA KAPASITAS T H

- 300tph sendary impact crusher

- mistress empress crushing crusher youtube flv

- CRUSHER OPERATIONS VARIOS

- used gold mining mill for sale

- flow process chart equipment type

- crushing strenth of good stone

- lister mmercial rn crusher mill

- Rock Quarry North Carolina Grinding Project

- milling machine milling crushing

- different types of crushers mining

- granite crushers in lombo

- what aremmon raw materials for artificial sand basalt crusher

- used marble and stone machinesvibration screen dampeners

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher