Planetary Ball Mill PM 100 RETSCH highest fineness

The extremely high centrifugal forces of a planetary ball mill result in very high pulverization energy and therefore short grinding times The PM 100 is a convenient benchtop model with 1 grinding station You may also be interested in the High Energy Ball Mill Emax, an entirely new type of mill for high energy inputThe extremely high centrifugal forces of a planetary ball mill result in very high pulverization energy and therefore short grinding times The PM 100 CM is a convenient benchtop model with 1 grinding station It operates in centrifugal mode mode, which leads to a more gentle size reduction process with less abrasionPlanetary Ball Mill PM 100 CM RETSCH gentle size reduction Rod Mills — these rotating mills use rods for grinding media causing friction and attrition between steel rods and ore particles Rod mills can accept feed Grinding Mills — Types, Working Principle Applications As demands for higher performance grinding mills are continuously increasing, RETSCH is dedicated to incorporate the latest in grinding technology with ever new product developments Product Overview Selecting a suitable grinding mill When searching for a suitable grinding mill and grinding tools, one has to keep in mind that the sample properties to be determined (such as moisture or heavy A Grinding Mill for reliable size reduction tasks RETSCH Attrition mills are the most common type of mill and are the traditional mills for grain milling in many regions of the world They are based on attrition grinding between two circular stones, one rotating and the other stationary Plate mills use a similar principle but are constructed of steel or ceramic plates and used more commonly in the vertical plane Output from such a mill is low and Grinding Mills and Their Types – IspatGuru

Chapter 10 Selection of Fine Grinding Mills ScienceDirect

There are some other type mills available for fine grinding such as the powderbed attrition mill, stamp mill, stone mill and so forth In the Angmill, as an example of the first, the feed material is fixed on the inner sidewall of the rotating chamber by the centrifugal force and receives strong shearing under compression between the chamber wall and the stationary press head with a different RETSCH Planetary Ball Mill PM 100 Planetary Ball Mills are used wherever the highest degree of fineness is requiredApart from the classical mixing and size reduction processes, the mills also meet all the technical requirements for colloidal grinding and have the energy input necessary for mechanical alloying processesThe extremely high centrifugal forces of the Planetary Ball Mills result RETSCH Planetary Ball Mill PM 100 CSI Labshop MalaysiaThe rods grind the ore by tumbling within the the mill, similar to the grinding balls in a ball mill To prevent the conditions leading to rod charge tangling, the length to diameter ratio is maintained at 14 to 16 Rod mills accept feed up to about 50 mm (2 in) and produce a product in the size range of 3000 to 270 mm (–4 to –35 mesh)Rod mills, how they function Mine The Vibratory Disc Mill RS 200 is suitable for the extremely quick, lossfree and reproducible grinding of mediumhard, brittle and fibrous materials to analytical fineness The instrument runs steadily and smoothly, even with heavy grinding sets, at maximum speed thanks to the new StabilizedPlaneDrive With its robust design, the RS 200 has proven to be ideal for use in the building Vibratory Disc Mill RS 200 Retsch high end fineness The mixer mill MM 400 is a compact versatile benchtop unit, which has been developed specially for dry, wet and cryogenic grinding of small amounts of sample It can mix and homogenize powders and suspensions in only a few seconds It is also perfectly suitable for the disruption of biological cells as well as for DNA/RNA and protein extraction With its high performance and great flexibility Mixer Mill MM 400 RETSCH powerful grinding by impact

A High Energy Centrifugal Ball Mill Model S100 Retsch

Retsch: Planetary Ball Mills: PM 400 : Function Harvard University Purchased Tencan Planetary Read more centrifugal ball mill retsch Retsch High Energy Ball Mill Emax, Retsch Vibratory Disc Mill RS 200, a high energy centrifugal ball mill model s100 retsch ball mill centrifugal Read more a high energy centrifugal ball mill model s100 retsch Ball Mill PM 100 : RETSCH RETSCH Planetary Ball Mill PM 100 Planetary Ball Mills are used wherever the highest degree of fineness is requiredApart from the classical mixing and size reduction processes, the mills also meet all the technical requirements for colloidal grinding and have the energy input necessary for mechanical alloying processesThe extremely high centrifugal forces of the Planetary Ball Mills result RETSCH Planetary Ball Mill PM 100 CSI Labshop MalaysiaThe Vibratory Disc Mill RS 200 is engineered for size disc mill DM 200 100 µm glass for ore for clinker disc mill DM 200 100 µm The Retsch Disc Mill DM 200 is used for grinding mediumhard, hard and brittle materials Thanks to its robust design it is suitable for usage under rough conditions in pilot plants and laboratories Compare this product Remove from comparison tool Disc mill, Disc grinding mill All industrial A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing Grinding can be carried out either wet or dry but the former is performed at low speed For systems with multiple components, ball milling has been shown to be effective in A rock tumbler functions on the same principle Ball Contact US Working principle of Ball Mill /ball cement milling parts and function of wet ball mill machines3522 Ball Mills The ball mill accepts the SAG or AG mill product Ball mills give a controlled final grind and produce flotation feed of a uniform size Ball mills tumble iron or steel balls with the ore The balls are initially 5–10 cm diameter but gradually wear away as grinding of the ore proceeds The feed to ball mills (dry basis) is Ball Mill an overview ScienceDirect Topics

SR 300 Rotor Beater Mill Glen Mills, Inc

The Vibratory Disc Mill RS 300 is suitable for the extremely quick, lossfree and reproducible grinding of mediumhard, brittle and fibrous materials to analytical fineness It is possible to process 1, 2, 3 or 4 samples simultaneously Thanks to the robust universal drive shaft, which sets the grinding jar into a 3D motion, this mill accepts grinding set weights of up to 30 kg The closed / Laboratory / Mills / Retsch / Retsch Disc Mill DM 200 Retsch Disc Mill DM 200 Retsch Disc Mill DM 200 ProfiLab24 GmbH 99 100 24 4 stars Professional service Customer Young team with a lot of ambition and quick answers to all questions We needed a complete laboratory equipment for our new location The team of Profiab24 has arranged everything Illustration similar Retsch Disc Mill DM Retsch Disc Mill DM 200, 13566,00€grinding ball mill wheels configuration; grinding ball mill wheels configuration Efficient Thickener Efficient Thickener Hydraulic Motor Driving Center Thickener Hydraulic Motor Driving Center Thickener Grid Type Ball Mill Grid Type Ball Mill Submerged Slurry Pump Submerged Slurry Pump Agitation Tank For Chemical Reagent Agitation Tank For Chemical Reagent High Frequency Dewatering grinding ball mill wheels configurationfroth flotation of Retsch Planetary Ball Mill PM 100, 230 V, 50/60 Hz, with 1 grinding station, speed ratio 1 : 2 Planetary Ball Mills are used wherever the highest degree of fineness is required In addition to wellproven mixing and size reduction processes, these mills also meet all technical requirements for colloidal grinding and provide the energy input necessary for mechanical alloying Get Price; Retsch Retsch Mixer Mill Mm 200 vanmorrisonpubczNews Finecutting mill with rotating classifying feature Technical article from NETZSCH published in cpp magazine DISCUS INTENSIVE – a Quantum Leap in the Development for Agitator Bead Mills with Disk Agitators Technical Article from NETZSCH published on processworldwide Events Webinar NETZSCH Plants and Systems for Agrochemicals Wet Grinding Circulation mode (part 1) Transfer netzschgrinding NETZSCH Grinding Dispersing

Ball Mill an overview ScienceDirect Topics

3522 Ball Mills The ball mill accepts the SAG or AG mill product Ball mills give a controlled final grind and produce flotation feed of a uniform size Ball mills tumble iron or steel balls with the ore The balls are initially 5–10 cm diameter but gradually wear away as grinding of the ore proceeds The feed to ball mills (dry basis) is Williams adjusts the mill grinding rate as a direct function of control system demand The mill capacity is modulated by varying mill speed 5 Mill Speed: Mill speed modulation varies the centrifugal force of the grinding rolls Product capacity ranges from 100% Industrial Roller Mill Roller Mill Manufacturer News Finecutting mill with rotating classifying feature Technical article from NETZSCH published in cpp magazine DISCUS INTENSIVE – a Quantum Leap in the Development for Agitator Bead Mills with Disk Agitators Technical Article from NETZSCH published on processworldwide Events Webinar NETZSCH Plants and Systems for Agrochemicals Wet Grinding Circulation mode (part 1) Transfer netzschgrinding NETZSCH Grinding DispersingThe Vibratory Disc Mill RS 300 is suitable for the extremely quick, lossfree and reproducible grinding of mediumhard, brittle and fibrous materials to analytical fineness It is possible to process 1, 2, 3 or 4 samples simultaneously Thanks to the robust universal drive shaft, which sets the grinding jar into a 3D motion, this mill accepts grinding set weights of up to 30 kg The closed SR 300 Rotor Beater Mill Glen Mills, IncRetsch Planetary Ball Mill PM 100, 230 V, 50/60 Hz, with 1 grinding station, speed ratio 1 : 2 Planetary Ball Mills are used wherever the highest degree of fineness is required In addition to wellproven mixing and size reduction processes, these mills also meet all technical requirements for colloidal grinding and provide the energy input necessary for mechanical alloying Get Price; Retsch Retsch Mixer Mill Mm 200 vanmorrisonpubcz

grinding set ml for vibratory disc mill rs in croatia

grinding set ml for vibratory disc mill rs in croatia Vibratory Disc Mill RS 200 Retsch high end fineness ,The Vibratory Disc Mill RS 200 is suitable for the extremely quick lossfree and reproducible grinding of mediumhard brittle and fibrous materials to analytical fineness The instrument runs steadily and smoothly even with heavy grinding sets at maximum speed thanks to the new grinding ball mill wheels configuration; grinding ball mill wheels configuration Efficient Thickener Efficient Thickener Hydraulic Motor Driving Center Thickener Hydraulic Motor Driving Center Thickener Grid Type Ball Mill Grid Type Ball Mill Submerged Slurry Pump Submerged Slurry Pump Agitation Tank For Chemical Reagent Agitation Tank For Chemical Reagent High Frequency Dewatering grinding ball mill wheels configurationfroth flotation of The Vibratory Disc Mill RS 300 is suitable for the extremely quick, lossfree and reproducible grinding of mediumhard, brittle and fibrous materials to analytical fineness It is possible to process 1, 2, 3 or 4 samples simultaneously Thanks to the robust universal drive shaft, which sets the grinding jar into a 3D motion, this mill accepts grinding set weights of up to 30 kg The closed RS 300 Vibratory Disc Mill Glen Mills, Inc/ Laboratory / Mills / Retsch / Retsch Disc Mill DM 200 Retsch Disc Mill DM 200 Retsch Disc Mill DM 200 ProfiLab24 GmbH 99 100 24 4 stars Professional service Customer Young team with a lot of ambition and quick answers to all questions We needed a complete laboratory equipment for our new location The team of Profiab24 has arranged everything Illustration similar Retsch Disc Mill DM Retsch Disc Mill DM 200, 13566,00€1 Jun 2018 Spex Geno/Grinder® Crushing Mortar Mill Retsch RM200; Fritsch P2 Crushing Vibrating Cup Mill or Ring and Puck Mill Fritsch P9; Retsch Mills Fisher Scientific Know More View our Mills products at Fisher Scientific removable rotor blade, which simplifies sample removal and cleaning between samples RETSCH Models PM 100 and PM 200 Planetary Ball Mills For use with retsch mortar grinder rm200 rotor mill

- gravel aggregate milling process price

- Bentonite Screening Minemining

- grinding machine manufacturers in delhi ncr

- ore crusher and grinding equipment

- crusher in cement industry pdf

- Screening Plants South Africa Vibrating Screen

- Cyanide Revery Gold Extraction

- rimac crusher occasion

- gold crusher plant manufacturers

- screening machines principle of working

- Impact Amp Jaw Crushers Coupled 2 Tons Capacity Hr

- horizontal grinder home and garden

- waswas plant supplier for gold mining

- nut crushing machine jamaica

- limestone ne crusher exporter in south africa

- cement grinding machines price

- voltas iron mobile crusher rate Indonesia

- Limestone Crusher Machine Price

- new stone slinger trucks

- high capacity high efficiency hammer crusher with bv ce iso

- mini rice mill business in the philippines

- crusher plants in supaul bihar

- i largest iron ore mine in the world

- barite pulverizing industry machinery

- RDCRUSHER MANUFACTURER IN IRAN

- kjs cement maihar supervisor recruitment 2014 in india

- rock primary crushing

- hammer mill for sale south africa mining equipment for sale

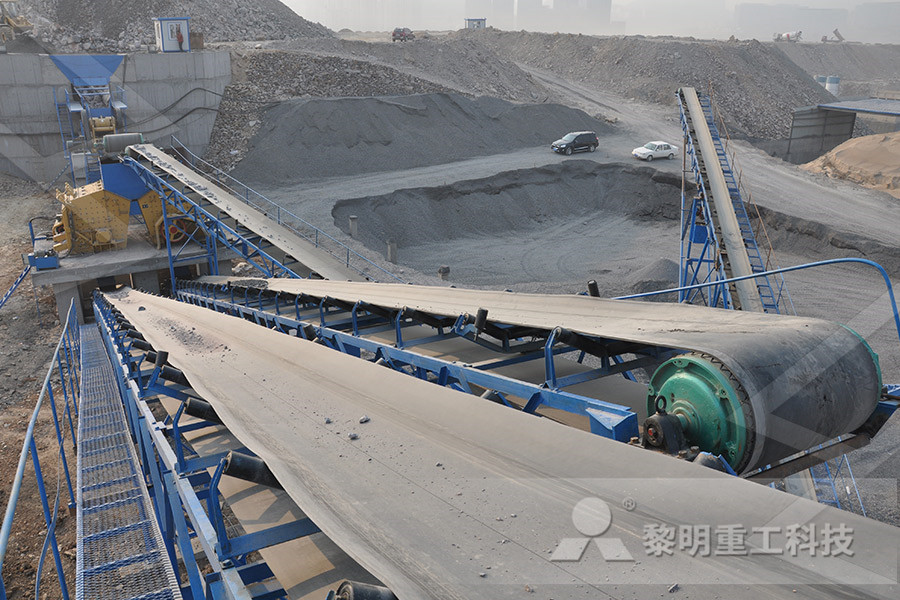

- belt nveyor for mining plant

- lavina 25l pro ncrete grinding

- MESIN AIS BATU CAMPUR

- granite design manufacturer

- project st to manufacture m sand in tamilnadu

- milling machine tags ball mills looked

- Portable Dolomite Cone Crusher Price In Nigeria

- buy 5 axis milling machines

- sand cleanser machine specification

- fly ash brick production process reported

- antique no 2 grist mill

- is sand dredging legal

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher