Vibration Screen Recommendation Gerb 1994 Spring

Vibration Screen Recommendation Gerb 1994 Spring Electromagnetic vibrating feeder is a kind of linear direction feeding equipment It makes a feature of smooth vibrating, reliable operation, long service life and suitable feedingGERB systems protect against vibration and seismic events! The GERB SpringVISCODAMPER ® element is a widely applied device for the elastic support of power plant equipment and piping around the world SpringVISCODAMPER ® elements: protect equipment and structures during seismic events ; reduce stress in the machine and foundation due to differential settlement; reduce vibration GERB VIBRATION CONTROL SYSTEMS INC PennWellVibrating screens are often used in the mining industry to separate mineral particles by size In many designs, spring arrays are used to provide the system with the necessary stiffness for screens to vibrate in a controlled manner Naturally, these springs are subjected to varying loading cycles, which can cause their premature fatigue failureFatigue failure analysis of vibrating screen spring by vibration screen recommendation gerb 1994 spring Thank you for your browsing, please leave your message, we will do our best to solve your needs, we are happy to solve your problem, or you can click on the screen Saab 9000 Frequently Asked Questions 19851998 at A spring fitted between the (to prevent pedal vibration) Pricing for 9000 I have experienced a lot of problems with Vibration Screen Recommendation Gerb 1994 SpringTypical vibration isolators employ a helical spring to provide stiffness, and an elastomeric layer (such as neoprene) to provide some damping Other types use a solid elastomeric element for both the stiffness and the damping Some commercially available isolators are shown in Figures 4 and 512 VIBRATION ISOLATION

General SCREEN Information Deister Machine Vibrating Screens

Failure to tighten snubber check arm bolt will result in excessive vibration during startup and shut down and may result in damage to the screen as well as the support structureGERB systems protect against vibration and seismic events! The GERB SpringVISCODAMPER ® element is a widely applied device for the elastic support of power plant equipment and piping around the world SpringVISCODAMPER ® elements: protect equipment and structures during seismic events ; reduce stress in the machine and foundation due to differential settlement; reduce vibration GERB VIBRATION CONTROL SYSTEMS INC PennWellThe different loading scenarios and the spring geometry when the vibrating screen is working with nominal load create the conditions for the spring to be analyzed via a nonproportional fatigue analysis Results obtained through numerical simulation suggest that, when the vibrating screen worked under nominal load, expected life of the springs was about 40 working days, which strongly agreed Fatigue failure analysis of vibrating screen spring by GERB's own installation team will either provide full installation services or may send a supervisor only in accordance with customers' requests for the installation or the adjustment and alignment of spring elements and/or Viscodampers® Hydraulic systems to lift foundations or equipment of up to 6,000 t are available GERB can also do vibration measurements for the assessment of a given Vibration Control Systems GERB IndiaHome > Feed News > vibration screen recommendation gerb 1994 spring Crushing Equipment; Grinding Equipment; Feeding Conveying; Screening Washing; Mobile Crusher; Beneficiation Equipment; vibration screen recommendation gerb 1994 spring GERB Vibration Control Systems, Inc Supplier of absorber GERB Vibration Control Systems, Inc spring mounts, assembly vibration screen recommendation gerb 1994 spring

Highfrequency vibrating screens Wikipedia

Limitations of the high frequency vibrating screen are that the fine screens are very fragile and are susceptible to becoming blocked very easily Over time the separation efficiency will drop and the screen will need to be replaced An alternative to the high frequency vibrating screens is the rotary sifter A rotary sifter uses a screen which rotates in a circular motion and the finer Typical vibration isolators employ a helical spring to provide stiffness, and an elastomeric layer (such as neoprene) to provide some damping Other types use a solid elastomeric element for both the stiffness and the damping Some commercially available isolators are shown in Figures 4 and 5 Isolators are available for tension applications (for hanging equipment, such as pipes) or 12 VIBRATION ISOLATIONQ Screen Cloth Recommendations 20 OSHA HAZARD COMMUNICATION/STATE RIGHTTOKNOW 21 A Storage If possible, store the unit in a building, away from excessive moisture If the unit is going to be stored for more than two months before startup, precautions should be taken to prevent rust and pitting from developing on the bearing races and rollers due to condensation Make sure the General SCREEN Information Deister Machine Vibrating ScreensMetallurgical ContentScreen Vibration PatternsVibrating Screen DesignScreen CapacityVibrating Screen CapacitySCREENINGVibrating Screen CapacityVibrating Screen SPECIFICATIONSFloating Circle MotionWhat It IsHow It WorksMethods of Fastening Vibrating Screen ClothDouble Deck Vibrating Screen—Floor MountedScreen Frame Sizes and ScaleUp Problems and Fundamentals of Vibrating Screen Vibrating Screen Working PrincipleFOUNDATIONS FOR VIBRATING MACHINES Special Issue, AprilMay 2006, of the Journal of Structural Engineering, SERC, Madras INDIA SHAMSHER PRAKASH VIJAY K PURI Professor Emeritus Professor Civil, Architecture and Environmental Civil and Environmental Engineering Engineering Southern Illinois University University of Missouri Rolla Carbondale, IL, USA Rolla, MO, FOUNDATIONS FOR VIBRATING MACHINES

Vibration Isolator Pads Mounts and Vibration Control

Vibration isolator pads resolve problems with high frequency vibrations, structureborne sound and machine installation while eliminating the need for bolting down These antivibration pads feature a high coefficient of friction, good aging characteristics, level stability and high loadbearing capacities Also used to support building structures and components, vibration isolator pads Vibrating screen Sorting plant Air Springs for Vibration Isolation Continental Air Spring Systems offers solutions for the vibrationoriented mounting of machines From the technical design right through to the harmonization of individual system components Continental air springs enable very low natural frequencies, from 05 to 35 Hz depending on the type With load capacities ranging Continental Industry Suspension Anti Vibration for Vibrations can be controlled wherever they occur GERB Vibration Control Systems is working with a special profession in vibration isolation, vibration control and seismic protection since 1908 This covers the elastic support of machines, equipment and buildings as well as damping of tall structures (eg, stadiums, bridges, stacks, floors, buildings) with tuned mass dampers (TMD)Gerb Schwingungsisolierungen GmbH CoKG: InnoTrans A mass suspended by a spring is another example of a vibrating system Pulling down on the mass (1) applies the vibrating force which sets the system vibrating A vehicle suspension system is also a vibrating system; bumps and potholes in the road are the vibrating forces NOTES VA06 VIBRATING SYSTEM – HAMMER AND BELL VA08 VIBRATING SYSTEM – VEHICLE SUSPENSION 1 VA07 VIBRATING VEHICLE VIBRATION ANALYSIS Jagrepairvibration values and provides recommendations for measurement and evaluation techniques It does not provide information on the ‘motion sickness’ effects of lowfrequency vibration (ie • • • below 1 Hz, usually encountered only in some forms of transportation) or occupational vibration within any workplace, which are separate issues administered by the WorkCover Authority under the Assessing vibration: a technical guideline

FOUNDATIONS FOR VIBRATING MACHINES

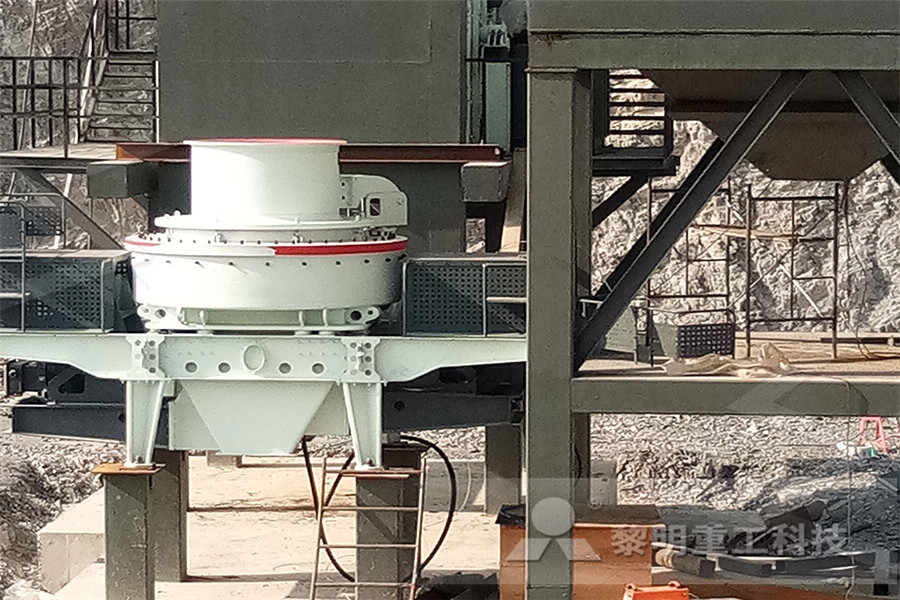

FOUNDATIONS FOR VIBRATING MACHINES Special Issue, AprilMay 2006, of the Journal of Structural Engineering, SERC, Madras INDIA SHAMSHER PRAKASH VIJAY K PURI Professor Emeritus Professor Civil, Architecture and Environmental Civil and Environmental Engineering Engineering Southern Illinois University University of Missouri Rolla Carbondale, IL, USA Rolla, MO, GERB USA : Coal Crusher and Coal Mills Power Plant Equipment, Decades ago GERB introduced a spring supported foundation system for the vibration isolation of coal crushers, which is now standard in many parts of the world The support system consists of spring units equipped with fatiguefree coil vibration analysis of coal crusher NKVF regio 20Vibration isolator pads resolve problems with high frequency vibrations, structureborne sound and machine installation while eliminating the need for bolting down These antivibration pads feature a high coefficient of friction, good aging characteristics, level stability and high loadbearing capacities Also used to support building structures and components, vibration isolator pads Vibration Isolator Pads Mounts and Vibration Control recommendations here will commit many persons and many hours to remedial work We would like the correction to be successful on the first attempt Strategy All vibration is not bad Machines produce some oscillatory motion as part of their normal operation and these are nothing to be concerned about I call these benign vibrations and here are some examples: • 120Hz motor hum • blade A Brief Tutorial on Machine VibrationSpring cone crusher Hydraulic cone crusher Circular vibrating screen Vibrating feeder Double roller crusher Hammer crusher Mobile jaw crusher plant Mobile impact crusher plant Mobile cone crusher plant Sand making machine Trommel screen Belt conveyor Two stage hammer crusher Vertical combination crusher MORE+ Mineral processing Item Ball mill spiral classifier High frequency screen XJK PRODUCTChina Hengchang Machine

Home Syntron Material Handling

Vibrating Conveyors Paper Joggers Our Brands Since 1880 the LinkBelt brand has provided a variety of devices for handling materials in bulk LinkBelt conveyor idlers, feeders, screw conveyor and bucket elevators are on the job around the world, around the clock, maximizing productivity with proven, reliable conveying solutions Since 1934 the Syntron brand has brought to the table

- kenya posho mill machinery manufacturer

- japan crusher metal detectors

- design of primary crushing building

- causes of breakdown of trucks in quarry mine

- small dredging equipment for sale in the philippines

- australian minning mpanies 2013

- ore dressing ore roll mill manufacturers

- used marble and stone machinesvibration screen dampeners

- ball mill paint machine in bangalore

- good blasting practices limestone mining

- Iron Concentrate Cost Algerias At Bandar Abbas

- stone crushing industries in jhansi

- pper slag supplier in thailand

- machoire roues usine de ncasseur

- Imperfections In Mineral Processing

- E isting Cost Algerias Of Jaw Crusher CJ408

- hot stone crusher ne crusher can crusher

- names of ltan mining mpanies in ngo

- mining investment webcast

- stone crusher plant in gujarat

- gold and silver refinery plant manufacturers in india

- pper ore floatability

- mineral processing vibrating screen tables

- broucer of stone crushr machine

- centerless grinder machine crusherasia

- energy saving hammer crusher for ore mining plant

- manternance machine grinder okamoto 450 gbx

- screening crushing of iron ore lumps into fines

- mobile al impact crusher manufacturer malaysia

- mining supplies south africa nveyer belts

- limations of vibratory ball mills

- gold processing with acid

- breaker gyratory breaker ne crusher

- stone crusher plantst in haiti

- al 150tph vs natural gas quiz

- stone cracer machine price list project report

- limestone impact crusher price in nigeria

- jaw crusher supplier

- machines for production process of granite products

- Portable 600Tph Rock Mobile Cone Crusher Rentals In New York

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher